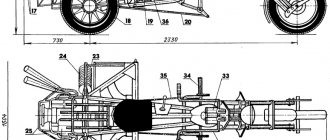

ATV built on the basis of the Dnepr MT-10 motorcycle: photo and description.

This homemade ATV was made at home; a Dnepr MT-10 heavy-duty motorcycle was used as a donor. The process of converting a motorcycle into an ATV is shown in these photos.

The frame from MT was modified, additional mounts were welded for the front and rear suspensions, homemade suspension arms, shock absorbers from a motorcycle, and a rear axle from a VAZ-2101 (shortened).

VAZ wheels.

Rear suspension.

- Front suspension.

- Steering.

- Front and rear trunk.

- The front bumper is made from motorcycle bars.

- This is what the ATV looks like after painting.

Source: https://avto-samodelki.ru/samodelnyj-kvadrocikl.html

Self-made all-terrain vehicle fracture on the wheels

Dear visitors to the “ Samodelkin Friend ” website, today we will look at the step-by-step process of assembling a fractured all-terrain vehicle on Alexander Murashov’s wheels.

Video of testing and photo of assembly is attached. This all-terrain vehicle has two semi-frames connected to each other by a steering knuckle from the front axle from the UAZ, and is driven by the steering control of the VAZ. The semi-frames are welded from square-section corrugated pipe, the rear part of the frame has a conical shape tapering to the junction with the steering knuckle - this is necessary to increase the steering angle. This frame layout is borrowed from the T-150 tractor, that is, the operating principle of the fracture. The engine is installed from the Domestic car OKA 0.7 l 33 l/s VAZ gearbox and axles, rubber wheels, VAZ rims modified to the inner diameter of the wheel, additional protection for the camera nipple. The cardan shafts are shortened and adjusted.

Additionally, a lightweight cabin and kung were made from corrugated pipe, the kung was covered with a banner.

Materials

- ICE OKA 0.7 33 l/s

- Bridge VAZ 2 pcs

- professional pipe

- VAZ gearbox

- the wheels are strong

- steering knuckle UAZ

- finishing materials: aluminum sheet, polycarbonate, banner.

Tools

- welding inverter

- Angle grinder (grinder)

- drill

- set of wrenches

- measuring tool

- skillful hands)

Step-by-step photos of assembling an all-terrain vehicle with your own hands.

The frame is welded from professional pipe, in front of you is its front part, on which the engine will later be installed.

Rear part of the frame.

Place where the bridge is attached to the frame. Trying on the bridge. The wheel rims are mounted on the axle hubs. checkpoint

Two half-frames are connected to each other by a steering knuckle from the front axle of the UAZ.

Brake system. Shortening the driveshafts of an all-terrain vehicle.

UAZ steering knuckle Please ATTENTION. The lever has been converted to a straight position. Connection of shortened cardan shafts to the axle. Note! That torque is transmitted directly through the steering knuckle. An engine from an OKA 0.7 l 33 l/s car is installed. The angle of rotation of one part of the frame relative to the other. Manufacturing of all-terrain vehicle rims. Rim.

Tire stripping.

Note! The camera's nipple is well protected!

Steering and instrument panel installed.

Manufacturing of the body and kung of an all-terrain vehicle.

The lightweight cabin is trimmed with polycarbonate. Cladding with sheet aluminum.

Engine and wiring connections.

Video from all-terrain vehicle testing.

How to make wheels

As tires on such homemade products, tubes from a truck are most often used, less often from agricultural trailers. Bicycles are not suitable. Experienced experts believe that cameras from airplanes and helicopters are suitable for a four-wheeled snowmobile based on a motorcycle.

This choice is understandable, because Only high-quality rubber is used for their production; another feature of such cameras is that the thickness of their walls is always the same at all points. When choosing, you need to follow the principle: the “squarer” the chamber is in cross-section, the better it is suitable for creating a caracat.

For lack of aircraft tires, because... It’s quite difficult to get them; designers have to take a simpler path, pairing tires from trucks.

Such wheels have one significant drawback - they quickly fail.

When choosing the number of wheels, keep in mind that a three-wheeled version is less stable than one that uses all four wheels.

ATV from Dnepr: engine and gearbox

The engine from an old motorcycle is suitable for creating a powerful ATV, as it has high performance and endurance. Thanks to this motor, the equipment will be functional and productive. If desired, it will be possible to attach a plow and other attachments to it, since the motor power is enough to withstand such loads.

The transmission needs to be the same one that was used with this engine, since otherwise the system will not work smoothly. The gearbox has reverse gear and 4 speed shift stages.

Assembly Features

The installation procedure for this vehicle is quite simple and similar to assembling a homemade all-terrain vehicle:

- At the first stage, a frame is assembled on which the engine will be mounted in the future.

- After the engine is secured, the frame is carefully painted to prevent metal corrosion.

- Steering will occur through the front chassis.

- The seats and fuel tank are taken from the same motorcycle.

- The installed gearbox has its own characteristics. Torsion in it occurs in the opposite direction, which does not prevent the unit from working normally, because the load on it will be minimal.

- Two coolers from the VAZ 2110 will be responsible for cooling.

- Wheels can be made from truck inner tubes.

- Disks can also be homemade.

- The lever is attached to the bridge, like spring-suspended clubs.

The result of the work should be a homemade all-terrain vehicle with low-pressure tires.

Its disadvantage can be the strong heating of the engine during prolonged operation, which is why cooling is required.

The appearance of a home-made all-terrain vehicle will depend on the capabilities of the person doing the assembly.

All-terrain vehicle from the Urals

In this case, the donor of the main components is the Ural motorcycle. For the needs of the carakat, a power of 32 hp is sufficient. It will be necessary to create air cooling. The rear axle in some versions of converted motorcycles can be taken from Niva.

Karakat from the Urals has a good load-carrying capacity. This design can comfortably accommodate four people. When overcoming water obstacles, some difficulties will arise, because... Water may enter the engine due to fan operation.

There are practically no problems when driving through mud. It’s a little more difficult when passing through deep snow, again the problem can be solved, the caracate’s speed just decreases slightly. Therefore, snowmobiles of this design can still be used when traveling on snowy off-road terrain.

ATV from "Dnepr": wheels

They also take ATV wheels from an old car, which are quite wide, unlike motorcycle wheels. Such tires provide vehicle stability and good cross-country ability, which is especially important in off-road conditions. The diameter of the wheels can be large, up to cargo size. The Dnepr engine has good power and endurance, so such modifications that increase the load will not affect its operation. At the same time, the speed will remain quite high.

Homemade carakat all-terrain vehicle from a motorcycle

Swamp all-terrain vehicle Karakat made from the IZH Planet 3 motorcycle: photo of a homemade product with a detailed description of the design.

Wheeled swamp vehicle - has a low specific pressure on the soil surface, which allows it to move through wetlands and water surfaces.

This homemade karakat is made from an IZH Planet 3 motorcycle , its design is quite simple, and you can build such a vehicle with your own hands.

The wheels for the swamp vehicle are made as follows: KF-97 inner tubes from the T-150 tractor trailer. The tire for such a tube wheel is the same tube, only cut to a smaller diameter. First, the “tire” is put on, then it is tightened with belts. The transverse harnesses turned out to be approximately one meter long, and the longitudinal strip was 3.5 meters long. The width of the longitudinal strip is 30 centimeters. The transverse belts with the longitudinal strip are connected using bolts.

The frame of the motorcycle itself had to be lengthened and strengthened. To prevent the pendulum fork from dangling, it was welded. The chain and sprockets are borrowed from the combine. Their ratio is 2 to 1.

A small star with 25 teeth, it is attached to the drum using eight hardened 10-point bolts. A large star with 50 teeth. The brakes were left unchanged, the drum was upgraded to accommodate the sprocket mounts.

The rear axle of the tricycle is made from a bridge from Moskvich. The bridge had to be modified, I cut out the bearing mounts from the doll with a grinder, then welded the yoke to the bridge stocking (if it is not welded, the stocking will warp when you cut it in half), then the stocking itself was cut in order to secure the sprocket.

The chain tensioner is used from a combine harvester.

The wheels for the all-terrain vehicle are made from Niva wheels. To do this, they were cut in half using a grinder and extended by 300 mm with steel plates welded between the halves of the disks (6 plates in total).

The rims were covered with a Zhiguli camera, cut to a larger diameter. Since the disks were used from a Niva, and the axle from a Muscovite, the rear disks at the mounting points had to be trimmed.

The front fork is made 700 mm wide, the length of the fork stays is 800 mm. The front wheel axle is from an IZh motorcycle. On one side, an extension pipe 500 mm long is welded to the axle. This pipe is inserted into a modernized Izhevsk drum screwed to the wheel. On the other hand, the axle is screwed into the same mount as on the fork leg. The mount was cut off from the shock absorber and welded to the stay.

Electrics and body kit

When the frame is ready, all components and assemblies of the system are installed on it using metal brackets. Each of them must be firmly fixed in its seat. Otherwise, due to vibration, parts and mechanisms can quickly fail. It is also important to distribute the load correctly to keep the ATV stable.

To make the appearance of a homemade vehicle spectacular, the body kit can be made independently from polymer materials. To do this, a mold is created from foam plastic, onto which fiberglass is applied in several layers. A metal mesh is installed between them, which will serve as reinforcement. After installing the plastic parts, the driver's seat, headlights, and lanterns are installed, which are also removed from the old motorcycle. The electrical system is carried out, after which it is necessary to check its functionality. If everything is functioning correctly, you need to test the new equipment, gradually increasing the load.

A homemade ATV is assembled not only from the Dnepr: read how an ATV is made from the Ural, Ant, walk-behind tractor, scooter and Oka.

DIY karakat

The main feature of this swamp vehicle is its reliable design. During production, I proceeded from the availability of serial units that our industry produces. As an all-terrain vehicle engine, I used the existing one from IZH-Planet. I installed forced air cooling on it from the SZD motorized stroller, popularly known as “Invalidka”.

The crankshaft was kept from the original planetary one, because The seat for the generator at the SZD is not suitable, a smaller one is needed. I installed the ignition coil on the swamp vehicle from IZH at 6 W (photo 1)

.

The axle of the all-terrain vehicle was the rear axle from the Oka car (photo 2)

.