Adjusting carburetors K-301, K-302 (Page 1 of 4)

Supply system.

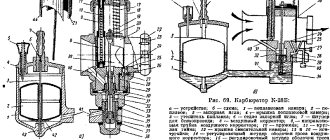

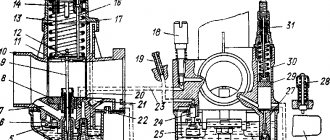

Carburetor. Carburetor K-301, K-302. The diagram of the K-301 carburetor is shown in Fig. 3.3. The carburetor includes metering systems: main and idle systems. Compensation of the mixture composition is carried out by a metering needle 22 and an air nozzle 21. The idle system is supplied with fuel directly from the float chamber through channel 36. Fig. 3.2. Carburetors K-301 and K-302: 1, 27 - cover screw; 2 — spring of throttle valves; 3 - spacer spring; 4 — throttle body; 5 — needle lock: 6 — regulating needle; 7 — idle screw nut: 8, 9 — idle screw and jet; 10. 16 - plugs: 11. 15, 25 - gaskets; 12 - main jet; 13,18 - jet gaskets and plugs; 19 — filter: 20 — air filter housing: 21 — air filter; 22 — carburetor body; 23 - float; 24 — throttle pin; 26 — float chamber cover: 28 — throttle valve lift limiter; 29 — cover: 30. 32 — nuts; 31 — guide tube; 32 — guide cable Fig. 3.3. Carburetor K-301 B: I - throttle thrust screw; 2 — quencher: 3 — float chamber cover; 4 — float needle; 5 - float; 6 — filter plug; 7 - gasket: 8 - filter spring: 9 - fuel filter; 10 - main jet; 11 - plug; 12 — gasket; 13 - gasket; 14 - plug; 15 — low speed jet; 16 — air filter housing: 17 — air filter mesh; 18 — screw for adjusting the mixture quality at low speeds; 19 - spray hole of the low speed jet; 20 - sprayer: 21 - nozzles: 22 - dosing needle; 23 — throttle needle lock; 24 - throttle body; 25 — throttle spacer spring; 26 — carburetor body; 27 — throttle travel limiter; 28 — carburetor cover: 29 — spring: 30 — stop lock nut; 31 - fitting; 32 — throttle cheek; 33 — low speed jet air channel; 34 — air channel of the sprayer; ^5 - fuel supply channel to the spray hole: 36 - main fuel channel

The carburetor consists of three main parts: body 26, cast together with the float chamber, body cover 28 and float chamber cover 3. The carburetor is attached to the engine cylinder at an angle of 15° relative to the horizontal, while the carburetor float chamber is in a vertical position.

The carburetor body houses all its metering and adjustment elements: main fuel jet 10; idle fuel jet 15; throttle 24 with a metering needle 22 attached to it; sprayer 20; nozzles 21; idle air screw 18 and throttle limiter 27, as well as throttle spring 29.

The air supply from the carburetor inlet pipe to the nozzle is carried out through channel 34, and to the idle air screw through channel 33.

The K-301 carburetor throttle is flat, consists of two parts - body 24 and cheek 32. A spring installed between the throttle body and its cheek presses these parts to the walls of the throttle well, while simultaneously preventing their spontaneous separation when removing the throttle from the well. The dosing needle in the throttle is secured with a special lock 23.

A constant fuel level in the float chamber is maintained by a brass float 5 with a fuel valve needle 4.

Fuel is supplied to the main jet and the idle jet through a mesh fuel filter 9 located in the lower part of the float chamber. The filter consists of a housing and a brass mesh, which is fixed in the float chamber socket with a spring 8.

The float chamber cover has a float quencher 2 and a fuel inlet fitting, the lower part of which is also a fuel valve seat. A sealing gasket is installed under the cover.

The float chamber communicates with the external environment through a hole in the float quencher column.

The carburetor body is closed with a cover, which is secured with two captive screws. A throttle lift limiter is pressed into the cover, which is removed after the motorcycle is broken in. A curved brass tube is also fixed to the cover, into which the stop of the throttle control cable sheath is screwed and secured with a nut 30.

The carburetor is attached to the cylinder using a flange. To prevent water hammer when starting the engine, the carburetor is equipped with a drainage device in the form of a channel closed by a strainer 16, 17. When the engine is running, air enters the idle system through the drainage channel.

Thus, air comes to the idle propeller from two sources - from the inlet pipe through channel 33 and through the drainage channel - past the air filter.

The channels of the main jet and metering needle are closed with plugs 14 and 11.

K-301 B carburetors differ from the K-301 carburetor only in the height of the throttle cutout.

K-302 carburetors are designed for installation on K-750 and IMZ-8.103 motorcycle engines. They are made according to the same design scheme as the K-301 carburetors, but differ in the design of the body. The axis of the float chamber is parallel to the axis of the throttle well, since carburetors are mounted horizontally on the engine.

The parameters of the metering elements of the K-301 and K-302 carburetors are the same.

Supply system. Carburetor. Carburetor K-301, K-302. Adjusting carburetors K-301 and K-302.

The presence of a separate carburetor on each of the cylinders improves starting and increases engine power, however, this system requires careful implementation of the same adjustment for each of the carburetors. Only synchronous operation of both carburetors ensures maximum power output from the engine. Let's consider the adjustment sequence using the example of the most common carburetor K-301 B (Fig. 3.3).

Caring for K 88A

The occurrence of problems with Zilov carburetors can be minimized if this device is provided with proper care. To do this, you just need to follow simple rules:

- The most important thing to remember is that during each maintenance, check the tightness of all carburetor plugs and plugs. If a leak occurs in at least one place, this may, over time, disrupt the normal operation of the unit.

- Another thing that should not be forgotten during every ZIL maintenance is the mandatory cleaning of the float chamber, from which the sediment must be washed out. In addition, it would not be superfluous to blow out and wash the jets and channels once every six months (if not more often). It is best to do this with high-octane gasoline. If there is too much dirt, you can use acetone.

- It is not advisable to put all washed parts back immediately. It is better to dry them thoroughly and then clean them again with a soft cloth.

A clogged carburetor is not a breakdown. However, negligence regarding the correct maintenance will sooner or later end sadly.

Adjusting the carburetor for 301 Moto Ural

Adjusting the K-302 carburetor Before adjusting, it is necessary to warm up the engine, since adjustments made on a cold (unheated) engine will be disrupted when it warms up. Adjustment at low idle speed is of great importance for engine performance. Before starting the adjustment, it is necessary to check and adjust: • the size of the gap between the contacts of the spark plugs (0.5 - 0.6 mm); • the size of the gap between the breaker contacts (0.4 - 0.6 mm); • the size of the thermal gap in the gas distribution system.

Each carburetor is adjusted separately. It is necessary to adjust the left carburetor K-302 in the following sequence: a) REMOVE the cap from the spark plug of the right cylinder;

b) loosen the locknut 28 of the stop of the sheath 29 of the left carburetor spool drive cable and tighten the stop, ensuring a gap between the cable sheath and the stop;

c) loosen the locknuts of throttle screw 9 and idle speed screw 21, tighten the idle speed screw all the way, and use screw 9 to set the minimum stable engine speed;

d) by unscrewing the idle speed screw 21, set, possibly, a higher number of engine revolutions at a given position of the throttle valve screw;

e) gradually unscrewing screw 9 of the throttle valve, set the lowest stable speed. After adjustment, tighten the lock nuts of the screws. Turning off the left cylinder, proceed to adjust the right carburetor. The adjustment procedure is the same as when adjusting the left carburetor. Be sure to short the spark plug cap to ground, otherwise the spark will disappear on the other cylinder! Carburetors must provide the same number of engine revolutions when one (left or right) cylinder is idling. The operation of carburetors is checked as follows. With a running warm engine with adjusted carburetors, turn off the cylinders one by one by removing the cap from the spark plug of either the right or left cylinder. The change in engine speed during operation on each cylinder is determined by ear. If the engine speed when operating on the right and left cylinders is different, then the carburetors are adjusted by screwing in and unscrewing the set screws of the throttle valves until the same number of revolutions is achieved. After this, tighten the locknuts of the throttle valve set screws. When adjusting low idle speed, you must pay attention to ensure that the idle speed screws are not screwed in all the way. Operating a motorcycle with the carburetor idle screws turned all the way is under no circumstances permissible. The synchronized operation of both engine cylinders in different modes is achieved by simultaneously raising the spool valves of the right and left carburetors. Non-synchronous operation of even well-adjusted carburetors can cause overheating and rapid wear of parts of one of the engine cylinders. To achieve synchronized operation, you need to turn the throttle lift handle to set the engine speed corresponding to a speed of 30 - 40 km/h with 4th gear engaged, and then, alternately removing the caps from the spark plugs of the right and left cylinders, determine by ear whether the number changes. engine speed.

Kempo › Blog › Practical methodology for tuning Ural motorcycle carburetors

I have a motorcycle Ural M8-103-10, manufactured in 1989. I drove it continuously for 9 years. A lot of building materials and crops from the garden plot and vegetable garden were transported (up to 10 bags of potatoes are carried in one trip, but it is more convenient to carry 5-6). Then, in 2001, I purchased a 9, and therefore, I began to travel to the Urals periodically - mainly, I carried large cargo, potatoes, garbage, and occasionally went fishing (the Ural is still a “rogue”