Carburetor java 250 adjustment

The editors receive many letters from owners of Panonnia motorcycles.

They ask to tell us about the operation and repair of this motorcycle. In addition to the already published materials (see “Behind the Wheel”, 1963, No. 9), we are publishing an abbreviated translation of two articles from the Hungarian magazine “Avtomotor”, which will undoubtedly be of interest to our readers. CARBURETOR ADJUSTMENT

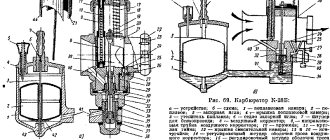

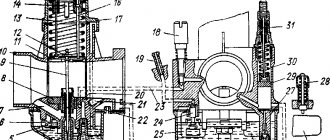

produces two types of carburetors. The first is the TL-250 and TL-250F carburetors (Fig. 1). Both have a diffuser suction neck diameter of 25 mm, and the float and mixing chambers are located separately. The second type is the TL-250/59 and TL-250B carburetors (Fig. 2). The diffuser diameter of these carburetors is 27 mm, and the float and mixing chambers are located in one block.

Rice. 1. Carburetor TL-250 : 1 - cotter pin; 2 - throttle valve; 3— throttle valve spring; 4— carburetor assembly; 5 — needle lock; 6 — quencher button; 7 — level adjustment nut; 8 — drowner spring; 9 - sealing ring; 10 — quencher fastening hose; 11 — float chamber cover; 12 - sealing ring; 13 — needle valve; 14 - lower part of the mixing chamber; 15 — float; 16 — float chamber; 17 - sealing ring; 18 — cable sheath stop; 19 — stop nut; 20 — nut of the mixing chamber cover; 21 — mixing chamber cover; 22 — air cleaner coupling ring; 23 — air cleaner; 24 — clamping ring screw; 25 — nut of the clamping ring screw; 26 — throttle valve needle; 27 — diffuser; 28 — idle speed adjustment screw; 29 — spring of the idle speed adjustment screw; 30 - mixing chamber; 31 — throttle adjustment screw nut; 32 - sealing ring; 33 — sprayer socket; 34 - sprayer; 35 — throttle adjustment screw; 36 - main jet; 37 - mixing chamber plug.

How do these carburetors work?

The air flow in the mixing chamber is mixed with fuel, which passes through the main jet with a diameter of 1.05 mm. The metering needle limits fuel consumption. When the throttle valve is fully open, the metering needle does not play a role, because it is fully raised, the nozzle hole is open, and the composition of the combustible mixture depends on the vacuum. But most often the throttle valve with the engine running is open in the range from 1/4 to 3/4. The composition of the mixture is regulated by the position of the metering needle and spool. When leaving the factory, the needle is fixed raised to the limit. After running in, it must be lowered one notch.

When the engine is idling, the required mixture composition is created using an idle jet with a diameter of 0.35 mm located in the mixing chamber. Its performance is adjusted with a screw. The air passes through a channel in the chamber body with a diameter of 1.5 mm. Air access is also regulated by a screw. This adjustment is of great importance. If it is performed poorly, then with the throttle valve fully closed or open no more than 1/3, so much fuel can pass into the cylinder that it will “throw” the spark plug.

Both the idle jet and the main jet are easy to replace. In the new type of carburetors they are located one above the other: the lower one is the main one, the upper one is the idle speed one. This carburetor has a great advantage. Using a shifter on the steering wheel, suction is provided, ensuring easy starting of the engine. The air enters through the air purifier. “Over-suction” that occurs when starting a cold engine with the air cleaner closed is eliminated.

In winter, when the engine is not warm enough and the working mixture is poor, suction is necessary for some time. Then, even in cold weather, easy starting is ensured, and when the engine is under heavy load, the working mixture is enriched.

Final adjustment of the carburetor is made only with a technically sound engine and after the car has traveled 2 thousand kilometers. To do this, choose a flat section of the road.

When starting to adjust, you need to have a set of main jets (with a diameter of 0.90 to 1.05 mm) and a metering needle (with a diameter of 2.65 mm).

It is known that at maximum speed the working mixture becomes depleted, which often disables the engine: the piston may jam. Therefore, during the process of adjusting the carburetor, it is necessary that a slightly enriched mixture be supplied to the cylinders.

Where to start? From checking the cleaned and reassembled carburetor. The float chamber must be filled with gasoline until the needle valve closes access to fuel. After this, the carburetor is tilted towards the mixing chamber by 15 degrees. Gasoline should seep out of the idle speed screw socket. Then the carburetor is set to its previous position, and the leakage of gasoline should stop. After this check, the adjusting screw together with the spring is put in place and screwed in completely, and then turned back one and a half turns.

Idling

Immediately after the engine starts, the system begins to idle. Like a starting carburetor, this system operates when the throttle is low. It consists of a hole, emulsion pipes, a bolt that regulates the quality of the mixture and translational channels. Since the air supply is much lighter than fuel, adjustment is made using a bolt. The more you tighten it, the lower the air flow will be. Do not overdo it with the air supply; if there is too much of it, the mixture will become leaner and the loss of power will become very noticeable.

Carburetor adjustment for JAVA

Adjusting the carburetor at YAVYN The composition of the combustible mixture is influenced by the following structural and adjusting elements of the carburetor: the flow area of the mixing chamber, the throughput of the main jet, the taper value of the metering needle and the height of its attachment in the throttle valve, the flow area of the nozzle, the cutoff height of the throttle valve from the side of the main flow supply air and the position of the low idle speed screw.

The carburetor is capable of providing the correct composition of the combustible mixture in all engine operating modes. The composition of the mixture is determined when the throttle valve is raised:

up to 1/8 of its full stroke - by positioning the screw at low speeds;

from 1/8 to 1/4 - cut height on the front part of the spool;

from 1/4 to 3/4 - the annular gap between the sprayer and the conical needle, i.e., it depends on the diameter of the sprayer and the height of the conical needle. When the needle is raised, the mixture becomes richer; when lowered, it becomes leaner;

from 3/4 to full opening - the throughput of the main jet.

However, due to differences in the quality of gasoline used for motorcycles, no standard adjustment can be recommended.

The optimal carburetor adjustment depends on many factors and may vary depending on the operating conditions of the motorcycle. Carburetor adjustment is affected by atmospheric conditions, road height, route profile and its length, total frontal area of the vehicle, driver weight, and lubricant content in the fuel.

Carburetor adjustment at the factory is a complex and time-consuming process, carried out both in the laboratory on an engine stand using advanced measuring equipment, and during high-speed tests on the highway and in city traffic.

Therefore, when running a motorcycle to adjust the carburetor, it is advisable to use the data given in the manufacturer’s instructions. In table Figure 3 shows the adjustment data for the 2926SBD carburetor. The carburetor should be adjusted only if it or the engine has been subjected to inept and poor disassembly or adjustment.

You can only adjust the carburetor of a run-in motorcycle, and the run-in should be done on a highway under normal climatic conditions for the area.

Before adjusting the carburetor, you should completely disassemble it and thoroughly clean and rinse all holes and channels with acetone or another solvent. It is also necessary to flush the fuel valve. Do not clean jets with metal wire. After assembling the carburetor, you need to check the presence of fuel in the tank. After this, you need to fill the float chamber with fuel through the gas line from the tank and check whether the float shut-off needle tightly closes the fuel hole in the float chamber fitting. After the carburetor is installed on the engine, it is necessary to check the ignition timing as indicated in the “Electrical Equipment” section.

Starting system

The 634 model had its own feature - a float quencher. It served to start the engine in the cold season. The Java 638 does not have such a system, but there is an additional carburetor to start the engine. It is located inside the main one. When starting a cold engine, it makes the fuel mixture more saturated. For it to start its work, a special toggle switch is turned on. After warming up it is turned off. This system only works well when the throttle is lowered, otherwise the starting carburetor will not perform its function.

It is important to keep the jet clean. Its close location and pressed fit in the float chamber ensures injection into the diffuser hole. The amount of emulsion supplied depends on the location.

It is important not to forget that adjusting the YAVA 638 carburetor greatly affects the fuel supply and thereby creates the correct air-fuel mixture. In cases where a lack of power is noticeable or popping noises are heard in the exhaust system, it is necessary to adjust the needle valve that injects fuel into the combustion chamber.

Modernization of cross-country motorcycles ChZ

The Czech motorcycle factories in Strakonice are traditional motorcycle manufacturers. They were the first in the world to begin serial production of motocross motorcycles. On “43” motorcycles, riders from various countries have several times won the laurels of world champions in the 250 cm3 and 500 cm3 classes.

OLYMPUS DIGITAL CAMERA

The modernized 43-125 motorcycle, to which this article is devoted, also contributes to ensuring the leading position of the “43” cross-country motorcycles. The 43-125 model 996 motorcycle retains the justified layout of the 43 model 984 motorcycles and, thanks to the use of standardized parts, is closely related to other classes of motorcycles produced at the plant.

Compared to the 984, the following significant changes have been made:

- The front wheel is new, with a die-cast hub and with a brake diameter of 125 mm

- the front fork has improved suspension performance

- Newly shaped fuel tank used

- a new chain tensioning device was used

- a new type of rear suspension was installed at an angle, suspension travel 100 mm (rear wheel travel 170 mm)

- a new way of arranging spokes of increased diameter

Technical description

Internal combustion engine, two-stroke, carburetor, single-cylinder with reverse scavenging, with one exhaust, air-cooled - pressure cooling, exhaust silencer is installed under the engine. The engine is in one block with a gearbox and clutch.

The clutch is dry, multi-plate, located on the left side of the engine on the input shaft of the gearbox. The primary transmission is gear-type. Shift gears using the shift lever located on the left side of the engine. Access to the shift gate and forks after removing the engine top cover. The castings of the crankcase, covers, cylinder head and the cylinder itself are made of aluminum alloy, the pressed cylinder liner is made of alloy cast iron.

Engine accessories

Carburetor brand "JIKOV 2932 SE 2800". For each competition, adjustments should be made depending on atmospheric conditions, track characteristics and fuel type. The motorcycle is supplied with main jets 120, 130, 135 and idle jets 35 and 45. The basic carburetor adjustment made at the factory is suitable for conditions at an altitude of 350 m above sea level and a relative humidity of 70%. For other conditions, adjustments need to be made. The intake silencer consists of a silencer chamber into which a filter element is inserted.

The frame is made of steel pipes, bifurcates at the rear and forms a wide support for installing the rear pendulum fork.

Suspension. The front wheel is suspended in a telescopic fork with two steel springs and telescopic shock absorbers - a stroke of 200 mm. 2X225 + 5 cm3 of MRR oil is poured into the suspension.

The rear wheel is suspended in a pendulum fork with two hydropneumatic spring elements with a stroke of 100 mm. 190+1 cm3 of AM 610 mash oil is poured into one element. The air pressure in the element is 3 atmospheres. The inclined installation of the elements improves driving properties and increases the travel of the rear wheel. Rear wheel travel is 170 mm.

Steering

The steering wheel is equipped with a transverse amplifier, the steering column is mounted in ball bearings in the frame head.

Fuel tank

The fuel tank has been given a new streamlined shape, the tank is made of stamped parts and is equipped with the “43” emblem. At the bottom of the tank there is a “YIKOV” drain valve without a fuel reserve. The fastening of the tank in the frame is elastic.

Wheels

Front and rear wheels with light alloy hub, with brake insert, aluminum alloy rims, with reinforced spokes. The rear wheel sprocket has 62 teeth and is replaceable on the rear wheel hub. The chain transmission is made with a “43” chain of 112 links. The new design of the chain guide element, in addition to its main purpose, also provides chain tension.

Main dosing system

When the throttle rises to a height of five millimeters, the main dosing system is activated. Here a complete mixture is created for enhanced engine performance. However, before creating the mixture, the fuel passes through an annular channel. A small amount of air gets into it there. After entering the diffuser, the fuel is enriched with air from the main flow.

The quality of the mixture can be influenced by changing the angle of the injection needle or the size of the main hole. In this case, the hole plays the main role of enriching the mixture when the throttle is raised, while the needle only plays a role in the middle position. When the diffuser is fully open, maximum output must be achieved. This can be achieved with a higher quality of the combustible mixture. In this case, you can select the jet of the required size and install it. Usually the new jet is a standard one, in which the hole is enlarged.

Carburetors for motorcycle jawa (java) 350, 250

Carburetors for motorcycle Jawa (Java) 350, 250 in Ukraine

In our online store Motozilla you can buy Carburetors for the Jawa (Java) 350, 250 motorcycle at prices 15-20% lower than the market average. You can verify this by looking at the price of Carburetors for your Java 350, 250 motorcycle.

Unlike our competitors, we do not have a minimum order price; we will ship your product for any amount. In our large catalog, which contains 9 product(s), you can filter Carburetors by price and brand and choose the most suitable set in JAVA.

The fuel system is a very important link in the Java 350, 250 motorcycle. Prices for Carburetors in Motozilla start from 134 UAH. In more expensive and high-quality brands, the cost of goods reaches 1,619 UAH. You may not find the products you need on page number 1, click on the following pages in the catalog, because we have 1 of them. Our catalog of products and categories is formed according to a logical structure to make it easier for you to find the necessary parts.

If you accidentally lost your browser tab on the Carburetors for JAVA page, go to the main page of the Motozilla store and go to the following categories Motorcycle parts Fuel system > Carburetors and make a filter by JAVA.

Especially for you, dear customers, we have made several payment options:

- cash on delivery is when you pay for the received Carburetors only after receiving the goods at Nova Poshta

- online payment through the secure payment system LiqPay Privat24 - when you can pay for the completed order directly on the website with a bank card by filling out the details

- prepayment to a card is an opportunity to pay for goods through self-service terminals or by transfer to our bank account from your card

We are loyal to our customers and want to provide the highest quality service and protect you if the purchased Carburetors turn out to be defective, defective, and so on. We will easily replace damaged items with others or issue a full refund. By repairing and buying spare parts for your JAVA motor vehicle at Motozilla, you do not risk anything.

We are a large online store of motorcycle parts; our product catalog contains more than 55,000 thousand items. Therefore, you can easily find the necessary Carburetors for the Jawa (Java) 350, 250 motorcycle. Motozilla works throughout Ukraine, sends goods to Kiev, Kharkov, Dnepr, Lviv, Odessa and all regional and military centers, as well as towns and villages, where there is a branch of Nova Poshta.

We also have special discounts, bonuses and a cashback program for JAVA owners (when you get back part of the money spent on Carburetors in our store, which you can use as a discount on your next orders for the Fuel system and accessories). If you have any questions or need advice on the selection of components, call the phone number and our managers will help you and solve the problem.

Current sources

On a motorcycle, current sources are two devices:

- Battery;

- Generator.

In the above figure, the generator is designated by the letter – G, and the battery – GB.

- Letter L – generator stator excitation winding;

- Letters EL2 – ignition system;

- Letter S – ignition switch;

- The battery charge or discharge level lamp is designated EL1.

JAWA Motorcycle Generator

The “634” model was equipped with a six-pole generator with a power of 75 watts and a voltage of 6 volts:

- Equipped with two breakers (one for each cylinder);

- Six pole coils with iron shoes;

- And a self-excitation system (works without a battery).

JAWA motorcycle battery

A 6 Volt 14 Ah battery was installed on the motorcycle (as in the IZh Planet 3 wiring diagram).

Features of the battery include:

- Location under the seat;

- The negative terminal was connected to the frame;

- Directly next to the battery there was a 15 A fuse on the bracket;

- The battery had a vent tube leading to the bottom of the motorcycle.

For reference: the lack of spare parts led to the fact that owners were forced to operate the motorcycle without a battery. This was possible thanks to the design of the generator, as well as minor alterations to the electrical circuit.

Refinement and tuning

Since the new Java 638 is very popular and the demand for this motorcycle does not subside, craftsmen continue to refine both the appearance of the motorcycle and its characteristics. On the Internet you can find many reviews and interesting technical solutions for tuning this motorcycle.

The change in appearance is sometimes so dramatic that it is difficult to believe that this motorcycle was once a classic java. The wheel rims are replaced with cast light alloy ones, the old front steering wheel fork is replaced with a more advanced, longer one, the seats and headlight are changed. There are simply no limits to the imagination of inventors.

To improve driving characteristics, drum brakes are replaced with higher quality disc brakes. To increase the service life of the engine, the bearing seats are changed, thereby improving their lubrication.

Alternative way

There is a simpler method for determining the correct position of the floats, which does not require measurements. Place the carburetor cover on a flat table and look at the stampings made on the side surfaces. When the floats are in a normally adjusted position, these strips are parallel to the lid.

Then we lift the floats up and look at their bottom, which after lifting should be parallel to the surface of the lid. If necessary, adjust the position of the floats by bending the tongue.

After adjustment work, we assemble the carburetor.