Do-it-yourself side trailer for an alpha moped

But as always happens, everything turned out spontaneously and far from the original plan. At first I planned to make a cultural homemade side trailer

from a 25*40mm profile pipe, similar to a factory trailer, and I also wanted to buy a wheel and a shock absorber with a wing.

But in the end, I brought a moped to work and a side trailer was born from scrap metal in two hours. I also wanted to buy a ready-made trailer for the alpha, but for some reason it was thin and the fastenings were weak, and the price with delivery of 9,000 rubles scared me off.

In the photo, I think it’s clear what kind of trash it was welded from. Wheel hub from the front wheel of a VAZ “classic”. The hub is welded and slightly reinforced with gussets made of metal 2.5 mm thick. Total price

for the trailer, including the wheel and hub, it cost me less than 1000 rubles. The metal itself is free, a used hub costs 500 rubles, I found an old wheel and took it to a tire specialist to have the tube sealed for 100 rubles, and small things, lugs, studs, washers.

But before making the trailer, I had to think about how to attach this trailer to the moped. After some thought and a thorough inspection of the moped to see where to attach the side trailer, it was decided to weld a reinforcing frame from a profile pipe onto the flimsy frame of the moped. The photo below shows how it was done.

The frame-reinforcing frame was attached at three points, the first point under the tank in the place where the original arches were screwed on. By the way, they are very flimsy and will not protect at all if a biker falls. My moped fell out of the bag and these arches fell off at the attachment points, what can you do, it’s a cheap moped and the same quality.

The second attachment point is at the bottom of the moped, where the main footrest of the moped is located. It was removed as it was in the way and a plate was welded from 2.5mm steel, and a section of profile pipe was already welded to it.

The third point is not welded, but screwed to the place where the rear shock absorber is attached. The result was a fairly strong base and four points for attaching the side trailer to the moped.

The lower two attachment points of the trailer are on M10 bolts. The rods ligating the trailer relative to the moped are also homemade. They are made of tubes to which M12 nuts were welded, and the studs were screwed into the tubes and by rotating it was possible to adjust the length of the rods, thereby adjusting the trailer so that the steering wheel did not pull.

The attachment points for the rods are made of large washers, which are welded like ears. It turned out quite durable, easy and fast. By the way, all this was dictated by the materials at hand, and everything was conceived differently, but everything was born exactly like that.

This trailer was made specifically as a cargo trailer and, of course, you can’t carry people on a bare frame, but everything else, and even very heavy things can be transported without fear that something will fall off. The trailer itself is designed for hauling firewood and the moped was bought specifically for this purpose, to carry firewood. Although initially I thought about a walk-behind tractor.

For small loads, I made a box from furniture panels, which I put on the side trailer when I need to bring something small but heavy, for example clay in buckets, water in cans, or something harvested from the garden. In general, it is very convenient and there is no desire to ride alone, since the moped is very unstable on the road, and with a side trailer you don’t have to constantly choose a road that is level and without sand and dust, on which thin wheels do not hold the road when on a single vehicle.

Do-it-yourself scooter trailer - a necessary household item

About how I cut down a trailer for a scooter without drawings from my mom and dad and loans from what I had, the simple purpose was to carry anything that didn’t fit on the moped.

in my case, for transporting ferrous metal - you can evaluate what happened. And I made it from what I had and had to buy a little more.

But the wheels from the ant had to be purchased from scrap metal

The design is simple, from a corner I cooked it myself

The body itself was made from boards from an old pallet

The most confusing and complex thing, of course, is the tow hitch; it must be reliable, functional and quickly detachable

I messed around with it but it all worked out

Complete freedom of fastening ensures good connection performance when turning.

and even in unusual situations when a cart or scooter turns over, the connection works as expected

Well, this is what we ended up with - a small trailer for a scooter.

Who is interested in watching the creation process itself, here is the full video

Transportation of ferrous metal. I think the variator will be damned in the future

one large vertical bolt that can be pulled out - unscrew one nut in short

You're a genius BRO. Super badass. Cool.

Metal scrapper 80 lvl!

How and where to buy a trailer

The design of the trailer itself is not distinguished by any special design idea; it is quite simple to assemble and for installation on a moped. You can purchase it at any motorcycle store in the city, or order it online. Well, those who want to save money can assemble such a stroller themselves.

Homemade side trailer

Prices for an Alpha moped already assembled with a side trailer fluctuate around $500-600. Separately, a side trailer will cost from 100 to 150 in the same monetary terms. It is interesting that such a difference in price is not caused by the difference in the models of the trailer stroller, but by a banal markup of the reseller store. Therefore, you should not rush to make a purchase in the first store that comes to hand; it is better to spend a little time and save the same, but 50 dollars. They won't be redundant.

Choosing a trailer for transporting a motorcycle up to 50,000 rubles

The range of motorcycles on the market is huge. Trailers for transporting motorcycles are selected according to:

- Load capacity and weight.

- Internal dimensions for side or enclosed models.

- Dimensions.

- Suspension (stronger is better).

- Tires (more - less shaking / winter - summer).

- Complete sets (to be purchased if necessary):

- Lodgment is a stand that prevents lateral movements.

- Ladder.

- Bracket for the front fork - front wheel stop/locker.

- Straps for fixation.

- Support stands that protect against tipping during loading and unloading.

- Counter-kickbacks.

- Awning/removable roof.

MZSA 817701.001-05

A flatbed single-axle trailer with a total weight of up to 0.75 tons is compatible with motor vehicles of different sizes and has the following features:

- AL-KO Kober spring suspension from Germany;

- Folding front/rear sides;

- Galvanized body, durable and reliable;

- Cost from 42,000 rubles.

Trailer MZSA 817701.001-05

MZSA 817703.001-05

Specialized for transporting motor vehicles (motorcycles/ATVs). Adapted for off-road use. Fits most models. Characteristics:

- Load capacity - 0.49 t;

- Total weight - 0.75 t;

- Dimensions - 4.07 x 2 x 0.87 m;

- Body dimensions: 2.74 x 1.51 x 0.29 m;

- Ground clearance - 172 mm;

- Moisture-resistant plywood on the bottom of the trailer;

- Tilting platform;

- One axis;

- Rigid galvanized sides;

- Price - from 48,500 rubles.

Trailer MZSA 817703.001-05

Trailer "Sport" 829450 ("Trailer")

The single axle has:

- Load capacity - 0.5 t;

- Total weight - 0.75 t;

- Dimensions: 3.93 x 1.81 x 0.52 m;

- Body dimensions: 2.51 x 1.27 x 0.31 m;

- Ground clearance - 231 mm;

- Tires - 170/75 R13;

- Tailgate;

- Anti-corrosion coating;

- Height-adjustable support leg;

- Rings for securing a motor vehicle;

- Reinforced plywood tailgate;

- Cost - from 44,300 rubles.

Trailer "Sport" 829450 ("Trailer")

Trailer 8213 05 “Universal” (“Kurgan trailers”)

The multifunctional trailer includes a stand for a two-wheeled unit, fits most sizes and includes the following characteristics:

- Load capacity - 0.55 t;

- Total weight - 0.75 t;

- Dimensions - 3.56 x 1.71 x 0.98 m;

- Body dimensions - 2.38 x 1.22 x 0.38 m;

- Tires - VAZ/Niva/UAZ;

- The bottom and sides are reinforced with Finnish plywood, resistant to moisture;

- Rails increasing the height by 0.08 m;

- Price - from 47,900 rubles.

Trailer 8213 05 “Universal” (“Kurgan trailers”)

Trailer device

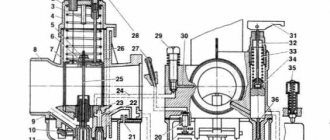

The standard side trailer of an Alfa moped consists of just a few simple components:

Side trailer for Alpha moped

The structure itself is rigid, since the manufacturer does not install any shock absorbers or other dampers on it. Although, if you wish, all this is very easy to do yourself.

The side trailer on the Alpha moped, according to the manufacturer’s documentation, is designed for transportation weighing one hundred kilograms. These limitations are not due to the fact that the power of the moped engine does not allow it to transport more, but to the fact that the standard fasteners to which the adjusting rods are attached are very weak. If you load the trailer more than expected, you can simply break off the fastenings . But this is the case if the trailer or moped together with the trailer was purchased with installation from the manufacturer. By assembling the cradle for the moped with your own hands, all this can be taken into account and improved.

Side trailer design

Advantages and disadvantages of homemade trailers for walk-behind tractors

Many people who decide to acquire a walk-behind trailer do not know whether it is worth making it themselves. To understand this, you need to familiarize yourself with the main advantages and disadvantages of homemade structures. Among the main advantages are the following:

- the ability to create a trailer with optimal dimensions;

- using only durable and strong materials, which will significantly increase the service life of a hand-made product;

- the ability to create a design from scrap materials, which allows you to save money on branded parts.

Despite the above advantages, a do-it-yourself towbar for a walk-behind tractor also has disadvantages. The main disadvantages include the complexity of assembly. The fact is that not every person can make such a device on their own.

Also, the advantages of homemade products include the fact that additional devices can be attached to them. For example, quite often homemade structures are equipped with brakes or reflectors.

Solid-type structures - most often used for attachment to walk-behind tractors

Assembling a side trailer with your own hands

According to the standard homemade scheme, all the required material for the towed side device of a moped can be found in your garage. The only thing you may need to buy is a wheel on a rim. Although it will do if you have an old VAZ. However, it will need a corresponding hub. Let's get started.

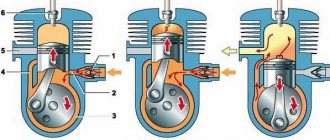

Welding of main parts

First of all, you need to weld the frame of the future trailer. Considering the dimensions of the Alpha moped itself, the frame dimensions will be 1200x550 mm. This is optimal, but not essential. The main thing is that the front wheel has free space for maneuvers.

Then we will weld the reinforcing frame and attach it to the moped. The frame will be attached to it, since the standard moped mounts, we remember, are weak. The reinforcing frame will be welded in three places. The first is where the standard mountings of the adjusting arcs are located under the gas tank. Second, from below in place of the footrest, having previously removed it from there. Third, it will not be welded, but screwed to where the rear wheel shock absorber is attached. This makes a very good, strong base and four points for mounting the side trailer.

Alpha side trailer mounts

Fastenings for structural strength

The two lower fastenings are made using ordinary M10 bolts inserted into pre-drilled holes on the frame. The top two are two studs screwed between two tubes. One of which is fixed to the frame, and the second to the frame. They will also play the role of adjusting arcs.

If you have your own wheel, a corresponding hub is purchased for it and welded to the cart frame. This is a rigid, shock-absorbing design.

Wheel shock absorber

In order to install a shock absorber along with a wheel, you will need to add a small structure to the trailer for attaching the wheel with a shock absorber. If desired, you can install a wing to protect against dirt flying from under the wheel.

A carriage of this design is quite powerful and, according to its creator, can transport up to 600 kg of weight at low speed without damaging the engine. Well, what to choose: buy or make it yourself is everyone’s personal choice.

Source

Multi-Task Motorcycle Trailer

A long time ago, my brother wanted an efficient way to deliver newspapers along the road route and maybe also a way to get his two beagles to the dog park on his motorcycle. Side hacks and trailers were discussed, and finally we chose a trailer that fit the bill.

While exploring, we came across a one-wheel trailer. Several of them were for scooters and motorcycles. Lots of good ideas here, some of which were incorporated into my trailer design.

I thought something like this would be great for carrying things while traveling. Now that I'm retired, I seem to have the free time to take longer trips. So, after some thought, some sketching, and some specifications in mind, I contracted with a welder to build my trailer.

Close the hitch point. This high hitch height presented some problems. But I managed with what I had, and there are other trailers that are being lifted successfully. I may have installed the hitch lower after some time. It will take some time to figure out how to fit the hitch attachment into the available space without cutting holes in the plastic. This hitch has been slightly modified since this picture appeared. Some reinforcement was added to prevent the rear fender mounted tongue from bending, and closer tolerance bolts were used to remove any loose play in the fittings. This would allow for some pretty severe trailer wobble without these fixes. But now everything is fine.

Alpha moped trailer

Initially, the Alpha moped, like any other, is not intended for transporting goods. But many owners of this motorcycle tune the moped and install a trailer or stroller on the scooter, which you can buy, but it’s cheaper to do it yourself. Of course, it is easier and safer to order cargo transportation from Avtotrans in Kharkov to transport the cargo you need. The article discusses how to make a rear and side trailer for an Alpha moped with your own hands , as well as a review of the factory version of the stroller.

Types of trailers for walk-behind tractors

People who decide to make a walk-behind trailer on their own should familiarize themselves with their main varieties in advance.

They are:

- Solid. They have the simplest design. All walls and bottom have a fixed connection.

- With opening sides. This is a universal model that is suitable for motor cultivators, as well as Neva and MTZ mini tractors. Used for transporting large cargo.

- Tipper. Such structures resemble the body of dump trucks. They are used for unloading bulk materials.

For attachment to a walk-behind tractor, one-piece models are most often used.

Sidecar trailer for Alpha moped

Let's start our publication with a photo report on how to make a sidecar on the Alfa moto . To save money, the moped trailer is made from scraps of pipes and profiles, and if desired, it can be made more neat and practical. The hub for the one-wheel trailer was taken from a VAZ car and welded with reinforced gussets. As you can see, the wheel is also Zhiguli. The side wheelchair trailer for the Alpha moped itself is simple in design and making it with your own hands will not be particularly difficult. There will be more problems with where to attach this stroller to the moped.

In this version, a reinforcing frame is welded to the Alpha frame (see photo).

This frame is attached at three points:

To prevent the steering wheel from moving, homemade rods were made from tubes. M12 nuts are welded into them for screwing in the rod studs. By turning the studs you can adjust the moped trailer.

This side trailer for the Alfa was made in a hurry and will undoubtedly be improved over time. It can carry cargo up to 500 kg. To transport small-sized cargo, it is possible to make a wooden box (as in the example of a homemade wheelchair trailer).

Delivery of materials for a homemade stroller can be carried out by Avtotrans.

Project “Motortrain”, one-wheeled trailer for a motorcycle

It all started when I got tired of going on picnics loaded down like Eeyore. There is enough space under your feet in the scooter, a lot of things can fit in there, but you have to use the techniques of the fascinating Kama Sutra to ride.

It was decided to make a trailer. The two-wheeled option was immediately discarded, because... When traveling over rough terrain, the load on the motorcycle increases; you have to lay two tracks instead of using one.

A version of a one-wheel trailer was put into work; the idea was borrowed from the Internet. Because There was no pipe bender at hand, so the frame was welded from a square twenty pipe. I invented the bicycle myself, so I first cut the fragments according to the developed drawing, so that later a professional would put it all together. As he later explained to me, everything could have been done simpler, but since your hands are itching, why not scratch them.

After the assembly began, the thought came to me that the creation process should be recorded, darting like a hog behind the camera, I managed to photograph most of the stages

The first photos - a set of scrap metal “crazy hands” began to take on the shape of a product.

Then the swivel hitch assembly was welded, we had to cut off the crosspiece with forks from the Kumovsky Zhiguli driveshaft with swearing and singing

Then I thought about it and decided that the pocket did not have enough reserve and the central jumper was pinned into the frame, just in case, for rigidity

Rear trailer for Alpha moped

This version of the moped trailer has a number of advantages compared to the previous stroller:

First, let's look at an amateur drawing of a homemade rear trailer for a moped .

We make the trailer frame from pipes and angles. The ears on the sides are where the wheels are installed.

To install the towing mechanism, you can use car towbars, but they are too expensive and bulky. The front ball joint from a Zhiguli car is used here. You can choose another suitable hinge.

We manufacture and weld the drawbar to the trailer frame.

Painted metal frame of a moped trailer.

Wooden beams and plywood were used to assemble the box. It is not forbidden to make it from metal, which is more expensive, but also more reliable.

We upholster the frame with 6 mm plywood and paint it.

We install stops and turns, and, if desired, hooks for attaching the tarpaulin. Wheels from a construction truck were installed on the trailer and the bearings were replaced with domestic ones.

With such a homemade trailer for the Alpha moped, you can safely travel at a speed of 40 km/h and with a load of more than 100 kg without dangerous consequences for the life of the driver and mokick. Naturally, you should connect the turns and brake lights in accordance with the wiring diagram of the Alpha moped.

Assembling a trailer for a walk-behind tractor

Before you attach a car trailer to a walk-behind tractor with your own hands, you need to figure out how to make it.

Welding machine - often used when creating a homemade trailer

Required Tools

Before you start creating a walk-behind trailer, you need to familiarize yourself with the list of tools that will be used during the work.

You need to prepare the following in advance:

- welding machine for connecting metal components of a structure;

- grinder and cutting discs that will be used for sawing iron parts;

- tools for determining the size of a trailer for a walk-behind tractor - tape measure, ruler and square;

- drill for drilling mounting holes.

You may also need a hammer, vise, and welding clamps to create the towbar.

Homemade device option

What materials may be needed

Before making a tow hitch for a walk-behind tractor, you must be sure to familiarize yourself with the list of materials that can be used for this. For example, the frame is made of metal pipes, channels, steel beams and angles.

The wheel axle is made of metal rods with a diameter of 3-4 centimeters. Its length should not be more than 100 centimeters. The rod must be attached to the frame supports.

The body is made of ordinary wooden boards. However, some people prefer to use iron sheets. They make the structure more durable.

When choosing materials to create a walk-behind trailer, do not forget about the wheels. They can be removed from cars or mopeds. Quite often they use the rear wheels of motorcycle strollers.

Metal pipes - needed to create a reliable structure body

Drawing

Before you start assembling a trailer for a walk-behind tractor, you need to create a drawing of it. It is needed to determine the dimensions of the device and its design features.

First you need to develop a general drawing. It notes:

- wheels;

- frame;

- body;

- cardan;

- drove.

Then it is necessary to develop a detailed drawing of the frame. It indicates its dimensions and location of the main parts. An additional drawing of the carrier may also be useful.

Drawing of a simple trolley for a walk-behind tractor

Chassis

When assembling a trailer, special attention should be paid to its chassis. First you need to prepare the wheel axle. In this case, any wheels can be used. However, to make it easier to control and increase driving safety, it is better to use rubber ones.

The axle must be welded to the hinge and side members. In this case, the products must be welded at several points to make the fastening more reliable. In order to make the fastening even stronger, you can use metal corners.

You should not make the axle too long, as this may cause it to begin to protrude beyond the body.

Approximate drawing of a universal hitch for a walk-behind tractor

Body and frame trim

The creation of the body begins with the installation of the sides. The front and side ones must be tightly connected so that they do not dangle. The tailgate is mounted on hinges and made removable.

The removable board is assembled in the following sequence:

- Installation of side frame.

- Fitting the metal sheet to the dimensions of the installed frame.

- Cutting and installation of side panel.

After fastening the sides, it is necessary to install the bottom. It is connected to the main frame by welding. The bottom should be welded every 4-5 centimeters. If desired, you can additionally use factory metal bolts.

Metal sheets are a high-quality material that is often used for body cladding

Other design details

After the creation of the body and installation of the chassis is completed, they begin installing the brakes. You can install a car brake system on a walk-behind trailer.

To make the brakes more reliable, another clamp is installed for the lever.

Buy a side trailer for an Alpha moped

For those who don’t want to bother with homemade trailers, there is a factory Chinese solution for a sidecar for Alpha. Alpha with a stroller is quite rare in Ukraine and Russia. The price, compared to a do-it-yourself stroller, is steep. But if you don’t spare the money to buy such a trailer, you will get a good side stroller for a moped with a shock absorber and the ability to detach it from the scooter. By the way, delivery of such a side trailer can be ordered from the Avtotrans company.

If you do not want to additionally load your moped with cargo in a trailer or you need to transport a large amount of something, use the services of the Avtotrans company https://autotrans-ua.com/gruzoperevozki-gazel.html for cargo transportation in Kharkov. We recommend!

I hope that now you can easily make a trailer for a moped with your own hands.

Source

Air suspension on a VAZ: is it possible to install it yourself, how much does the kit cost?

In order for the cart to be securely attached to the mini tractor, you will have to make a reliable coupling device. Of course, you can use a regular tow bar. However, many people prefer to create such a retainer themselves.

It is recommended to make a device with a built-in adjustment mechanism. Thus, it will be possible to connect almost any cart to the walk-behind tractor.

To install a spider hitch, the hitch bracket must be positioned to the side. It must be attached to the structure using strong metal pins. For additional fixation, you can use spacer bolts. This will allow you to get rid of strong vibrations during transportation of goods in the future.

A towbar is a special device that is used for attaching trailers or trailers.

Many people are interested in how to attach a homemade cart to a walk-behind tractor and what might be needed for this. To deal with this, you need to know in advance the main features of creating towed devices and the nuances of attaching them to walk-behind tractors.