The three-wheeled cargo scooter Ant was produced at the Tula Machine-Building Plant named after Ryabikov from 1961 to 1995. By this time, the plant was already confidently producing motor scooters of its own design instead of copies of German motor vehicles, which made up the majority of its production immediately after the war.

The ant was the result of the efforts of designers who had been working on the project since 1956. There was a need to create an inexpensive and compact alternative to cars so that residents in rural areas could transport goods without extra costs. First, the first domestic scooters T-200 Tulitsa rolled off the assembly line, and a few years later the cargo “Ant” was designed on their basis.

Description of the “Ant” scooter gearbox

The Ant gearbox consists of high-quality manufactured parts that have a very long service life and are ready for immediate use. Despite this, sometimes you have to remove and disassemble this device, since nothing lasts forever. You can, of course, contact specialized technical services that have extensive experience in this field. But you can repair the gearbox at home, provided you have the tools, basic knowledge of mechanics and a reference book on this device. He will become an indispensable guide in this matter.

Device Description

The Ant is much lighter than ordinary motorcycles, so everyone dreamed of buying one. The approximate weight was only 240 kg, which is not enough considering that he could carry loads several times heavier than himself. Actually, that’s why he got the name Ant.

Another advantage of the scooter was and remains that it can be bought for little money. So, you can buy an “Ant” scooter for only 30-50 thousand rubles.

Engine

The Ant has a single cylinder engine. At the same time, it is quite greedy, so it’s impossible to call the scooter a cheap piece of equipment. After all, even a new Ant engine consumes about 8 liters of gasoline out of 80 liters per hundred, and what can we say about used equipment? Indeed, with slight wear of the piston or gearbox, costs increase to 10 liters per hundred. In this case, you can replace the damaged parts, but they are not easy to buy since they are rarely available for sale.

Ant scooter engine

You can buy a pre-assembled Ant motor, but it's a bit expensive.

Suspension

Overall, the Ant scooter is a very durable piece of equipment. The front arm suspension is particularly well thought out. It can last for decades. Many scooter users even claim that they are made better than modern telescopic forks.

Nowadays, most fans of the Ant scooter install the rear shock absorbers of the scooter instead of front shock absorbers, since there are few of the former now.

The rear suspension is independent. The gearbox drives the rear wheel. This is facilitated by a roller chain passing through it. At the same time, the box itself is made well. Located in the center of the rear axle, it can be easily removed if necessary.

Easy to repair

Thanks to its light weight, the owner of this equipment can easily transform the Ant scooter, which will allow for easy repair work. There is no need to remove the wheel to change a tube, tire or even transmission.

The scooter is large in size, making it an ideal piece of equipment for field work.

The scooter can reach a maximum speed of 50-60 km/h.

What is a gearbox?

The Ant gearbox is a special mechanism that transmits and converts angular velocity into one or more mechanical gears.

- cylinder (excellent reliability and high degree of performance, standardly applicable for transmissions and conversions of enormous power);

- globoid (high gear ratio, not very high efficiency, excessive heat generation);

- wave (has a reduced efficiency when compared with cylinder);

- spiral (very high load capacity, low weight, and size proportional to mass);

- combined (combines many gears, has an optimal cost, good technical components and a relatively small size).

The standard housing of this device is cast. Very often it is cast from high quality cast iron, in rare cases from steel. If it is necessary for the product to be as light as possible, then a material is used that melts quite easily. At the base of the case there are special “ears”, by which the device is attached to the base.

To prevent oil from leaking, a seal (oil seal) is installed at the shaft output, which prevents oil leakage.

To prevent an increase in internal pressure in the gearbox, it has unusual design features. It is they who do not allow the pressure inside the device to increase during heating of the device.

How to disassemble?

The gearbox itself is removed from the Ant in a certain sequence. It needs to be disassembled if its operating functions are no longer satisfactory during operation. Sometimes it happens that when it breaks, it is sent to a landfill. But this is fundamentally wrong. This device can almost always be repaired, and it will continue to function and serve for quite a long period. Also, the “Ant” scooter is currently a rarity, and spare parts for it are extremely difficult to find. Therefore, there is no need to “throw away” them in vain.

- The first step is to remove the gearbox from the Ant without damaging it. Then clean the body from contamination and remove all excess.

- Next, you need to unscrew the bolts that tighten the body of the product, and warm up the entire device with a hair dryer. After this, you need to knock on the body with a wooden hammer. This is done until it is divided into 2 parts.

- The next step is to remove all the gears. To do this, you will need to bend the special plates and unscrew all the bolts that hold the body halves together. Then these body bowls are separated, and the corkscrew pin itself is removed. Next the wheel axle is removed. Then the retaining ring and the axle shaft are removed from the housing half.

The device itself is dismantled and mounted on a scooter quite simply, there are almost no problems.

Disassembling the gearbox will also not bring unnecessary trouble. But assembly will also require increased attention; you need to carefully assemble everything, not miss anything or confuse anything. Gears are made of high strength steel (alloy steel), so they very rarely become unusable or deformed. The main problem in most cases lies in the bearings. Therefore, regular and careful attention to these parts is required, in particular to elements such as oil seals.

Improving the carrying capacity, or making a dump truck out of Ant

The Ant scooter is a powerful device, but most owners would not mind increasing the model's carrying capacity. You can also redesign the body and make it foldable (like a dump truck).

However, there are some nuances, and the main thing is not to overdo it. As you know, the load capacity is about 250 kg; In practice, large loads can also be accepted. But it should be remembered that with such a load the speed will be much lower (up to 35 km/h).

The carrying capacity can be increased by increasing the sides. However, the scooter frame will need to be strengthened.

Welding can be considered the best option, but you can do without it (the production of an additional frame is made of wood).

In this situation, the body moves forward or remains in place, but moving backward is prohibited.

You can consider the option of installing separate cabins on such scooters, which will require separate costs.

The following mechanisms are often used for a dump truck:

- cable winches;

- hydraulic with automatic drive;

- methods using door hinges, etc. (the so-called “manual”).

As for the plumbing, you will also need to use a pump. The total cost of this approach may exceed the cost of the scooter itself.

Let's consider options for implementing the idea:

1. Using automation.

The body is attached to an additional frame, which is connected to the main frame with hinges. Lifting can be done using a diamond jack, which is powered by a simple electric drive. Electric traction itself is easily accomplished using the windows of a simple car. This is the essence of automation, turning the body over at the touch of a button.

The only drawback of such a conversion is the final cost of the work. The price depends on the spare parts used.

2. Manual method.

The body, as in the automatic method, is mounted on an additional frame. The frame is also connected to the main one.

The convenience of this method is that if necessary, you can simply remove the housing (for example, when you need to carry long pipes, etc.). Such long items can be attached directly to the frame.

Subtleties of production

In practice, it is recommended to install additional chains to prevent the hinges from slipping. Ordinary door handles of electrical appliances or car mechanisms can act as locks.

When designing a replacement body, it will also be necessary to mount the tank, numbers, and turn signals directly on the chassis (not to be confused with the body). It is necessary to ensure that the center of gravity is close to the axis of the hinges (approximately 30 cm from the rear edge). This is the only way to turn the body over manually without any problems.

So, today the Ant scooter is not only a means of transportation, but also a powerful mini-dump truck at home. Despite the fact that the car has not been sold on the car market for a long time, it is still worth buying it by hand. Thus, from a simple moped, with little effort, we get a powerful dump truck and a perfect vehicle.

The Ant scooter is a three-wheeled Soviet scooter. For the first time, the production of such equipment, which was quite difficult to purchase, since it was initially in short supply, was resumed by the production plant in Tula. Subsequently, several modifications of the scooter were released, but all of them were created on the basis of the original version. Now the Ant scooter has become a common technology available to almost everyone.

Previously, a scooter had one purpose, one main purpose - to transport a wide variety of cargo. Of course, at the moment the Ant scooter is not as in demand as it was during the Soviet era, so it is now very difficult to find one. However, in some Asian countries such a device is still in great demand, so it will not be difficult to buy the missing parts here.

How not to make a mistake when choosing a gearbox?

When choosing this device, it is worth considering the work it will perform. Both its reliability and performance, as well as its operational period, will depend on this. If you make a mistake when choosing a device, you can “kill” the gearbox ahead of time. It is advisable to entrust the choice to qualified specialists. They will make all the calculations and advise you on the best option for the task at hand.

But there is not always a chance to get advice from an experienced specialist. In this case, you need to take the initiative into your own hands. The first step is to create the kinematics of the drive. It will tell you what type of gearbox is required for the selected system.

Features of purchasing motorcycle parts at Moto Life Market

If a rarity originally from the Soviet Union needs repair, then replacing original parts with Chinese analogues is not always possible; you need spare parts from the USSR. Parts for Ant and Tula scooters are presented in a wide range in the USSR Motorcycle Parts store. We only have high-quality components made to strict requirements from trusted manufacturers. We know all the intricacies of repairing Soviet motorcycles, so you can safely contact our managers for advice - they will advise the best option and send spare parts within the agreed time frame.

Pros and cons of helical gearbox

This device has the following advantages:

- very high level of efficiency (up to 98%), and it is extremely economical;

- transmitting high power without losing it;

- very high kinematic accuracy (much higher than that of a globoid, i.e. worm);

- despite the high efficiency, the case does not heat up much, and at the same time energy transfers from the sender to the recipient with almost no losses;

- models perform well under shock loads;

- very high reliability, can continuously operate for at least 25 thousand hours;

- the shaft itself can be rotated.

But, despite the advantages, there are also disadvantages:

- in order to increase the gear ratio, the number of steps should be increased, this will lead to a significant increase in size;

- the noise threshold is very high (this device is much noisier than other modifications);

- in some cases, self-braking is required, but this type of gearbox does not provide it, so an additional device must be installed.

MY MOTORCYCLE

The rear axle of the Ant cargo scooter consists of a main gear with a differential, suspension and rear wheel drive.

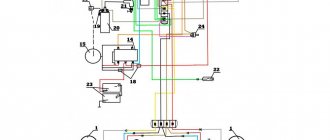

The main gear is designed to increase torque and transmit it to the differential and then to the wheels. Torque is transmitted to the main gear itself by a chain. Let's look at the design and operation of these units in more detail. The differential housing 15 (Fig. 1) rotates together with the driven gear 22. It contains bevel gears 13, axle shafts and satellite gears 19. Each satellite is meshed with both gears 13. When the wheels roll along a flat, straight road, the satellites evenly distribute forces on bevel gears and do not rotate on their axis. If the speed of one wheel decreases, the satellites will begin to rotate and increase the speed of rotation of the other wheel. On a cargo scooter, the main gear and differential are combined in one unit along with a mechanism for shifting forward and reverse gears.

The main gear is geared with an intermediate gear 27. The crankcase consists of two halves 1 and 5, cast from aluminum alloy AL-2. At the end of the drive shaft 10 protruding from the housing, rotating in the crankcase in bearings 11, a driven sprocket 8 of the drive is installed on splines. Inside the crankcase, drive gear 6 is freely mounted on the shaft, having cams on the left end; and on the splines - primary gear - clutch 24.

The intermediate shaft, made together with gear 27, rotates on two bearings 26. The differential housing 15 with the housing cover 14 rests on ball bearings 21, pressed into the crankcase. On the cover 14 and the differential housing 15, bolted together, there are driven gears: 22 forward and 17 reverse, and inside there are two more gears 13 and two satellites 19. The satellites rotate on an axis 18, secured with a pin in the housing 15. At the ends of the gears 1 3, rubber-metal hinges 12 are installed, protected by covers. Through chain 7 and driven sprocket 8, torque is transmitted to drive shaft 10. When the scooter moves forward, the cams of gear 24 are connected to the cams of drive gear 6, which transmits torque through the intermediate shaft-pinion 27 to driven gear 22. When reverse gear is engaged, the gear 24 engages with the reverse driven gear 17.

How to disassemble the gearbox

The Ant gearbox is disassembled according to a certain scheme. This process is necessary if for any reason the Ant reducer stops working. Some do it badly: if the gearbox breaks down, they throw it away. But with the right approach to this matter, the device can be repaired, after which the Ant scooter will work the same as before. It's also difficult to buy spare parts for the Ant scooter, so don't waste them.

Gearbox for Ant scooter

- If the Ant gearbox has been disassembled for some time, it would be a good idea to first clean it of dust and dirt.

- Remove all the bolts that hold the transmission together. Buy a hair dryer. Use it to heat the Ant gearbox from all sides, then hit the body with a wooden hammer. Until it splits into two halves.

- Now you can find out what caused the failure. The gearbox could fail for two main reasons: the input shaft bearing is broken or the gear teeth are worn out. Both parts will need to be replaced.

- The gears and bearings must be removed so they can be replaced with new parts.

- Remove the mounting plate.

- Remove the retaining ring and remove the axle shaft from the bowl.

- Before you begin reassembling all parts, you must check their integrity. Once the Ant reducer is assembled, it can be sent to its designated location.

The Ant scooter can become a useful piece of technology today. If you have your own farm or garden in the countryside, you won't find anything better than this scooter.

First of all, I would like to thank the editors of the “Modelist-Constructor” magazine for promoting the ingenuity, intelligence and talent of ordinary people, for the opportunity to use their rich creative experience, concentrated in the magazine. So go ahead!

For my part, I would like to draw the readers’ attention to the description of a very practical mini-truck. It is practical in the sense that it is simple in design, easy to use and inexpensive to use.

This simple vehicle is designed to transport various goods, as well as a passenger. I have been hatching plans to make such a mini-truck for a long time - it is simply necessary in the house. And when sometimes a used Ant scooter fell into my hands, I decided to put its components and main parts into the base of my four-wheeled machine, since it is more stable than a three-wheeled one. These components and parts, with minor modifications (thanks to the Tula machine builders for the quality of their products!) made the design economical in production and reliable in operation.

The truck, called the Pathfinder, is a converted Ant body. Outwardly, it somewhat resembles the chassis of the T-16 self-propelled gun. But unlike it, it has front-wheel drive. The choice of the layout of the self-propelled chassis is explained by the following consideration: the rear drive wheels of the Formica, becoming the front wheels of the truck, increase its cross-country ability, and the front drive wheels becoming the rear wheels increase its maneuverability. This gives a clear advantage when driving off-road or in a cramped backyard.

To implement the idea, we had to redo the stock front suspension; make a rear axle beam with sets of bearings at the ends; adapt the steering wheel from Moskvich-412, steering and ball joints from Niva; install gas controls, clutch, brakes, make seats and a dump body.

Mini-truck "Pathfinder" (protective tray with spare tire not shown in front view).

Mini truck equipment:

1 — passenger seat: 2 steering joint: 3 — seatpost frame; 4 — rear wheel assembly, swivel; 5 — gear shift lever; 6 steering gear; 7 — steering wheel; 8 — reverse lever; 9 — fuel tank; 10 — engine hood; 11 — dump body; 12 folding boards; 13 — protective pan; 14 — spare tire; 15 — exhaust pipe; 16 — working wheel; 17 — front wing; 18 — muffler; 19 — brake rod; 20 chain drive; 21 — mini-truck chassis; 22 — kickstarter lever; 23 — brake pedal; 24 — gas pedal; 25 — pull the gear shift lever; 26 — steering wheel fork; 27 — steering wheel: 28 — rear shock absorber; 29 — bumper-bumper; 30 — rear wing; 31 — driver’s seat; 32 — suspension spring; 33 — front shock absorber; 34 — main gear; 35 - driveshaft with cardan joints.

The Ant scooter chassis and the main parts that transform it into the Pathfinder mini-truck chassis (the rear engine mounting bracket is not shown):

1 — axle bushings; 2 - sleepers (pipe 30 × 2); 3 — floor brackets (angle 30x30); 4 — arches of the frame of the old seatpost; 5 — fuel tank hatches (steel, sheet s2); 6 — brackets for fastening the front wings (angle 70x70); 7 — floor brackets (pipe 25x25x2); 8 — eye for fastening the seat frame of an enlarged size, rotated (2 pcs.); 9 — rear axle beam (pipe 48 × 5); 10 — scarves (steel, sheet 50 × 50, s2); 11 — knee of the scooter frame, central; 12 — clutch pedal mounting bracket (angle 30 × 30); 13 — frame for scooters; 14 — bracket for fastening the seat frame (4 pcs.); 15 - stand (pipe 25x25x2).

It took four months. The work went like clockwork because in my mind I was already in control of Pathfinder. The finished and painted car was properly registered. True, like... a mini tractor. This metamorphosis can be explained simply: at that time I only had a license for a tractor. However, this circumstance does not in the least prevent me from using the Pathfinder primarily as a means of transportation.

“Pathfinder” is a good helper in the farmstead. In addition to gogo, I ride it to pick mushrooms and berries, as well as for fishing. I mainly use the truck only in the hot season, so I didn’t make a cabin. Sometimes I ride 100 km and don't feel too tired. The car is easy to operate: all controls are located directly in front of the driver. And although the pedals are a little wider than in a car, you quickly get used to it.

This is convenient not only for the driver, but also for the passenger: the car’s driving is soft, and it’s not without reason that all wheels have independent suspension. In his opinion, anyone who has ever driven a Pathfinder in the passenger seat has not encountered any inconvenience. Later, when armrests and a removable awning were added to the seats, the definition of “comfortable” also found a response in travel reviews.”

In short, I'm happy with my mini truck. Pay attention to its maneuverability, especially when loaded, since the drive wheels are wide-profile, from Tula motorcycles (the handlebars are from scooters). But the power of the “native” engine was not always enough. Therefore, before towing a heavy load, it is necessary to replace the wheels of motorcycles with wheels of scooters, and coupled ones.

The body of the mini-truck is folding and rotating. But this can also be fixed. So it’s easy to connect the Zhiguli bump stop (engine crankcase protection) with the “spare wheel” - the scooter wheel from below it. In this configuration, the Pathfinder looks quite unusual, attracting the attention of passers-by.

Seat frame:

1 — seat frame (pipe 22 × 2, 2 pcs.); 2-seater leg (tube 22 × 2, 8 pcs.); 3 support beam (pipe 25x25x2); 4 bandages (pipe 22 × 2, 2 pcs.); 5 — support (pipe 25x25x2, 2 pcs.); 6 — bumper-bumper (pipe 50x25x2); 7 — stop (pipe 25x25x2.2 pcs.); 8 brackets for attaching to a mini-truck chassis (4 pcs.); 9 crossbar (pipe 22 × 2. 2 pcs.).

Steering gear:

1 — ball axle (from “Zhiguli”): 2 transverse rods; 3 — rubber-metal hinge (from Moskvich-2141); 4 — rocking chair (strip s10); 5 — swinging head (pipe 30 × 5); 6 — thrust bushings (pipe 26 × 3); 7 — clamp for fastening to the central knee of the frame (bar s5); 8 — bearing housing (pipe 77 × 15); 9 — bearing 204; 10 — crankshaft (rough 20 × 4); 11 — steering bipod; 12 — longitudinal thrust; 13- fixing pins.

Steering diagram:

1 — steering wheel (from Moskvich-412): 2 — steering mechanism (from Niva); 3 — steering rod, longitudinal (from “Zhiguli”); 4 — adjustable transverse steering rods; 5 - rocking chair; 6 — rotary levers; 7.9 — bearing supports; 8 - crankshaft; 10 — steering bipod.

Rotary block:

1 — rotary lever; 2 — heel (flat s5); 3 — bolt M12x1.25; 4 — additional elbow (bar d14); 5 — wheel fork; 6 — pin: 7 — anthers; 8 — pin bushing; 9 — bearing 46204; 10 — spacer sleeve; 11 — bearing 204; 12 - nut M 12 × 1.25

Location of some controls (driver's side view):

1 — clutch pedal; 2 — steering mechanism; 3 — steering bipod; 4 — steering rod, longitudinal; 5 — brake lever; 6 — push gear shift lever; 7 — gas pedal; 8 — brake pedal; 9 — steering wheel.

Gear control mechanism:

1 — gear shift lever; 2 — frame elbow, central; 3 — bracket for fastening the bracket; 4 — adjustable draft; 5 — toothed driver (the engine is not shown)

When designing a mini-truck, I was guided by the need to ensure: sufficient strength and reliability of the structure, good stability and handling, effective braking, optimal location of all components, functional arrangement of controls, comfortable seating for the driver and passenger, and, finally, an aesthetic aspect.

Mini truck FRAME. It was based on the chassis of the Ant scooter, to which a rear axle beam, cross members, wing mounting angles and tank cradles were added.

REAR AXLE. It should be noted that the rear axle is one of the busiest parts of a minivan design. To successfully withstand alternating torsional and bending loads, the rear axle beam must be rigid and strong, which is why it consists of a thick-walled tube. It is fixed in place of the former Ant steering column (at the end of the central knee of the frame) and reinforced with two gussets.

In addition, the beam is supported on the right and left by crossbars that follow the curve of the central knee of the Formica frame (the latter is important to ensure that the floor for the driver's and passenger's feet is uniform). There are tabs at the bottom of the crossbars for attaching a seatpost, and on the sides there are floor mount brackets.

Technological subtlety: I attached the rear axle beam to the frame complete with suspension: forks, shock absorbers and wheels. First I grabbed the beam and welded it to the center knee, then, after positioning it relative to the frame and finally deciding on the size, I welded it to the knee and crossbar.

The 12° angle of the pivot bushings is due to the use of 6.70-10" idler wheels and 4.00-10" idler wheels. At this angle, the plane of the mini-truck's chassis is parallel to the road. The angle can and should be changed when using four wheels measuring 4.00-10 inches.”

The rear suspension is the modified front suspension of the two Ant scooters. The modification was reduced to replacing the hinge and attaching an additional elbow to the fork, which strengthens the connection of the fork with the hinge lever.

The seat frame with driver and passenger seats is attached to the rear axle beam with four upper brackets. With the help of two lower brackets (hinges) this frame is connected to the eyes of the crossbars.

FORE DECK, remember, boss. Included: reverse gear, wheel suspension, springs, shock absorbers, driveshafts, brakes - all from Ants. With some modifications, these units are located in their original places under the body.

Mini-truck ENGINE - “native”, T-200. Its power is increased to 14 hp due to the installation of a cylinder head with a reduced combustion chamber. Instead of the standard ignition system, a “magneto” is used, which makes servicing the power unit easier. The engine mount to the frame remains the same.

Gas control mechanism":

1 - sheathed cable; 2 - emphasis; 3 - traction; 4 — pedal mounting bracket; 5 — gas pedal; 6 - carburetor (engine not shown).

Differential bearing cover:

1 — bearing 104; 2 — gasket (rubber ring); 3 — housing cover.

Modified cardan fork.

Torque from the engine to reverse is transmitted through a chain from the moped. To do this, the driven (z - 14) and driven (z = 27) sprockets are adapted to the mounting dimensions of this chain by reducing the thickness of their teeth on a lathe. High traction force was achieved by replacing the standard drive sprocket (z = 17) with a “Minsk” one with a smaller number of teeth (z = 14). The Pathfinder's chain drive worked well; Having traveled 800 km, the possibilities for customizing it are far from exhausted. The sprockets show no obvious signs of wear.

TRANSMISSION. The standard gear shift lever has been replaced with a lever

from the diesel injection pump corresponding to the size of the landing grooves.

The Pathfinder is equipped with the reverse of the Ant cargo scooter. Its weakest parts are the drive shafts. At peak loads, they break, as they are weakened by the holes for the fastening pins and have significant play: cardan shafts with rubber hinges, as well as conventional suspension, do not in the least contribute to the long service life of the semi-automatic shaft seats.

So that the chassis of the car does not fail, I solved the problem radically. To do this, I made new differential bearing caps, into which I pressed 104 bearings that matched the seat size of the drive shaft.

The cardan forks have also been modified: firstly, shortened; secondly, it rotated from the outside so that the forks could be immersed deeper into the covers and thereby increase the reliability of their splined connection with the drive shafts. Subsequently, the pins holding the forks on the splined shafts became unusable.

I also plan to install final drives on the drive wheels. This will improve the overall distribution of the structure, make the engine easier to run and improve the towing performance of the mini-truck.

STEERING. When it was placed on a mini-truck chassis, I was faced with a challenge: how to link the steering wheel in front of the seats with the swing arms under the seats without disturbing the driver and passenger?

After considering several options, I used a rocker arm that connects the entire steering kinematics. The rocking chair is mounted on a vertical shaft, which rotates in two hinged supports attached to the central knee of the frame using clamps.

Variable length tie rods are made of steel pipes and rods. At one end they have spherical fingers from the Zhiguli, at the other - rubber-metal loops from Moskvich-2141. The rods allow you to adjust the degree of toe-in of the steered wheels so that when moving, all the gaps in the steering transmission are selected under the influence of rolling friction forces, and the wheels become parallel.

The steering mechanism itself is taken from a Niva car. A homemade column with a Moskvich-412 steering wheel is welded to it.

CONTROL SYSTEM. By the way, I mean the mechanisms for controlling the brakes, clutch, carburetor throttle, and reverse.

The mini truck uses an automotive control system: below

the driver's right hand is the gear shift lever, under the left is reverse, under the right foot are the gas and brake pedals, and under the left is the clutch (the last two pedals are from a UAZ car, replaced at the installation site). The brake pedals of the Tourist scooter are used as clutch and accelerator pedals.”

Clutch and throttle control mechanisms - cable; brakes, gearbox and reverse - traction, hard. The brake rods and gear shift lever are adjustable in length.

The carburetor air enrichment (“intake”) lever is located under the driver’s right hand on the seat post.

Reliable brakes are the key to the safety of any car. Even if the engine fails, the brakes should always be in order - these words have a lot of meaning. Therefore, the design of the mini-truck uses the standard “Ant” mechanical brake system.

The brake pedal is connected by a rigid adjustable rod to a rocker arm - a brake force equalizer, and then to the drive (front) wheels. In the future, the Pathfinder will also have parking brakes acting on the steering wheels (rear).

The SEAT FRAME is a simple structure, welded from round, rectangular and square steel pipes, bolted together in six places: four of them are located on the rear axle beam and two are located under the cross members. If necessary, the frame can be easily disassembled, leaving free access to the steering mechanism.

The seat frames are made of thin-walled pipes with a diameter of 22 mm, the seat cushions and backrests are taken ready-made - from transport equipment. Vertical backrests are comfortable for the driver and passenger. In addition, to prevent lateral movement of motorcyclists during sharp turns, the seats were subsequently equipped with armrests.

The FUEL TANK consists of a reservoir for the brake system of the KrAZ heavy-duty vehicle. To accommodate it, the arches of the former “Ant” seat frame were chosen: they are equipped with cradles to which the tank will be pulled up using tapes and rubber seals. Its capacity is about 35 liters, which is enough for a long journey. Fuel from the tank flows by gravity into the engine carburetor.

WHEELS. For steering, scooter tires with a small tread, the so-called road pattern, are used. They hold less dirt, self-clean quickly for satisfactory off-road handling, and create less drag on pavement.

For presenters, the choice is much wider. On a mini-truck, depending on the route and driving conditions, you can install any of four sets of wheels: single or double “original” ones, homemade ones with an “evil” off-road tread for off-road use, or wide-profile wheels. Motorcycle "Tula". The latter option is the most beneficial for Pathfinder."

EXHAUST SYSTEM. His positioning was not associated with any difficulties. There is only one innovation here - an additional elbow at the outlet of the muffler, which allows exhaust gases to be diverted from under the body to the right. This saved the driver and passenger from the inevitable inhalation of exhaust gases.

The mini-truck BODY is made by hand and has dimensions of 1200x800x350 mm. Its load capacity is approximately 300 kg.

The housing consists of sheets of metal air duct (sheet thickness - 1.5 mm). The sides are edged at an angle, but it is also possible with a small-diameter pipe, having previously selected a gutter from below along the entire length. The edge is connected with an intermittent weld.

The fact that the body is a dump truck is very convenient to use. Among other things, this allows you to lift it and carry out routine inspection and repair of the transmission without crawling under the car!

SPECIAL EQUIPMENT. For safe driving on the roads, the mini-truck is equipped with a rear-view mirror and lighting devices from Ant.

This equipment includes a rear bumper, as well as a cup to protect the crankcase from Zhiguli cars with a spare tire installed under the body.

To protect the driver and passenger, as well as the engine and other structural components, from water and dirt, all four wheels are equipped with mud flaps and splash guards.

The wings of the drive wheels consist of parts of the inner chamber of a domestic refrigerator. Parts of the front wings of an Izhevsk motorcycle were used as rear wheels.

Three years of Pathfinder's activity have shown that it is quite viable. The good design of a mini-truck is attractive - many people mistake it for an industrial design.

Based on the Pathfinder, you can make a four-wheeled motorcycle, a mini-tractor and an all-terrain vehicle with tires. Each of these machines will make the work of a summer resident, farmer or builder easier.

S. YAKISHEV, Krasnoyarsk region

Did you notice the error? Select it and press Ctrl + Enter to let us know.