To watch online, click on the video ⤵

Adjusting the bearings of the rear wheels of the Ant scooterMore details

replacing bearings and crankshaft seals without disassembling the motorcycle engineRead more

How to remove the drum on an Ant scooter. + answers to questions about wheels. Read more

Restoring a used gearbox from the Ant Motor Scooter for a mini tractor. Part 1 Disassembly and troubleshootingRead more

Pressing the crankshaft of the engine Ant, Tula, TulitsaMore details

Assembly of the TG200 gearbox, Ant (Restoration of the 1966 TG200 scooter)More details

I am preparing the Ant Motor Scooter, I have changed the oil seal and bearing, everything is to the highest standard. Read more

Ant rear bearing 2Read More

Scooter Tulitsa | Replacing steering column bearingsRead more

Dismantling the engine of the “Tula” motorcycle, “Ant” and “Tulitsa” scooters. Part 1. Read more

Assembly of the Tula TMZ Tourist Ant engine (Restoration of the Tula T200K scooter) Part 1Read more

Installation of cone bearings on the Ant Motor ScooterRead more

elimination of play in the rear wheel of the antRead more

How to disassemble the wheel hub and suspension pendulum of motor scooters “Ant”, “Tourist”, “Tulitsa”Read more

Engine assembly, “Tula”, “Tulitsa”. Part 2More details

TMZ. Motor scooter Ant. Restoration of Motor Scooter Ant 2m-02. Day 3Read more

Engine, "Ant", "Tulitsa". Troubleshooting, part 2. CrankshaftRead more

MIRACULOUSLY THE BRAKE DRUM HAS BEEN REMOVED. I'M SENDING A PACKAGE TO MOTAKI!More details

Source

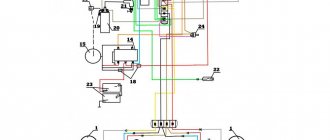

Electrical circuit of the Ant scooter

Ant scooters are cargo versions of the Soviet retro scooters Tula, Tulitsa and Tourist. Despite the huge number of modifications, the electrical circuit of the Ant scooter fits almost all mopeds of the Tula Machine-Building Plant.

In this publication we will look at the wiring diagrams for Ant scooters, models TG-200 and 2M, as well as their modifications.

Electrical circuit of the motor scooter Ant TG 200

The Ant TG 200 is based on its passenger car predecessor, the Tula T-200. The wiring diagram does not have complex components and is suitable for analogues of the Ant TG 200 scooter: TG-200F, TG-200I, TGA 200, TGA 200-01.

Download the electrical diagram of the Ant TG 200 scooter:

- Direction indicators

- Scooter battery

- Speedometer

- Speedometer backlight

- Spark plug

- Ignition coil

- Capacitor

- High beam and horn buttons

- Front side lights

- Low and high beam headlight

- Turn signal switch

- Sound signal

- Turn signal relay

- Switch

- Side light switch

- Battery charging indicator

- Neutral indicator

- Neutral sensor

- Clutch

- Scooter engine starter

- Breaker

- Egnition lock

- Fuse

- Brake light switch

- Relay regulator

- Switch block

- Brake light

- Tail light

Download the diagram

Photo report: Disassembling the rear gearbox of the “Ant” scooter

The gearbox that we are going to disassemble today had been lying in a barn for several years and was found there by pure chance. It would be a pity to throw it away, so it was decided to disassemble it and, if necessary, repair it, for further use as the basis of a homemade walk-behind tractor - no more, no less! Moreover, I have a practically new engine from SZD, which would be an excellent match for this gearbox.

Unfortunately, the technical condition of this gearbox was unknown; during the first inspection, some details became clear: The output shafts of the axle shafts did not rotate, nor did the drive sprocket... Most likely, the gearbox simply “caught a wedge.” Therefore, they removed him and threw him into a barn where he lay for many years...

We clean the housing from dirt, remove all excess, after removing the drive sprocket it turned out that the input shaft bearing had crumbled.

We unscrew the bolts holding the gearbox housing together, take a hair dryer, heat the housing evenly on all sides with a hairdryer, then take a wooden mallet and tap the housing until it separates into two halves.

So the cause of the “wedge” was found - a crumbling input shaft bearing, but these are still “flowers”. During operation of the gearbox, the bearing balls fell between the gears, which led to serious damage to the teeth, and this is serious... Such gears will have to be replaced with new ones.

The damage to the teeth of the input shaft turned out to be the most significant.

Damage to the idler gear teeth.

Crack on the outer race of the bearing.

Unbend the locking plates and unscrew the bolts that tighten the differential housing cups, remove the gears.

Separate the differential cups.

Remove the locking pin.

Using a special puller, remove the retaining ring and remove the axle shaft from the cup.

The differential parts passed the test “excellently”, the gear teeth are intact without signs of wear, cracks, wear - as expected. The permissible wear of rubbing surfaces does not exceed 0.1mm.

Source

Photo report Conversion of Ant scooter on magneto

What is a truck traffic law? What is a truck, traffic rules. Maximum speed, parking restrictions and other traffic rules innovations

I just finished overhauling the Ant engine and decided to write a short report on installing a magneto. Of course, the engine had to be half charged with spare parts made by no one. I suspect that the counterfeit goods with which I had to tinker for the last two days are being produced in some garage in Rostov-on-Don, or that the local workers are secretly making this nonsense at the factory. In any case, according to my information, traders bring this disgusting stuff from Rostov.

The engine to which I have devoted the last two days has already been converted to a magneto. Plus, there was another “Ant” in my yard, also converted by someone to use a magneto, but the store spacer to which the magneto is attached was “pinned” from it at one time... I had to buy a new spacer and the owner at the same time bought a coupling . I don’t know why he bought it - I didn’t ask him for it. The old one was in good condition. Well, since I bought it, we’ll install it.

The feasibility of installing a magneto

It’s none of my business, of course, but I have an extremely negative attitude towards this kind of collective farm tuning. Moreover, the magneto does not solve the problem with the reliability of the standard ignition system, but only replaces it with another problem. And this, in my opinion, is complete stupidity: convert the engine to a magneto, and then suffer even more with it...

Yes, the dyno starter is not an ideal device. Which also needs to be constantly monitored and, if necessary, serviced. So what? Well, I cleaned the collector and breaker contacts at the beginning of the season and that’s it. Are there fewer problems with the magneto? More than a hundred times!

- Firstly, due to the fact that the rubber coupling constantly breaks, the ignition timing is lost, and this entails detonation, loss of power, overheating and increased fuel consumption.

- Secondly, after installing the magneto, they usually stop monitoring the dyno starter, deprive it of its battery, and it eventually dies completely... Accordingly, the on-board network of the scooter is deprived of its power source. And this means that “there is no light - there will be no cinema”...

- Thirdly, due to the fact that this whole alteration is a complete collective farm - the axes in which the magneto rotor and the dynostarter rotate diverge within significant limits. And this leads to the fact that the parts of these two devices begin to work with a large axial misalignment relative to each other, which is why the magneto’s output shaft of the rotor constantly breaks off and its support bearings fall apart.

- Fourthly, the magneto was not initially designed for long-term operation, much less to work with such a horse-like misalignment along the axes, which leads to an increased radial load on the rotor, which is not typical for a magneto.

- Fourthly, a magneto is very expensive - plus you need to buy a spacer and a coupling.

We buy a spacer at the nearest store (it costs 450 rubles), a coupling (100 rubles) and a magneto (used from 1500 and above...).

Installation

We screw the coupling to the dynostarter rotor directly on top of the fan. The option of fastening the coupling with bolts in a hidden way, in my opinion, looks more preferable.

Than the option with regular bolts.

We break out the protective grille from the cooling volute.

Using a round file, we align the snail from the inside so that the spacer fits into it. We insert the spacer into the volute, mark the holes along the spacer mounting eyes. We drill holes and cut M6 threads into them, the main step.

We install the magneto and voila!

What is a gearbox?

The Ant gearbox is a special mechanism that transmits and converts angular velocity into one or more mechanical gears.

- cylinder (excellent reliability and high degree of performance, standardly applicable for transmissions and conversions of enormous power);

- globoid (high gear ratio, not very high efficiency, excessive heat generation);

- wave (has a reduced efficiency when compared with cylinder);

- spiral (very high load capacity, low weight, and size proportional to mass);

- combined (combines many gears, has an optimal cost, good technical components and a relatively small size).

The standard housing of this device is cast. Very often it is cast from high quality cast iron, in rare cases from steel. If it is necessary for the product to be as light as possible, then a material is used that melts quite easily. At the base of the case there are special “ears”, by which the device is attached to the base.

To prevent oil from leaking, a seal (oil seal) is installed at the shaft output, which prevents oil leakage.

To prevent an increase in internal pressure in the gearbox, it has unusual design features. It is they who do not allow the pressure inside the device to increase during heating of the device.

How to disassemble?

The gearbox itself is removed from the Ant in a certain sequence. It needs to be disassembled if its operating functions are no longer satisfactory during operation. Sometimes it happens that when it breaks, it is sent to a landfill. But this is fundamentally wrong. This device can almost always be repaired, and it will continue to function and serve for quite a long period. Also, the “Ant” scooter is currently a rarity, and spare parts for it are extremely difficult to find. Therefore, there is no need to “throw away” them in vain.

- The first step is to remove the gearbox from the Ant without damaging it. Then clean the body from contamination and remove all excess.

- Next, you need to unscrew the bolts that tighten the body of the product, and warm up the entire device with a hair dryer. After this, you need to knock on the body with a wooden hammer. This is done until it is divided into 2 parts.

- The next step is to remove all the gears. To do this, you will need to bend the special plates and unscrew all the bolts that hold the body halves together. Then these body bowls are separated, and the corkscrew pin itself is removed. Next the wheel axle is removed. Then the retaining ring and the axle shaft are removed from the housing half.

The device itself is dismantled and mounted on a scooter quite simply, there are almost no problems.

Disassembling the gearbox will also not bring unnecessary trouble. But assembly will also require increased attention; you need to carefully assemble everything, not miss anything or confuse anything. Gears are made of high strength steel (alloy steel), so they very rarely become unusable or deformed. The main problem in most cases lies in the bearings. Therefore, regular and careful attention to these parts is required, in particular to elements such as oil seals.

Motor scooter repair Ant

Before starting repairs, you need to buy all the necessary spare parts and tools. Of course, you first need to diagnose the device in order to understand what the real problem is.

It is also necessary to take into account a few tips on how to change certain spare parts:

- If you want to change a tube or tire, you don’t need to bead the wheel at all. It is enough just to unscrew all the bolts securing it.

- The wheel begins to spin thanks to a roller chain running through the gearbox. At the same time, the rear suspension is completely independent.

- The gearbox can be easily removed without any additional tools, because it is located in the very center of the scooter.

Repair is accompanied by the following basic actions:

- drain the oil from the engine, then remove the engine and place it on some flat surface;

- remove the cooling casings and dynastrater;

- remove the final drive sprocket;

- loosen the clutch cover from the bolts and remove it;

- remove several clutch discs;

- after this it will be possible to easily remove the basket along with the chain and sprocket, the washer and the bushing;

- to disconnect the cylinder head, you need to unscrew the four washers that secure it; if there are noticeable burrs on the cylinder mirror, then it should be sharpened;

- remove the cylinder, remove the piston pin ring using pliers;

- unscrew the crankcase tightening bolts; an impact screwdriver can help, which is very useful in such cases;

- turn the engine to the disassembled side, gently hit it with a mallet until the crankcase separates into two equal halves;

- lay the engine straight, using a mallet, carefully knock out the driveshaft;

- After this, access to the bearings and seals appears.

ATV from "Ant": assembly stages

Based on the Ant three-wheeled scooter, you can assemble a full-fledged ATV. These two types of motorcycles have relatively similar characteristics. The only significant difference is the volume of the gas tank, as well as engine power. The Ant engine is equipped with a multi-disc clutch located in an oil bath.

Gasoline is supplied by gravity, and a chain drive is also installed. The engine of this scooter is single-cylinder and has a power of 11 hp. With. The gearbox is four-speed, and the drive is supplied to the rear wheels. The gas tank has a volume of 12 liters, and the average gasoline consumption is about 7 liters per 100 km.

This allows you to assemble an ATV from Ant, which will have characteristics no worse than the factory models.

So how to make an ATV from Ant? First you need to prepare the necessary parts and components. Most of them come from a three-wheel scooter, but some parts will need to be purchased or taken from a car. Work is most often carried out in a heated garage, where there is high-quality ventilation.

The tool set includes an angle grinder, a welding machine, and a set of hand tools. To assemble an ATV from “Ant” with your own hands, you will need to work out the drawings yourself.

You need to create a diagram with an accurate description of all components, thinking through every detail. Drawings of a homemade ATV can also be standard.

But before proceeding with the assembly, they need to be considered in great detail.

How to assemble an ATV from Ant?

To assemble an ATV, you will need to complete 9 steps:

- Purchase of necessary components and mechanisms, materials, equipment.

- Welding work, creating a frame.

- Installation of brakes, suspensions, shock absorbers, chassis and wheels on the frame.

- Engine installation, gearbox, drive assembly.

- Installation of the fuel tank.

- Creation of an electrical system, installation of turn signals, headlights, battery, dashboard.

- Production of body kit.

- Finishing of the body, possibly the author's tuning.

- Installation of the body and seat.

Frame

You can assemble the frame from new pipes or use an old structure. If you plan to make the base from scratch, you should purchase pipes whose wall thickness should not be more than 3 mm. For the spars, blanks with a thickness of 25 mm are needed, and for crossbars and struts - 2 mm.

To assemble an ATV from the Ant scooter, you will need to assemble the pipes into a single structure using spot welding. If all elements are assembled correctly, the welding is complete. You will immediately need to attach the shock absorber lugs to the frame, as well as the levers. The brackets can be welded later, when components and mechanisms are installed on the frame.

To reconstruct a finished scooter frame, you need to remove all components from it. Pipes are built onto the bare frame from which the rear part is removed. After this, you can weld brackets and other small parts to install the corresponding components and assemblies. You will need to move the racks under the saddle 40-45 cm.

The structures of the rear and front trunk are created from a sheet of metal, which also need to be welded to the frame. The metal parts of the structure must be primed and painted.

Engine

The Ant's lightweight engine makes the ATV maneuverable and controllable, but it is not suitable for transporting cargo. This all-terrain vehicle can be pulled out of the hole almost manually, which is made possible thanks to the presence of a lightweight engine.

The motor and transmission must be inseparable to ensure proper operation of the entire system. It is worth considering that older scooter engines did not have cooling, so it is recommended to add it yourself. You can remove this system, for example, from a VAZ engine.

ATV from "Ant": suspension

The suspension from a scooter can be used as a front or rear axle. The choice is made by the master himself, but the first option is preferable. The rear suspension can be done in two ways:

- Take the rear axle from an old car, and then shorten it to fit the dimensions of the ATV. The disadvantage of this design is its significant weight.

- Cardan-gear type design. A gearbox is mounted on the rear axle, to which the drive is supplied.

An ATV requires an independent suspension that will have high ground clearance. Its levers are fixed to the frame using bolts through silent blocks. The front suspension strut must be inclined, otherwise the ATV may roll over.

Steering, braking system

To create the steering, a steering wheel from a scooter is used, along with which it is advisable to immediately take a fuel tank. The shaft is made from pipes with a diameter of 20 mm, and a travel limiter must be mounted below.

After installing the steering control, you need to remove the corresponding parts to connect them to the lever, pedals and other structural elements.

The main element of safety for the driver and passenger of an ATV is the braking system. It is better to purchase this element new, since a worn-out mechanism cannot be considered reliable. As a last resort, the brakes can be taken from a car with low mileage.

Frame

Creating a case is one of the difficult stages. Suitable materials for this are fiberglass or fiberglass. Sheet metal can also be used, but an artificial body kit will weigh less.

First, a “blank” of the body is cut out of pieces of foam plastic, for which you will need to develop a preliminary drawing. Fiberglass is applied to the prepared form.

There will be several layers, so metal fasteners are installed between them for subsequent fixation of the new body kit to the frame. To ensure that each layer is properly bonded to each other, they are additionally coated with epoxy resin.

The body needs to be thoroughly dried, and then primed and painted.

After installing all components and connecting the systems, you need to check the functionality and run the vehicle, gradually increasing the load.

How not to make a mistake when choosing a gearbox?

When choosing this device, it is worth considering the work it will perform. Both its reliability and performance, as well as its operational period, will depend on this. If you make a mistake when choosing a device, you can “kill” the gearbox ahead of time. It is advisable to entrust the choice to qualified specialists. They will make all the calculations and advise you on the best option for the task at hand.

But there is not always a chance to get advice from an experienced specialist. In this case, you need to take the initiative into your own hands. The first step is to create the kinematics of the drive. It will tell you what type of gearbox is required for the selected system.

To determine the subordinate number, use the formula:

In this formula, ninput means the number of revolutions that the input shaft has, that is, it shows the engine speed in 1 minute. The noutput parameter means the required number of revolutions that the output shaft needs (also revolutions per minute).

Having made the calculations, the resulting transmission value will need to be compared with the values of the standard series for all types of gearbox. It is important not to forget that the resulting calculation is not exact, it is only approximate. When choosing an electric motor whose shaft rotates at a frequency not exceeding 1500 revolutions per minute, you should take into account the technical characteristics of the electric motor or mechanism itself, and then carry out an analysis and carefully select.

Spare parts price

Despite the fact that the production of the device stopped long ago, you can still find new spare parts for it that are produced by the industry. Some parts are imported, some come assembled. Supplied in sets:

- Clutch discs.

- Gaskets for power plant and gearbox.

- Nuts.

- Pipes.

- Levers.

The necessary parts can be found on the Internet using store catalogs. Prices for spare parts for the Ant scooter are fair. Here are some examples:

- Clutch disc – 400 rub.

- Kickstarter shaft – 1100 rub.

- Front shock absorber – 1600 rub.

- Gearbox seals – 100 RUR.

- Piston – 2500 rub.

- Gearbox – 14,000 rub.

- Wheel hub – 2000 rub.

Judging by the prices, the device is more than cheap to repair. This is an important operational property for people in rural areas.

In terms of tuning the Soviet Ant vehicle, the owners can’t think of anything. After all, these are often tech-savvy people who like to spend time in the garage. Several directions can be distinguished:

- Weight loss.

To do this, you will need to remove “extra” equipment. This includes body kit in the form of wings, hood and fairings, as well as all electrical equipment. To transport goods around the village in the summer, all this is unlikely to be needed. - Increased output from the power plant

. To do this, cut off the dynostarter shaft. The operation will add power and dynamism. The recoil during starting is leveled by trimming the crankshaft. - Installation of other wheels.

Front 4.5 - 9, and rear 7 - 10. Cross-country ability and speed will increase. - Improvement of the piston group .

You can buy a piston with three rings and make an additional window in the cylinder to supply the fuel mixture. - Magneto and increasing the efficiency of the cooling system

are additional tuning.

The main task when tuning is to increase reliability and less tinkering with details due to breakdowns.

In terms of engine tuning, some owners took radical measures and installed a Lifan engine (Lifan 188f), which has a volume of 400 cubic meters, on the Ant scooter. cm. And its power is 13 hp. A distinctive feature of this assembly is the variator and centrifugal clutch.

A centrifugal clutch is not the best option for trucks, since when driving on rough terrain on a loaded scooter at low speeds, it may slip. And this incapacitates him.

What modifications of the “Ant” scooter are there in the video:

On the agenda: motor scooter Ant tuning and modernization

The Ant scooter today, unfortunately, has already been discontinued from production and sales by the manufacturer. However, it is still possible to purchase a used model.

Such scooters have already won a lot of fans due to their characteristics. More carrying capacity compared to motorcycles, affordable cost, ease of use - all this makes the model a priority among other motorcycles.

Characteristics of the Ant scooter:

According to the official documentation, the Ant scooter has the following parameters:

- load lifting capabilities - 250 kg,

- cargo compartment - 1250*1130 mm,

- loading platform height - 600 mm,

- weight - 240 kg,

- turning radius - 3.5 m,

- maximum permissible speed - up to 60 km/h,

- fuel consumption - up to approximately 6l/100km,

- single cylinder engine,

- fuel reserve - up to 13 l,

- Gearbox: 4-speed

- independent, hydraulic suspension.

As you can note, the characteristics of the model are quite attractive. Ant is a scooter worthy of attention.

Every driver dreams of upgrading his own vehicle. And here fantasy knows no bounds, and external tuning becomes a way out of the situation. How can you improve your Ant scooter - tuning will be the best solution. You can paint the wings, hood, body and thus transform the model.

Before carrying out work, the vehicle is carefully prepared: cleaned, sanded, degreased.

As you know, scooter owners love to use various stylish bells and whistles, and external tuning allows you to transform the device.

There are a great many options for external transformation of your favorite iron horse, and the owners of the Ant scooter are not alone in their desire, because the Voskhod 3M motorcycle is an equally popular model for tuning.

Even an inexperienced motorcyclist can do tuning of Voskhod 3M with his own hands. You just need to pay attention to this and use your imagination to make your old man sparkle with new colors and get an attractive appearance.

The Ant scooter is a powerful device, but most owners are not averse to increasing the model’s load-carrying capacity. In addition, you can remake the body and make it folding (like a dump truck).

However, there are some nuances and the main thing is not to overdo it. As you know, the load capacity is about 250 kg; in practice, large loads can also be accommodated. But it should be remembered that with such a load the speed will be much slower (up to 35 km/h).

You can increase the load capacity by increasing the sides . However, the scooter frame will need to be strengthened.

Welding can be considered the most optimal option, but you can do it without it (the additional frame is made from wood).

In this situation, the body is moved forward or left in its place, but it is prohibited to move it back.

It is possible to consider the option of installing separate booths on such scooters, which will require separate costs.

The following mechanisms are most often used for a dump truck:

- cable winches;

- hydraulics with automatic drive;

- methods using door hinges, etc. (so-called “manual”).

As for hydraulics, you will also need to use a pump. The total costs with this approach may exceed the cost of the scooter itself.

Let's consider options for implementing the idea:

1. Using automation.

The body is attached to an additional frame, which is connected to the main frame using hinges. Lifting can be carried out using a diamond jack, which operates with a simple electric drive. The electric drive itself can easily be made using the window lifters of a simple car. This is the essence of automation, when the body tips over with the press of one button.

The only disadvantage of such a conversion is the final cost of the work. The price depends on the spare parts used.

2. Manual method.

The body, as in the automatic method, is mounted on an additional frame. The frame is also attached to the main one.

The convenience of this method is that, if necessary, it is possible to simply remove the body (for example, when you need to transport long pipes, etc.). Such long objects can be attached directly to the frame.

Subtleties of production

In practice, it is recommended to additionally install chains that will protect the loops from being pulled out. Ordinary door handles from household appliances or car mechanisms can serve as closures.

When constructing a removable body, you will also need to attach the tank, license plate, and turn signals directly to the frame (not to be confused with the body). It is necessary to ensure that the center of gravity is near the axes of the loops (about 30 cm in relation to the rear edge). This is the only way the body can be tipped over manually without any problems.

Bottom line

So, the Ant scooter today is not only a means of transportation, but also a powerful mini-dump truck at home. Despite the fact that the vehicle has not been sold on the auto market for a long time, it is still worth purchasing it second-hand. Thus, from a simple moped, thanks to little effort, we acquire a powerful dump truck and a sophisticated vehicle.

On the agenda: motor scooter Ant tuning and modernization

Yasak0v

Rating (3)

Pros and cons of helical gearbox

This device has the following advantages:

- very high level of efficiency (up to 98%), and it is extremely economical;

- transmitting high power without losing it;

- very high kinematic accuracy (much higher than that of a globoid, i.e. worm);

- despite the high efficiency, the case does not heat up much, and at the same time energy transfers from the sender to the recipient with almost no losses;

- models perform well under shock loads;

- very high reliability, can continuously operate for at least 25 thousand hours;

- the shaft itself can be rotated.

But, despite the advantages, there are also disadvantages:

- in order to increase the gear ratio, the number of steps should be increased, this will lead to a significant increase in size;

- the noise threshold is very high (this device is much noisier than other modifications);

- in some cases, self-braking is required, but this type of gearbox does not provide it, so an additional device must be installed.