Over the six years of production, the Izh-56 road motorcycle has become one of the most popular and indispensable two-wheeled vehicles designed for movement both on dirt roads and on city streets. Excellent cross-country ability and good load capacity made it an excellent assistant and vehicle for movement in difficult weather conditions.

Motorcycle IZH-56 technical characteristics

Motorcycle IZH-56 technical characteristics general data

Motorcycle type - single Base, mm - 1360 Ground clearance, mm - 135 Dimensions, mm: Length - 2115 Width - 780 Height - 1025 Saddle height - 780 Motorcycle dry weight, kg - 158 Maximum speed, km/h - 100 Fuel tank capacity , l — 15 Fuel consumption rate on the highway, l/100 km — 4 Fuel range, km — 375 Filling oil capacity, l: gearbox housing — 1 of each front fork leg — 0.5 rear suspension elements (two) — 0.2

Motorcycle IZH-56 engine specifications

Engine type - two-stroke with two-channel return purge Number and arrangement of cylinders - one, vertical Cylinder diameter, mm - 72 Piston stroke, mm - 85 Displacement, cm cubed - 346 Compression ratio - 6.5 - 6.8 Maximum power, l . With. — 13 Number of revolutions at maximum power, rpm — 4200-4500 Tax power, n. p.- 1.33 Cylinder head: material - aluminum alloy combustion chamber shape - hemispherical Gasket material - asbestos Piston: material - aluminum alloy shape - convex Number of piston rings - 3 Piston pin (type) - floating Piston pin diameter, mm - 15 Protection against axial displacement - stoppers Valve timing, in degrees of crankshaft rotation: beginning of intake to c. m.t. - 60°30′ end of intake after c. m. t. - 60°30′ beginning of release to c. m.t. - 73°30′ end of release after n. m.t. - 73°30′ beginning of blowing after n. m.t. - 61° end of blowing after n. m.t. - 61° Engine lubrication - oil with gasoline Carburetor - K-28 D Air cleaner - dry centrifugal Fuel filter - mesh in the sump

Motorcycle IZH-56 power transmission

Clutch - multi-plate in an oil bath Gearbox: type - four-speed control - foot gear ratios: in first gear - 4.32 in second gear - 2.24 in third gear - 1.4 in fourth gear - 1 Total gear ratio (from the engine to the rear wheel): in first gear - 23.15 in second gear - 12 in third gear - 7.5 in fourth gear - 5.36 Front gear: type - roller chain gear ratio - 2.17 Rear gear: type - roller chain gear ratio - 2.47

Chassis

Frame - tubular, non-separable, welded Front fork - telescopic with hydraulic shock absorbers Rear suspension - spring lever with hydraulic shock absorbers Tires: type - straight-sided size in inches - 3.25-19 Brakes - shoe Brake drive - separate mechanical

Ignition characteristics

Ignition system - battery Battery: brand - 3-MT-7 capacity, a-h - 7 voltage, V - 6 Generator: brand - G 36 M 1 voltage, V - 6 power, W - 45 Drive - the generator is mounted on the right axle of the engine crankshaft Regulator relay - two-stage Ground connection terminal - minus Signal - S-37 Headlight - F G-38

Back to contents — ↑

Motorcycle engine IZH-56

Motorcycle IZH-56 two-stroke single-cylinder engine with two-channel return purge and air cooling. The clutch, gearbox and generator are mounted in the same block with the engine.

The engine cylinder has an aluminum jacket with a pressed inside liner made of special cast iron. The jacket contains inlet, purge and exhaust ports. The outer surface of the cylinder jacket has ribs that increase the cooling surface, and two pipes for attaching the exhaust pipes of the mufflers. The lower part of the cylinder ends with a flange having four holes for attachment to the crankcase. The top of the cylinder has six studs for attaching the head.

The cylinder head is cast from aluminum alloy and has cooling fins on the outside. The cylinder head has two threaded holes for screwing in a spark plug and a decompressor. The head is attached to the cylinder with pins.

The piston of the IZH-56 motorcycle engine has a spherical exhaust head and an oblique cut, which gives the skirt springy properties and makes it possible to reduce the gap between the cylinder and the piston.

Piston rings are made of special gray cast iron, which has a fine-grained structure and has great strength and good springing properties.

The connecting rod is steel, stamped, I-section in the middle part, with two heads. A bronze thin-walled bushing is pressed into the upper head.

The crankshaft is an assembly of flywheels with a connecting rod and connecting rod bearing. Both flywheels are connected to each other by a pressed pin of the lower connecting rod head.

The IZH-56 engine crankcase is made of aluminum alloy and consists of two halves with a connector along the longitudinal axis. In addition to the main two halves, the crankcase has detachable covers for the clutch (left) and generator (right) and, in addition, the gearbox cover. The crankcase halves are fixed together with control bushings, and the covers with bushings and keys, which is necessary in order to ensure that during disassembly and assembly they can be accurately installed in relation to each other and align the holes for the crank axes and gearbox shafts.

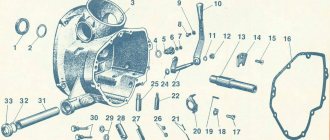

1 – candle; 2 – head; 3 – cylinder; 4 – piston; 5 – piston ring; 6 – piston pin; 7 – connecting rod; 8 – crankcase; 9 – channel for lubrication of the main bearing; 10 – main bearing; 11 – left oil seal; 12 – left oil seal cover; 13 – small chain; 14 – ball bearing; 15 – crankshaft sprocket; 16 – left crankshaft axle shaft; 17 – large clutch drum; 18 – clutch discs; 19 – small clutch drum; 20 – clutch pressure plate; 21 – clutch spring; 22 – clutch release pusher; 23 – clutch spring; 24 – ratchet gear; 25 — foot shift pedal; 26 – kick starter pedal; 27 – kick starter spring; 28 – kick starter sector; 29 – kick starter roller; 30 – ball bearing; 31 – foot switch stop; 32 – foot switch pedal roller; 33 – switching sector; 34 – gearbox cover; 35 – right crankcase cover; 36 – decompressor; 37 – exhaust window; 38 – bypass channel; 39 – flywheel; 40 – cylinder gasket; 41 – roller bearing; 42 – connecting rod roller bearing; 43 – right oil seal; 44 – right axle shaft of the crankshaft; 45 – generator cavity cover; 46 – generator; 47 – crank pin; 48 – worm leash; 49 – rubber cap; 50 – worm ball; 51 – clutch release worm; 52 – clutch release adjusting screw; 53 – input shaft; 54 – secondary shaft; 55 – secondary shaft oil seal; 56 – roller bearing; 57 – drive sprocket of the large chain; 58 – gear shift fork; 59 – shift roller.

Back to contents — ↑

Motorcycle engine power supply systems IZH-56

Motorcycle IZH-56 power system - consists of a fuel tank, carburetor and air cleaner. The fuel tank, stamped from sheet steel, is mounted on the motorcycle between the frame's steering column and the saddle and is bolted to the frame at the front and rear.

A neck is welded at the top of the tank, which is closed with a special plug. The plug is sealed with a gasket made of petrol and oil resistant rubber.

At the bottom of the plug there is a cup with a capacity of 0.1 liter for measuring oil when preparing the fuel mixture.

The gasoline tap has three positions: open, closed and reserve.

On the IZH-56 motorcycle, the power system is equipped with a K-28 D carburetor. The float chamber consists of a body 1 and a cover 4. A float suppressor 5 is mounted on the cover, and in the center of the cover there is a reinforced fitting 7 for the gas line. Inside the float chamber there is a float 2 made of thin sheet brass. A shut-off needle 3 passes through the float, which, when a certain level of fuel in the float chamber is reached, closes the hole in the fitting. The float chamber is attached to the mixing chamber using a connecting plug 38; fiber washers 34 and 37 are installed for sealing. The float chamber communicates with the mixing chamber through channel 41. The mixing chamber consists of a housing 18, into which the mixing chamber insert 29 is inserted from below, secured with a shaped nut. The insert is sealed with a fiber washer 30. A sprayer with a main jet 36 is screwed into the center of the insert. A throttle valve 21 and an air corrector 8 are installed inside the mixing chamber housing.

A conical metering needle 32 is attached to the throttle valve using a latch 20. The throttle valve and the corrector are lifted with the help of cables and returned back under the action of springs 9 and 17. The upper part of the mixing chamber is closed with a cover 12, which is secured with a nut 11. Adjustment fittings are installed in the cover shell of the throttle cable 15 and air corrector 14. In the mixing chamber housing and insert there are channels for the passage of gasoline and air 40, 24, 25, 27 and 28. The mixing chamber has two pipes: one for connecting to the air filter, and the other to the cylinder pipe . Fastening to the cylinder pipe is carried out using a clamp and a tightening screw.

1 — float chamber body; 2 — float; 3 - locking needle; 4 — float chamber cover; 5 — float sink; 6 — locking needle seat; 7 - fitting; 8 — air corrector; 9 — air corrector guide tube; 10 — air corrector spring; 11 - round nut; 12 — mixing chamber cover; 13 - lock nut; 14 — adjusting fitting of the air corrector cable sheath; 15 — adjusting fitting of the throttle valve cable sheath; 16 — lock nut; 17 — throttle valve spring; 18 — mixing chamber housing; 19 — locking grooves of the dosing needle; 20 — locking plate; 21 — throttle valve; 22 - clamp; 23 — clamp screw; 24 — small load fuel channel; 25 — idle fuel channel; 26 — idle jet; 27 — adjusting screw for air supply to the idle jet; 28 — channel for supplying fuel to the idle jet; 29 — jet block; 30 - fiber washer; 31 — spray pipe; 32 — dosing needle; 33 - shaped nut; 34 - fiber washer; 35 — hole for fuel; 36 - main jet; 37 - fiber washer; 38 — fitting-plug of the mixing chamber; 39 — diffuser; 40 — channel for braking air; 41 — channel for fuel; 42 — locking needle lock; 43 — locking needle guide; 44 - bevel on the front of the throttle valve.

Back to contents — ↑

Main settings

The Izh-56, a motorcycle of a fundamentally new design, was noticeably different from its predecessors. The supporting frame was made of tubular profiles in combination with a stamped channel supporting the engine. The front and rear fenders have taken a different shape, their configuration has become deeper, and the effectiveness of protecting the driver from dirt and dust has increased significantly. A comfortable saddle made of corrugated rubber with springs at the base made the ride comfortable. The rear passenger seat, made of a microporous component covered in leatherette, was located above the driver's seat, which provided a good view for the person sitting in the back. Some Izh-56 motorcycles were produced with a double seat, and this option had its advantages - both the driver and the passenger felt more comfortable.

Motorcycle air purifier IZH 56

The IZH-56 motorcycle air cleaner is of a centrifugal type and consists of two cleaning elements of the same design. The elements are connected to each other by a pipe, which also serves to connect the air cleaner to the carburetor. Each element consists of a housing, in the upper part of which spiral blades are installed that direct the air flow; A dust collector is installed at the bottom, which has a lid with a hole for collecting dust. There is a rubber gasket to seal the cover with the element body and the dust collector.

1 — direction of movement of purified air; 2 - pipe; 3 - reflector; 4 — spiral blades; 5 — jet of atmospheric air; 6 — body; 7 - cover; 8 - dust collector.

Back to contents — ↑

History of creation

Back in the days of Tsarist Russia, industrial hunters in Siberia and the Far East realized how big the prey could be if they used the right weapons. However, carrying a rifled carbine and a smoothbore shotgun at the same time turned out to be not the best solution, because the hunter simply got tired after several hours of moving through the forest. With the advent of Soviet power, Russia began to develop models of weapons that previously existed only in the thoughts of science fiction writers.

The creation of the IZH-56 gun began in the mid-50s of the last century. The IZHK design was taken as the basis for the new model, and the trigger mechanism was transferred from the trouble-free IZH-17.

However, the procedure for crossing trunks of fundamentally different types turned out to be not as simple a task as the engineers initially thought. So the first Belka came off the assembly line only in 1964. At first, hunters were somewhat skeptical about the hybrid of a carbine and a shotgun, but after a few years people realized how useful such a weapon could be in the right hands.

Power transmission of the motorcycle IZH 56

Motorcycle IZH-56 power transmission consists of a front chain drive, clutch, gearbox and rear chain drive. The front chain drive of the IZH-56 road motorcycle consists of a drive sprocket, a double-row bushing chain and a clutch drum with a ring gear. The drive sprocket is bolted to the cone and key of the left axle shaft of the crankshaft. To prevent unscrewing, the bolt is secured with a cap placed on the bolt head and secured at two points on the outer diameter of the sprocket hub. The transmission from the crankshaft drive sprocket to the clutch drum is carried out by a double-row bushing chain. The clutch drum is mounted on the input shaft of the gearbox and rotates freely on it.

Front gear parts: 1 - drive sprocket; 2 — clutch; 3 - chain; 4 - trigger sector; 5 - trigger sector spring

The power transmission clutch of the IZH-56 motorcycle is multi-disc, operates in an oil bath and is mounted on the left end of the input shaft of the gearbox. The clutch consists of outer and inner drums, drive and driven disks, and springs for the clutch release mechanism. The outer drum is made of cast iron and rotates freely on the gearbox input shaft on a steel bushing. The outer crown of the drum has teeth on which a chain is put, connecting the outer drum with the crankshaft sprocket. Inside the drum there are five longitudinal grooves that serve to secure the clutch drive discs, which are made of plastic, with the protrusions. The inner cast iron drum is splined to the input shaft of the gearbox and secured with a nut, which is locked with a toothed washer. On the outside of the drum there are longitudinal grooves into which seven steel driven disks fit. The lower one is supporting and has increased thickness. Five threaded rods are pressed into the bottom of the drum, onto which are placed centering cups, inside of which springs are inserted; the springs are compressed using nuts. The clutch is disengaged using a worm installed in the right crankcase cover, which has a trapezoidal cut and can be rotated in the cover at a certain angle. When turning, the worm moves in the axial direction and the end of the adjusting screw presses on the ball, which transmits pressure to the rod and the rod fungus. The rod fungus, resting its head against the pressure disk, releases the springs, and as a result, the driven and driven disks are separated.

1 and 3 - nuts; 2 — lock washer; 4 — hairpin; 5 - spring; 6 - glass; 7 - inner drum; 8 — steel bushing; 9 — pressure disk; 10 - outer drum; 11 — driven disks; 12 — driving disks; 13 - support disk.

The gearbox of the IZH-56 motorcycle is four-speed and consists of primary, secondary and intermediate shafts, gears and a gear shift mechanism. The input shaft 3 is manufactured integrally with the first gear gear 4 and mounted on two supports; left support – ball bearing 1, the outer race of which is pressed into the left half of the crankcase; right - bushings inside the secondary shaft 11. Inside the primary shaft there is a hole through which the clutch release mechanism rod passes. The second gear gear 5 and the second and fourth gear gears 6 (sliding) are mounted on the input shaft. A support washer 7 is installed between gear 6 and the secondary shaft. The secondary shaft 11 is made integral with gear 8 and rotates on roller bearings 9. At the end of the secondary shaft, a rear gear drive sprocket 10 is installed on splines, which is secured with a nut. The seal is carried out on the input shaft side with an oil seal, and on the secondary shaft side with a cap. Intermediate shaft 2 rotates on two ball bearings 1 installed in the box housing. The intermediate shaft is fitted with gears 15, which rotates freely on the left journal of the shaft, and a gear-carriage 14, which moves along the splines and rotates together with the intermediate shaft; gears 13 and 12 rotate with the shaft.

The switching mechanism consists of a shift roller 22, at one end of which a shift pedal 23 is fixed, and at the other end a holder 20 and a return spring 21 of the worm shaft 17 are fixedly mounted, as well as shift forks 16 and 18 and a gear shift sector 19. When the shift pedal is lowered The shift roller rotates, and with it the holder with pawls. One of the pawls enters the stop window and rests against one of the teeth of the switching sector, turning it until it itself rests against the wall of the stop window. The outer teeth of the sector rotate the worm shaft, which with its grooves moves the gear shift forks. The switching control is double: manual, located on the right side, and foot, on the left side.

The rear chain transmission of the IZH-56 motorcycle from the secondary shaft of the box to the rear wheel is carried out by a roller chain put on the drive sprocket of the secondary shaft and the driven sprocket of the rear wheel. The rear chain sprocket rotates on a ball bearing (series 205, GOST 8338-57) pressed into the hub. The bearing is locked against axial movement by a spring ring. The sprocket hub has splines that are used to attach the rear wheel. The sprocket casing body and the cover are connected to each other with screws and are attached to the right leg of the pendulum fork using the axle shaft and nut.

Back to contents — ↑

Shooting

Firing at targets revealed an interesting logic. Small targets can be reliably hit only from a small rear sight at a distance of twenty-five meters. If the distance is doubled, the target will completely fit into the aiming slot.

If we consider shooting from rifled barrels in a general way, it should be taken into account that you will have to shoot at a hazel grouse or squirrel from a distance not exceeding thirty meters. In this case, optics are not needed. You will have to use it if the distance to the target is about sixty meters. By the way, optics are allowed to be replaced with a collimator sight.

In the process of shooting, the shortcomings of the shotgun’s shotgun trigger appear, it is rough and does not have even the slightest “pull”. This feature has a negative impact on the accuracy of shotgun fire.

Loading the gun and removing spent cartridges is simple. A small cartridge causes certain inconveniences, which is quite difficult to manipulate in winter.

When shooting from a rifled barrel, the hunter practically does not feel the recoil, but the shot barrel behaves quite noticeably. Additionally, bullets from different manufacturers produce different results. Therefore, it is recommended to zero the gun using certain cartridges designed for 28 mm caliber.

Chassis of the IZH 56 motorcycle

The IZH-56 motorcycle chassis consists of: a frame with a pendulum fork, rear suspension, wheels with brakes and a side trailer. The frame is welded, made of steel pipes. In the steering column of frame 3, the front fork is mounted on two thrust bearings. An engine is installed in the middle part of the frame; tank. Saddles are installed on the upper rear pipe 8 and the welded edge 10. The top point of the rear suspension is attached to bracket 11. On brackets 13, a pendulum fork is installed on the axis.

The rear suspension of the IZH-56 motorcycle chassis consists of two spring-hydraulic shock absorbers and a pendulum fork. The pendulum fork is simple in design and reliable in operation. It consists of a body in which steel bushings 6 are pressed inside the main pipe 5 at both ends. Bushings 8 are inserted into the holes of the bushings, between which a spacer tube 10 is installed. Pipe 5 is sealed with oil seals 7, and to lubricate the bushings there is a press grease nipple 1. On the right A sleeve 3 is welded to the body, in which the rear brake drive lever is attached. Brackets 11 and 12 are welded to the stays, with the help of which the pendulum fork is connected to the shock absorbers. 13 strips are welded to the ends of both feathers, into the holes of which the axle extensions are installed. In grooves 14, the rear sprocket casing is installed and an axle passes through, with which the rear wheel is attached.

The shock absorber is spring-hydraulic and consists of a cylindrical spring 4, which rests on the housing 12 and the upper tip 2. A shock absorber cylinder 11 is installed inside the housing, in the lower part of which there is a valve 13 with a limiter. The upper part of the body is threadedly connected to the rod body 7. A nut 5 is screwed onto the upper part of the rod body, which secures the oil seal 6 and at the same time regulates its tension. A rod 3 passes into the hole in the housing sleeve, the upper end of which is screwed into the tip 2 and secured with a lock nut and a cotter pin. At the lower end of the rod there is a valve 8 and a piston 9, secured with a nut 10 and a spring washer. The internal cavities of the body and shock absorber tubes are a reservoir for fluid. To soften shocks when the moving part of the shock absorber moves upward, a rubber buffer 1 is installed in tip 2.

The front fork IZH-56 is telescopic, with hydraulic shock absorbers, mounted on two angular contact ball bearings. The main components of the front fork are a telescopic body, a shock-absorbing element and a steering shock absorber. The leg of the telescopic fork has a steel supporting pipe, which is rigidly connected to the pipe of the other leg by two bridges: on top - by an upper bridge and a threaded plug, and from below - by a lower bridge and a coupling bolt. Outside, a sliding pipe moves along the supporting pipe of the airfoil on bushings, inside which the shock absorber body is installed. The shock-absorbing element of the feather consists of a cylindrical spring 4 and a hydraulic shock absorber.

Wheels – easily removable, interchangeable, with straight spokes; have hubs, rim, spokes and tires. The wheel hub consists of two stamped discs that are welded to a hub. The right disk has a steel ring, spot welded to the disk. The bushings have splines with which the wheels are connected to the reverse gear; on the other side of the bushing, a thread is cut into which the oil seal housing with a felt seal installed is screwed. Ball bearings (No. 203, GOST 8338-57) are pressed into the holes of the bushing on both sides, and a spacer sleeve is between them. The wheel rim is made of sheet steel and its dimensions correspond to GOST 5652-57.

Back to contents — ↑

New design

Unlike its predecessors, the Izh-56 now has special covers that cover the air filter and carburetor. In addition to directly protecting these devices from contamination, the design of the new motorcycle has been significantly improved. In addition, the side containers of an elegant round shape, in which tools and small things needed on the road could be placed, became a continuation of the protective casing. The lids of the boxes were locked with a key. The protective covers and containers smoothly transitioned into the rear wing, and thus a unique exterior complex was created, which also carried a payload; a muffler was attached to it in the lower part.

Electrical equipment of the Izh 56 motorcycle

Motorcycle IZH-56 electrical equipment consists of a generator, a relay regulator, a headlight, a central switch, a battery, a rear light and connecting wires. The IZH-56 is equipped with a G-36 M 1 generator, the armature of which is mounted at the end of the crankshaft, and the stator is mounted on the engine crankcase. The G-36 M 1 generator differs from the G-36 M generator by the presence of a device mounted on the breaker cover. The battery is type 3-MT-7.

The PP-30 relay-regulator has a voltage regulator and a reverse current relay, combined into one device with a common electromagnet and two windings: current and voltage. Adjustment of the PP-30 relay regulator is described here in great detail. The ignition coil and breaker are similar to those discussed above. The headlight consists of a housing 1, an optical element 3 and a rim 2. A central switch with an ignition switch, a battery warning light and a neutral warning light is mounted in the headlight housing.

The central switch has a panel with terminal posts for connecting wires and a rotor with a slider. Depending on the position of key 1, which turns the rotor together with the slider, the necessary connections of lighting devices and current sources are made.

The central switch of IZH motorcycles has the following positions: 1. The key is removed in the middle position of the rotor - all consumers are turned off. 2. The key is fully inserted, the rotor is in the middle position - the ignition devices and the sound signal are turned on. 3. The key is fully inserted and turned to the left - the ignition devices, parking light, headlight, taillight and sound signal are turned on. 4. The key is fully inserted and turned to the right - the ignition devices, the large headlight bulb, the rear light and the sound signal are on. 5. In position 3, the key is removed - the headlight parking light is on.

Back to contents — ↑

The IZH-56K motorcycle is a modification of the IZH-56 motorcycle and differs from the latter only in the rear gear ratio, the presence of a side trailer and the electrical circuit due to the presence of a side light on the side trailer.

You can learn more about a motorcycle only in its characteristics.

Motorcycle type - with sidecar Base, mm - 1400 Ground clearance, mm - 115 Dimensions, mm: Length - 2180 Width - 1650 Height - 1170 Motorcycle dry weight, kg - 250 Maximum speed, km/h - 70 Fuel consumption on the highway, l/100 km — 6 Fuel range, km — 250 Filling oil capacity, l: each front fork leg — 0.15 rear suspension elements (two) — 0.12

Total gear ratio (from engine to rear wheel): in first gear - 26.8 in second gear - 13.53 in third gear - 8.51 in fourth gear - 6.07 Rear gear: roller chain type gear ratio - 2 ,8

Similar articles:

- Motorcycle IZH Jupiter 4K technical specifications

The last notes

Popular customization areas

Retro style

Antique cars and motorcycles are now back in fashion, with owners taking them out of barns and trying to restore their appearance and performance.

The most popular for making retro custom Izh Planet 5. Restoring it to its factory appearance is not an easy task, because it is quite difficult to find original dashboards, which often break due to their fragility. There is also a shortage of original saddlebags and uncreased gas tanks.

The most expensive and labor-intensive task would be to restore the Soviet chrome and paint all the chips and cracks.

Cafe Racer

This is also a type of retro style, only British, from the 60s and 70s. The main modifications for the cafe racer style are:

- flat seat,

- The original shank

- streamlined tank,

- Round mirrors,

- Instead of a dashboard, one round gauge,

- Solid dark color

- Lots of chrome elements.

Chopper

Izh Planet 5 is often made into a real chopper. This option is not suitable for most as it is very complex. First of all, it will be necessary to carry out large manipulations with the frame, and for this you need special equipment. To do this, make the following changes:

- Extend the front fork

- Install a wide rear wheel of small diameter,

- They make a wide seat with a characteristic fit,

- Create a high steering wheel

- The parts are painted dark and chrome plated.