During the operation of the scooter, various breakdowns occur. It doesn’t matter at all who the manufacturer is (Japan or China). The difference is that one vehicle breaks down earlier, while the other breaks down over time. Problems can occur with the wiring, engine, or chassis. But, as a rule, almost everyone is faced with replacing the CPG. This abbreviation implies the term “cylinder-piston group” or, as people say, “piston group”. Looking ahead, it must be said that replacing the piston, piston and rings separately is not as difficult a task as it might seem at first glance. It is also worth knowing that the process of removing and replacing the CPG is almost the same on all scooters. Therefore, the article will discuss the main points. Looking ahead, let us remind you that the power of the CPG can vary. It is recommended to install a piston engine with the same power as a standard CPG.

Preparatory moments

Before replacing the piston or rings (CPG in total), you need to get to the cylinder. For beginners who have no idea where this element is located, we will tell you. The muffler is just bolted to the cylinder. If you have no idea how to correctly install the piston on a 4t or 2t scooter, then first you need to remove the old CPG. The upcoming repairs can be divided into the following stages:

- Removing the scooter trim (plastic);

- Disconnecting electrical wires;

- Disconnect the oil hose;

- Engine dismantling;

- Removing the old piston, rings (CPG in total);

- Installation of new parts;

- Engine installation, wire connections and hose;

- Plastic fastener.

The plastic is folded to the side so as not to be crushed if careless. All bolts and screws are placed in a pile and, if necessary, sorted separately. After making sure that all hoses with gasoline and oil are disconnected, remove the engine. It is necessary to understand that engine removal differs depending on the design features of the scooter model. Once the engine is removed, you can begin to remove the plastic casing, which protects the CPG from external factors. Then remove the cylinder head. It is secured with 4 bolts. In order not to break the thread, all bolts are unscrewed crosswise.

We remove the cylinder and immediately inspect it. If there is no damage, then it can continue to be used. While the piston most likely cannot be used back.

How to repair a chainsaw cylinder block?

To restore, the master completely disassembles the engine and inspects its working parts. Measurements are taken that allow you to accurately assess the condition of the equipment and understand what repair procedures need to be performed. During major repairs, parts can be bored if they are made of materials suitable for this.

The recovery process also includes other stages:

- assessing the efficiency of the piston stroke, measuring the compression created in the working chamber;

- checking the integrity of equipment, searching for mechanical damage and scratches;

- analysis of the condition of piston fasteners, elimination of backlash and other problems;

- checking other equipment that affects the operation of the piston group.

In order for the restoration of the chainsaw cylinder to be successful, the master carries out a number of checks after assembling the equipment

It is important that the power corresponds to the factory parameters, and that the saw exhibits stable speed at idle and under load. Only after such checks can equipment repair be considered complete

How to properly install a piston on a scooter

The new piston is equipped with a pin, two retaining rings and additional rings. If the scooter is 2-stroke, then the number of additional rings is 2. In 4-stroke engines, 3 rings are almost always installed, one of which is an oil scraper ring. Let's look at installing a piston and rings using the example of a 2-stroke scooter. First, two compression rings are placed on the piston in special grooves. Next, we use the so-called “finger” to connect the piston and crankshaft; the fastener is considered complete after installing 2 retaining rings on both sides of the finger. The rings should fit tightly in the intended holes. Remember: the arrow on the piston should point downward, towards the floor. The “processes” described above are not complicated if you look at them. It is best to watch a training video or read the scooter maintenance instructions. Then, for sure, questions like “How to install rings on a scooter piston” will not arise.

Features of choosing rings

In order for the engine to operate reliably after repair, it is important to choose the right rings. Don't buy the cheapest set

Such rings will not last long, and you will have to go through the labor-intensive replacement process again.

It is also important to inspect the packaging and the parts themselves. The packaging must contain all the information about the manufacturer, material of manufacture

The rings must be marked. It denotes the top side. Manufacturers usually include instructions inside the package that tell in detail how to correctly install rings on the piston. The latter should not have any defects, even the smallest ones.

Cylinder installation

This is the final stage and must be approached with caution. After all, if the fastening is incorrect, the slightest gap will not provide the necessary compression. As a result, the scooter will not start. Install a gasket between the engine and the cylinder, and between the cylinder and its head. The head is clamped with bolted connections crosswise. It is easy to check the correctness of the work performed. To do this, you need to start the engine. If the motor runs smoothly, everything is done correctly. You can also make a few efforts with the kick starter to feel the compression.

As you have already killed yourself, there is nothing complicated. Installing rings on a scooter piston and replacing the CPG in total do not require any special knowledge. All you need are details, time and desire.

Help

Need help finding spare parts?

We will help and advise!

+7-927-653-31-57

Gradually the time comes and your two-wheeled four-stroke friend needs to change the piston. There may be 2 reasons for this: wear or installation of a more powerful piston. In this article we will tell you how to replace the piston (CPG) on a 4-stroke scooter with a 139QMB engine.

If you have a different engine model, for example 152QMI or 157QMJ (150 cc scooter), then this article will also suit you to replace the CPG, since there are no fundamental differences. For 2-stroke scooters, we recommend reading the article “Replacing the piston on a 2-stroke scooter”

Read also: Homemade compressor from a refrigerator for painting

We will describe the process gradually step by step. First of all, we need to remove the plastic that prevents us from getting to the engine.

The next step is to unscrew and remove the carburetor (In this case, it is not necessary to disconnect all the hoses from the carburetor, but simply move it to the side).

We unscrew the muffler at the place where it is attached to the cylinder head and at the place where it is attached to the engine crankcase (2 long bolts). Now remove the muffler.

The next step is to unscrew the plastic cylinder head cover. (2 halves connected by two screws) After this, remove the cylinder head cover by unscrewing the 4 bolts. We unscrew the chain tension regulator, which is located near the carburetor.

Next, you need to unscrew the 4 cylinder head nuts, after which we can remove the cylinder head. When we removed the chain tension regulator, we freed the chain and can easily remove it (after we removed the chain from the camshaft, it is necessary to secure it, for example with a wire, so that it does not fall into the engine crankcase)

In this photo the head has not yet been removed, but only the camshaft has been removed and the chain is fixed. The next step is to remove the cylinder from the studs. If problems arise with this, you can lightly tap with the wooden part of the hammer on all sides of the cylinder.

We put the piston in the top dead center position (the highest position of the piston, we are guided by the marks on the generator rotor.) It is necessary to ensure that the chain does not fly off the drive sprocket, so as not to mess with installing it in the reverse position. Take a clean rag and cover the hole in the engine crankcase to prevent any debris from getting into it. Remove the retaining rings from the piston and thereby free the pin (here you can use round-nose pliers or small pliers.) Remove the pin using a small wooden block (while trying not to create a load on the crankshaft connecting rod). This completes the process of removing the old cpg.

We take a new piston kit for 72 or 80 cubic meters (piston diameter 47mm or 50mm, respectively). You can, of course, use a standard new 50 cc CPG. The kit includes: cylinder, piston, piston rings, pin, retaining rings, as well as head and cylinder gaskets. You can buy a 72 cc cpg at a low price in our online store.

Installation is carried out in the reverse order, having previously lubricated the cylinder, piston and rings with a small amount of oil. We first install a thin ring on the piston in the lower groove, then an oil scraper ring and again a thin ring (the wavy ring - the oil scraper ring will thus be between the two thin ones in the lower groove). Next, install 2 compression rings (which are thicker). The cuts of all rings should not be located on top of each other. After installing the rings, place the piston on the crankshaft connecting rod, fix its position with a finger and locking rings. We take the connecting sleeves from the old cylinder and insert them into the new one.

We put a gasket under the cylinder on the studs. Carefully place the cylinder on the piston with rings so as not to damage the cylinder. We push the chain into the groove for the chain. Then install the chain bar on the cylinder head. Now we can put the chain on the camshaft sprocket (the position of the sprocket should be as follows: a large hole at the top, and two small ones on the sides, parallel to the edge of the cylinder head). We fix the position of the cylinder head with the gasket by screwing it on. Then we install the plastic cylinder head cover, chain tensioner, carburetor and muffler. The installation is now complete!

If you haven’t changed the oil for a long time, you need to change it before starting with a new piston. Before putting a full load on the scooter engine, it is necessary to run-in, i.e. drive 300-500 kilometers at a speed of no more than 40-45 km per hour.

Along with an increase in the power of the scooter with the installation of a tuning cpg, the load on the variator with the gears of the gearbox also increases. Remember this and if possible, replace the variator with gears with tuned ones (more reinforced.)

How to correctly insert a piston into a cylinder. How to insert correctly. KakPravilno-Sdelat.ru

» How to insert correctly

DIY caliper repair

Anyway, yesterday I tried to tighten the cylinder onto the piston with new rings. I couldn’t find the sheet metal for the clamp recommended in the book - I tried to fit it in like that. Got laid and went home. Does everyone use tightening clamps made of tin, or has anyone else found a way out of the situation? And also, there is a large gap in the valve guides. If you change it, you have to hot press it in and then, due to misalignment, rip the seats, etc. Then the repairs threaten to drag on until the end of the season. Is it possible to give up and ride for a year or does this threaten something terrible?

You can install it without a clamp - the piston is slightly askew, use a screwdriver to press the ring into the groove from one edge of the ring to the other gradually, and so that there is constant pressure between the piston and the cylinder. We have to struggle.

To follow up: you must immediately put the rings (one at a time) into the cylinder without a piston, use the piston to align them in the cylinder and check the gap in the lock. If there is no gap in the lock, then you can’t even use a hammer.

And carbon deposits from the piston grooves must be removed. There's a lot of it there. New rings may not sink completely because of this. It is convenient to remove it with a piece of the old ring. You can't say anything about the guides; you need to know the gap. If it is less than 0.3 mm, it will knock a little and burn up the oil, but this is not critical, you can roll off the season. If more, then everything is possible, from killing the valve seat and guide to pressing the guide out of the head. Well, it will eat oil, the candles can give off oak. Anything can happen.

Thanks. Perhaps the carbon deposits remained - I just tried to dissolve it with some kind of cleaning agent. I did not measure the gap in the guides, but it feels like the valve in them can be shaken and this will be felt. In principle, I traveled last year - I’ll try again.

I would recommend installing the piston rings without anything at all. With just your fingers, yes + a hammer handle. And this is how it is done. A hammer handle is placed under the piston skirt to prevent the piston from running away, which means inside the crankcase when pushing the cylinder onto the piston. Then the lowest oil scraper ring is put on the piston. Using your thumbs, you need to push the ends of the rings slightly apart so that the side of the rings is located. Place the opposite ends obliquely onto the piston. THEN pushing the ring apart to the size of the piston beyond the ends, but certainly obliquely. forward with the whole side to catch up to the desired groove. Do the same with everyone else. Of course, the rings must be pre-selected, for a normal piston - normal, and for a repair piston - appropriate. The ring grooves must be free of carbon deposits. When installing the piston into the cylinder, the rings, as they are put on, must be pressed one by one as much as possible with your fingers and put on the cylinder on them in a circular rotation. This procedure took me 1-2 minutes for each cylinder. Having put on the piston, remove the hammer handle and place the cylinder on the mounts.

Piston rings are a child's task - there are no problems with that. But the problem with circular rotations is that I immediately place the cylinder on the studs. I'll try to clean the grooves again, and if that doesn't help, I'll have to turn out the studs to get circular rotations. Phoenix everyone.

You need to be careful with the broken ring when cleaning the grooves. If the ring is worn, then the edges are VERY sharp. The ring somehow went almost to the bone in my finger. And so, I always installed the cylinders alone, without any mandrels, screwdrivers, or hammers. I set the pistons to TDC, engaged the gear, pressed the ring into the groove with my fingers, and tightened the cylinder. I drowned the next ring and pressed it with a cylinder. And so that’s it. For convenience, the piston is slightly warped. There is a wonderful cone on the cylinder, it helps a lot in the process. On the M-72 and K-750 the process is more complicated, where the cylinders weigh awesome.

Our production

In our online store you can find and purchase new piston groups at low prices. A complete list of piston engines can be found at this link

Installing a piston with a larger volume than stock is perhaps the simplest, most affordable, affordable and effective way to significantly increase the maximum speed and power of a scooter. There are, of course, even more effective ways to increase maximum speed and power, but these methods, or rather the hardware, cost simply unrealistic money...

If you charge the engine of the same 139QMB to the maximum, then such tuning before the “increase” cost the client about 35,000 rubles and this does not include work.

Read also: Applying paint to plastic

It is clear that not everyone can afford such amounts. Yes, even if it’s affordable, what’s the point? It’s easier to buy an old branded scooter and ride it than to charge the “Chinese” and then throw it in the trash after a season. But that's what I think.

Engine wear

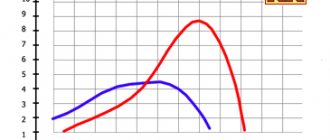

The main question of this article is whether driving at low speeds leads to premature wear of the engine? And what modes are the most “wear-inducing”. The organization of expert tests is, in general, clear. The engine is the same: a VAZ eight-valve engine. A stand, equipment, gasoline and several cans of oil - each test cycle requires its replacement. The task is simple - you need to “travel” the same distance, at the same speed, but using different engine operating modes. In different gears... How to achieve this? You can drive at the same speed, maintaining engine speeds of 1500, 2500, and even 4000 rpm

The higher the speed, the lower the gear; it is important that the power produced by the engine is the same. This is easy to do at the stand - we measure the torque using a dynamometer, the speed is known - therefore, we know the power

We multiply “speed” by engine hours, which we also record – that’s the mileage. With wear it is more difficult - every time, after running the engine at a fixed time for a given time, the engine will have to be disassembled and weighed the main parts that form the friction units, these are bearing shells and piston rings. Plus, there is additional intermediate control, which we will carry out by determining the content of wear products in oil samples. If they found chromium, it means that the first piston rings are wearing out; found iron - cylinders and shaft journals; tin has appeared - it will determine the wear rate of the bearing liners (since it is part of the anti-friction layer); aluminum is a consequence of wear on the pistons and camshaft bearings. The engine worked at the specified constant modes with approximately the same power, 50 hours each. Not much for the resource, but we get wear rates, and then by simple extrapolation we estimate the approximate service life of the motor. At the same time, the engine speed during the test cycles varied from 1200 to 4000, that is, more than three times. And then the load on the motor was increased - and the cycle was run again. And then - more... The result was a voluminous table, where for each point of the regime its own wear rate was recorded, and divided by units - bearings and rings.

Preparation

So that you don’t have green snot later about the fact that the tuning piston does not fit into the crankcase and you were allegedly deceived here - remove the old piston from the engine and measure the hole for the liner with a caliper. If the hole is smaller than the tuning piston sleeve, the “meat” of the crankcase allows it, hands grow from where it is needed - a round file will help you (only before boring - disassemble the engine, assemble the empty crankcase with bolts, bore the hole, make sure that the piston enters the crankcase without problems - wash the parts from shavings and reassemble the engine. Or, as a last resort, coat the crankcase and file with grease to at least somehow protect yourself from sawdust getting into the inside of the engine.)

The hole for the 162QMK engine sleeve (such engines are installed on Chinese scabs, more popularly known as “Leika”) in stock is 65 mm. Without boring, a piston of 57mm (150CC), 61mm (1700CC) and 62mm (180CC) easily fits into this crankcase. You won’t find a 62mm piston on sale during the day, so it was decided to install a regular 61mm piston on this engine.

By the way, for those who do not know, a piston with a diameter of 61 mm can be easily installed not only on the Leica engine, but also on any other Chinese 150 equipped with a 157QMJ series engine. There, if you put your hands to it, you can stick a piston at 62mm, but only if the “meat” of the crankcase allows it. Everything is individual, you need to look at the place. In any case, the distance along the studs is the same for both the 61mm piston and the 62mm piston.

From left to right: 61mm, 57mm

On the 139QMB series engine from a regular Chinese 80-six, you can easily install a piston 39mm (45CC), 47mm (72CC), 50mm (84CC)

From left to right: 39mm (45CC), 47mm (72CC), 50mm (84CC)

Parting recommendations

If diagnostic results are unsatisfactory, experienced owners usually act by elimination. First, an attempt is made to decarbonize the oil scraper rings. If this is your first time encountering this concept, we recommend reading about what decarbonization is and why the engine needs it, as well as about the technology for decaburning piston rings using dimexide, as one of the inexpensive and effective means.

If an attempt to remove coke does not bring results, then work is planned on the cylinder head. If replacing the valve stem seals is unsuccessful, then a “overhaul” is performed.

Good afternoon .

Today I decided to check the oil level, looking at the dipstick I saw the level was at min. At 154 thousand. There was an oil change now 159 thousand mileage during this period a total of 1 liter of oil was added. I decided to go to the service station today during rush hour to check the compression. There were almost 15 on all cylinders. I wanted to consult with the motor mechanic about why the compression is so high and why it takes oil. As I understand it, either rings or caps? Well, if there is a lot of compression, I understand that these are not rings but caps?

Having removed the spark plugs, they said to immediately replace them, I say, and I haven’t driven 5 thousand on them before, too, when replacing them they were the same. Another person came up and said that your compression is high due to the fact that oil gets into the cylinder and most likely through the caps, and your spark plugs are in this condition.

Quite often you notice that increased smoke appears from the exhaust pipe of a car. Sometimes situations get to the point where the car is literally shrouded in clouds of thick smoke. It is quite obvious that for every car enthusiast, the appearance of excessive smoke indicates the emergence of certain problems with the internal combustion engine.

Let us immediately note that not always, but often, increased smoke indicates serious problems with the engine. At the same time, it will not be difficult for experienced drivers to determine the cause by the color and composition of the exhaust. However, for beginners it is not always easy to understand why the engine smokes, as well as to determine the cause and identify the rings or caps. Let's figure it out.

Installing piston rings

Remove the set of piston rings from the box. A piston ring set for a Chinese four-stroke scooter usually consists of five items. Three of which are a single assembled oil scraper ring, the other two: upper and lower compression.

A typical set of piston rings looks something like this

Carefully unpack the kit with perfectly clean hands.

In the kit you will find two of the thinnest rings and one thick corrugated ring (expander) - this will be an assembled oil scraper ring that needs to be installed on the piston first.

We place an expander in the lowest groove of the piston

We place thin oil scraper rings in the same groove - one under the expander, the second on top of the expander

We find the lower and upper compression rings in the kit and install them, respectively, in the middle and upper grooves of the piston - with marks on the side surface to the cylinder head (cylinder head). The lower compression ring differs from the upper one in color (not always) and the shape of the working edge (always). In most kits, the lower compression ring is painted black, and its working edge has a slight bevel.

The top compression ring in the vast majority of piston ring sets is a uniform light color. But this is in most cases, and in practice it happens that the kit comes with upper compression rings that are black or even red. By and large, the color is not particularly important to us, something else is important to us: the working edge of the upper compression ring has small roundings (chamfers) on the sides, and the working surface of the edge of the upper compression ring is covered with a shiny protective coating.

For example, in this kit both compression rings are black. But the working surface of the upper compression ring is covered with a layer of protective coating, and small chamfers are removed on the edges of the working surface.

The lower compression ring has a matte working surface, and the working edge is beveled at a slight angle. All these moments are clearly visible in the photo.

The compression rings in this kit are red and black. As in the first case, the upper compression ring has chamfers on the working edge and a protective coating, and the lower one has a matte working edge beveled at an angle.

On classic piston ring sets, the upper compression ring has a light color and a rounded working edge. The bottom is dark in color and the working edge is beveled at a slight angle.

Read also: Silicate-free antifreeze based

When installing the piston rings, do not forget about the marks. The marks on the rings after installation on the piston should be oriented towards the cylinder head (cylinder head).

How to determine piston wear

Now let's check the gaps at the joints of the rings by placing them in the cylinder. The rings need to be removed from the piston and inserted inside the cylinder. To obtain correct readings, the ring must be in the working plane. You can set them exactly by pushing them deep with a piston.

Scooter piston ring clearance

- The nominal gap at the junction of the compression rings should be within the range of 0.1-0.25 mm. With an opening of 0.4 mm, the rings must be replaced

- The nominal gap at the junction of the oil scraper rings must be within 0.1-0.4 mm

- The nominal end clearance (compression ring - piston groove) should be within the range of 0.03-0.05 mm, and the largest - 0.1 mm

- The numbers in the interface between the piston pin and the connecting rod head. The difference in the measurements obtained should be 0.005-0.01mm (without needle bearing)

If the gaps are larger, the piston is rejected, including if you are satisfied with the other points of suitability. A more significant gap indicates that the service life is completely exhausted and the need for complete engine repair. If, according to all the characteristics, the scooter piston is suitable for subsequent use, you need to diagnose the unit. Experience shows that very often, with fully working pistons, the block can have a lot of wear, and on the contrary, the “death” of the piston does not mean the “death” of the block.

Piston installation

Insert a retaining ring into any boss of the piston pin. It is most convenient to insert the ring with small round nose pliers. After installation, check how well and tightly the retaining ring fits.

- If the retaining ring does not cover the entire surface, but only a small part of it, replace it with a new one.

- If the retaining ring does not lie tightly in the groove and dangles, straighten it a little

Lubricate the bearings of the lower and upper connecting rod heads and the piston pin bosses with clean engine oil. We put the piston on the connecting rod, orienting it with the “IN” mark to the inlet port; if there is an “arrow” on the piston instead of the “IN” mark, orient the arrow to the exhaust port. We insert the piston pin into the boss - orient the piston on the connecting rod so that the pin hits the connecting rod - install the pin all the way into the locking ring and secure it from falling out with the second locking ring.

We install the cylinder guide bushings on the studs and put on the gasket. It is advisable to place the gasket on the sealant, but without fanaticism.

Sequence of operations for removing pistons and connecting rods:

- Remove the cylinder head and oil sump from the engine.

- Rotate the crankshaft until the piston to be removed is at bottom dead center (BDC).

- Undo the cotter pins and unscrew the nuts of the connecting rod lower head bearing mounting bolts and remove the connecting rod cover.

- Push the connecting rod with the piston and remove the set of these parts from the cylinder. Before removing the pistons and connecting rod assembly from the cylinder, you need to check the condition of the upper edge of the cylinder bore. If there is a shoulder here (a premature section of the cylinder mirror), it must be removed with a special cutting tool.

- Mark the piston with the cylinder serial number and check for the presence of the factory mark of the cylinder serial number on the connecting rod and its cap on the side facing the camshaft (see symbols A and 2 in the circle in the figure). The remaining pistons, complete with connecting rods, are removed from the cylinders in a similar way.

Cylinder installation

Fill the rings and piston with clean engine oil. We tighten the piston rings with a clamp. We cut the clamp from a piece of any sheet metal - cut out a strip of the required length, give it a profile along the piston and make a retainer from the same piece of sheet metal.

Lubricate the cylinder mirror with clean engine oil

We hook the timing chain with a piece of wire, pull the chain through the cylinder and put the cylinder on the studs.

Very carefully and slowly insert the piston into the cylinder. After the rings are completely inserted into the cylinder, unfasten the clamp and install the cylinder into the crankcase.

How to properly install piston rings

To answer the question of how to replace piston rings without removing the engine, it is necessary to troubleshoot the CPG at the initial stage. To do this, you will need to remove the cylinder head, after which the general condition of the pistons and cylinder walls will be assessed.

This is done to identify possible defects (scores on the walls, wear, destruction or melting of the piston, etc.). Let us add that there are engines on which it is impossible to assess the condition of the CPG without removing the pan. There is often a high probability that simply replacing the rings with new ones may not be enough, since if serious wear is detected, it is necessary to bore the cylinder block.

Moreover, the rings wear out both the cylinder bore and the inner surface of the piston groove. For these reasons, new piston rings, which are installed without replacing the pistons and repairing the cylinders, either do not grind in at all, or the grinding in occurs very slowly and ineffectively.

Taking into account the above, the best option would be to bore the cylinder block, perform honing of the cylinders, after which new repair pistons and piston rings are installed. It is not possible to carry out such repairs without removing the engine. At the same time, the positive results of repairs involving engine removal are much more predictable.

Setting the valve timing ch1 (in collective farm style - ignition)

We push the cylinder all the way into the crankcase and set the piston to top dead center (TDC). It is best to set the piston at TDC using an indicator or, at worst, visually/touch. You can also align the piston according to a special mark on the generator rotor, but I have more than once encountered the fact that the marks on some engines are stamped incorrectly and, in order to avoid troubles, I advise you to use them only as a last resort, for example, when the cylinder head is not removed and you need to adjust valve

We insert the cylinder head guide bushings and the lower timing chain guide into the cylinder, degrease the surface and install the gasket.

We install the cylinder head, insert the valve bed guide bushings.

What will be needed for replacement?

For such a procedure, it is worth preparing a set of wrenches, a ratchet with socket heads, a torque wrench, a piston ring puller and the set of rings itself.

You may be interested in: Mishlene tires: brand history, popular models

The tool for mounting/dismounting piston rings has a simple design and affordable price. Without this device, the replacement process can turn into an almost impossible task. Of course, in the past, car enthusiasts made do with a couple of screwdrivers. But it is better to have such a tool, otherwise without it you can damage the rings or the piston surface. Moreover, it is always available in auto stores.

Setting the valve timing ch2 (in collective farm style - ignition)

Without knocking the piston off from TDC, we orient the camshaft so that the large hole and marks on its sprocket become as shown in the photo and, while putting on the chain, install the camshaft in bed.

Ideally, the marks on the sprocket should be strictly parallel to the plane of the valve cover connector. In practice, unfortunately, such accuracy is difficult to achieve. And this is mainly due to the stretching of the timing chain. And there’s nothing you can do about it - either change the timing chain to a new one or catch the phase by switching the teeth, but this method of setting the valve timing is not acceptable to me personally.

We orient the camshaft bed with a mark in the form of the letters “E” and “X” towards the exhaust channel and install the bed.

Tighten the bed nuts crosswise and then tighten the two bolts on the side boss of the cylinder head.

Hydraulic front wheel disc brake

The disc brake mechanism on a scooter is usually hydraulically driven, as opposed to a drum mechanism. The disc (or two discs) is rigidly attached to the wheel hub, and the brake caliper (caliper) is attached to the fork. During braking, the disc is clamped on both sides by the brake pads. Brake calipers vary in design and can have from one to eight pistons. Scooters typically use two- and four-piston options. The brackets also differ in the way they are attached to the fork - they can be fixed or floating. The difference between them is that in fixed calipers, each pad is pressed by its own pistons, but in a floating caliper, the piston is located on only one side and uniform force is applied to the pads due to the movement of the entire brake caliper along the guides. When the pressure on the pads decreases, the bracket returns to its original position, forming gaps between the pads and the disc. However, on small-capacity vehicles, drum brakes are often sufficient, since the speeds here are low, but on modern “large” scooters there are often disc brakes both front and rear; there can be two brake discs on the front wheel hub, and, accordingly, two brake discs. hydraulic calipers on the fork. The brake systems on most scooters are separately controlled, meaning the rear and front wheel brakes are operated independently of each other. The rear brake is usually operated by a lever on the left handlebar. The front brakes are applied with the right handle (like on a motorcycle). Recently, scooters with large engine capacities have also begun to use combined hydraulically driven brake systems, where the right lever controls not only the front brake caliper, but also directs part of the force to the brake of the rear wheel. In addition to service brakes, some “older” scooter models may have a parking brake, which is used to hold the scooter on a slope. Typically, it consists of a drum brake built into the rear wheel hub and operated by a separate lever. On modern models of scooters with large engine capacities, anti-lock braking systems are not uncommon, which help to avoid wheel locking during sudden braking. There are several varieties of such systems, but they all have the same ultimate goal: to prevent the brakes from locking the wheel, which can lead to the scooter falling. ABS systems are integrated into the hydraulic braking systems of scooters, and consist of a control unit, wheel rotation sensors and a system of hydraulic valves that are “responsible” for reducing the pressure in the brake line when signs of wheel locking appear.

Installing the timing chain tensioner

If you have a 157QMJ series engine, do the following: unscrew the plug on the tensioner body; We insert a thin flat screwdriver into it and begin to tighten the bolt until the tensioner rod goes inside the body.

Without releasing the screwdriver while simultaneously holding the tensioner body, with your free fingers, insert the tensioner into the cylinder, screw it in with bolts, and only then release the screwdriver and screw the plug into place.

If you have a 139QMB series engine, then do this: unscrew the plug from the tensioner housing and remove the spring; push the rod inside the body; install the tensioner in the cylinder; insert the spring into the housing and screw in the plug.

After installing the piston, do not forget to adjust the thermal clearances of the valves and break in the engine.