If your carburetor is not set up quite correctly, a situation may occur that the engine will run on a lean mixture. A lean mixture is when there is less gasoline in it and more air. It would seem - well, what’s wrong, well, it will burn more quietly, but it won’t overheat. But in fact, the opposite is true!

A two-stroke engine does not have a separate lubrication system. Oil gets into moving parts (piston and cylinder walls, as well as crankshaft main bearings, connecting rod needle bearing) from the fuel mixture. A lean mixture is not only a lack of gasoline, but also a lack of oil. The crankshaft rotates at enormous speeds - thousands of revolutions per minute, so the bearings must always be well lubricated.

Ultimately, an insufficient amount of lubricant will lead to severe heating of engine parts. The bearings will burn out and may fall apart. The piston head will burn out. Broken pieces of parts will damage the inside of the engine.

Of course, it’s not necessary that everything will fall apart at once, but thermal seizure of the piston, one might say, is guaranteed.

Therefore, it is extremely important to control the quality of the mixture. This can be done visually by turning out the candle (I have already written about this more than once). Signs of a lean mixture are a white insulator.

What can cause a lean mixture? First of all, an unadjusted carburetor. You can read how to adjust the carburetor in a separate article.

Another reason is air leaks in the fuel lines. This is usually a bad or missing gasket.

And the third reason is the zero-resistance filters installed instead of the standard foam filter. If you have installed FTS on your scooter, it is necessary to adjust the carburetor, because such a filter, by its design, leans the mixture.

In general, on a two-stroke engine it is better to overdo the mixture than to run it too lean. Although a rich mixture leads to the formation of soot, this soot is not as bad as overheating.

Please note: This article and the images in it are subject to copyright. Partial or complete reproduction on other resources without permission is prohibited.

One of the main components in the fuel mixture supply mechanism in a vehicle such as a scooter is the carburetor. Before moving directly to the description of the adjustment process, let's talk about why it is needed at all.

Carburetor - a device that ensures the formation and supply of a fuel mixture (consisting of air, gasoline and oil) directly to the engine

What exactly is the purpose of a carburetor? In a nutshell, this is a device that ensures the formation and supply of a fuel mixture (consisting of air, gasoline and oil) directly to the engine. That is, the quality of this mixture and, accordingly, the power that the power unit produces depends on it.

Scooters typically use carburetors of a type called “float” carburetors. The main element is a Venturi tube, which houses a damper that regulates the amount of air supplied to the mixture, as well as a needle that supplies gasoline. By unscrewing the throttle, we thereby open the throttle and raise the needle, increasing the amount of air-fuel mixture entering the engine.

Naturally, the movements of the valve and the needle must be clearly synchronized to ensure its (mixture) homogeneity. The float chamber is designed to ensure the constant presence of gasoline in the tube. The principle of its operation is based on the fact that when the fuel level drops, the float lowers and opens a channel for supplying gasoline to the tube. When it is full, the float rises and closes the valve, thereby stopping the flow of fuel.

If the scooter's engine power drops, it is impossible to start the engine or the engine stalls - these are signs of a carburetor failure

Signs that the carburetor is faulty may include:

- Engine power drop

- Inability to start the engine

- The engine stalls.

Tuning the carburetor of a two-stroke engine

Author Reading time: 13 min.

Published 12/12/2019 If your carburetor is not configured quite correctly, a situation may occur that the engine will run on a lean mixture. A lean mixture is when there is less gasoline in it and more air. It would seem - well, what’s wrong, well, it will burn more quietly, but it won’t overheat. But in fact, it’s the other way around!

A two-stroke engine does not have a separate lubrication system. Oil gets into moving parts (piston and cylinder walls, as well as crankshaft main bearings, connecting rod needle bearing) from the fuel mixture. A lean mixture is not only a lack of gasoline, but also a lack of oil. The crankshaft rotates at enormous speeds—thousands of revolutions per minute—so the bearings must always be well lubricated.

Ultimately, an insufficient amount of lubricant will lead to severe heating of engine parts. The bearings will burn out and may fall apart. The piston head will burn out. Broken pieces of parts will damage the inside of the engine.

Of course, it’s not necessary that everything will fall apart at once, but thermal seizure of the piston, one might say, is guaranteed.

Therefore, it is extremely important to control the quality of the mixture. This can be done visually by turning out the candle (I have already written about this more than once). Signs of a lean mixture are white insulator.

What can cause a lean mixture? First of all, an unadjusted carburetor. You can read how to adjust the carburetor in a separate article.

Another reason is air leaks in the fuel lines. This is usually a bad or missing gasket.

And the third reason is the zero-resistance filters installed instead of the standard foam filter. If you have installed FTS on your scooter, it is necessary to adjust the carburetor, because such a filter, by its design, leans the mixture.

In general, on a two-stroke engine it is better to overdo the mixture than to run it too lean. Although a rich mixture leads to the formation of soot, this soot is not as bad as overheating.

Please note: This article and the images in it are subject to copyright. Partial or complete reproduction on other resources without permission is prohibited.

One of the main components in the fuel mixture supply mechanism in a vehicle such as a scooter is the carburetor. Before moving directly to the description of the adjustment process, let's talk about why it is needed at all.

Carburetor - a device that ensures the formation and supply of a fuel mixture (consisting of air, gasoline and oil) directly to the engine

What exactly is the purpose of a carburetor? In a nutshell, this is a device that ensures the formation and supply of a fuel mixture (consisting of air, gasoline and oil) directly to the engine. That is, the quality of this mixture and, accordingly, the power that the power unit produces depends on it.

Scooters typically use carburetors of a type called “float” carburetors. The main element is a Venturi tube, which houses a damper that regulates the amount of air supplied to the mixture, as well as a needle that supplies gasoline. By unscrewing the throttle, we thereby open the throttle and raise the needle, increasing the amount of air-fuel mixture entering the engine.

Naturally, the movements of the valve and the needle must be clearly synchronized to ensure its (mixture) homogeneity. The float chamber is designed to ensure the constant presence of gasoline in the tube. The principle of its operation is based on the fact that when the fuel level drops, the float lowers and opens a channel for supplying gasoline to the tube. When it is full, the float rises and closes the valve, thereby stopping the flow of fuel.

If the scooter's engine power drops, it is impossible to start the engine or the engine stalls - these are signs of a carburetor failure

Signs that the carburetor is faulty may include:

- Engine power drop

- Inability to start the engine

- The engine stalls.

Another way to assess the quality of the carburetor (more precisely, the correctness of its operation) is as follows - unscrew the spark plug and look at its color. If it is white, it means the fuel mixture is lean, that is, there is too much air in it, and if the spark plugs have a black tint, it means the carburetor is “pouring” too much fuel. With any of these options, one thing is clear - it needs adjustment.

It should be noted that, globally, this process does not depend on the engine stroke, therefore the answer to the question of how to correctly adjust the carburetor on a Chinese 4t scooter and how to correctly adjust the carburetor on a 2t scooter will be the same. Let's now move on to describing the sequence of actions.

How does a lawn mower carburetor work or its operating principle?

Adjusting the carburetor of a Chinese lawn mower is completely identical to the adjustment of lawn mowers from European, Russian and other manufacturers. To cope with the task of adjusting the carburetor on lawn mowers and gas trimmers, you need to understand the principle of their operation. How a carburetor works on a lawn mower is described step by step and in an accessible manner below.

- The operation of the lawn mower carburetor begins with the supply of fuel through the channel, as shown in the diagram

- Fuel is sucked into the carburetor using a pulse channel connected to the engine crankcase. Due to rarefaction of air, the flexible membrane at number 4 in the diagram above moves

- Fuel is supplied through valves 3 and 5. Valve 3 is an inlet valve, due to which fuel is supplied to the sub-membrane space, and valve 5 is an outlet valve

- Next, the fuel moves along the channel and, passing through a fine filter, reaches the needle valve 14

- The needle valve is connected via a lever to the control diaphragm 18

- The needle valve is activated by pressure on the membrane. When it is necessary to pump up fuel to start the engine, it is necessary to operate the soft cover of the hand pump. When exposed, the needle opens and the chamber is filled with the fuel mixture

- When the engine starts (cold), the needle opens due to vacuum when the air damper is closed. This vacuum acts through the idle and high speed jets on the membrane 18

- The membrane acts through a lever on the needle valve, thereby filling the chamber

- After starting the engine, the air damper opens, causing the engine to run lean as fuel mixes with air.

- When the chamber is full, the fuel mixture is supplied (sucked in) through the idle and medium speed jets (when the engine is running)

- The throttle valve is shifted from its original position by 10-15 degrees

- When work is carried out under load, fuel begins to flow into the chamber through the high-speed nozzle, and at the same time the throttle valve rotates at an angle of up to 90 degrees (depending on the force of pressing the gas). In all operating modes, the air damper must be open, through which the fuel is mixed with air, thereby igniting the mixture in the cylinder

Below is a diagram of the operating principle of a lawn mower carburetor. Based on the diagram, you can not only understand the principle of operation, but also identify breakdowns and other malfunctions of the mechanism.

When operating the tool, it is necessary to take into account the presence of another jet. This jet is located between the idle and full power passages. It is necessary in order to avoid severe leaning of the mixture, which occurs when the engine operates at partial load. In such a situation, the occurrence of a bullying couple cannot be ruled out. Through an additional channel (nozzle), fuel is sucked into the chamber, thereby enriching the fuel-air mixture. The diagram below shows an additional jet, which is designated by the number 1.

Having an idea of the design of the diaphragm carburetor of a brush cutter and the principle of operation, it will not be difficult to configure it yourself. To adjust the carburetor of a lawn mower, adjusting screws are used. The diagram above shows two screws for adjustment, however, most modern models of gasoline trimmers are equipped with three screws. The presence of three adjustment screws allows for more precise adjustment, while achieving stable and uninterrupted operation of the internal combustion engine.

How to adjust the carburetor on a scooter

This procedure can be conditionally divided into two parts - adjusting the idle speed and adjusting the quality of the carburetor mixture. However, first, the carburetor must be removed and cleaned.

Refer to your vehicle's manual to ensure proper disassembly. Thoroughly clean all its channels, as well as the jets. Unscrew the spark plug - even if it does not have the visual defects described above, it is better to replace it. Fortunately, their price is usually not high. On the fuel metering needle, find the locking ring and install it in the middle groove. After all these steps, install the carburetor back.

After checking and cleaning, which we have just completed, we proceed directly to the adjustment. You will need to find elements such as the screw that regulates the quality of the fuel mixture (hereinafter referred to as the KTS screw), as well as the idle screw. Screw the KTS screw all the way (this is done clockwise), and then unscrew it one and a half turns, and then start the engine.

Using your scooter's tachometer reading, adjust the idle speed screw so that the engine speed is at 1800 rpm. Go back to the KTS screw and, by rotating it, achieve maximum engine speed, then tighten the screw half a turn. Find the idle screw again and return the speed to 1800 rpm, while not forgetting to check the operation of the engine by ear - there should be no failures or extraneous sounds.

When the specified value is set, you need to check the operation of the power unit. Turn the lever that controls the throttle a couple of times, adding gas and releasing it.

If you don’t hear any extraneous noise in the sound of the engine and it doesn’t stall, the carburetor adjustment has been made correctly, that is, you can safely get on the scooter and go about your business.

If the problem is not resolved, then it is necessary to look for the cause in other components of the vehicle.

It is worth noting that sometimes adjustment is not enough - it is also necessary to check and, in some cases, adjust the fuel level in the float chamber.

Locate and unscrew the butter screw, which is located at the very bottom of the device. Next, you should lift the tube and check the fuel level. It is necessary to carry out these actions with the engine running, and keep the upper edge of the tube slightly above the carburetor itself. The fuel level should be slightly lower than the junction of the lower and upper parts of the carburetor.

Video tutorial on adjusting the carburetor on a scooter:

If the level is lower than required, you will need to remove the cover and adjust the timing of the valve by carefully bending its holder (this should be done in very small ranges). You can perform this entire procedure at the very beginning, so if you don’t want to remove the part once again, start the process of servicing the fuel system by adjusting the fuel level in the scooter’s carburetor.

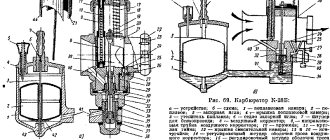

2t scooter carburetor design

The carburetor that we will consider today is installed on most Chinese two-stroke scooters with a chain transmission, which are popularly called “chain Chinese”. This carburetor has a very simple device, the enricher is driven mechanically, that is, simply by hand, this is of course not very convenient, but on the other hand, there is nothing complicated - pull the trigger and start it.

Unscrew the top cover of the damper and take out all the contents.

The needle in the valve is fixed with a special bracket, remove the bracket and take out the needle.

As you can see in the photo, there are adjustment grooves on the needle, by moving the lock washer along which you can adjust the quality of the working mixture within certain limits. To enrich the mixture, raise the needle; to lean the mixture, lower the needle. As you can see, there is nothing complicated about this.

With this adjustment, unfortunately, you can adjust the composition of the mixture only in a certain position of the needle in the carburetor, since the main metering system comes into operation only after the damper is raised by 1/4 of its stroke and turns off after the damper is raised by more than 3/4 of its stroke. When the throttle valve is fully raised, the quality of mixture preparation is affected only by the main fuel jet and partially by the idle system (on this carburetor model).

This carburetor model has a mechanical starting enricher; here it is presented as a separate module.

The starting enricher is essentially the same carburetor that turns on during a cold start of the engine when a rich mixture is needed; turning on and off the enricher can be manual, as on this carburetor, or fully automatic, as here.

Remove the cover of the enrichment unit and take all the elements out.

To ensure the operation of the enricher, the carburetor has two channels and a nozzle with a fuel pipe.

Starting enrichment jet.

Air channel of the starting enrichment.

Emulsion channel of the starting concentrator.

We continue to further study the structure of the carburetor with a float mechanism.

To remove the float mechanism you need to remove the axle.

If for some reason you are not satisfied with the operation of the carburetor, try adjusting the fuel level in the float chamber using a tongue that can be slightly bent within reasonable limits.

Main dosing system.

The main metering system ensures engine operation in the mid-speed range and consists of a sprayer (emulsion tube), a jet, a needle, and to ensure its operation, there is a special air channel in the carburetor into which an air jet is additionally integrated.

To remove the nozzle, you need to unscrew the fuel nozzle and remove (carefully) the O-ring.

Unfortunately, fuel jets on Chinese carburetors are not marked, which complicates the search for their analogues.

The sealing ring is located inside which is very convenient to remove with a large sewing needle.

After you have removed the ring, you can remove the sprayer; use a stick or pencil from the side of the valve to simply squeeze it out.

The air channel of the main dosing system into which an air jet is additionally integrated (unfortunately the jet is not visible in the photo).

Idle system.

It consists of a sprayer, a screw for adjusting the air supply to the air channel of the idle system, a screw for adjusting the number of idle speeds, and to ensure the operation of the idle system, there are two channels in the carburetor - air and emulsion.

Screw for adjusting the air supply to the idle air system channel (quality screw).

Idle speed adjustment screw.

To assemble the carburetor, we perform the same steps only in reverse order.

Admin

You may also like

Scooter engine design

How does a scooter battery work?

Japanese-made scooters - Honda, Yamaha and Suzuki

A few words about the required frequency of adjustments

Of course, it is better to perform such maintenance more often, without waiting until the engine begins to stall or simply does not start. It is recommended, as a preventative measure, to perform this procedure approximately once every six months.

adjusting the carburetor 2T scooter

Having bought a motorcycle, scooter or other motorized equipment, owners have to become familiar with the operation and adjustment of their main components. One of the important elements of a two-stroke or four-stroke power unit is the carburetor, which is responsible for supplying fuel to the combustion chamber and mixing gasoline with air in the required ratio. Many people do not know how to adjust the carburetor on a scooter using the adjusting screw. This need arises if the device does not start well, shows increased appetite, or the tachometer needle indicates unstable speed.

Methods for adjusting and tuning a scooter carburetor

The carburetor is an important part, without which the engine will not work. How to set up the carburetor on a scooter determines how smoothly and correctly the engine will run and whether it will be possible to start it in cold weather. The task of this unit is to mix gasoline with air in certain proportions, resulting in the formation of a working mixture, the composition of which determines the behavior of the power unit. The standard ratio should be 1 to 15, if you need the scooter to idle well, you can lean the mixture a little by making 1 to 13; enriched mixture - 1 to 17. For a more in-depth study of the design of a scooter carburetor, we recommend reading the article “The design of a scooter carburetor and the principle of its operation.” Well, now let's learn everything about adjusting the 2-stroke and 4-stroke carburetor of a scooter.

Purpose and principle of operation of the carburetor

The carburetor is an important component of an internal combustion engine, responsible for preparing the air-fuel mixture and supplying it to the working cylinder in the required ratio. A scooter engine with an unadjusted carburetor cannot function properly. The stability of speed, the power developed by the engine, gasoline consumption, response to turning the throttle, as well as ease of starting in the cold season depend on the correct settings of the engine power supply.

This unit is responsible for preparing the air-gasoline mixture, the concentration of the components of which affects the nature of the operation of the power plant. The standard ratio is 1:15. Leaning the mixture to a ratio of 1:13 ensures stable engine operation at idle. Sometimes it also becomes necessary to enrich the mixture by maintaining a ratio of 1:17.

Knowing the structure of the carburetor and knowing how to adjust it, you can ensure stable operation of the engine on two-stroke and four-stroke scooters.

Thanks to a properly configured carburetor, easy and quick starting of the vehicle engine is ensured, as well as stable operation of the engine, regardless of the ambient temperature. Any carburetor is equipped with jets with calibrated holes, a float chamber, a needle that regulates the cross-section of the fuel channel, as well as special adjusting screws.

The adjustment process involves specially rotating the screw in a clockwise direction or in the opposite direction, which causes, respectively, the enrichment or depletion of the working mixture. Adjustment measures are carried out on a warmed-up engine. In this case, the carburetor unit must first be thoroughly washed and cleared of blockages.

Operation and causes of engine failure

Most often, two-stroke engines are found in motorcycles, boat engines, lawn mowers, chain saws and other devices that require the use of a lightweight and reliable engine. However, even such a simple engine can fail due to violation of operating rules.

To extend the service life and delay major repairs, you should properly break in a two-stroke boat or motorcycle engine. To do this, the proportion of oil mixed with gasoline should be slightly higher than that established for normal operation. With this mixture, let the engine run at partial power for several hours, which is equivalent to 500-1000 km for a scooter and motorcycle.

Nevertheless, due to exhaust toxicity, two-stroke engines are gradually being replaced by modern four-stroke engines. They continue to be used only where high power density with minimal weight and simplicity of design is required - motorcycles, chainsaws and trimmers, model airplanes and much more.

Source

Why do you need to regulate?

During the adjustment process, the scooter carburetor needle is adjusted, the position of which affects the proportions of the air-fuel mixture, as well as a number of other adjustments.

Adjusting the scooter carburetor needle is done during the adjustment process

Each tuning operation has a different effect on engine operation and fuel preparation:

- adjusting the idle speed ensures stable operation of a running engine when the transmission is turned off;

- changing the quality of the air-gasoline mixture using a special screw allows you to deplete or enrich it;

- adjusting the position of the carburetor needle affects the change in the quality of the fuel mixture;

- Ensuring a stable level of gasoline inside the float chamber avoids flooding of spark plugs.

A power unit with an adjusted carburetor operates stably in any conditions, is economical, throttle response, develops rated power and maintains speed, and does not cause problems for its owner.

Principle of operation

One revolution of the crankshaft is one cycle of the operating process of an internal combustion engine.

Fuel (gasoline + oil) with air is supplied to the working combustion chamber of the cylinder, after which, due to the formation of a spark from the spark plug, an explosion of the combustible mixture occurs, the energy of which sharply pushes the piston down.

When the piston moves down, the outlet window opens and a little later the transition window opens, through which a new portion of fuel is injected.

The fuel mixture enters the engine crankcase through a window that opens due to vacuum as the piston moves upward from bottom dead center (BDC) to top dead center (TDC). This movement also opens a window for the release of gases from the burnt mixture. After milliseconds, the purge window opens. A new portion of fuel is supplied through the purge window.

Signs that adjustment is needed

Based on certain signs that appear in abnormal engine operation, we can conclude that the carburetor needs adjustment.

The list of deviations is quite wide:

- the power plant does not develop the required power under load;

- when the scooter accelerates sharply, failures in engine operation are felt;

- a cold engine is difficult to start with the starter after a long period of parking;

- the scooter's power unit consumes fuel in increased quantities;

- there is no quick response of the engine to a sharp turn of the accelerator handle;

- The engine may suddenly stop due to insufficient fuel mixture.

The carburetor should be adjusted if there are signs that adjustment is necessary.

If one or more of these symptoms is present, you should adjust the carburetor, and then diagnose its condition and check the operation of the engine.

Design and adjustment of the carburetor on lawn mowers and trimmers

A petrol mower or trimmer with an internal combustion engine requires not only constant refueling of the fuel mixture of gasoline and oil, but also periodic adjustment of the supply of this fuel. The carburetor is responsible for supplying fuel to the cylinder of the lawn mower, and the efficiency and performance of the tool depends on its proper operation. If during operation a faulty (abnormal) engine operation is detected, the first step is to adjust the carburetor of the lawn mower. Before adjusting the carburetor of a gasoline trimmer, let's first understand its design.

How to adjust engine idle speed

Work on setting up the power system is carried out after the engine has warmed up to operating temperature. All types of carburetors installed on scooters are equipped with a screw designed to regulate idle speed. Changing the position of the adjusting element allows you to ensure that the engine operates at stable speeds during idling.

Depending on the vehicle model, the adjusting elements are located in different places, so you need to carefully study the instructions and determine where the idle speed adjustment screw is located on the scooter.

Rotating the screw in a clockwise direction allows you to increase the crankshaft speed. Turning in the opposite direction, accordingly, ensures a decrease in speed. To perform adjustment operations, it is necessary to warm up the power unit of the scooter for a quarter of an hour.

Setting the engine idle

Then the screw is screwed in or unscrewed until a stable and precise speed of rotation of the vehicle engine is achieved. The adjustment is made in small increments by smooth rotation. After each manipulation, the engine should be run for several minutes to stabilize the speed.

Diagnostics

Before installing the air filter, turn on the ignition and jerk the kickstarter foot several times until the engine starts.

If it does not start, then the most common reason is that the cold start system is malfunctioning.

We check this way: cover the carburetor hole with your fingers to maximally enrich the mixture with gasoline, and continue to push the kickstarter.

If the engine starts and the speed does not drop during operation, then look for the reason in the cold start system.

If the cold start system is working properly, then after starting the engine the speed will rise and gradually, within 10 minutes, begin to fall. On a warm engine, gradually unscrew the large screw (amount of mixture) until the speed drops to medium, confident idle.

At the same time, drops of gasoline should not splash or pour out of the carburetor.

How to change the quality of the fuel mixture

For all scooter engines, it is important to receive fuel with an adjusted ratio of gasoline to air. A lean mixture leads to improper operation of the engine, a drop in power and overheating of the engine, while a rich mixture leads to an increase in consumption and the formation of soot.

Adjustment operations are performed by changing the position of the quality screw and moving the throttle needle.

Turning the screw to the right causes the mixture to become richer, and unscrewing in the opposite direction causes it to become leaner. The same happens with the needle: when the needle is raised, the mixture becomes richer, and when lowered, it becomes poorer. The integrated use of both methods allows you to achieve optimal results during setup. However, not all carburetors have this feature, so, as a rule, one of two options is used.

The principle of operation of a chainsaw carburetor - the purpose of the regulators

Returning to our diagram, it is worth mentioning what the adjusting screws are for.

The diagram shows that the screw on the right side 10 is intended for setting idle speed and medium speed. Screw 17 on the left side adjusts the fuel supply at high speeds. Details of carburetor adjustment are described in another material on this site.

Following the instructions for adjusting the carburetor of a chainsaw, it will not be difficult to carry out the corresponding manipulations correctly. If you want to adjust the chainsaw as accurately as possible, you will need to use a special tachometer. You can buy a tachometer for a chainsaw in a tool store or online, especially since its price is not as high as the cost of repairing a chainsaw carburetor.

A detailed step-by-step description of how a chainsaw carburetor works is described in detail in the video material.

Setting the gasoline level and the correct position of the float in the chamber

A correctly adjusted fuel level in the float chamber does not allow the spark plugs to get wet and the engine to stall. In the chamber where the floats and jets are located, there is a valve that provides fuel supply. The correct position of the floats determines the closing or opening phase of the valve and prevents fuel overflow in the carburetor. The position of the floats is changed by slightly bending the fastening bar.

Gasoline level is monitored with the engine running using a tube made of transparent material attached to the drain point and raised up. The gasoline level should be a few millimeters below the flange mounting of the cover. If the level is insufficient, remove the cover and adjust the needle firing phase by slightly bending the metal antennae.

Types of carburetors

Carburetors of VM and TM snowmobiles differ from each other in the shape of the throttle valve. The TM has a rectangular throttle valve that allows more air to be supplied to the snowmobile engine. Control of the throttle valves is made easier, since it is carried out through one rod with one spring, and in VM - springs in each carburetor.

The carburetors on ROTAX engines are positioned high enough to ensure that fuel for operation flows into their float chamber by gravity. Therefore, in order to raise the fuel to the required height, you need to have a snowmobile fuel pump. Fuel pumps, used on equipment with a carburetor power supply system, are of the diaphragm type, using alternating pressure generated in the crankcase of a two-stroke engine during its operation to pump fuel. The pump has two types of valves, inlet and outlet. Slam-shut type valves that pump fuel in one direction only. The pumps are also equipped with automatic safety valves built into the design and used to prevent fuel from flowing through the pump when the engine is stopped.

When the snowmobile piston moves away from the snowmobile crankshaft, negative pressure (vacuum) is created in the crankcase. When the piston moves in the opposite direction towards the crankshaft, excess pressure is generated in the crankcase. These pressure fluctuations cause the snowmobile's fuel pump diaphragm to vibrate. When negative pressure is applied to the diaphragm, the fuel pump inlet valve opens and the outlet valve closes. Fuel tends to fill the fuel pump chamber. The atmospheric pressure pressing on the fuel in the fuel tank forces the fuel to fill the fuel pump chamber. When excess pressure from the engine crankcase is applied to the diaphragm, the exhaust valve opens and the intake valve closes. In this case, the fuel, under the influence of pressure on the diaphragm, tends to leave the fuel pump to the carburetors.

Medium and high speed tuning

Using the quality adjustment screw, the fuel proportions at idle speed are ensured. For medium and high rotation speeds, the engine operating mode is adjusted using a different method. After turning the gas handle, the fuel nozzle starts working, supplying gasoline to the diffuser. An incorrectly selected jet cross-section causes a deviation in the fuel composition, and the engine may stall when gaining power.

To ensure uninterrupted operation of the motor at a higher frequency, it is necessary to perform a number of operations:

- remove debris from internal cavities;

- set the gasoline level in the carburetor;

- adjust the operation of the fuel valve;

- check the cross-section of the jet.

The correct operation of the engine is indicated by its quick response when turning the throttle.

How to find out if your lawn mower's carburetor needs adjustment

Many craftsmen use lawn mowers for a long time, and do not think about the need to adjust the carburetor of the tool. When is it necessary to adjust the carburetor on a lawn mower or brush cutter? If you are asking this question, then you are probably seeing changes in the operation of the engine that are not for the better. In order not to guess and not to miss the moment when it is necessary to adjust the carburetor, you should adhere to the following recommendations on the need for adjustment measures:

- After the engine has been run-in. Typically, running-in lasts for the duration of burning 4-5 liters of fuel.

- When a fuel mixture of a different composition is poured into the tank, that is, the type of oil (even its color) and the brand of gasoline change

- When weather conditions change, however, this is more relevant for chainsaws, gas generators and motor pumps, which are used not only in summer, but also in winter.

- If the lawn mower has not been used for a long time. The reason for the need for adjustment may be the winter break.

- When fuel consumption increases

- If black carbon deposits are detected on the spark plug electrodes

- If there is no gasoline entering the cylinder or the engine starts poorly

- If a large amount of exhaust gas is detected

- Unstable engine operation, as well as difficult starting and “sluggish” speed gain

As you can see, there are enough reasons to adjust the carburetor of a lawn mower. Typically, craftsmen who have been working with a tool for a long time can hear changes in the operation of the motor, which indicates the need for an adjustment process. Even if you are not sure about the need to carry out adjustment work, then performing it out of turn will definitely not be superfluous.

How to set up a carburetor on a scooter - features for the 2t model

Adjusting the carburetor of a two-stroke scooter differs from adjusting the power system of four-stroke engines. Most two-stroke engines are equipped with a simple carburetor with a mechanical enricher, the trigger of which is pulled before starting the device. Scooter owners call the starting enrichment a choke; it is closed after the engine warms up. To adjust, the power system is disassembled, the needle is pulled out and mechanical intervention is carried out in the fuel chamber. Further adjustment is carried out in the same way as for four-stroke engines.

You can adjust the carburetor of a lawn mower yourself

Petrol mowers, like all petrol-powered garden tools, are not difficult to maintain equipment.

You can and should repair and configure yourself. For example, adjusting the carburetor of a lawn mower with your own hands is a matter of five minutes. The carburetor from a lawn mower is a component in the power system. In it, like any carburetors, the process of mixing air and fuel (gasoline) takes place for further supply to the engine cylinders.

In this process, the main thing is the correct proportion of fuel and air, for which the carburetor is adjusted.

Setting up the carburetor on a 4t scooter - important points

Setting up the carburetor on a four-stroke scooter is easy to do on your own and is not difficult for motorcyclists. Setting up the carburetor of a 4t 50cc scooter (China) requires certain skills and patience and is performed according to the above algorithm. It is possible that the manipulations will have to be repeated many times until the desired result is achieved. If the carburetor setting on a 4t 139 qmb scooter or a similar model with a different engine is done correctly, the engine will operate stably.

It will be able to start regardless of the ambient temperature and the piston group in the engine will wear out less.

Features of setting up the carburetor of a 2-stroke scooter

The carburetor on the 2t scooter is slightly different in design and does not fit the 4t motor. The question of how to set up such a device worries all owners of two-stroke machines.

Most Chinese models have a fairly simple carburetor without unnecessary adjustments. The enrichment here is mechanical, although if you are tuning a scooter or you have a Japanese model, the enrichment can also be electric. In order to use the mechanical option, you must first pull the trigger on it, and then try to start the equipment.

Adjusting the carburetor of a 2T scooter is not difficult, but it does require some patience. In order to do this, you will need to disassemble the carburetor: first you will need to unscrew the top cover. The needle in it is fixed with a staple; it needs to be pulled out. The quality of the mixture is adjusted in the same way as described above. A feature of the push-pull system is that the needle affects the quality of the mixture only in a certain position. If the throttle valve is raised to its maximum, only the main fuel jet will be responsible for the fuel mixture. Sometimes the idle speed system interferes with it. Depending on what carburetor you have installed.

For a cold start, you need to use a starting enrichment, which must be closed after the engine warms up; Simply put, it's a suction. In such carburetors, the fuel level plays an important role. It is also regulated by mechanical intervention in the operation of the float chamber. It is configured in the same way as in the four-stroke version. In fact, the carburetor for 2t engines differs from models for engines on a 4-stroke scooter only in jets and some other parameters, but it is designed similarly, and therefore is regulated in the same way.

Tips and tricks

Setting up the carburetor on a 4t 50cc scooter is an important and responsible procedure for servicing motorcycle equipment.

When performing adjustment operations, it is important to follow a number of rules:

- perform adjustments only after the engine reaches operating temperature;

- rotate the adjusting elements smoothly, observing the operation of the engine;

- Make sure there is no debris inside the fuel chamber and the jets are clean.

Before starting work on setting up the carburetor, you must study the operating instructions and clearly determine the location of the quality and idle screws. If you have a 150cc scooter, the carburetor adjustment is done in a similar way. After all, the process of regulating the fuel system is the same for engines of different powers.

Features of tuning the carburetor of a 4-stroke scooter

Adjusting the carburetor of a 4t scooter is quite possible with your own hands and should not cause any difficulties, the main thing is to act according to the instructions described above. It’s not always possible to adjust; the carburetor on a 4t scooter works right away. You will have to be patient: you may have to repeat the procedure several times until you get a result that suits you. The smooth operation of the engine, the ability of the vehicle to start in cold weather, and what kind of piston wear will depend on how to correctly configure the carburetor in a 4t scooter.

4T scooters are usually equipped with similar carburetor models, so the VLC carburetor adjustment scheme described above is also applicable to other types of devices.

COMBUSTIBLE MIXTURES

For the combustion of gasoline in the cylinders of a motorcycle, it is necessary that the fuel meets air, the meeting point of gasoline and air is the carburetor, and a mixture of these substances is formed here. For normal combustion of air, the mixture changes its composition depending on the time of year, engine load and other factors. Even small errors can lead to deviations in carburetor operation.

negatively affect engine performance.

Signs: motorcycle revs and speed decrease, spark plug is black or dark brown;

In addition to these types, there are 2 more intermediate ones, in which the manifestations of symptoms are weaker than in the extremes - these are “enriched” and “depleted” mixtures. In these options the excess is insignificant.

How to adjust the carburetor of a gas tool so that it works powerfully and economically

It just so happens that today only those who at one time drove cars with carburetor engines, or lovers of all kinds of motor vehicles today, are familiar with carburetors.

The absolute majority of users of any garden gasoline equipment are not so much afraid, but treat carburetors as something very sacred, they say only specialists can touch them. Nevertheless, there is nothing scary or terrible about carburetors; they are very simple devices and are very easy to configure. I will now tell you how to do this to someone even seeing a carburetor for the first time.

I’ll also say that in the working carburetor settings I ate the dog and heard a lot of kind words after the cars of grateful drivers simply started to drive normally. And economically, which is important!

Any carburetor, be it a car, a motorcycle or a gas-powered one, has only two settings available to the user: adjusting the idle speed (quantity screw) and adjusting the composition of the fuel-air mixture (quality screw). Both are shown with arrows in the photo.

It's easy to remember:

quantity screw (white arrow) and quality screw (yellow arrow).

On the carburetor of your instrument, their location may be different, but they are very easy to distinguish externally - the quality screw

always comes with a spring on all carburetors

. She prevents him from rotating on his own.

The principle of carburetor tuning

I will not describe the theory and will tell you the bare-bones practice using a simple example of setting up my lawn mower (for clarity, the lining has been removed).

It all starts with the fact that the engine of the tool must be started and warmed up (idling for a couple of minutes). In this case, the damper regulator (it is blue in the photo) must be set to the position corresponding to the operating mode (in the photo the lever is raised for clarity, but should be lowered).

After warming up, the quality screw is tightened smoothly and slowly until the idle speed begins to falter and the engine begins to stall. From this position the screw is unscrewed half a turn. Next, the engine is sharply given full throttle - the engine should not choke or stall.

If this happens, then the quality screw is unscrewed another quarter of a turn and this operation continues until, with sharp gas, the engine revs quickly and evenly, without pops or dips. In the same way, it should operate smoothly and stably on long-term gas.

In principle, this is the main setting on gas tools

, you can limit yourself to this, but you can configure it more subtly, i.e. also reduce the idle speed (this parameter has very little effect on fuel consumption in gas-powered tools) - pay attention to the quantity screw.

In this photo the blue lever is already in the correct position for a warm engine

position - I’m telling you this so that you don’t have confusion in your head because of its different positions in the photo and you don’t swear at me. :))

The principle of adjusting the idle speed is the same as when adjusting the quality of the mixture - it is tightened until the engine starts to choke and after that it is unscrewed half a turn or a full turn at once.

E

This adjustment is performed after adjusting the quality of the mixture.

This makes it very easy to set up not only any gas mower, but also any gas powered tool in general.

(saws, generators, cultivators and everything else that we have is gasoline). The main thing is not to be afraid that something will spoil there. It won't spoil. And if you set it up unsuccessfully, this does not mean that your hands are hooks and your head is not ice. This means that you simply did not complete the setup. Here I have a cultivator and a lawn mower - they whisper. :))

Source