What will be needed for replacement?

For such a procedure, it is worth preparing a set of wrenches, a ratchet with socket heads, a torque wrench, a piston ring puller and the set of rings itself.

The tool for mounting/dismounting piston rings has a simple design and affordable price. Without this device, the replacement process can turn into an almost impossible task. Of course, in the past, car enthusiasts made do with a couple of screwdrivers. But it is better to have such a tool, otherwise without it you can damage the rings or the piston surface. Moreover, it is always available in auto stores.

Running in the engine after replacing the piston rings

Regardless of whether the piston rings were only replaced or the engine underwent a major overhaul, the engine will require a break-in. This is due to the need to break in new parts. Running in the engine after replacing the piston rings should be similar to running in the engine of a new gasoline or diesel car.

After replacing the rings, the engine cannot be operated in heavy loaded conditions (high speeds when driving, idling, driving at low speeds in high gears, etc.) for at least 3-5 thousand km. Also, you should not start a trip without first warming up the internal combustion engine.

Next, we will consider the opinions of experienced auto mechanics and answer the general question of how long the engine needs to be run in after replacing the piston rings. It is a fairly common statement among experts that it will take about 10-15 thousand km to completely grind in the rings. This leads to the conclusion that after a minimum run-in of the car after engine overhaul or replacement of rings (up to 5 thousand km), it is highly undesirable to spin the power unit above the average speed range for another 5 or even 10 thousand km. mileage

Features of choosing rings

In order for the engine to operate reliably after repair, it is important to choose the right rings. Don't buy the cheapest set. Such rings will not last long, and you will have to go through the labor-intensive replacement process again.

It is also important to inspect the packaging and the parts themselves. The packaging must contain all the information about the manufacturer and material of manufacture. The rings must be marked. It denotes the top side. Manufacturers usually include instructions inside the package that tell in detail how to correctly install rings on the piston. The latter should not have any defects, even the smallest ones.

Carrying out compression measurements in cylinders

Let's look at an example of working on classic VAZ models. It is necessary to measure compression on a warm engine. Readings from a cold engine can distort the picture. For measurements, you will need a special pressure gauge equipped with a threaded tip. It can be bought at any auto store.

Compressometer appearance

The check begins by unscrewing all the candles from their sockets. Then the central cable from the ignition coil is disconnected. We set the gear to neutral and turn the throttle valve to the maximum opening. After this, screw the compression gauge into one of the spark plug holes. At this time, an assistant must turn the starter handle. Two or three pumps will be enough.

Level 10 to 12 is also acceptable. But if the numbers are below 10 kg/cm2, then this indicates low compression. If compression still reaches a satisfactory level, but a little late, then the valves may be responsible.

To clarify, you can pour about 20 ml of oil into the disputed chamber and crank the starter again, taking a measurement. When normal compression is established at 12 kg/cm 2, the reason lies in the rings. Correct installation of the piston rings can solve this problem. If the pressure remains low, then the valves are the cause of the decrease.

Installation using a mandrel

How to change rings?

From this instruction you can learn how to install rings on the piston of a VAZ and other cars, including foreign cars. To replace, the oil pan is removed. Then unscrew the connecting rod caps and push out the connecting rods. Remove the rings using a special tool.

It is important to remove carbon deposits from the grooves - you need to clean down to the metal. Uncleaned carbon deposits will interfere with the installation of new rings in their seats. It is convenient to clean the piston with a piece of an old part. To speed up the process of removing carbon deposits, you can soak the piston in dimexide or any other cleaning liquid.

Now we need to consider how to install the rings on the piston. This requires care and precision. The rings are very fragile, and the middle one is considered the most fragile among them. During installation, the part is very easy to break. When installing, it is important to correctly orient the rings, otherwise there will be no positive result from such a replacement, and even vice versa - the driver will face even greater oil consumption.

The first step is to install the top rings. They are marked “TOP”. With this marking, the element should face the piston bottom. The part is installed with the scraper down. Chamfered rings are mounted so that they face upward.

If the parts are assembled, oil scraper with a two-function spring expander, then the upper and middle ones are installed first.

There is another procedure for installing rings on the piston. In this case, first install the oil scraper. The second one is installed first, then the first one. After this, compression is installed. The second compression ring and oil scraper parts should be installed very carefully. They are very fragile and do not tolerate excessive expansion.

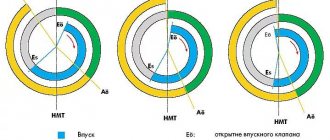

Then it is important to monitor the locks of the rings. They should be at an angle of 120 degrees to each other. If they come together, there will be oil consumption and smoke will appear from the crankcase ventilation system.

Tools and accessories for work

Proper installation of piston rings is impossible unless you have a complete set of tools. It is unlikely that you will be able to replace it, so prepare in advance:

- Expanding pliers for piston rings. They are inexpensive, so it's worth buying them.

- Torque wrench with socket set. The clamping must occur with a certain force, which cannot be withstood with a conventional wrench.

- Swage.

- Hammer to press parts. A nylon or wooden mallet is very convenient for these purposes.

- Good bench vise.

- Oil for lubrication.

- A rag to wipe away excess.

Replacement on motorcycles

On scooters and mopeds this is a common procedure that is performed approximately once or twice a season. Rings in such engines are consumables. Even if the engine is Japanese, the piston elements in it are at best Taiwanese, and most are Chinese.

In Japan, after a breakdown, it is customary to get rid of equipment - it is cheaper and easier to buy a new scooter. There, a serious breakdown is considered to be a drop in compression due to wear of the rings and pistons. In fact, repairs come down to replacing parts of the piston group. Let's look at how to install rings on a scooter piston.

Checking engine operation

The last thing you need to do is check the operation of the engine. Start the car and listen to the sounds. There should be no additional sounds (metal clanging, knocking, rattling) or vibrations! If everything is in order, then break in the car.

There is no need to “rip the engine”; try to drive carefully and only on asphalt. Moreover, do not try to increase the speed above 3,000. Constantly monitor the oil consumption - it should drop sharply.

If efficiency has not increased, but oil consumption has increased, another reassembly is needed.

It is necessary to remove the pistons, revise the installation, or even buy new rings. Often problems arise due to the fact that cheap, unlicensed spare parts with defects were purchased. It is recommended to purchase spare parts only from authorized dealers with a certificate.

Four-stroke scooter engines

So, there is a set of rings, and the owner does not know what to do with them. The set contains five rings - two thin, one oil scraper, and two compression rings. The scooter piston has three grooves.

After lubricating the piston with oil, very carefully place a thin ring into the lower groove. An oil scraper is put on it. Then thin again. Three rings must be installed in one groove. The oil scraper should be between two thin ones.

After this, compression rings are put on. They must be installed in the upper grooves. It is not recommended to use any third-party tool for installation. It should be remembered that the rings are very fragile and break easily. If the compression parts are different, then one is usually rounded, and the second is trapezoidal. The rounded one is placed in the upper groove, and the trapezoidal one is placed below. The bevel should expand from top to bottom. The ring should be wider at the bottom of the groove than at the top.

Locks are not stacked on top of each other. They should be at an angle of 120 degrees to each other. Here's how to install rings on a moped piston. As you can see, there is nothing complicated here.

Preparatory stage

First of all, you need to disconnect the battery. After this, you will need to drain the coolant from the cooling system and the engine oil from the oil pan. Replacing piston rings is possible in two ways: with or without removing the engine from the car. A check will help determine whether the engine needs to be removed: you need to remove the cylinder head and visually assess the condition of the liners.

If signs of wear are visible on the cylinder walls (wear, any scratches or scuffs), the power unit will definitely have to be removed in order to bore the liners to the next repair size. If this is not done, simply changing the rings will not be enough, since they will quickly become unusable due to damaged cylinders.

If there are no exhausts, new ones can be installed without removing the engine from the car. The work steps for replacing piston rings, with the exception of dismantling the engine for restoration work, are the same.

Mopeds “Alpha”

This technique is very popular in Russia. When do you need to replace rings and pistons? This work is carried out when the compression is reduced to 450 kPa. It can also be measured with a compression meter. The outlet will also indicate the need for replacement: if there is smoke in the gas, then the rings need to be changed. They are changed on such mopeds every 10-12 thousand kilometers.

Before installing the parts, they must be manually adjusted to the groove in the piston. They are sawed through with a file and treated with sandpaper. Then it is worth measuring the gap in the ring lock, which is inserted into the cylinder without distortion. The normal parameter for new compression parts is 0.04–0.08 millimeters. The ideal clearance for oil scrapers is 0.025–0.065 millimeters.

If compression parts are replaced, they are replaced with non-chrome ones. Experts tell us how to install rings on an Alpha piston: a ring that is correctly fitted to the piston fits into the groove under its own weight. If it doesn't fit, you can press it down a little manually.

Signs of piston ring wear

To understand whether the piston rings need to be replaced, it is necessary to study the symptoms that directly or indirectly indicate the need for such a replacement. Let us immediately note that you should not count on the amount that was initially announced by a mechanic or car service in response to a customer’s question about how much it costs to replace piston rings.

The fact is that it is often not possible to change only the piston rings and completely solve the problem, since after opening the engine, additional hidden defects are usually revealed. For this reason, it is necessary to be prepared in advance for more serious engine repair costs.

An impending replacement of piston rings is determined by the following signs:

- the engine loses power;

- the car is very bad;

- in some cases, the engine is difficult to start “hot”;

- there is an increased consumption of engine oil;

- the engine produces blue or gray smoke;

- fuel consumption increases;

The compression indicator, by which the condition of the engine can be determined, depends on the general condition of the rings and the entire CPG. Typically, with the symptoms described above, compression in the cylinders decreases and crankcase gas pressure increases.

We also recommend reading the article on how to measure engine compression yourself. From this article you will learn about the features and available methods of measuring engine compression with your own hands.

Loss of power, increased fuel consumption and difficult starting are most often the main reasons that force the owner to change the piston rings or do a comprehensive repair of the internal combustion engine. A power unit with faulty rings has difficulty starting, especially after being idle in the cold season. When driving under load, such an engine does not “pull”.

Piston ring failures can be caused by natural wear and tear, as well as engine overheating. In the second case, even on a new motor, the rings lose their properties and cease to fulfill their intended purpose. Box-type oil scraper rings are most susceptible to overheating.

Significant engine oil consumption often occurs due to the fact that a worn oil scraper ring does not remove the required amount of oil from the cylinder walls and actively passes lubricant through leaks into the combustion chamber. The result is coking and smoking of the engine. Also, the remaining unburned oil in the engine actively pollutes the exhaust system, damaging filters and catalysts. The problem gets even worse.

To accurately diagnose the condition of the CPG, compression measurements must be supported by analysis of the color and content of exhaust gases. The fact is that the deterioration in the quality of the piston ring seal can be compensated by engine oil. In this case, the compression indicator is close to the permissible value, but oil consumption will still increase.

Remember, operating an engine with worn rings causes the wear of the cylinder bore to progress significantly. For this reason, it is necessary to change the piston rings as soon as possible after the fault has been accurately determined. This recommendation will help avoid increasing the cost of subsequent engine repairs.

Increased fuel consumption in the event of problems with the piston rings occurs as a result of the fact that compression is reduced and power has dropped. At the same time, the driver continues to drive at his usual pace, pressing the gas pedal harder to compensate for losses. As a result, an enriched fuel-air mixture enters the cylinders, which does not completely burn. Spark plugs often become flooded with fuel in such conditions.

Another unpleasant moment is the penetration of gasoline or diesel fuel through worn piston rings into the engine crankcase and subsequent mixing of fuel with engine oil. The oil in the lubrication system dilutes, loses its protective and other useful properties, and the wear of the loaded parts of the cylinder head and CV gear greatly increases.

Let us add that today the practice of using an additive to clean piston rings into oil or fuel is quite widespread. Also, owners sometimes pour so-called engine decoking into the cylinders. This is done in order to clean carbon deposits in the combustion chamber and try to restore mobility to the underlying piston rings to increase compression.

It should be noted that if obvious signs of a malfunction appear (heavy smoking, high oil consumption, low compression, etc.), an additive instead of replacing the piston rings is either a temporary measure or does not help correct the situation at all.

Installation procedure

Branded products from trusted manufacturers have convenient markings, which make it clear how to correctly install the piston rings. On one side is written "TOP", which means "top" in English. This side should face the combustion chamber or the top of the piston.

This is interesting: The advantage of an atmospheric engine over a turbocharged one

Designation on the sides of the rings

If no inscription is found, then there should be a groove along the entire diameter. With this step you need to turn the ring down.

There are usually two installation methods used. One of them is safer, and the second is more often used by either great professionals or absolute beginners. Both are suitable for independent use during repairs.

Installation using metal plates

In the first case, you will need to cut several flat pieces of tin, approximately 0.3 to 0.5 mm thick. Three or four such sheets are placed along the diameter of the piston. Rings are put on them. And they drop down to the level of the slot. Then the mandrel for the piston rings is removed from the plates, and the ring fits into the desired groove. The method is perfect for any master.

Piston ring installation

The second option requires certain experience and skills. It consists of using your fingers to open the gap, increasing the inner diameter of the ring to the extent that you can pass the piston through it and install it in the desired groove. The disadvantages are that often inexperienced locksmiths break many rings by using more force than necessary.

Checking rings and pistons

Each ring is removed from the pistons and checked in its own cylinder. In order not to confuse them with each other, it is necessary to immediately lay out the parts in a certain order. When checking old rings, their outer diameter should not create a gap with the cylinder walls of more than 1 mm. For comparison, you can insert a new ring into the same cylinder.

Checking the thermal gap in the rings

Measurements will usually be more accurate at the top of the block bore since wear is minimal.

The gap can also be checked in special gauges. You need to pay attention to the thermal gap in the piston rings, which should be in the range from 0.25 to 0.45 mm. It can be checked with a dipstick. If the parameter is smaller, then it is possible to increase the gap by filing the end plane with a diamond file.

The diameter of the pistons is checked at the bottom (skirt). This is done with a micrometer.

It is necessary to compare this indicator with the table of acceptable values. Additionally, you need to check the gap between the piston groove and the ring. If exceeded, the pistons must be changed. The tolerance limit is 0.15 mm. The pistons are also checked visually for cracks and the integrity of the ring bridges. After washing, satisfactory pistons can be used further.