Features of replacing and restoring the throttle cable on a scooter

When using a scooter, the owner may encounter a situation where the gas does not work correctly. The problem can occur both when driving at high speed and during the start/climbing downhill. To “revive” a scooter, replacing the throttle cable is not always necessary, although there are cases when it is necessary to purchase and install a new part.

Reasons for failure

Practice shows that the owner may encounter this problem for several reasons:

- storing vehicles indoors with high humidity levels or outdoors. Condensation appears inside, which causes corrosion of the part;

- wear. The cable rubs against the shirt as it moves. If you changed the spare part a long time ago, or did not do it at all, you will have to purchase a new part;

- lack of lubrication inside. Some manufacturers do not add special oil to the jacket to reduce friction. A characteristic sign of a lack of oil in the jacket is a creaking sound when turning the throttle;

- gap This problem occurs very rarely, since the cable has a good margin of safety. In combination with the above factors (lack of lubrication, corrosion, low strength), the part begins to suffer from thread rupture, which ultimately leads to complete rupture. In addition, the cable can break during an accident, when the moped falls on the right side, or when the throttle is turned very hard.

Service Features

The cable plays an important role in the scooter control system. If it fails, the gas can become seized, usually resulting in an accident and serious injury. Therefore, the task of any owner is to timely check the condition, maintain and replace (as necessary).

Adjusting the free play of the scooter throttle

The free play of the throttle (the movement of the throttle until the carburetor flap is set in motion) should be within 2 - 6 mm. If this value is greater than the required value, then because of this your hand may get tired, the throttle valve may open late or not open completely. On the other hand, if the free play is very small or there is none at all, this may lead to the impossibility of adjusting the idle speed; it may be higher than normal. It also makes throttle control more difficult.

So, let's check the free play. To do this, lightly (with two fingers) twist the gas handle. If the free play value is greater than the set value, then it is necessary to make an adjustment. To do this, remove the rubber dustproof cover from the throttle cable adjustment mechanism towards the lower end of the cable. If you do this at low temperatures, then you must act carefully, trying not to damage the shell. It will be useful to warm it up with a regular hair dryer; I don’t recommend using a construction hair dryer because of the possibility of damaging the plastic.

We loosen the locknut (with an open-end wrench, this is one of the few places where you can’t do without it) and start setting up. If the free play of the throttle handle is large, then unscrew the adjusting nut (counterclockwise), if it is small, then tighten it. We check the amount of free play, while the carburetor damper drive lever should hit the idle speed adjustment bolt. If it is normal, then tighten the locknut and put on the rubber band.

If it happens that it is impossible to achieve optimal free play using the adjustment mechanism on the steering wheel, then you need to use the adjustment mechanism on the carburetor. To do this, open the hatch located at the bottom of the luggage compartment. Screw the adjusting nut on the steering wheel all the way. Loosen the locknut (1) of the adjusting mechanism on the carburetor. If we need to decrease the free play, then turn the locknut (2) counterclockwise, and increase it clockwise. Next, tighten the locknut (1). The direction of unscrewing/tightening the nuts relative to the photo. And we adjust the free play, as described above, using the regulator on the steering wheel.

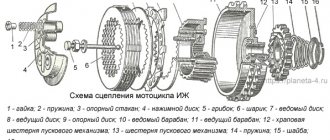

Photo report: Repair of speedometer gearbox gear of a moped, scooter

It is impossible to predict fate, let alone avoid it, but to deceive it is quite possible! Fate: the gear drives of the speedometer gearbox, which is usually located in the front wheel support (in most small-capacity Chinese garbage dumps equipped with drum brakes, the speedometer drive gearbox is located there) - at one time some “figure” broke off.

“Activists” break this part very often: they farm their garbage dumps and instead of checking whether the gear drives are in the grooves on the wheel, they put the wheel on at random, clamp the axle and then think for a long time about why the speedometer stopped working. How will it work if the gear drive leads did not fall into the mating grooves during wheel assembly and became bent or broken off?

For example, the drive pins of this gear are bent

Let's tighten the leashes slightly and the speedometer will begin its vigorous activity again. We bend it carefully: the metal is hot, if you bend it a little, it will break.

At first glance, the fate of this gear is quite predictable: replacement with a new one so the leads are broken off.

Price: 150-200 rubles + time to travel to the store + transportation costs. Is it necessary? We are looking for a suitable strip of metal with a thickness of 1.5-2 mm, welding new leads (of course we weld with a thin electrode - 1.6 mm and the lowest possible current).

We get used to the role of Michaelangelo - we cut off everything unnecessary.

We lubricate the gear, insert it with the drivers strictly into the grooves, close it with the support, and install the wheel.

Adjusting the throttle cable on a scooter

Attention: most likely for this operation you will have to remove the plastic from the steering column, since on most models it completely covers the adjusting screws.

With the engine off, twist the throttle and make sure it rotates freely from the fully closed to fully open position with any rotation of the steering wheel. The handle should return to the closed position on its own when released.

If the handle sticks or is difficult to rotate, the problem is most likely in the cable. Remove the cables and lubricate them. The best option is to soak them in brake fluid for a while. Do not forget to wipe the cables thoroughly after this, since brake fluid is very dangerous for painted surfaces. Reinstall the cables and check the handle travel again. If the problem is not solved, the cables should be replaced. In extremely rare cases, the problem may be with the oil pump or carburetor, but this is the exception rather than the rule. In any case, check these components for damage and correct operation.

A normally functioning throttle stick should have a slight free play, but no more than 2-3 degrees. If the free play is less or more, the handle needs to be adjusted. To do this, loosen the lock nut on the adjusting screw and, by unscrewing or tightening the adjusting screw, adjust the free play of the throttle handle.

If the screw does not provide normal free play even in the extreme position, it means that the cable is stretched and needs to be replaced. If the engine idle speed is too high, you have tightened the cable and it is already pulling the throttle up. After adjustment, be sure to tighten the locknut, not forgetting that when tightened, it slightly moves the adjusting screw and loosens the cable.

© 2010 Haynes, photo by Haynes, translation by gilerarunner.ru

ATTENTION! To order the necessary spare parts or tuning for your scooter, send an email to This e-mail address is being protected from spambots. To view it, you must have JavaScript enabled a letter with a list of necessary parts, or leave a message in the comments under the article, or a message on our forum in the section Purchasing spare parts. I will contact you as soon as possible and tell you all the details. In your message, be sure to indicate the model name, engine size and year of manufacture of the scooter to avoid errors when selecting parts.

We bring from Germany and the USA any original and non-original parts and accessories for European scooters Aprilia, Gilera, Piaggio and Vespa, tuning and equipment, tires and much more from more than 30 catalogs. To clarify order details, you can call tel. in St. Petersburg, Alexander.

- Tags: tuning, adjustment, scooter repair, scooter, throttle cable

Other answers in this thread

#2 Zuko

- Participant

- Group: Stalled

- Posts: 307

- Registration: 27 November 07

#3 genri_grin

- Participant

- Group: Users

- Posts: 353

- Registration: 20 January 08

#4 Jarrus

- Participant

- Group: Users

- Posts: 78

- Registration: 15 October 07

#5 Italian

- Participant

- Group: Users

- Posts: 209

- Registration: 06 November 06

Zuko (25.3.2008, 16:38) wrote:

#6 Jarrus

- Participant

- Group: Users

- Posts: 78

- Registration: 15 October 07

#7 Hind

- Participant

- Group: Users

- Posts: 420

- Registration: 05 June 06

#8 SPONSOR32

- Participant

- Group: Users

- Posts: 27

- Registration: 27 June 08

#9 Andrij_SH

- Participant

- Group: Users

- Posts: 16

- Registration: 11 June 08

#10 Alliance

- Participant

- Group: Users

- Posts: 302

- Registration: 22 November 06

SPONSOR32 (22.7.2008, 9:50) wrote:

#11 Airpound

- Participant

- Group: Users

- Posts: 17

- Registration: 04 April 08

Attached images

Post edited by Airpound: 09 April 2009 - 14:30

Adjusting the throttle stroke of the scooter

At its core, throttle free play is the position of the stick from the moment the throttle valve is closed to the moment it begins to move. It is important to know that this figure should be in the range from 2 to 6 mm.

Let's figure out what happens if there is no free play of the throttle at all:

- Firstly, it is difficult to adjust the idle speed. It is possible that the throttle cable is too tight and the throttle is slightly raised. At the same time, the engine speed is increased, and we think that the whole problem is the inability to adjust the idle speed, we are looking for problems in the carburetor, etc.

- Secondly, if the cable is pulled higher than normal, the scooter can simply move away on its own (simulating turning the throttle), then there is no question of any idle adjustment at all.

- Thirdly, throttle control becomes uninformative at low speeds, there are problems during stopping, and moreover, a complete stop can only be achieved by turning off the ignition.

Now let's look at what happens if the free play of the throttle is greater than normal (more than 6mm):

- The throttle valve may open with slight delays.

- In some cases, when increasing the free play of the throttle, the throttle valve may not open completely, as a result of which it is impossible to achieve the maximum speed of the scooter.

- If you constantly have to turn the throttle more than 6 mm in order for the damper to start moving, this will simply tire your hand and reduce driving information and comfort.

That is why it is so important to carry out a timely inspection and, if necessary, correct configuration of this unit.

How to adjust the free play of the throttle on a scooter

- Place the scooter on the center support.

- Remove the rubber boot from the adjustment mechanism.

- Now you need to loosen the locknut with an open-end wrench and turn the adjusting nut to adjust the free play. It can be either decreased (by turning the adjusting nut counterclockwise) or increased (by turning it clockwise).

- Now we check the stroke length (approximately possible), and if the indicators correspond to the norm, tighten the lock nut and put the boot in place.

- However, if this adjustment screw fails to achieve results, it is possible to make additional adjustments using the mechanism on the carburetor (not on all scooters). To check if your scooter has this adjustment feature, open the carburetor and check how the throttle cable fits into it, directly or through a mechanism with lock nuts.

- Adjusting the mechanism on the carburetor is very simple. First, loosen the locknut a little. Now, if the free play needs to be reduced, unscrew the locknut counterclockwise by the required number of turns and tighten it with the nut.

- If you need to increase the free play of the throttle handle, you need to loosen the nut and unscrew it a few turns, then tighten it with the nut.

Photo report: Repair of speedometer gearbox gear of a moped, scooter

It is impossible to predict fate, let alone avoid it, but to deceive it is quite possible! Fate: the gear drives of the speedometer gearbox, which is usually located in the front wheel support (in most small-capacity Chinese garbage dumps equipped with drum brakes, the speedometer drive gearbox is located there) - at one time some “figure” broke off.

“Activists” break this part very often: they farm their garbage dumps and instead of checking whether the gear drives are in the grooves on the wheel, they put the wheel on at random, clamp the axle and then think for a long time about why the speedometer stopped working. How will it work if the gear drive leads did not fall into the mating grooves during wheel assembly and became bent or broken off?

For example, the drive pins of this gear are bent

Let's tighten the leashes slightly and the speedometer will begin its vigorous activity again. We bend it carefully: the metal is hot, if you bend it a little, it will break.

At first glance, the fate of this gear is quite predictable: replacement with a new one so the leads are broken off.

Price: 150-200 rubles + time to travel to the store + transportation costs. Is it necessary? We are looking for a suitable strip of metal with a thickness of 1.5-2 mm, welding new leads (of course we weld with a thin electrode - 1.6 mm and the lowest possible current).

We get used to the role of Michaelangelo - we cut off everything unnecessary.

We lubricate the gear, insert it with the drivers strictly into the grooves, close it with the support, and install the wheel.

Adjusting the free play of the scooter throttle

The free play of the throttle (the movement of the throttle until the carburetor flap is set in motion) should be within 2 - 6 mm. If this value is greater than the required value, then because of this your hand may get tired, the throttle valve may open late or not open completely. On the other hand, if the free play is very small or there is none at all, this may lead to the impossibility of adjusting the idle speed; it may be higher than normal. It also makes throttle control more difficult.

So, let's check the free play. To do this, lightly (with two fingers) twist the gas handle. If the free play value is greater than the set value, then it is necessary to make an adjustment. To do this, remove the rubber dustproof cover from the throttle cable adjustment mechanism towards the lower end of the cable. If you do this at low temperatures, then you must act carefully, trying not to damage the shell. It will be useful to warm it up with a regular hair dryer; I don’t recommend using a construction hair dryer because of the possibility of damaging the plastic.

We loosen the locknut (with an open-end wrench, this is one of the few places where you can’t do without it) and start setting up. If free

The throttle stroke is large, then unscrew the adjusting nut (counterclockwise), if it is small, then tighten it. We check the amount of free play, while the carburetor damper drive lever should hit the idle speed adjustment bolt. If it is normal, then tighten the locknut and put on the rubber band.

If it happens that it is impossible to achieve optimal free play using the adjustment mechanism on the steering wheel, then you need to use the adjustment mechanism on the carburetor. To do this, open the hatch located at the bottom of the luggage compartment. Screw the adjusting nut on the steering wheel all the way. Loosen the locknut (1) of the adjusting mechanism on the carburetor. If we need to reduce free

stroke, then turn the locknut (2) counterclockwise, increase - clockwise.

Next, tighten the locknut (1). The direction of unscrewing/tightening the nuts relative to the photo. And we adjust the free

play, as described above, using the regulator on the steering wheel.

When making adjustments, it will be useful to lubricate the throttle cable so that you are not distracted by this procedure later. There are several lubrication methods.

With the adjusting bolt on the steering wheel screwed in completely, drop some oil on the cable (not on its casing!) and move the cable back and forth. Perform this operation several times, namely until the seat appears at the other end of the cable.

Disconnect the cable from the carburetor. To do this, remove the boot, unscrew the locknut (1) and pull the regulator out of the hole.

Next, disconnect the cable by threading it through the cut in the damper drive lever. Raise the free end of the cable above the level of the throttle handle. Drizzle oil and move back and forth. You can also use various devices for lubrication, the simplest of which is a plastic bag and a rubber band. Wrap the bag around the free end of the cable like a funnel and secure with an elastic band. Pour some oil into the resulting funnel and move the cable back and forth. As an alternative, you can use a technique I found on the Internet. Instead of a bag, an empty tube of silicone sealant is used, into which oil is poured, and the spout is put on the cable. The cable is pumped with a similar design. Moreover, if the cable is rusty, then instead of oil you first need to fill in gasoline or a rust remover. A piece (about 20 cm) of rubber hose with a suitable diameter will allow you to pump the cable under higher pressure. (the hose should fit tightly on the cable jacket). We put this hose on a cable and secure it with a clamp. Hold the hose vertically and pour oil into it (gasoline if necessary). We connect the other end of the hose to the pump, for example, you can insert an old nipple from the camera into the hose) and pump it. Proceed with caution, do not pump too much, as you may get oil all around, including yourself.

Photo report: Repair of speedometer gearbox gear of a moped, scooter

It is impossible to predict fate, let alone avoid it, but to deceive it is quite possible! Fate: the gear drives of the speedometer gearbox, which is usually located in the front wheel support (in most small-capacity Chinese garbage dumps equipped with drum brakes, the speedometer drive gearbox is located there) - at one time some “figure” broke off.

“Activists” break this part very often: they farm their garbage dumps and instead of checking whether the gear drives are in the grooves on the wheel, they put the wheel on at random, clamp the axle and then think for a long time about why the speedometer stopped working. How will it work if the gear drive leads did not fall into the mating grooves during wheel assembly and became bent or broken off?

For example, the drive pins of this gear are bent

Let's tighten the leashes slightly and the speedometer will begin its vigorous activity again. We bend it carefully: the metal is hot, if you bend it a little, it will break.

At first glance, the fate of this gear is quite predictable: replacement with a new one so the leads are broken off.

Price: 150-200 rubles + time to travel to the store + transportation costs. Is it necessary? We are looking for a suitable strip of metal with a thickness of 1.5-2 mm, welding new leads (of course we weld with a thin electrode - 1.6 mm and the lowest possible current).

We get used to the role of Michaelangelo - we cut off everything unnecessary.

We lubricate the gear, insert it with the drivers strictly into the grooves, close it with the support, and install the wheel.

Reasons for failure

Practice shows that the owner may encounter this problem for several reasons:

- storing vehicles indoors with high humidity levels or outdoors. Condensation appears inside, which causes corrosion of the part;

- wear. The cable rubs against the shirt as it moves. If you changed the spare part a long time ago, or did not do it at all, you will have to purchase a new part;

- lack of lubrication inside. Some manufacturers do not add special oil to the jacket to reduce friction. A characteristic sign of a lack of oil in the jacket is a creaking sound when turning the throttle;

- gap This problem occurs very rarely, since the cable has a good margin of safety. In combination with the above factors (lack of lubrication, corrosion, low strength), the part begins to suffer from thread rupture, which ultimately leads to complete rupture. In addition, the cable can break during an accident, when the moped falls on the right side, or when the throttle is turned very hard.

Service Features

The cable plays an important role in the scooter control system. If it fails, the gas can become seized, usually resulting in an accident and serious injury. Therefore, the task of any owner is to timely check the condition, maintain and replace (as necessary).

A scooter rider cannot always afford to replace a part with a new one (lack of money, a trusted store, and so on). Maintenance may be a temporary measure, consisting of adding lubricant inside the casing and further adjusting the cable. Practice shows that a serviced part can work for more than one season without problems.

In order to get started, you first need to place the scooter on the central support. Next, remove the problematic cable. During the dismantling process, it is worth ensuring free access to all ends of the product. For further lubrication, the cable is placed so that one end is placed above the other. It is best to fix it in a vertical position.

The next step is to ensure free movement in the inside of the casing. This must be done, since the quality of lubrication depends on the correctness of the work performed. Move the cable, holding one end of the casing parallel. If you can't handle this task, read on to learn how to do it right.

Photo report: Repair of speedometer gearbox gear of a moped, scooter

It is impossible to predict fate, let alone avoid it, but to deceive it is quite possible! Fate: the gear drives of the speedometer gearbox, which is usually located in the front wheel support (in most small-capacity Chinese garbage dumps equipped with drum brakes, the speedometer drive gearbox is located there) - at one time some “figure” broke off.

“Activists” break this part very often: they farm their garbage dumps and instead of checking whether the gear drives are in the grooves on the wheel, they put the wheel on at random, clamp the axle and then think for a long time about why the speedometer stopped working. How will it work if the gear drive leads did not fall into the mating grooves during wheel assembly and became bent or broken off?

For example, the drive pins of this gear are bent

Let's tighten the leashes slightly and the speedometer will begin its vigorous activity again. We bend it carefully: the metal is hot, if you bend it a little, it will break.

At first glance, the fate of this gear is quite predictable: replacement with a new one so the leads are broken off.

Price: 150-200 rubles + time to travel to the store + transportation costs. Is it necessary? We are looking for a suitable strip of metal with a thickness of 1.5-2 mm, welding new leads (of course we weld with a thin electrode - 1.6 mm and the lowest possible current).

We get used to the role of Michaelangelo - we cut off everything unnecessary.

We lubricate the gear, insert it with the drivers strictly into the grooves, close it with the support, and install the wheel.

Complete cable replacement

Replacement is very easy. It is enough to remove the old cable, disconnecting it from the controls, install a new one and adjust its tension if it is lost. Practice shows that adjustment is usually not required, since during adjustment we practically do not touch the carburetor bolts. In some models, it is necessary to adjust the tension of the spool, which is screwed into the carburetor. Therefore, before starting work, you should, if possible, count the number of thread turns visible to you, and then tighten the cable to the same level.

Correct adjustment of the throttle stroke

Not many people pay attention to the free movement of the throttle .

How to install the throttle cable on a scooter if it has leaked -. However, even minor deviations from the norm in one direction or another in this case lead to discomfort when driving the scooter, limit the idle speed setting, etc. throttle free play is the position of the stick from the moment the throttle valve is closed to the moment it begins to move. How to install the front bumper on Removing the rear bumper on the Daewoo Nexia with your own hands too. I wanted to install tires that are not as adjustable as the oil pump on a Honda Scooter. It is important to know that this indicator should be in the range from 2 to 6 mm .

Let's figure out what happens if there is no free play of the throttle at all :

- Firstly, it is difficult to adjust the idle speed. Throttle cable: how to put plastic on a scooter is not an easy task and can put in... How to install a trunk on a VAZ 2110 Install the trunk. It is possible that the throttle cable is too tight and the throttle is slightly raised. I have a Chinese scooter 75 at the top, but there is enough gas at the low and low. Hello everyone. Help me with information on how to install the rings correctly. The manual says that the second compression ring should be placed with the internal recess towards the piston bottom, but actually on the ZMZ rings. At the same time, the engine speed is increased, and we think that the whole problem is the inability to adjust the idle speed, we are looking for problems in the carburetor, etc.

- Secondly, if the cable is pulled higher than normal, the scooter can simply move off on its own (simulating turning the throttle ), then there is no question of any idle adjustment at all.

- Thirdly, throttle control becomes uninformative at low speeds, there are problems during stopping, and moreover, a complete stop can only be achieved by turning off the ignition.

Now let's look at what happens if the free play of the throttle is greater than normal (more than 6mm):

- The throttle valve may open with slight delays.

- In some cases, when increasing the free play of the throttle , the throttle valve may not open completely, as a result of which it is impossible to achieve the maximum speed of the scooter.

- If you constantly have to turn the throttle more than 6 mm in order for the damper to start moving, this will simply tire your hand and reduce driving information and comfort.

Why doesn't the speedometer on a moped work?

A speedometer is a must for every vehicle, because it not only shows the speed of movement, but also determines the distance that the moped has traveled over the entire time.

The speedometer on a moped (scooter) does not work. What to do?

There are three reasons why the speedometer does not work:

- The speedometer itself is faulty.

- The speedometer cable is damaged.

- Front wheel drive problems.

How to change the speedometer cable on a moped (scooter)?

First of all, you should check the speedometer cable, because it can break (usually it breaks near the front wheel). It's easy to change. First, unscrew the end of the cable from the drive of the moped (scooter) located on the wheel, then try to pull it out. It should have square ends that drive the speedometer. How to change the speedometer cable is shown in detail in the video below.

Why doesn't the speedometer on a moped work? Link to main publication

How to adjust the free play of the throttle on a scooter

- Place the scooter on the center support.

- Remove the rubber boot from the adjustment mechanism (1).

- Now you need to loosen the locknut with an open-end wrench and turn the adjusting nut to adjust the free play. It can be either decreased (by turning the adjusting nut counterclockwise) or increased (by turning it clockwise).

- Now we check the stroke length (approximately possible), and if the indicators correspond to the norm, tighten the lock nut and put the boot in place.

- However, if this adjustment screw fails to achieve results, it is possible to make additional adjustments using the mechanism on the carburetor (not on all scooters). To check if your scooter has such an adjustment option, open the carburetor and check how the throttle , directly or through the mechanism with locknuts (2) and (3).

- Adjusting the mechanism on the carburetor is very simple. How to remove the front bumper on a Daewoo How to remove and install bumpers on a Daewoo Nexia. How to install a throttle cable on a scooter? — Duration: 2:12 How to bleed the brakes. First, loosen the locknut (3) a little. Now, if the free play needs to be reduced, unscrew the locknut (2) counterclockwise by the required number of turns and tighten it with the nut (3).

- If you need to increase the free play of the throttle , you need to loosen the nut (3) and unscrew it several turns, then tighten it with the nut (2).

The carburetor can be accessed through a hatch under the seat (most Chinese scooters) or another way, depending on the design of each particular scooter.

You can also read other articles on the topic: