The switch on a 150cc scooter is a component in which electricity is stored to supply a charge to the coil when the motor starts. The accumulated energy at the moment of start increases sharply, which allows current to be supplied to the spark plug.

If the component provided is faulty, it will be difficult to start the scooter. Therefore, if you have problems starting the engine, you need to know how to check the switch on a 150cc scooter. In our Dvako online store you can buy a 150cc scooter in China, as well as other new and used motorcycles. Our service center technicians will help you diagnose and repair your vehicle.

Posts 1 page 1 of 1

Share12012-12-05 20:22:31

- Author: ilya

- Administrator

- Registered: 2012-10-22

- Invitations: 0

- Posts: 234

- Respect: [+0/-0]

- Positive: [+0/-0]

- Spent on the forum: 1 day 10 hours

- Last visit: 2013-01-16 12:39:02

Scooter switch - electronic ignition device for a scooter See also Diagram of the simplest switch, without electronic advance.

Scooter ignition advance Operating principle and design of electronic ignition/switch. An excellent article about this is taken from the site ntscooters.moy.su

Over the years of developing cars and motorcycles, we came to the conclusion that this scooter system should be as reliable as possible, because scooters are intended for carefree people

Therefore, Japanese scooters do not have cam ignition systems like IZ motorcycles and scoops (old mopeds). Even the oldest Hondas use an electric sensor. But more on that later. After all, not all scooters have it. For example, Suzuki Sepia has a rather clever shaft position control system. Therefore, you will not find diagrams of this switch on the Internet. It is quite complex in its internal architecture. I'll tell you about this later. Now I want to classify and break down the existing ignition systems on Japanese, Chinese, Korean and European scooters.

Depending on the type of engine, several systems are distinguished. 2-stroke Chinese mopeds have a system exactly copied from Sepia. But in terms of reliability it is simply terrible! The switches in it are on fire, only the noise is there! Personally, they brought me about 5 such mopeds with this symptom. Maybe a defective batch, but still take note. I’ll immediately note a significant difference between this system and Honda’s and Yamaha’s: the absence of an ignition sensor (also known as an induction sensor). I will describe the entire internal process later.

Japanese mopeds from Honda have several types of switches. I won’t write about tuning, we’ll limit ourselves to the standard. 18E engines have the simplest and most reliable ignition system of all scooters. In its design, it strongly resembles the ignition of the Carpathian mopeds, if it does not copy it exactly, which is quite likely. It differs from narrow ignition by the presence of an ignition sensor (induction) and a separate coil on the generator, which is in no way connected with the rest of the scooter’s electronics. This has advantages: if the generator is overloaded with lighting fixtures and other things, the ignition system will not fail. But it also has one significant drawback. A large amplitude voltage comes out of this coil on the generator, about 160-600 volts (at different speeds), which can be felt if water gets lightly on the contacts of the switch. Also, this coil can, under certain conditions, simply short out in turns (due to the amplitude), and then your scooter will stop, and you won’t even understand what’s wrong. You will spend a very long time looking for the cause of a weak or completely absent spark. Also, tuning switches for this system are complex in design. After all, you know that they non-linearly change the ignition timing at different speeds. And here there is also current and voltage jumping. Therefore, it is necessary to create a stabilization system, and a serious one at that. This is not the case with stock switches, but if you want to understand the nuances at low levels, then you need to know this.

For some reason I have a hunch that the tuning switches do not have microcircuits, and the advance is done simply by an RC timing chain, but this is just a guess.

I will also write about the ignition system of the 34 Honda engine. Things are a little different here. There is also an induction ignition sensor, it is identical to the sensor from the 18th engine. But the switch is powered not from a separate ignition coil, but from a common battery charging circuit. That is, in other words, from the battery. Also the regulator is a little different. More current is supplied to the battery here so that it is not discharged by the switch.

There was a case with me: I was driving from the dacha, due to inexperience in assembling the engine, the wires coming from the generator were hanging at the bottom of the engine. I somehow didn't notice them. It was already starting to get dark when I ran over some rock. The headlight immediately turned off. I thought the lamp had burned out. But switching the headlight mode did not correct the situation: there was no light. I stopped and checked the taillight. It didn't burn either. I thought that the wiring had broken or the regulator had run out. Since I wasn’t particularly strong in electronics at that time, I gave up and went home. There were 4 kilometers left to the house. I arrived safely, but in the morning I discovered that the wires coming from the generator were simply broken. Except for the ignition sensor wire. The battery was in the trash. It turns out I was driving it! Of course, in some cases this can be seen as a plus!

Now for some science. This system was developed in order to completely free the scooter from water dependence, increase the reliability of the generator and get rid of “extra wires”. The design of the switch is more complex due to the lower supply voltage. But now we can easily install elements sensitive to energy surges. Therefore, it is not advisable to ride such scooters without a battery. It seems to smooth out ripples and stabilize the mains voltage.

Yamaha and Suzuki scooters, as well as Chinese scooters, have similar ignition systems.

Now I’ll tell you a little about how the switch works. With the generator, I think everything is clear. It produces an alternating voltage of a given amplitude at certain crankshaft speeds. In order for an arc to occur, it is necessary to know the dielectric properties of air. The breakdown voltage per 1 mm is approximately 3 thousand volts. Also, for reliable ignition, you need to create a spark of a certain duration. The main energy converter for igniting fuel on a scooter is the ignition bobbin or coil. It turns 100 - 400 volts into approximately 6000 - 20000 volts. However, the current also decreases proportionally. Those who have ever touched high-voltage wires know what it is.

Well, okay, the reel is not very complicated and practically eternal... Although, if we are not talking about a Sepia switch. It contains both the bobbin and the switch itself - in one.

The task of the switch is to apply an impulse to the reel at a certain point in time, of a certain duration and amplitude. What I will write next may not be clear to many, but radio technicians will definitely understand.

We will consider only thyristor or so-called. capacitor ignition systems. They are used in all the scooters described here... The commutator has a capacitor that stores energy. As soon as the moment of sparking arrives, this capacitor will short-circuit to the primary winding of the ignition coil. And this process is controlled by a thyristor. Therefore, the system is called thyristor or capacitor.

The stock commutator for the 18E engine on Honda and many Chinese cars works on this principle. In order for the amplitude to reach its operating value at the bobbin output, the capacitor must be charged with a capacity of 0.5 -1 µF and an amplitude of about 200 volts. And as you may have guessed, the switch has to be powered with high voltage in any case. Therefore, switches with 34 motors contain a pulse voltage converter. It makes 200-300 volts from 12 volts. And another plus is that at any speed the spark will be the same in power, which increases stability at idle and makes starting easier. This is the difference between the commutator of the 18th motor and the 34th. I have not seen such switches on Chinese mopeds, because... in production they are much more expensive than the previous ones. It is quite possible that they use them there too. I would also like to say something about limiters. They are performed in different ways, most often using a timing chain. And if you change the condenser, the limiter will move to one side or the other on the scale. There are also other types of limiters.

It is worth mentioning separately the switch from Suzuki Sepia; I repeat that the same is used by the Chinese, which our magazine does not recommend. That is, with a pipe curved in the letter S and a two-stroke engine. In them, the basic principle of operation is no different from the switch with the 18th motor. However, the shaft position control system is different. Exactly what it is, one can only guess. Personally, I have not disassembled any such switch. The Japanese deliberately made this knot uniform and mysterious so that no one would want to copy it, but there were still craftsmen in China. Scheme of a simple switch, without electronic advance.

Let's summarize the above

First, use a light bulb to check whether the switch generates a pulse or not:

In conclusion, I would like to warn you against the temptation to take a known-good switch from someone and plug it in instead of your own. Yes, with this express method the faulty switch will be identified immediately. If it was really faulty, then with a known good one, a spark will immediately appear.

Subj. The following glitch occurs on the parent’s machine: the switch lives for some time (a couple of months), and then dies with the same symptoms - as if there is not enough spark, it seizes one or two cylinders. 1) How to fight? 2) How to repair a switch (I know how to use a soldering iron :)).

Everyone said everything correctly. and now from the past life of a young green teapot. those. me. I struggled with this glitch for a week, fortunately I was on vacation. So the first problem is let’s go. holes, rest for half an hour, then a spark appears, we move on. The contacts of the DH connector are very loose - bend them (the car was a year old and 13 because) it breaks through the thermally insulating GASKET of the transistor onto the body. The transistor is imported with short-circuit protection. Otherwise it would have died a long time ago. The switch was standard, with a plastic cover. I replaced it with two layers of transparent adhesive tape - rulez :), I need to install a new gasket. I went and bought an AVANTGARDE ignition unit from a neighbor (Tavrista) (Kazan , military woman) The brick is so green (well, anyone who has seen defense equipment will understand) and forgot about this problem forever. Tablet. how much is there in this sound (I burned them :)). The only solid-state USSR with output protection from short circuits is the native PP14? (what was it called). All analogues were assembled almost on the knee. A dismembered Belarusian (VTN there are a lot of them in UP) showed a burnt transistor rated at 3A instead of 5A. Well, in general, the low-beam spiral shorted in the light bulb itself: (when heated, whatever. After replacing the lamp and installing the old relay and a new military switch, everything was in good working order.

Try placing a larger capacitor from the + generator to ground. Somewhere in the forum I read about voltage surges in the on-board network, which the capacitor removes. Maybe it’s limp from overvoltage, IMHO?

incorrect: a capacitor with a larger capacity from + the generator to ground. Somewhere in the forum I read about voltage surges in the on-board network, which the capacitor removes. Maybe it’s limp from overvoltage, IMHO?

The vehicle's on-board network is not a 100mA power supply. Such a “solution” will achieve nothing.

Absolutely right. : See the line “Some electrical results.”

Absolutely right.

You need to look for a common cause: - increased voltage - increased ripples - high voltage leaks (breakdowns in the cover, slider, lights under the hood, etc.), short circuits in the coil - increased gaps in the spark plugs or other breaks - poor grounding of the switch. Or the entire engine.

By the way, how many and which switches burned out?

In such cases I ask: +++In such cases I ask: which of us needs help? :)))

: : We need to look for a common cause: : : - increased voltage : == There is no such thing. +++ Is its size and type of measuring device classified? : : : — increased pulsations : == Pulsations of what? +++ I won’t mock you, because... Already answered below. : : : - high leaks (breakdowns in the cover, slider, lights under the hood, etc.), short circuits in the coil : : - increased gaps in spark plugs or other breaks : == The car starts up quietly at -30C. Therefore, everything is in order with breaks and leaks. +++ You want to convince me that it is working properly. :))) : : : — bad mass of the switch. Or the entire engine. : : : : By the way, how many and which switches burned out? : : == About four of them have already burned down. Ordinary Soviet switches of the ATE type are similar. +++ However, it no longer looks like an accident.

The switch is a kind of “brain” of the ignition system in cars and motorcycles, designed to generate a current pulse and supply it to the bobbin. In human terms, this is a microcomputer that supplies a certain charge of current to a spark plug to ignite fuel in an internal combustion engine.

Checking the ignition coil

Disconnect the battery and remove the beak on the scooter. We disconnect the connector on the switch and measure the resistance on the coil with a meter. We put one probe in the connector on the black wire, and the second on the negative (green wire). There should be 4 ohms - this means that the wiring and the primary winding of the coil are working properly.

We check the second winding of the coil. We take out the probe from the contact of the green wire and insert it into the candlestick instead of the candle. And we leave the other probe on the contact of the h/w wire. The resistance should be about 7.85 kOhm. This indicates that the second winding, the armored wire and the candlestick itself are in good working order.

Let me remind you that the armor wire and the candlestick separately from the coil have a resistance of 5 - 8 kOhm. Such resistance is needed to suppress radio interference from the spark discharge, so as not to interfere with others listening to the radio in the car or at home. If you make an armored wire and a candlestick without resistance and drive next to someone who is listening to the radio. Then the radio stops working normally and begins to crackle in time with the spark discharge on the scooter (moped).

And if the device shows a break (i.e. does not react at all), then remove and check the candlestick and armored wire separately. If they ring, it means a break has occurred in the ignition coil. It cannot be repaired, it is solid, you will have to replace it with a new one. It's inexpensive and you can always buy it without any problems.

Dealing with the candle

If the dio 34 does not start, then first of all we check the serviceability of the spark plug.

We unscrew the candle, insert it into the candlestick and connect the ground to it using an additional wire. We pull the kickstarter leg. Let's see if there is a spark. If it is not there, then disconnect the battery. And again we check with kickstarter for its availability.

If it does not appear, then you can determine the performance of the spark plug on another scooter or using a test gun.

In order not to waste time checking the old spark plug, it is better to immediately take a new one and continue working with it. I always take branded NGK or Denso from the catalogue, it is guaranteed to last for a year, or 5 - 6 thousand km.

When checking, with the battery disconnected, a weak spark may appear. The scooter will even start, but will not develop speed and will not move. The first impression is that the switch is faulty, but there is no need to rush to conclusions.

Egnition lock

This component in the circuit of a 4-stroke 50cc or 150cc moped represents a switch. Moreover, it is multi-positional.

The lock performs the task of a central switch. It turns off the power to the entire scooter and turns the circuit back on when you turn the key. The larva itself is connected to a slider, which closes the corresponding contacts.

In the first position, the main wires interact - red and black. Current from the battery is supplied to the main circuits of the scooter. Since then it has been ready to launch.

The remaining positions close the black and white wire from the ignition module to the ground of the scooter. The operation of the motor is blocked by interrupting the spark supply from the coil. Depending on the modification, some models have a stop button in the electrical circuit. It performs the same function as the lock.

Generator

Owners of 50cc who are familiar with the design of the scooter will immediately understand the purpose of this device. It produces an alternating electric current that powers the moped when the engine is running. But the second main task is to charge the battery while working. That is, the battery ensures the operation of the devices when the engine is turned off, and then the generator takes on this task.

The connection is made according to the following principle. There are several wires coming from the generator. The negative tire is attached to the frame of the scooter. There is alternating voltage on the white wire, which is immediately sent for rectification and stabilization.

In the electrical circuit, the yellow wire powers the low and high beam lights. Additionally, a Hall sensor is located in the generator housing. Its task is to generate impulses to control sparking. It is not electrically connected to the generator; it is connected to a white-green and red-black wire. The sensor is connected to the CDI block.

Types of scooter switches

Before connecting the switch, it is important to know what type your scooter requires. If you connect the wrong device or do it incorrectly, the switch will immediately fail. The problem is that the part has the same plugs, but you can tell them apart. It's worth starting with the fact that DC is much larger in size.

AC CDI is much more common. It is installed on most Chinese and some Japanese vehicle models. Most often, such a switch is found on those scooters that have a 139QMB or 157QMJ engine.

A slightly different AC switch is installed on “Alpha”, “Delta” mopeds, and other equipment with a 1P39FMB motor. Such a switch operates from a generator coil and requires alternating voltage

DC has a different type of power supply - from a battery, so it has

12V, and if you connect it to a generator, the switch will break. AC is more durable in this regard; most likely, it simply will not work until you connect it correctly.

Basic Concepts

In order to understand wiring, you need to understand a little about the types of current. A constant is one that does not change its direction and magnitude. Variable is one where the voltage and current change their value after some time, or the current flows in the opposite direction. Often direct current, as can be seen in the wiring diagram of the Alpha moped, is needed for light bulbs: headlights, turn signals, foot. There are models where the motorcycle is completely converted to direct current, but these are old models and they are quite rare.

Login

At the moment of switching on, the arrow will strive to show the nominal voltage value in the on-board network. When the engine is not running, the indicator is approximately 12 Volts.

The search continues if a spark does not appear on the spark plug. In other words, high voltage does not flow from the woman to the spark plug.

Checking the switch on a VAZ 2107

The armored wire and, in fact, the woman herself come into question. It is recommended to check the armored wire at its ends, at the points of connection with the spark plug and the woman.

The next element of the ignition system to be checked is the switch. It is attached to scooters thanks to an elastic band, so it will not be difficult to remove it.

Malfunction

There are 5 6 wires going to the scooter switch: How to check and repair the scooter ignition system The sensor is inspected if the spark plug, spool and switch are in order. One wire from the switch goes directly to the household, bypassing other elements of the system.

The sensor is located near the generator. Just re-solder or replace the capacitor with a working one.

Still won't start? This means that you carelessly disassembled the switch and damaged other parts. To find out which parts you damaged, contact a good electrician, let him find out which parts you damaged and replace them. You did everything right! We sit on the scooter while we temporarily secure the switch with tape or tape, or in some other way we drive out onto a straight, flat road and check the speed!

If your scooter does not run for more than 40, it means that you soldered the capacitor poorly or they sold you a defective one. You better calmly and carefully study exactly how the electronics in the scooter work, how checking the switch on a car and on a moped differs, and also what exactly you can do to check electronics for damage and repair your vehicle.

In general, before considering the question of how to check the switch on a scooter, you should understand what it actually is.

Switch and circuit device How to check the switch on a scooter if you don’t even know what it is and where to look for it?

This is why you need to start small. The first thing you need to do is find out what a switch is. In fact, everything is quite simple, since a commutator is an element of the electrical ignition circuit in a vehicle that produces a low voltage pulse that is transmitted to the ignition coil. In isolation from the overall picture, the definition does not look very clear, so it is worth considering the structure of the entire circuit.

So, the main element here is the generator, which generates the operating voltage in order for the switch discussed in this article to work. As mentioned above, using the energy of the generator, the switch generates a pulse for the ignition coil, but not just a pulse - a low voltage one.

The ignition coil, in turn, generates a high voltage pulse at a specific moment in time, which is transmitted to the spark plug. The spark plug is screwed into the cylinder head and, upon receiving a high-voltage pulse, ignites the combustible mixture, which powers the engine. Well, now you know how the electrical circuit works in a vehicle, which will allow you to better understand how to test the switch on a scooter.

Checking the Honda dio 34-35 switch before shipping

Malfunction What prompted you to study the article on how to check the switch on a 4T scooter or any other common model? Most likely, your vehicle has stopped starting, but you don't know what exactly the problem might be. Perhaps the ignition is acting up, perhaps the engine is stalling. All this may or may not have a cause in the switch - this is the main problem of repair.

Removing the rev limiter in the Honda dio af 34/35 switch

This article is suitable for Honda Dio AF 34, 35/35 SR/35 ZX scooters

ATTENTION! The speed limiter can be removed only for switches marked: CI649 and CI649A. For switches with other markings, it will not be possible to remove the limiter, and if you try, you will simply ruin the switch, and your scooter won’t even start...

If you don’t know how to solder, then contact a friend who knows how to do it and show him this article, and if you don’t know such a friend, then contact any electronics specialist or auto/motorcycle specialist and also show him the article, he He will do everything for you.

How to remove the switch and where is it located?

The switch is located at the front of the scooter under the beak (the largest part of the plastic is at the front). The beak is attached to 3 large bolts in front, and 4 under the dashboard (two on each side), unscrew 3 large and 4 small bolts. Now you can remove the beak! Removed? Now we are looking for a metal platform:

Scooters Maintenance and repair

The principle of operation of the scooter ignition system is based on the ignition of the fuel-air mixture supplied by the carburetor to the cylinder. The mixture is ignited by a candle, however, in order to supply the necessary voltage to the candle, the current must go through a number of transformation stages, from the moment it occurs to the moment a spark forms on the candle with a power of several thousand volts.

The principle of operation of the scooter ignition system.

The mixture must be ignited strictly within a certain period, until the piston reaches top dead center. Only this position can contribute to the maximum pressure of the burning mixture on the piston at the moment of the power stroke. Consequently, this contributes to maximum engine efficiency. The efficiency of the scooter also depends on this factor.

At a certain moment, set by the switch, a current of several thousand volts is supplied from the ignition coil to the spark plug through a high-voltage wire. In a spark plug, a spark jumps from an insulated central electrode to a grounded side electrode.

The spark must be strong enough to ignite the mixture as efficiently as possible. For this purpose, there is a variety of spark plugs depending on the type of engine. Each scooter manufacturer indicates in the vehicle operating instructions which spark plug is recommended for use for a particular scooter model.

Type of candle.

There are so-called hot and cold candles

. Based on the temperature conditions of the scooter engine, the manufacturer indicates this in the marking of the recommended spark plugs. A cold spark plug has a short insulator. In this case, heat is freely removed from the electrodes, which is why the electrodes are maintained in a colder state during engine operation. A hot plug has a long insulator, as a result of which heat is less efficiently removed from the electrodes. It is important to remember that for normal operation of the scooter engine, it is advisable to use a cold spark plug on a hot engine, and a hot spark plug, respectively, on a cold one. Based on the recommendations of the scooter manufacturer, you should buy this part with this in mind.

Cold candle.

It is known that a candle that is too cold

quickly becomes covered with soot, and this prevents normal operation and starting of the engine. This sign can be mistaken for a rich mixture, however, as you can see, the matter is in the incorrect selection of the working part.

Hot candle.

is too hot

promotes premature ignition of the fuel-air mixture. As a result, the scooter's engine power decreases. Sometimes this can lead to engine damage, such as piston burnout.

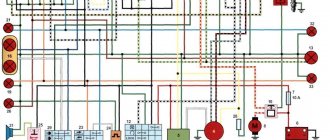

1 — rotor with magnets; 2 — sensor winding; 3 - charging coil winding; 4 — “stop” button; 5 - diode; 6 - thyristor; 7 - capacitor; 8 - primary winding of the ignition coil; 9 - secondary winding of the ignition coil; 10 - high-voltage wire; 11 - spark plug.

The role of the switch and ignition coil.

The main work in the ignition system is performed by the switch

and

an ignition coil

. All the high voltage supplied to the spark plug is generated in the scooter's ignition coil. The principle of its operation is very simple and is based on conventional electromagnetic induction.

A scooter's ignition coil consists of a primary and a secondary winding. They are wound on each other around a special metal core. The difference between the primary winding of the ignition coil and the secondary is that the first consists of several hundred turns of copper wire, and the second - of several thousand turns.

The current passes through the primary winding of the ignition coil and forms a magnetic field in it. During operation, this current is interrupted and the magnetic field disappears, however, a high voltage is induced in the secondary winding of the coil. It is this high voltage at a moment specified by the commutator that is supplied through the high-voltage wire to the spark plug through the spark plug cap. The high-voltage wire must be of a sufficiently large cross-section to prevent loss of current and overheating of the wire itself and insulation.

The spark plug electrodes are located inside the combustion chamber. “Earth” is supplied to the spark plug through the cylinder head at the point of contact after it is screwed in.

Older models of scooters and mopeds were equipped with a magneto ignition system. All modern scooters are equipped with a contactless ignition system that does not use breaker contacts. They have been a weak point of this system in the past and required frequent adjustment of the breaker contacts. This system is not currently used.

The switch fully controls the scooter's ignition system. Some scooters combine the switch and ignition coil in one unit. Usually they are not dismountable and must be replaced if they fail. Their cost is quite low.

The role of the thyristor.

Inside the switch, in addition to other electronics, you can find a thyristor

. At its core, it is an electrical breaker with three terminals. At the moment voltage is applied to one of the terminals, the thyristor turns into a conductor and electric current flows freely from the main terminal to the next one. As the current decreases to a certain level, the thyristor remains a conductor and upon reaching a certain value again becomes a breaker. After the break, the hall sensor again supplies a voltage pulse to the third terminal of the thyristor and the whole process begins again.

The role of the capacitor.

A mandatory element in the switch system is a capacitor

. It stores electrical energy with a voltage of several hundred volts, which is generated by the charging winding inside the flywheel. After the thyristor receives a control pulse from the sensor winding, it becomes a conductor, and the electrical energy that previously accumulated in the capacitor is released through the primary winding in the scooter's ignition coil. After this, a high voltage is created on the secondary winding of the ignition coil, which is the final voltage during supply to the spark plug.

The ideal layout for the ignition system of a modern scooter.

In the toga, the candle forms the necessary spark and the mixture ignites. In fact, this whole process is very simple and happens in a split second. This arrangement of the ignition system of a modern scooter is completely autonomous and does not require any intervention or adjustments on the part of the owner of the equipment throughout its entire service life. All that remains is to periodically monitor the condition of the spark plug and the gap of its electrodes, clean it in time and promptly replace it with a new one.

You can also read other articles on the topic:

Specifications

| Model | Today BA-AF61 FI/E (Honda Today AF 61) |

| Length | 1.695 m |

| Width | 0.630 m |

| Height | 1,030 m |

| Weight, kg | 75 (dry weight 71 kg) |

| Capacity | 1 person |

| Fuel consumption | 65 km/l (at 30 km/h) |

| Minimum turning radius | 1.8 m |

| Engine | 4-stroke air-cooled, single cylinder |

| engine's type | AF61E |

| The full amount | 49 cm3 |

| Bore × stroke | 37.8 × 44.0 mm |

| Compression ratio | 10,1 |

| Maximum output power | 2.8 kW (3.8 hp) at 8000 rpm |

| Torque | 3.6 N*m (0.37 kg*m) at 6500 rpm |

| Fuel supply form | Carburetor VK00A |

| Starting system | Electric starter and kick starter |

| Ignition | CDI |

| Lubrication | Separation by lubricant |

| Fuel tank volume | 5.0 l |

| Clutch | Dry multiplates |

| Transmission type | CVT (V-Matic belt) |

| Tires (front and rear) | 80/100-10 46J |

| Brakes (front and rear) | Mechanical drum |

| Suspension type (front) | Telescopic |

| Suspension type (rear) | Spring |

Simulation stand

If you do not have a second scooter, and also do not have access to it, then you should think about purchasing or making a special stand for yourself that would simulate the operation of your scooter. It is ideal for testing the switch on a Honda scooter, as well as on any other model, and if you regularly use such a vehicle, then the likelihood is that you will have to use the stand more than once or twice, so it is definitely worth the investment into it.

Now it is much more convenient to purchase it and install it in your garage, so that, if necessary, you can always check any part without using another scooter. But you can also do it yourself - only in this case you need to have very high skills and abilities in engineering, and it is also advisable to have impressive experience with such equipment. You should also know that such a stand has other advantages over a second scooter for control.

Difference between stand and second scooter

Let's say you wondered how to check the switch on a 2T scooter. You have read this article and realized that simply using a tester will not give you the results you need. Therefore, you are faced with the question of whether to get a stand, or try to find another scooter to check. Many people are inclined to the second option, as it looks much simpler and more convenient. However, you should still consider the former, as it has several significant advantages. One of the biggest is the depth of testing: if with a second scooter you can simply test the functionality of the switch and some details of its operation, then on the bench you will have the full range of possibilities. Everything will be before your eyes, you will be able to use the tester on any element, set the number of revolutions you need in order to test at various load levels, and so on. You can even check the compatibility of switches with ignition coils, as well as come up with any checks and tests that your imagination allows you to do.

In general, you will have a complete flight of fancy. You will get the answer to not only how to check if the switch is working on a scooter. You will be able to get an answer to any question that concerns your vehicle. However, it’s worth saying right away that if you just decide to buy a scooter for a couple of years and then switch to a motorcycle or car, then you shouldn’t waste time and money. The stand is more suitable for those people who are confident that they will ride a scooter for many years.

Checking the power supply of a DC CDI switch

If you have the wire of the high-voltage coil of the generator hanging idle (provided that everything was like this from the factory, and not after the intervention of some “guru”) - switch the tester to the DC measurement mode in the 20 V range. Look for the wire on the switch nutrition. Usually this is a black or gray wire; we touch the ground with one probe and the power wire with the other:

- If the display shows zeros, look for an open circuit in the power wiring.

- If the voltage is significantly less than 12v, look for oxidation or check if your battery is charged

- If the voltage is 12v or a little more, then everything is in order with the power supply and you can check further

The power supply to this switch is in perfect order.

Let's continue to figure it out

We remove the beak. It is secured with three bolts at the front, four self-tapping screws on the other side under the steering wheel, and two clips at the bottom, on the wheel side.

We get to the switch (with a 5-pin connector), the ignition switch (with three wires - two red, one pink) and the voltage regulator - rectifier.

We measure the voltage. Connect a charged battery to the scooter. We take a multimeter (tseshka) and set it to “V -” 20 V. Normally, when the ignition is turned on, the two red wires are closed together, +12 V on them,

and on the third pink one it goes through a zener diode to the switch 8 - 9.3V.

If the pink one shows 12 V or 0 V, then the fault is in the ignition switch, namely the zener diode has failed. And not a switch, as it seemed at first glance.

Sports Switch

Even such a modernized moped as Alfa Sport needs professional and high-quality tuning. This is necessary to increase speed and dynamics, as well as to improve the performance of the Chinese model.

Not only the cylinder-piston group, but also the commutator has a significant impact on the dynamics and speed.

Read also: OBD scanner for Android

The sports switch directly affects the speed of the moped

The factory switch assumes 2-5 thousand engine revolutions per minute. This ensures economy and maximum torque efficiency.

The difficulty lies in the fact that at medium and idle speeds the operation of the engine, which often overheats and periodically “shoots” at the carburetor, will not be stable. In order to protect the model from risks, it needs a sports switch. Unfortunately, such a switch is extremely rare on the market today.

That is why some owners of Chinese motorcycles make a sports switch themselves, or turn to a professional service for help. According to most experts, a tuning switch designed for an Asian scooter (4 tons) is a good alternative solution. Considering that the generators of such models have parameters similar to Alpha Sport, there are no problems with connection or subsequent operation.

Pros of the engine

The motorcycle engine does not overheat, accelerates and spins up quickly.

Tuning

The moped can accelerate to 13 kilometers per hour if you use a 15-17 tooth sprocket. It is important to remember that not only the rear and front sprockets need to be replaced, but also the chain.

To increase the speed of the moped, you can install a 15-tooth sprocket and replace the chain

The optimal solution would be to equip the equipment with additional:

- glove compartment for necessary tools;

- stand for a glass of water.

Considering that this model does not have a very comfortable seat, it can be replaced with a more rigid one, made of high-quality plywood (15 mm).

Repair

Like any other equipment, this moped also requires repairs periodically. To make a sports model as good as new, you need to:

- adjust valve clearances;

- remove and reinstall cylinder heads;

- if the valves lose their seal, the cylindrical heads should be disassembled;

- Reinstall the chain, piston and piston wheels.

Ignition circuit components

The ignition system is an important element in the operation of the entire scooter. The formation of a spark and a precisely calculated impulse that ignites the fuel depend on it.

The scooter ignition circuit includes many components that are responsible for a specific job.

CDI ignition module

The first item in the list is the CDI module. This abbreviation stands for Capacitor Discharge Ignition - ignition from a capacitor discharge.

The switch module is made in a non-separable box, so if it fails, it is replaced with a new one. 5 wires are connected to it, distributed throughout the entire ignition circuit of the scooter.

The block is hidden inside the scooter, so getting to it is not easy. The plastic covers will have to be completely dismantled.

Ignition coil

The purpose of this component is a fast pulse of high voltage voltage based on a signal from the switch. It goes directly to the spark plug, where it is converted into a spark.

The coil is located on the right side of the Chinese scooter and is attached to its supporting structure. It is easy to recognize - it is made in the form of a plastic barrel. On the reverse side there is a thick wire connected. It is he who transfers the discharge according to the circuit from the transformer to the spark plug.

To protect against dirt and dust, the coil is placed in a rubber cover.

Spark plug

Its function is simple - to form a spark and ignite the mixture inside the cylinder. The scooter uses an A7TC spark plug.

Its position is hidden from view, but experienced owners know where to look for it. Having passed along the high-voltage wire, we reach the engine block and the spark plug cap.

The rubber seal protects the contact from accidental electrical breakdown. Remove with a little effort towards you. Do not pull the wire too hard - the cap may come off.

The spark plug is unscrewed with a socket wrench. After removal, you need to inspect the color of the contacts and their condition. An indicator of good engine performance is a brown tint without traces of soot. Deviation from the norm indicates a malfunction of the carburetor.

Starter

The device is used to make it easier to start a scooter engine, without using a kick pedal. The starter is located in the middle part of the moped, near the engine. To open it, you need to remove the decorative plastic.

The starter is connected through the starting relay, which is located on the scooter frame.

Fuel gauge and indicator

The sensor measures the amount of gasoline in the tank and signals the need to refuel. It is located in the tank itself and is connected by three wires.

The indicator is directly connected to the sensor. Both are powered by stabilized current from the rectifier. If problems are observed in the operation of the indicator, you should check the connection to the circuit.

Voltage is supplied only when the ignition switch is turned on.

Turns relay

The breaker is used to control the turn lights. When the button is closed, the relay produces current pulses with a frequency of 1 Hz.

The block is located under the instrument panel. To change the relay you need to remove the plastic protection.

Switching the circuit is not difficult. When turning right, voltage flows through the blue wire, which is responsible for the corresponding lamps. The left position of the switch shorts the gray bus to the orange one.

Duplicate lamps on the instrument panel are connected in parallel to the turns circuit lines. They signal that the lamps are on on a specific side of the scooter.

My account

You should monitor the tread height of your tires and replace them as necessary. Riding a scooter with worn tire tread is extremely unsafe.

The turn should be done “pull”, controlling the gas or releasing it in advance. Always turn on low beam headlights when riding a scooter.

Float chamber It is important that the fuel in the float chamber is always within certain limits and does not drop below the permissible norm. It is also important that gasoline does not rise above permissible standards - this will help avoid overfilling

Actually, the float, which on the opposite side has a shut-off needle at its disposal, is responsible for the optimal level of fuel in the float chamber. Gasoline filling the chamber raises the float as it enters, which is constantly afloat.

cleaning the carburetor Honda Dio 27

When it reaches its maximum fulcrum, it closes the channel through which gasoline is directed from the gas tank to the carburetor. This is how the stable presence of a small amount of gasoline in the float chamber is regulated.

These are probably all the main systems of the Honda Dio 27 carburetor, so once you understand the operation of this device, it will not be difficult for you to put your scooter in order using the instructions in the manual.

Tags: accent, rear, replacement, stabilizer, struts, Hyundai

« Previous entry