Why does a scooter belt break?

A toothed belt in the drive of both 2t and 4t scooters is an indispensable attribute of most engines of modern mopeds.

Meanwhile, just some 20 years ago, the chain drive reigned supreme in the production of scooters. And some attempts to use belts were met with distrust and outright skepticism. It took decades and new technologies for belt drives to become dominant in scooters.

Although its advantages are quite obvious. Low noise, the possibility of simplifying engine designs and reducing its weight are good reasons for many manufacturers to give preference to a belt drive. At the same time, it is impossible to say unequivocally that the belt is better. The chain is much more durable. The chain drive can work as long as the motor. But the belt - alas, no.

Because of this, some companies continue to develop and produce engines with a chain drive that require virtually no maintenance. The service life of the belt is short and on average does not exceed 20-30 thousand kilometers. For the simplicity of the design, you have to pay for the maintenance of the belt drive. That is, periodically change the belt on your scooter, monitor its condition...

Only then can you be sure that the belt will not fail - it will not break or be left without teeth. And this usually happens at the most inopportune moment...

Breakage and shearing of belt teeth in a scooter transmission are the most common belt drive failures. Why is this happening? What happened to the belt?

Reliable operation of a belt drive is possible only under certain conditions: the belt is not exposed to oil and dirt, the pulleys and rollers on which the belt “runs” are in good condition, and the belt itself is correctly tensioned (that is, it has the correct length and width parameters, as advised scooter manufacturer).

To better understand why these conditions are so important, we need to take a closer look at the design of the variator timing belt. It seems to be quite simple. It is based on cord - strong fiberglass threads. The internal working part of the belt - the teeth - is usually made of nylon: it has high wear resistance and strength with good elasticity. On the outside there is a “stocking” - a layer of rubber 3-5 mm thick. Agree, this is somewhat reminiscent of a car tire: durable cord, wear-resistant tread (teeth)... It’s not without reason that many famous tire manufacturers (Continental, Firestone, GoodYear, Kleber, Pirelli, Semperit) also have variator belts for scooters and other motorcycles in their production program .

The belts used or have been used on scooters all over the world are very diverse in their parameters. For example, the number of teeth can vary from 44 to 257, the width of the belts can vary from 11.7 to 34 mm, and the tooth pitch can vary from 5 to 12.7 mm. In addition, there are about 20 types of tooth profiles - from simple trapezoidal on old motors to complex involute on modern ones. All this information is given in the catalogs of the main belt manufacturers - these are, in addition to those already mentioned by us, Bosch, Dayco, Gates, Rofan and many others.

Based only on an analysis of the design, it is already possible to determine what will happen to the belt if there are certain deviations from the normal conditions of its operation in the transmission of a scooter.

For example, if oil leaks through the seals (crankshaft or gearbox), and dust and dirt fly through the cracks in the joints of the variator cover and the scooter engine block, then the belt most likely does not have long to live. Oil destroys rubber (it swells and peels off from the cord), and dust, especially when mixed with the same oil, is an excellent abrasive that sharply increases wear on the pulley and belt teeth (although softer belt teeth suffer less).

A pulley worn out along the teeth causes a redistribution of the load - its maximum falls on the belt teeth in the places where it enters and exits the pulley. Other zones are less loaded or not loaded at all (the belt “does not lie” on the variator pulley). The consequences are obvious - cracks will appear at the base of the teeth, which will quickly lead to the teeth coming off or the variator belt breaking. In the described case, you will have to replace not only the old torn or worn belt, but also the damaged (worn out) front variator pulley, which turns into a stepped track. Otherwise, the new belt will quickly die. It is because of such mistakes that inexperienced scooter riders buy a seemingly inexpensive variator belt and then are indignant that it did not work for a long time.

We create a lot of trouble for ourselves by making mistakes when replacing the variator belt. It is very common to retighten it (replacing a belt whose length is shorter than required) - apparently, some “mechanics” think that the more you tighten the belt, the better it will work. And the fact that the overtightened belt “howls” is nothing, they say, it will work out.

This is wrong. After all, the strength of the cord threads is limited. And the tighter the belt is, the faster the threads will break. The same thing will happen if the belt was very bent during storage.

A loose belt will also not last long (this also applies to those who like to install a longer belt, thus achieving maximum speed of the scooter). The vibrations of the belt that occur in such a case lead to non-design loads on the teeth in the same place - in the places where they come off and, especially, where they enter the pulley. Undercutting and subsequent separation of the teeth from the base is inevitable.

Unexpected problems threaten those who manage to remove (or simply fail to install when replacing the belt) individual parts of the transmission (washers, for example, or the variator cover). One stray stone flying from under the wheels - and the belt can instantly break.

Absent-mindedness is generally always dangerous. Sometimes when replacing a belt, they forget to tighten the variator nut or something else. Many scooter manufacturers definitely recommend changing the variator rollers at the same time as the belt! And this is understandable: the roller bearing may begin to jam due to wear or insufficient lubrication. The result is overheating of the outer rubber layer of the belt, causing a network of transverse cracks to appear on it. Subsequently, the rubber peels off from the cord and the belt breaks.

Troubles with a belt drive can also arise under very “mysterious” circumstances. Let's say the engine of a scooter is being repaired, the variator belt of which has recently been changed. The question is, is it possible to install the same belt again? It is possible, but only as it stood before dismantling. If you confuse the direction of movement of the scooter transmission belt (say, without marking this direction before removing it), the belt will not move for a long time. Teeth that have been under load in one direction for a long time, when its direction changes to the opposite direction, begin to “crack” and are cut off. Here's a little subtlety...

To keep the belt running for a long time

You need to watch the belt. And follow some very simple rules.

The main thing is that the variator belt must be correctly tensioned, which means it must be the correct length. You can see which belt you need to choose for your scooter in the catalogs.

It is equally important that the entire transmission of the scooter works properly. This is especially significant for engines with increased displacement.

Another indispensable condition for the normal operation of a belt drive is the ease of rotation of all shafts. It is quite obvious that if one of them rotates tightly or with uneven force (sticks), then before installing a new belt, the cause of the jamming must be eliminated.

In addition, it is important to make sure that there are no oil leaks, as a result of which it could get onto the variator belt. If this happens, you must immediately fix the leak, thoroughly wash the belt and pulleys of oil , and best of all, replace the belt.

And the last, simplest rule: the belt drive should always be kept clean.

Otherwise, you won’t have to count on the reliability and durability of the variator on your scooter.

Source

How to choose a belt for a scooter

Health to all and forever! Sednya wanted to buy a belt for his 139QMB, but left the magician with nothing. Because I did not agree with the dimensions of the “standard” belt 669x18x30. "Mototech" was suggested. It turned out to be 13mm longer (I agreed with this) and narrower - 17.5mm (and I can’t get one like that). The seller tried to convince me that the belt does not stretch, because... The cord mesh of the belt will not allow this, and I cannot find the exact width, 18mm. To which I retorted: “What the hell are the inscriptions on the belt and why does the Chinese quality control department receive a salary and the purpose of such a belt - in the absence of any, how to get there, if anything.” And I'm harmful! The transmission pulleys are definitely made of metal, which means the belt should be. to the neck. Guys, whose side are you on? Mine or the seller's? And the main question is: who has experience buying belts? Is it really possible to buy a STANDARD belt with the appropriate dimensions, at least in width? (Recently the width size is indicated not just 18, but 18.1 - what is that?) Or - I just can’t find it?

I have a belt 669x18x30, some kind of endurance, I’ve done nothing on it. I bought it out of curiosity to try it, but it’s not 18 wide, but 17.7. Why can’t you just find the belt?

Added

(06/27/2015, 06:13) ——————————————— well, 13mm is a lot, although the belt needs to be measured, sometimes they write this on them

Yeah! With a belt, like with shoes at our bazaar, without looking at the size: - “You have to try it on.”

slaviks

, The length of the belt that is most suitable for your scooter can be selected as follows: take a cord or rope, apply one end to the variator bushing and, holding it with the other hand, pull it towards the clutch and draw the lace along the upper edge of the clutch cheek (in a circle), then pull it back to the variator and circle the bushing to the end of the rope, mark or cut off the length, measure with a tape measure - here is the length in your particular case, the width of the belt is equal to the distance from the inner cheek of the variator to the mating cheek along the bushing, but in practice it is better to measure from the inner cheek to the mating cheek with the cheeks together on the top, on the edges.

I measured the length of the ENDURANCE, the size is almost the same: 666mm, only 3mm, so you can take it if you find it, well, there is definitely one in Kharkov, it’s a Honda size, well, for a 139 engine

Scooter variator device

A variator is a part responsible for a smooth change in speed. It is a unit of two pulleys (driver and driven) connected to a belt. The degree of load on the main variator depends on the intensity of engine rotation. When driving at high speed, the number of rotations is maximum, which is why the variator parts wear out faster.

The belt is attached to the pulley at the sides. If the CVT bushing wears, the belt cuts deeper into the pulley. When the drive pulley operates, the belt smoothly compresses and unclenches. A sports CVT on a scooter makes more revolutions. The belt may need to be replaced sooner.

Even a new scooter can fail over time due to improper use.

How to replace a belt

The scooter's variator can withstand a mileage of up to 6 thousand km. The belt lasts the same amount of time. The part may last longer, but you still need to regularly diagnose it. You can do it yourself if you have special knowledge in this area.

Symptoms of a problem

Main causes of failure

The main causes of CVT malfunctions are violation of operating rules:

Mileage up to 6 thousand km. withstands the scooter's variator. The reasons for the breakdown may be other. One of them is a faulty bearing in the variator, which manifests itself in the appearance of a hum. Noise is often attributed to worn wheel bearings, making it difficult for a beginner to identify the real cause of the problem. The difficulty is that the bearings can be damaged even with low mileage due to aggressive driving.

Another cause of damage is metal dust. The chain and variator pulleys rub against each other, so they gradually wear down.

Dust gets into the oil and then to the bearings. To find this dust, oil filters are present in the design. But neither they nor regular oil changes prevent the appearance of dust.

Another reason for variator failure is the accumulation of metal dust in the oil pump. It penetrates the valves and disrupts their operation, and also leads to pressure surges in the pump. The pulleys move chaotically, causing the belt to wear off. As a result, the vehicle jerks while driving. If you don't fix the variator, you'll have to replace the gearbox.

The variator may fail due to belt damage. This part is a device consisting of many plates located on a bundle of metal strips. Due to the uneven surface, they are better attached to the pulleys. They gradually wear out, and accumulated dust prevents the device from working properly. Because of this, the variator belt slips, jerking the vehicle. In this case, repairs are required immediately.

Due to belt damage, the variator may fail

The most harmless malfunction is that when driving fast, a sign flashes on the panel, indicating that the transmission is overheating. The vehicle stops abruptly to cool down. This indicates that the oil pump cooling system is clogged and has stopped working normally. For preventive purposes, it is necessary to clean radiators twice a year.

How to choose a new one

Scooter belts vary in size and markings. The characteristics are indicated in the transport passport. You cannot fit a larger belt size. Because of this, the dynamics of the vehicle may be disrupted.

Example. The driver changed the belt, after which the variator began to operate in normal mode. But, when squeezing the maximum speed, the belt tore into pieces. The reason is the incorrect choice of belt size. It is necessary to follow the characteristics in the passport. It is allowed to install a belt 1.5 mm larger than necessary. When the maximum radius of the variator was reached, the belt slipped out and caught on the edge of the pulley.

The belt could not cope with the sudden increase in speed and broke. To increase the durability of the variator, you should install a belt of the right size.

How to install correctly

The first step is to remove the damaged belt.

Scooter belts differ in size and markings

You need to place the scooter on the central leg and perform a number of actions:

Mitsuboshi variator belts for scooters - choosing a model by marking

Section: Useful information for owners of scooters and mopeds

The reliability of the scooter, the efficiency of the variator and the entire transmission as a whole directly depends on the quality of the belt. Mitsuboshi Belting LTD is one of the world leaders in the production of V-belts for scooters, cars, motorcycles, agricultural machinery, special-purpose equipment, etc.

Many giants of the scooter industry complete their finished products with Mitsuboshi belts (Suzuki, a number of European, Korean, Taiwanese companies). As a rule, the size is not indicated on the belt (only the factory code is indicated).

To select the appropriate belt size or determine the size by serial number, you just need to use the table below.

The table is created in an intuitive format, where each code is accompanied by the width, length, height and bevel angle of the belt.

In some cells after the code you can find the following symbols:

- * — Special belt with increased strength.

- ° — Belt with double teeth.

Mitsuboshi belt sizes

| Factory number | D | Sh | U | IN |

| 27.37001 | 859 | 14,9 | 30 | 8 |

| 27.37011 | 733 | 15 | 30 | 8,5 |

| 27.37061 | 751 | 16,5 | 30 | 8 |

| 27.37081 | 700 | 17,7 | 30 | 8 |

| 27.37101 | 797 | 16,6 | 30 | 8 |

| 27.37171 | 805 | 18,7 | 30 | 8 |

| 27.37172 | 951 | 24 | ||

| 27.37181 | 830 | 18,5 | 30 | 8 |

| 27.37191 | 871 | 23 | 28 | 10,6 |

| 27.37201 | 871 | 23 | 28 | 11,4 |

| 27.37202 | 813 | 19,1 | ||

| 27.37211 | 769 | 18,9 | 30 | 8,5 |

| 27.37221 | 836 | 21,5 | 30 | 10,2 |

| 27.37231 | 832 | 22 | 28 | 9,3 |

| 27.37241 | 893 | 22,7 | 30 | 11,4 |

| 27.37251 | 785 | 18,4 | 30 | 8 |

| 27.37261 | 847 | 22,1 | 30 | 9,2 |

| 27.37271 | 816 | 22,5 | 30 | 10,2 |

| 27.37281 | 779 | 16,9 | 30 | 8 |

| 27.37291 | 785 | 18,4 | 30 | 8 |

| 27.37302 | 919 | 22,5 | ||

| 27.37332 | 797 | 20,1 | ||

| 27.71511 | 724 | 17,5 | 30 | 8 |

| 27.71631 | 804 | 17,5 | 30 | 8 |

| 27.71831 | 828 | 22 | 30 | 9,5 |

| 27.71841 | 736 | 18,3 | 30 | 8 |

| 27.71901 | 834 | 22 | 30 | 9,5 |

| 27.71941 | 732 | 18,5 | 30 | 8 |

| 27.71951 | 848 | 18,1 | 30 | 8 |

| 27.71961 | 850 | 17,7 | 30 | 8 |

| 27.71971 | 861 | 21,7 | 30 | 10 |

| 27.71981 | 774 | 17,7 | 30 | 8,3 |

| 27.71991 | 765 | 18,7 | 30 | 9 |

| 27.72001 | 937 | 22,5 | 30 | 10,2 |

| 27.72011° | 941 | 22,0 | 28 | 12,0 |

| 27.72021° | 1.011 | 27,7 | 28 | 14,0 |

| 27.72041° | 947 | 24,4 | 28 | 14,8 |

| 27.72051° | 892 | 32 | 28 | 14,7 |

| 27.72061 | 1.006 | 23 | 28 | 11,4 |

| 27.72071° | 827 | 22 | 28 | 13 |

| 27.72081° | 1.036 | 28,2 | 28 | 14 |

| 27.72091° | 1.262 | 28 | 30 | 14,4 |

| 27.72101 | 821 | 18,2 | ||

| 27.72111 | 995 | 24,1 | ||

| 27.72121°* | 947 | 24,4 | ||

| 27.72131* | 832 | 22 | ||

| 27.72141° | 913 | 30 | ||

| 27.72151°* | 892 | 32,2 | ||

| 27.72161° | 836 | 22,6 | ||

| 27.72171 | 796 | 22 | ||

| 27.72181° | 1.042 | 24,4 | ||

| 27.72191° | 1.036 | 28,9 | ||

| 27.72201 | 763 | 18,5 | ||

| 27.72301 | 678 | 17,8 | ||

| 27.72401 | 919 | 22,0 | ||

| 27.72501° | 1.244 | 28 | ||

| 27.72601° | 1.008 | 28 | ||

| 27.72701 | 924 | 24,4 | ||

| 27.72801 | 847 | 22,4 | ||

| 27.72901 | 883 | 22,6 | ||

| 27.73001° | 931 | 30,0 |

How to properly tighten threaded connections when repairing a scooter

Variations on the handle

So, with the general principles of changing the gear ratio everything should be clear, now it’s time to proceed to the mechanism of this change, that is, how to make the scooter’s variator pulleys move and move apart exactly when required. To do this, let’s immediately make a reservation that in a scooter variator it is customary to distinguish the driving pulley (located on the crankshaft) and the driven pulley (located on the clutch shaft). In the bowels of the drive pulley there are special cylindrical weights (sometimes also called rollers). These plastic-coated metal bushings are placed in special grooves in which they can move radially. If you move the weights in the drive pulley from the center outward, they will inevitably move the pulley cheeks together. In fact, of course, only one cheek of the variator pulley moves, but this is not important. When the pulley rotates, the weights, under the influence of centrifugal force, tend outward and, shifting the pulley cheeks, push the belt outward. The faster the pulley rotates, the stronger the centrifugal force acting on the weights, and the further outward the compressing pulley cheeks will push the belt. The driven pulley has no weights, but has a large spring that constantly tries to squeeze its jaws together and push the belt out. Like the driving pulley, the driven one has only one moving part - the external one (referred to in foreign literature as the torque driver). It is the torque driver that moves either outward, overcoming the resistance of the spring and allowing the belt to “fall” inside the pulley, or, conversely, inward, closer to the fixed part of the pulley. Thus, the change in the working radii of the scooter's variator pulleys always occurs synchronously. When the belt goes out in the driving pulley, then in the driven pulley, overcoming the resistance of the spring, the belt, on the contrary, moves inward, closer to the axis of the variator pulley.

For a more complete understanding of the process, let's see

how the scooter's variator behaves under different engine operating modes . At idle, the rotation speed of the variator drive pulley is minimal. Although a certain centrifugal force acts on the weights, it is not enough to pull the belt out. After all, this requires overcoming the resistance of the large spring of the driven pulley! But now the gas is open, the crankshaft speed jumps, and now the centrifugal force acting on the weights is already enough to push the variator belt in the drive pulley a little outward. Drive pulley coupling: cover; guide plate; coupling body; rollers. The gear ratio changes. The rotation speed of the driven pulley of the variator increases significantly, which forces the centrifugal clutch to operate. The scooter starts moving. The engine speed reaches its operating level, meanwhile the belt continues to move further and further outward in the drive pulley of the variator, and deeper in the driven pulley. That is, the speed remains unchanged, but the gear ratio gradually changes, making the scooter go faster and faster. This, by the way, hides one of the great advantages of the variator - acceleration occurs at constant speeds, so you can configure the entire system so that during acceleration the engine will operate at its maximum power (for example, this is impossible to achieve with a manual transmission). Finally, the belt reaches its maximum design radius in the drive pulley of the variator, and its minimum in the driven pulley. However, as a rule, it is possible to accelerate a little faster, but by increasing the speed of the scooter's engine, and not by increasing the transmission. When the throttle is closed while driving, the engine brakes the scooter for some time until the centrifugal clutch disengages. As soon as it is turned off, under the action of the large spring of the driven pulley, the belt returns to its original position, as when idling a scooter. But as a rule, the scooter’s clutch disengages only when it comes to an almost complete stop (10 - 25 km/h). By the way, about the scooter’s clutch. This device, although it performs independent functions, is very closely connected with the scooter’s variator itself: if the clutch does not work correctly, the variator will not work correctly, and vice versa. A scooter's centrifugal clutch is almost always three drum-type brake pads that are pushed outward by centrifugal force and engage the clutch drum. The clutch assembly itself is mounted on the driven pulley of the variator and rotates, but the clutch drum is on a shaft, which transmits torque to the rear wheel through a simple gearbox. Thus, in order to make the scooter move, you need to make the clutch drum rotate. This happens as soon as the driven pulley of the scooter's variator gains sufficient rotation speed so that the centrifugal force becomes large enough for the pads to overcome the elastic force of the clutch springs, which prevents their free movement outward. These same springs will “disengage” the clutch, squeezing the pads together when the rotation speed of the driven pulley drops below the critical level for the clutch to operate. As you can see, the system is simple. And it works almost flawlessly, reducing control of the power unit to twisting the throttle (hence, by the way, the name of one popular scooter magazine: Twist'n'go - “Twist and Ride!”). Which not least determined the current wave of popularity of scooters. This video shows the CVT in action. Shown in the best possible way.

What will extend the life of a CVT belt?

It cannot be said that CVT belts are too fragile mechanisms, but in order not to destroy them before the lifespan set by the manufacturer, you must follow the driving rules:

- do not make sudden gear changes (especially when trying to get out of the mud by rocking the car);

- Do not press the gas and brake pedals simultaneously in Drive mode;

- avoid towing and wheel slipping;

- move away smoothly, without a sharp jump in engine thrust;

- do not operate the transmission when driving off-road;

- do not switch the gearbox to neutral speed for coasting;

- Move the gear lever to P or N during short stops (lasting up to 1 minute).

You can ruin the variator belt even while moving at low speed. It is enough to hit the curb with your wheels when parking in reverse. The resulting shock will be transmitted to the belt moving in the opposite direction, and it may become deformed.

In order for the belt to serve as long as possible, it is necessary to strictly follow the maintenance regulations, and it is better to reduce the service intervals recommended by the manufacturer by half. During maintenance, special attention is paid to the oil channels and sump. They need to be thoroughly cleaned of friction wear products.

For each maintenance it is necessary:

- change coarse and soft filters;

- check the serviceability of heat exchangers and cooling system lines;

- Fill the gearbox only with gear oil prescribed by the gearbox manufacturer.

Did you know what you need to pay attention to during maintenance and how often to carry it out? Write in the comments.

Replacing the variator yourself

At this stage, it is important to remember about the calculation of the variator. Installing an incorrectly sized belt will cause the device to quickly fail. To maintain the durability of the variator, the belt must be secured in the drive pulley. Then rotate it until it is positioned properly. Next, you need to check the quality of the fastening of the nuts, since they could have become loose during operation. Finally, you need to test the belt. To do this, rotate the crankshaft, after which it will become clear whether the belt is positioned correctly. If yes, all that remains is to return the variator cover to its place.

Replacing the variator yourself

There is a second way to replace the variator chain. Removing the old belt is done in the same way. Next, you need to disassemble the variator and install a pulley on which the new belt will be mounted. To push the belt in, move the pulley halves apart. The belt will take the required position after turning the variator at maximum speed for several seconds. If everything is normal, then the last task remains: how to assemble the variator cover? Everything is very simple. You need to screw it to the workplace and check the quality of the bolts.

ProVariator.RU

In this review, I will talk about the variator belt that I chose for my Chinese scooter, I will look at issues such as price, quality, belt sizes and at the same time I will show you how to change it.

Actually, this is how we became acquainted with the variator belt.

Which variator belt to choose for a Chinese scooter?

As with most Chinese scooters, the dimensions for mine will be 729×17.5

If in doubt, just take your broken belt and look at the dimensions on us.

There were three options for the Chinese scooter:

No thanks, even for sale, I'll buy something better. Last time I pushed the scooter for 20 kilometers. I feel sorry for the people. ))))

My clutch was so loose that it was shaking, and since I didn’t know about it, the belts had to be changed 3 times. And three times I chose this one. In a situation in which it could break on the first day, I skated for half a year.

And the third option is really cool, it costs one and a half thousand. Is it needed? Well, if you are going to go to Crimea on a scooter, then why not?

How to change the variator belt?

It's called a pneumatic impact wrench.

Unscrew a few bolts. And we see:

This is how the belt should be. It will hang around, torn, or even crumble into crumbs.

Yes, yes, that’s what this wonderful tool is for.

Don’t put pry bar keys and other nonsense in there, otherwise you’ll just ruin the gear and cost yourself an extra thousand rubles.

“Guys, do you have a pneumatic impact wrench? Can you unscrew two nuts?

When they are removed, we check the videos:

Then we take the clutch and try to squeeze it:

If it moves tight and smoothly, you're in luck! If it's loose, you'll have to buy a new one.

Well, the easy part remains. We tighten the belt and assemble our scooter.

NO NEED TO LUBRICATE ANYTHING!

Yes, if you bought a new clutch, it will not be easy to tighten the belt. We'll have to do it together. One pulls the clutch by hand, as shown in the previous photo, and the other pulls the belt onto the shaft.

Source

Scooter variator device

A variator is a part responsible for a smooth change in speed. It is a unit of two pulleys (driver and driven) connected to a belt. The degree of load on the main variator depends on the intensity of engine rotation. When driving at high speed, the number of rotations is maximum, which is why the variator parts wear out faster.

The belt is attached to the pulley at the sides. If the CVT bushing wears, the belt cuts deeper into the pulley. When the drive pulley operates, the belt smoothly compresses and unclenches. A sports CVT on a scooter makes more revolutions. The belt may need to be replaced sooner.

Even a new scooter can fail over time due to improper use.

What happens if you put a longer variator belt?

When installing a longer variator belt, the equipment will lose dynamics, the maximum speed and fuel consumption may increase, and there will be a slight increase in torque. Since at idle and maximum speed the variator belt can protrude beyond the edges of the pulleys, there is a risk of damage to the belt and the variator housing. Also, when installing a variator belt that is too long, in addition to the consequences described above, at idle and maximum speed it may protrude too far beyond the boundaries of the pulleys and jump off (fall out).

How to replace a belt

The scooter's variator can withstand a mileage of up to 6 thousand km. The belt lasts the same amount of time. The part may last longer, but you still need to regularly diagnose it. You can do it yourself if you have special knowledge in this area.

Symptoms of a problem

Main causes of failure

The main causes of CVT malfunctions are violation of operating rules:

Mileage up to 6 thousand km. withstands the scooter's variator. The reasons for the breakdown may be other. One of them is a faulty bearing in the variator, which manifests itself in the appearance of a hum. Noise is often attributed to worn wheel bearings, making it difficult for a beginner to identify the real cause of the problem. The difficulty is that the bearings can be damaged even with low mileage due to aggressive driving.

Another cause of damage is metal dust. The chain and variator pulleys rub against each other, so they gradually wear down.

Dust gets into the oil and then to the bearings. To find this dust, oil filters are present in the design. But neither they nor regular oil changes prevent the appearance of dust.

Another reason for variator failure is the accumulation of metal dust in the oil pump. It penetrates the valves and disrupts their operation, and also leads to pressure surges in the pump. The pulleys move chaotically, causing the belt to wear off. As a result, the vehicle jerks while driving. If you don't fix the variator, you'll have to replace the gearbox.

The variator may fail due to belt damage. This part is a device consisting of many plates located on a bundle of metal strips. Due to the uneven surface, they are better attached to the pulleys. They gradually wear out, and accumulated dust prevents the device from working properly. Because of this, the variator belt slips, jerking the vehicle. In this case, repairs are required immediately.

Due to belt damage, the variator may fail

The most harmless malfunction is that when driving fast, a sign flashes on the panel, indicating that the transmission is overheating. The vehicle stops abruptly to cool down. This indicates that the oil pump cooling system is clogged and has stopped working normally. For preventive purposes, it is necessary to clean radiators twice a year.

How to choose a new one

Scooter belts vary in size and markings. The characteristics are indicated in the transport passport. You cannot fit a larger belt size. Because of this, the dynamics of the vehicle may be disrupted.

Example. The driver changed the belt, after which the variator began to operate in normal mode. But, when squeezing the maximum speed, the belt tore into pieces. The reason is the incorrect choice of belt size. It is necessary to follow the characteristics in the passport. It is allowed to install a belt 1.5 mm larger than necessary. When the maximum radius of the variator was reached, the belt slipped out and caught on the edge of the pulley.

The belt could not cope with the sudden increase in speed and broke. To increase the durability of the variator, you should install a belt of the right size.

How to install correctly

The first step is to remove the damaged belt.

Scooter belts differ in size and markings

You need to place the scooter on the central leg and perform a number of actions:

Checking and replacing the scooter's variator belt

Many new scooter riders, especially those who are not familiar with technology in general, when buying a scooter, have no idea that such an element as a variator belt will one day/soon become unusable, especially if the scooter is not new. However, it is always important to ascertain the “point of condition” of the belt in time, otherwise there is a danger of getting firmly stuck somewhere.

Generally speaking, a normal variator belt should last at least 6000 km under normal conditions - this is the minimum. Normal conditions here mean, firstly, the correct installation of the belt, with the stated dimensions. Secondly, the riding style of a scooterist, because you can “lose” a new belt in a week, endlessly skidding and accelerating in a childish way. Thirdly, it should be borne in mind that with prolonged inactivity the belt may also become unusable. In this sense, the belt on a new scooter (especially a Chinese one) may not pass the required minimum - a consequence of tedious downtime in damp warehouses.

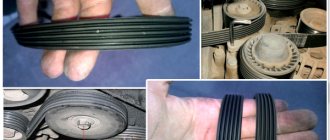

Although in most cases a worn-out belt begins to slip significantly*, which is noticeable (from the dynamics of the scooter) even without a visual inspection, I would recommend checking the belt every 1500 - 2000 km, but not only for signs of wear. Some belts (again, especially Chinese ones) during their first 1000 - 3000 km begin to “lose” the top layer, which is a fabric braid. The remains of this braid in the form of fluff clog all possible cracks, corners and ventilation holes in the inside of the variator body, which instantly leads to an increase in the operating temperatures of the scooter's variator components. You understand that this is extremely undesirable.

* belt wear is not the only reason for slippage; it could also be, for example, a weak spring stiffness of the driven pulley.

It is quite easy to determine the condition of the belt by eye - the presence of cracks indicates its imminent collapse. The belt can crack both along (delaminate) and across (fall apart). In this case, replacement is necessary without delay.

What are the dangers of a belt breaking on the road? The photo shows a typical case of belt delamination.

Replacing a torn belt is not so difficult; it is not necessary to disassemble part of the variator. But at the moment when the belt fails, the movable cheek of the drive shaft becomes “uncontrollable”, and at this moment it is very easy for the weights to fall apart. My belt broke twice, and both times the weights fell apart, in one case several flew out of my cheek, and in the other they remained inside, but fell out of their tracks. If you can disassemble the variator in the garage - using a gas wrench - then in road conditions it is extremely problematic, almost impossible, to unscrew the variator fastening nut, I was convinced of this. For this case, a special puller is needed:

But the same thing is done using a gas key:

What happens if you install a belt of the wrong size?

Maybe nothing special, just the dynamics of the scooter will change, perhaps the maximum speed. However, it is not for nothing that each scooter model has its own belt size. And installing a non-standard one can end badly. Here's a good example. After the scheduled replacement of the used belt, the new one (Taiwanese belt, decent quality) traveled only about 1500 km, when suddenly, on the descent from the hill, at high engine speeds, it was torn into pieces. It turned out that the new belt is about 1.5 mm wider than the standard, contrary to the dimensions written on it. As a result, at high speeds, the belt came out of the cheeks higher than necessary, and at one moment it simply caught on the edge of the cheek and came out “outside” (after all, the belt is under constant pressure “on the sides”, due to which it is pushed out by the cheeks larger diameter), where the cheek diameter is much larger. Unable to stretch any longer, the belt gave way at the ends, of which there were as many as 6 pieces - it was torn into 3 parts. So, even when buying a “true” belt, compare it with similar ones, otherwise you never know.

What happens if you install a variator belt of a different size?

Sometimes, for various reasons: lack of availability of the required variator belt; a desire to save money or just for the sake of experimentation - there may be a need to install a variator belt that differs in size from the original part. Whether the belt is longer or shorter, wider or narrower, in any case there will be consequences. But we’ll try to figure out below what consequences await when installing a variator belt of a different size! Ps: If you don’t want or don’t have time to read the entire article, go straight to the table.

Replacing the variator yourself

At this stage, it is important to remember about the calculation of the variator. Installing an incorrectly sized belt will cause the device to quickly fail. To maintain the durability of the variator, the belt must be secured in the drive pulley. Then rotate it until it is positioned properly. Next, you need to check the quality of the fastening of the nuts, since they could have become loose during operation. Finally, you need to test the belt. To do this, rotate the crankshaft, after which it will become clear whether the belt is positioned correctly. If yes, all that remains is to return the variator cover to its place.

Replacing the variator yourself

There is a second way to replace the variator chain. Removing the old belt is done in the same way. Next, you need to disassemble the variator and install a pulley on which the new belt will be mounted. To push the belt in, move the pulley halves apart. The belt will take the required position after turning the variator at maximum speed for several seconds. If everything is normal, then the last task remains: how to assemble the variator cover? Everything is very simple. You need to screw it to the workplace and check the quality of the bolts.