At some point, every moped driver wonders how to lift a wheel on a scooter. There are many reasons for removing a wheel, the most common (there are interesting articles in the links, I recommend reading):

- If the steering wheel is flat on the scooter

- The brake needs servicing (see the article “Maintenance of the scooter drum brake”)

- Sometimes drum brakes are tuned

- Disassembling the gearbox

- Replacing the brake pad

- For scooter wheel balance (I recommend reading DIY Scooter Wheel Balance)

- And of course replace the wheel

Removing the rear wheel on a moped is not as difficult as it seems, but to be honest, it is not easy. “How to remove and assemble the rear wheel on an Alpha moped. How to remove the dashboard on a Sharan 1999/2000 Garik got off to a bad start. Remove the torpedo. This process is very different from similar work on a car, since many other structural elements of the scooter, such as the exhaust pipe, shock absorber and other parts, interfere with the removal of the rear ramp with the disc in the scooter. Although she made the scooter wheel is fixed with only one nut.

Preparing to disassemble the rear part of the scooter wheel

Dismantling and removing the rear wheel of the scooter Let's start by installing the moped on the central strip. Articles on demand. Set how to remove the dashboard so it hangs during 2007. Choose a flat surface to do this. Remove the instrument panel and then remove the instrument panel on the instrument panel (the mount is equally loose. We recommend treating all threaded connections with a fluid such as WD-40, etc. before starting work).

In most cases, to remove the tire it is necessary to remove the muffler from the exhaust pipe, that is, unscrew two nuts from the bottom of the engine (photo above) and loosen the bolts securing the muffler plugs (item 2 in the figure below). ).

Moped like alpha raise your back steering wheel issue 1

Alpha moped as a way to remove the rear wheel Issue 1 promotion for your channel.

Removing the Alpha 110 Moped Rear wheel Replacing the camera

Amazed by the steering wheel, trying to change the camera.

Removing the rear wheel on a Chinese scooter in some cases (for example, on a Viper Storm 150 with a rear drum brake) does not require removing the exhaust pipe, but here everything is individual and even depends on the width of the wheel and tire pressure. In any case, if you pull out the hood, it will be more convenient to remove the rim. By the way, do not lose the paranitic gasket installed between the cylinder and the crankshaft.

So, after removing the muffler, unscrew the lower damper mounting bolt (point 1 in the photo above). How to remove the faceplate from the panel or who shoots the carp torpedo. carp Alpha moped, how to unlock the rear wheel 1. Tilt the stand to the side. In some scooter models, there is only one rear shock absorber on the variator side, which, of course, does not need to be unscrewed.

For scooters with rear disc brakes, unscrew the brake caliper (bolts item 4) and set it aside.

How to unscrew the back of the steering wheel on a scooter

If you don't have a key, we'll fix it by turning the steering wheel with a wooden block (it's unlikely that you can hold the disc by pressing the brake lever). When installing the bar, I recommend focusing on the bracket rather than the CVT cover, as it is not made of very durable material.

Now let's take the handle that fits the head and try to unscrew the rear wheel scooter mounting nut. Configure how to remove toolbar 2007. We don't lose any details.

Then remove the bolts that secure the splash guard to the bracket (item 3) and the bolts that secure the bracket to the power source.

We completely remove the bracket from the transmission axle without losing the gasket.

Remove the rear wheel from the axle. Removing the front wheel on an Alpha moped. How to remove the front wheel of an alpha moped. Alpha moped, how to remove the rear wheel. Issue 1 video. If the steering wheel contains something else, I slightly unscrew the adjusting nut on the brake cable, since the pads can pinch the disc. How to do this is described in detail in the section “Adjusting the drum brake on a scooter.”

There is another larger spacer inside the wheel.

This is all. Now you know how to remove the rear wheel of a scooter and you can do it yourself.

Attaching the rear wheel to the scooter is done in the reverse order.

Sooner or later, every moped driver wonders how to remove a wheel on a scooter. There can be many reasons for removing a wheel, the most common of them (there are interesting articles on the links, I recommend reading):

- If you have a flat tire on your scooter

- The brake mechanism requires servicing (read the article Servicing the drum brake on a scooter)

- Sometimes to adjust drum brakes

- Disassembling the gearbox

- Replacing brake pads

- To balance a scooter wheel (I recommend reading Balancing a scooter wheel with your own hands)

- And of course to change the wheel

Removing the rear wheel on a moped is not as difficult as it seems, but, frankly speaking, it is not easy either. This process is very different from a similar operation with a car due to the fact that many other structural elements of the scooter, such as the exhaust pipe, shock absorber and other parts, prevent the removal of the rear ramp with the disc in the scooter. Although the scooter wheel itself is fixed with only one nut.

Step-by-step instruction

First you need to prepare the necessary tools:

- socket wrench

- clean cloth

- wooden plank or block.

How to remove the rear wheel on a scooter:

Location of the main components on the scooter

- Choose a level place where all the work will be carried out. Due to the unstable surface, there is a risk of the moped falling to one side. Place the scooter on the center stand. If a similar procedure was last carried out a long time ago, the threaded areas of the parts should be lubricated with VD-40 aerosol product. It will help facilitate manipulation of oxidized rusty parts. Otherwise, difficulties may arise when trying to unscrew the nuts.

- Before unscrewing the nuts, remove the muffler along with the exhaust pipe. To do this, remove the seat and lower plastic frame. Then the bolts connecting the frame to the muffler are not completely unscrewed. The number of fasteners depends on the model - 2 or 3 pieces. Using a socket wrench, remove the fastenings to the cylinder. At this point you can remove the bolts. In this case, you should check for the presence of rubber gaskets that may fall out when moving the muffler. If there is black soot in the device, it is worth cleaning it with a heated blowtorch and a wire brush.

- To prevent the wheel from spinning, secure the brake levers with a belt, thereby pressing the pads. You can also block it using a wooden plank, inserting it into the disk. Now you can proceed directly to the planned repairs. After completing the procedure, the parts are assembled in reverse order.

Important! If major defects in parts are found during dismantling, it is better to contact a workshop.

To remove the rear wheel you will need a socket wrench

MTT TURBINE SUPERBIKE Y2K – 370 Km/H

Now come the really fastest motorcycles in the world! This bike is one of the most powerful production motorcycles. This beauty is powered by a Rolls-Royce 250-C18 turboshaft engine with a 2-speed semi-automatic transmission. This bike can accelerate from 0-100 in just 2.5 seconds. This is probably the time it took you to finish reading this sentence at your normal pace. Come on, try it. The MTT Turbine Superbike Y2K produces a maximum power of 320 hp. at 52000 rpm.

Reasons for withdrawal

There are usually several reasons why an owner has to remove a wheel:

- after a long ride, balancing is required;

- the disc is cracked or bent;

- drum brakes have stopped working properly (worn out pads, problems with the brake system, etc.);

- complete replacement of spare parts;

- restoring a tire after a puncture or replacing it completely;

- scheduled maintenance;

- failure of internal bearings;

- removing the gearbox;

- The bushing axle is cracked.

Rear wheel arrangement with brake pads.

Some information about management

Driving the scooter is very easy. You just need to know what is and where it is. On the right side there is a front brake lever, and on the left, respectively, a rear brake lever. There are also other elements on the dashboard.

On the right side there is a steering wheel handle. They use it to gas. To do this, you need to rotate it. There are also various kinds of switches, such as turn signals and lights. Here, among other things, you can see the starter and horn button.

Dismantling the wheel of a Honda Dio scooter

You may be interested in Review of winter studded tires Yokohama

During use, the tire is so firmly attached that it can only be torn off using machines. The average motorcycle enthusiast does not have such a unit. Therefore, you will have to use improvised means - corners.

Some models of Honda Dio scooters come with disc brakes. To avoid bending anything, it is important to remove the brake disc before mounting the tire.

How to dismantle the front wheel on a scooter?

- You should deflate the tire, place a metal corner under the rim and beat the tire with a hammer. At the same time, it is important not to hit the same place many times. There is a possibility of damaging the disc and causing a hole. After a couple of blows, it would be correct to shift the angle in a circle and repeat the movement. Continue manipulations until the tire comes off. The procedure is then repeated on the other side of the front wheel.

- At this stage, you will need factory tire mounting tools. Insert the crowbar under the rubber and turn it out so that it does not jump out. Pull back a little more and finally pull the tire out. The crowbar remains in place. Make the same movements in a circle, using the required number of “mounts”. As a rule, the rubber is easily removed halfway through the journey.

Tires are not beaded with wrenches and screwdrivers

Other modification options

In addition, you can also make other equipment from a walk-behind tractor. For example, you can get a dumper, a pneumatic duct or a vibrating plate. Also, some craftsmen make a loader or snowmobile from a walk-behind tractor. Many people use walk-behind tractors to harvest corn.

Snowmobile

This design allows you to move comfortably in the snow. To do this you will need fairly wide wheels. The caterpillar can be obtained from an old snowmobile. It will be able to fit under the wheels of a walk-behind tractor. The snowmobile itself is made from a frame, tracks, and some suspension elements. The mount can be used from a walk-behind tractor. After the modification, you get an excellent snowmobile, which is also suitable for hunting in swamps. Therefore, the result is both a swamp vehicle and a snowmobile.

Motorized towing vehicle

Sometimes when buying a factory motorized towing vehicle you have to face many disadvantages. Therefore, most often they are made with their own hands. They turn out to be quite durable if you use a walk-behind tractor for this. This design will do its job perfectly and also save fuel. In addition, it will be possible to attach compartments to this design to store the necessary tools.

Excavator

As a result, this technique will turn out to be quite compact and convenient. However, to cope with this work, you first need to make drawings. All work with drawings must be done in great detail - this will greatly facilitate further work. After this, you can move on to the design itself. First you need to make a frame, you can use a channel. After this, you need to attach the beam (up to 11 meters in size) to the frame. Springs and springs are not needed. For a simpler option, you can use a homemade axle on which wheels are mounted. The result is a chassis. Next, using a special machine, you need to grind out all the mechanisms that will be needed for movement, as well as brackets and fastenings for hydraulic cylinders.

The ladle can be purchased at the store. For hydraulics, you will need to buy a pump, and you can also use cylinders from an old KamAZ. You also need to purchase a hydraulic distributor, which will be needed to control the excavator.

When all spare parts have been purchased, you can begin assembly. Then you need to connect the power take-off shaft of the walk-behind tractor, as well as the oil pump through the cardan. After this, you need to connect all the hydraulics with high pressure hoses. Next, the finished structure must be painted, and all parts must be lubricated, after which it must be tested in operation.

Motor drill

Many fishermen no longer want to go fishing with a conventional drill, so some of them decide to convert a walk-behind tractor, which is not needed in winter, into an ice ax. You don't need to use any special effort for this. You just need to rearrange the wheels of the Zhiguli, and also make an attachment to set the drill in motion. After which you can safely go fishing. In the summer, the walk-behind tractor will be able to be used for its intended purpose again.

Motor winch

This homemade walk-behind tractor can be made at home. This will help save money. For manufacturing you will need a motor, a frame, and both shafts: upper and lower. The motor for this can be taken from a chainsaw. In addition, it is necessary to make drawings, and then begin assembly.

In addition, factory walk-behind tractors can be converted at your discretion into other designs, for example, a trike or a circular scooter.

Thus, if you show a little ingenuity, as well as get some parts and make high-quality drawings, you can use the walk-behind tractor as the starting material for the manufacture of a large number of devices that will become indispensable assistants in the household at different times of the year. However, it is important to strictly follow the assembly instructions and follow all recommendations.

Necessary tool

Replacing a wheel on a Honda Dio is not difficult to do. Even an inexperienced beginner can slowly complete the task in 20 to 40 minutes.

To do this you need a modest set of tools:

- hex heads for 24, 12, 10

- a wrench and a small extension for the wrench.

If you need tire mounting and you want to repair it yourself, you will also need the following tools:

- a metal cap for unscrewing the nipple (spool valve),

- a vice for squeezing the tire and removing it from the wheel rim seats,

- 2 - 3 motorcycle mounts for tire removal,

- a compressor for inflating a tubeless tire, and if the tire has a tube, then a regular pump is sufficient.

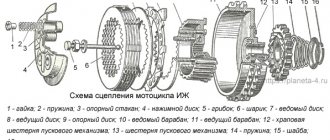

How to replace the clutch on an Alpha 110, 125 or 50 cc. cm?

Since the design of all small-capacity scooters is identical, these instructions are suitable for all two-wheelers. If the rider needs to change the clutch, he needs to:

- Remove the cap from the spark plug.

- Disconnect the cable from the gearshift foot.

- Remove the chrome cover, behind which there is an adjusting screw.

- Unscrew the bolts holding the engine cover and remove it. When performing the procedure, it is advisable to loosen the brake foot so that it does not interfere.

- Take out the bushings.

- Remove the clutch cover.

- Bend back the lock washer.

- Unscrew the central nut.

- Remove the clutch itself and install a new component.

After replacing the unit, you should readjust the clutch of the Alpha moped.

Note: When installing a new component, it is recommended to lubricate it immediately to avoid seizing and excessive wear of the discs. In parallel with replacing the clutch of an Alpha 110 or 125 cc moped, it is recommended to change the oil filter.

If a motorist can replace the unit independently, then it is advisable to entrust complete disassembly and repair of the element to specialists. Dvako Moto specialists have the necessary equipment to diagnose and service all scooter components.

Source

Wheel trim

In what cases is tire replacement required:

- Product wear and non-compliance with tread height standards. Typically the standard is 0.8 mm.

- Tires have defects: cracks due to aging or mechanical damage and punctures.

- Presence of tubercles. Blisters appear when driving under high pressure or during an impact. The normal value is 2 atm.

How to install new tires:

- One bead of the tire is placed on the rim. If a camera is used, then sprinkle it with talcum powder and place it inside. The hole must be completely blocked by the valve without displacement. Now you can bead the tire using mounting crowbars. Next, inflate the tires with a regular pump to the standard recommended by the factory for the specific scooter model. These pressures should not be increased.

- If the tire is without a tube, a special compressor is required. To carry out the procedure, you need to deliver a large amount of air in a short period of time.

In winter, when there is ice, you should reduce the tire pressure.

A compression pump is required to inflate tubeless tires

Consequences of driving without a battery

A two-wheeled friend can take the owner anywhere without a battery at all. However, manufacturers build it into the design for a reason. Electric current powers headlights, turn signals, lighting and built-in electrical appliances. The battery also plays an important role in creating engine impulse, so you can start the scooter by turning one handle.

This is how moped electronics work. While the engine is running, the generator produces electric current. It recharges the battery, which, in turn, powers the headlights and lighting. If the battery is not installed, the generator continues to operate and feeds the electrical network. The energy it produces cannot go anywhere. However, the current strength depends on the engine speed. At low speeds it is less, so the headlights will blink and go out.

Without a battery, the voltage is distributed unevenly, with fluctuations, which will cause light bulbs to burn out and other electronics to wear out. This applies equally to the injector, if it is on your model, and to the generator itself. So while maintaining your battery requires time, effort, and expense, driving without it will eventually require repair. Which will cost more. Installing a new battery is easier, and with proper care you won’t have to change it often.

And yet, experienced owners of a two-wheeled friend know how to start a scooter without a battery and ride it anywhere. Moreover, if the battery is simply dead, then there will be no harm to the scooter.

Results

Every scooter needs repairs from time to time. Malfunctioning of a vehicle not only interferes with a comfortable ride, but also endangers the life of its driver. Repairing a scooter with your own hands is quite simple, if you sit down first and properly understand the details. Sometimes the process may stall at some element, then it is recommended to carefully follow the entire sequence of steps from the very beginning - perhaps a mistake was made somewhere. When replacing a rear wheel, you need to take your time and be careful, and then you will succeed.

Good luck with the repair and good luck on the roads!

Making a “cutter”

In this operation we will need: a birch log, calipers, a marker, a chisel, a saw, a cylinder (the one we are going to sharpen), a piston (new and old), a rasp (you can use a file), a drill, a long bolt with a nut or a hairpin with two nuts , sandpaper sheets “10”, “6”, “5” and “0” (on a fabric basis - not suitable on paper). There are a few caveats - the stud or bolt must be at least 8mm in diameter. The best solution would be 12mm. Sandpaper is selected independently, depending on the type of boring. It is advisable to go through the “rough process” and bring it “to clean water”, and not to drive the rough one until you are blue in the face. Then fix the finishing one, and buy and select a new piston.

Let's start - measure the sleeve with a caliper:

Let's take an allowance of 10mm and measure it on the already trimmed log:

Let's outline approximately where we have “more meat”, and set some simple markings there and drill:

Immediately take a larger chisel and chop off the excess “meat”. Shape it into a cylinder.

But the shape of a cylinder will not work, it will turn out something like an oval:

The next step is to tighten the resulting cylinder onto the stud/bolt. Tighten until your teeth creak. When inserted into the drill, tighten until your teeth creak - it will unwind with a bang. If you tighten it harder, it won’t run away. Now secure the drill, make a stop for the chisel, and unwind the cylinder by pressing the gas on the drill. Take technology breaks more often. During breaks, tighten all nuts. If it comes loose, the results could be disastrous.

By substituting a chisel (smoothly substituting a chisel!) we ensure that we first get an oval:

Then the shape will remind us of a cylindrical object:

Later you will get a natural, perfect cylinder. I think there is no need to explain that the fine-tuning was no longer carried out with a chisel, but with a rasp, and later even with a file.

You should now have a long wooden piston for the cylinder.

. Only well weakened. Somewhere by 0.3-0.6 mm.

How to remove a wheel without removing the muffler

If a scooter has a punctured wheel, it can be replaced without removing the muffler. It is usually secured to the engine with 4 bolts. The exhaust system of some Chinese-made moped models consists of several parts that are connected by fasteners. They can be removed one piece at a time, making tire replacement easier. This recommendation can be used if there is no time or opportunity to carry out the full procedure according to the rules. In the case where the muffler is made in the form of a solid block, the only option is to bend it to the side. This can be done in case of emergency replacement of a broken wheel.

You may be interested in this About plastic and rubber linings on wheel arches

If the muffler consists of several compartments, those parts that interfere should be removed. These can be side mounts, knee and plastic. There are variations in designs when it is enough to move the weakened pipe to the cylinder through the gasket. Next, unscrew the fastenings on the sides and remove them so that nothing unnecessary gets in the way.

Before installing all parts back, check the condition of the gasket. If it has shrunk and cracked, it needs replacement.

Before you start adjusting the valves

Therefore, after purchasing a new Alpha RX, I checked the valve clearance. For this procedure I had to buy a set of probes. In our case, you will need a probe with a thickness of 0.05 mm.

In order to calmly begin adjusting the valves, I had to unscrew the safety bars. For this we need a key of 8.

To get to the valves, you need to unscrew the valve covers located on the top and bottom of the cylinder head. To do this we need a 17 wrench. I used a spanner.

How to remove rubber from a rim

You can disassemble car wheels using a homemade machine in the following sequence:

- remove the wheel and install it on the flange of the tire changing machine, secure it using a clamp;

- Use the narrow end of the pry bar to move the edge of the rubber beyond the disc;

- complete the tire removal by removing it completely from the rim;

- do not allow the edge of the disk to deform, otherwise it will be very difficult to put on a new tire;

- it is advisable to lubricate the edges of the rim with grease, this will preserve the integrity of the tire during removal;

- when installing a new tire with your own hands, you can use a soap solution, which will help perform the operation with less physical effort;

- When working, you should use special sets of tools.

A few more tips. Before removing the tire, wrap the profiles on which the disc will rest with soft material. This will protect it from scratches and damage.

A machine made by yourself may have an unsightly appearance, but it has a number of advantages.

Firstly, the car owner will not need to constantly go to the service station to do simple work. This saves time and money.

Secondly, the cost of such a machine is minimal; it can be made from scrap materials with your own hands. Another advantage is ease of assembly and compactness.

In addition, such a machine is universal and suitable for any type of vehicle, including trucks.

The disadvantages of a machine created by yourself include the impossibility of balancing; you can only remove the rubber from the disk.

The above version of the machine is just one of many designs designed to remove tires from the rim at home without the use of professional equipment.

SUZUKI HAYABUSA – 399 Km/H

1340cc. It is a four-cylinder, short-stroke, 16-valve DOHC engine that truly lives up to the hype. Suzuki's dual throttle valve ensures maximum engine performance at all times. This bike gives you the ability to customize it to its optimal settings using a wire-by-wire system combined with Suzuki's ride mode switch. The Suzuki Hayabusa accelerates from 0-60 in 2.6 seconds and its clutch assist system i.e. Suzuki Clutch Assist System helps reduce back torque. Its maximum power is 197 hp. at 6750 rpm.

Let's get down to business

Before starting repairs, it is advisable to wash the scooter.

Then place the scooter on the stand on a flat and hard surface.

First, remove the exhaust pipe. For example, in older Honda Dio models, such as af 18 and af 27, for this we remove the luggage compartment along with the seat.

Then unscrew the two nuts from the cylinder and the two bolts from the engine and remove the muffler. Starting from af 34 to the latest Honda models, as well as Suzuki models, there is no need to remove the luggage compartment with the seat; access to unscrewing the exhaust pipe of the muffler is from below near the center step.

Disconnect the muffler from the cylinder. To do this, unscrew the two nuts using a 10mm socket and a wrench with an extension, having previously lubricated the threads of the studs with penetrating lubricant.

Unscrew the two side muffler mounting bolts with a diameter of 8 mm using a 12mm hex head and remove the pipe.

Be sure to check the condition of the O-ring between the cylinder and the muffler. It must be intact, without signs of burnout. And if there are defects in the sealing ring, then it is better to replace it with a new one, or lubricate the connection with a high-temperature sealant during assembly.

In order not to spoil the thread when unscrewing, we treat the axle and rear wheel nut with lubricant - liquid wrench or WD-40.

After this, we put the rear handbrake on the latch, and if it is not there, then we tie the clamped rear brake handle with a rag or rope that is at hand.

16.04.2020

Moped Alpha

BMW K1200S – 280 Km/H

If the number 10 bike is this fast, you know what to expect from the rest. BMW has designed this motorcycle to be lightweight and agile, making it extremely easy to ride. The power unit of this motorcycle, that is, its engine, is a four-cylinder in-line engine with a capacity of 1157 cc. See with built-in transmission.

The engine is mounted diagonally, which provides a low center of gravity. This bike can go from zero to sixty in just 3.2 seconds. The EVO brakes combined with BMW Motorrad's partially integrated ABS are what give it its grandeur. The motorcycle develops a maximum power of 164 hp. at 10250 rpm and maximum torque of 129 Nm at 8250 rpm.

Let's start repairing the Chinese miracle of technology

The Alpha 72cc moped is one of the most famous representatives among Chinese motorcycles. This moped is perfect for use both in rural areas and on city roads. A durable iron frame, complete absence of plastic parts, large diameter wheels - simply created for domestic roads, the quality of which is far from European level.

If you ride often, the rather high seating position of the ALPHA moped makes it possible to overcome low obstacles. A big advantage when choosing a moped is its low price, which makes the purchase quite affordable. This would be a good choice for a beginner.

There are models with a side trailer. Practical to use in rural areas. A reliable assistant in the household.

Economical, with an engine capacity of 72 cubic meters and air cooling, the Alpha moped is unpretentious. This is an extremely simple transport and servicing it couldn’t be easier! You simply cannot find a simpler engine, and spare parts cheaper than Alfa’s can only be found in a dream.

Anyone can carry out tuning or repairs on an Alpha moped with their own hands.

Before you start disassembling the motor, you should fix it on the center stand and completely remove all the plastic. All power systems should be turned off - tank, carburetor and fuel filter; The oil should also be drained.

The engine should be removed along with the transmission, and the Alpha moped should be repaired on a flat surface.

You can remove the alpha engine according to the following diagram:

- remove the muffler and exhaust pipe;

- remove the camshaft gear cover;

- unscrew all 4 bolts from the cylinder cover;

- remove the top cover and cylinder head;

- We study the degree of wear of the valves, check how dirty the insides of the system parts are.

Is this your first time repairing an Alpha moped yourself? No problem! A moped is not a hadron collider; nothing has changed in 50 years of moped construction. For convenience, draw a diagram of the location of the parts so that later you can complete the assembly without any problems.

A smartphone can help, take photos of each step so that later you can reassemble in the reverse order without confusion.

If it is necessary to replace the valves, or if there are gaps in the fit, then they need to be removed:

- Place the head on a level place. To prevent the valve from being damaged during dismantling, it is better to place a layer of thick rubber or a rag under it;

- we select the socket head, place it on the valve plate and hit it hard with a hammer;

- release the crackers, remove the top plate and valve washer;

- remove the valve and guide bushing. To complete the repair of the Alfa moped engine, after replacing the parts, we begin assembling the engine in the reverse order, putting everything in its place, observing the marks. Don't forget to add fresh oil.

The gearbox of an Alpha moped often fails and requires constant attention. The author of this article got the sprockets stuck in the box while driving in 4th gear 10 years ago. When trying to force a gear change, for some reason the gearbox automatically selected first gear and the moped was driven at a speed of under 100 km/h. I just braked without throwing the author of this article over the steering wheel. Yes, there are difficulties with gearboxes. Repairing it at home is not particularly difficult for a beginner.

The author of this article got the sprockets stuck in the box while driving in 4th gear 10 years ago. When trying to force a gear change, for some reason the gearbox automatically selected first gear and the moped was driven at a speed of under 100 km/h. I just braked without throwing the author of this article over the steering wheel. Yes, there are difficulties with gearboxes. Repairing it at home is not particularly difficult for a beginner.

BMW S1000 RR – 305 Km/H

Now it seems that all BMW motorcycles are the fastest! And this bike is powered by a 999cc 16 valve engine. The CM features a new intake cam and lighter intake valves compared to its predecessor. The BMW S1000 is built for speed with a truly lightweight frame. The bike weighs 4kg less than the previous one and comes with updated HP4 Dynamic Damping Control semi-active suspension.

The BMW S1000 RR accelerates from zero to 100 in 2.7 seconds. Even at these speeds, the bike's new power curve makes turning in effortless and effortless. Features like ABS, cruise control, etc. show that the bike is also suitable for the street. It reaches its maximum power of 195.2 hp. at 13500 rpm. The fastest motorcycles in the world are not over yet, let's continue!

Alpha moped engine repair

Let's take it slowly, in order:

- first remove the cylinder, then the rotor and clutch block;

- carefully remove the retaining ring (you need a screwdriver and a thin knife or blade) and the drive gear;

- To remove the speed unit, unscrew the fastener - the bolt on the back side.

- remove the gear shift fork;

- remove the crankshaft and drum.

When the repair of the Alpha moped box is completed, assemble the gearbox using the reverse algorithm.

Recently, on the repair forum, Alf found an article from the manufacturer with recommendations. The article began with the words “Repair of an Alpha moped for many begins almost immediately after purchase.” Alas, this is the bitter truth. If you are choosing between a used Alfa with a mileage of 10 thousand and a new Alfa three times more expensive, then it is better to buy a used one, since many problems will begin in the new one, in time you will not “win” even one season.

And the problem is not that the alpha moped is a bad transport, but that it is cheap, which means many of the components in it are assembled from slightly more fragile materials. This means that it needs to be closely monitored, serviced on time, and the driving style should be calm.

There are three types of simple upgrades that can be made on the first day of purchase:

- Replace the seat with a more comfortable one.

- Install a 110 or 125 cylinder instead of the standard 49 or 72.

- Replace sprockets from 14 to 16 to increase speed or, conversely, from 14 to 13 to increase traction. The standard 14 teeth are no good at all.

Increase in cylinder volume - replacement from 50 cc. at 125 cc., will add power, which is never enough. To do this, in addition to the cylinder head, you will have to change the pistons and carburetor. You can carry out such maintenance of the Alpha moped yourself. The author of this article saw with his own eyes how a man bought only a 110 cylinder and installed it right next to the store instead of the standard one. Nothing else was changed - neither the carburetor nor the head.

Did the moped go after that? Yes. How long? No. Everything jammed, right down to the connecting rod and crankshaft.

Once you have disassembled the timing belt and CPG, put the parts in separate boxes. Sketch the position of the gears and forks on paper before removal or take a high-quality photograph on your smartphone.

Do not hurry. Think more, do less. Don’t be afraid and don’t be lazy to study the hardware, watch a lot of video tutorials until the structure of the motor is completely clear to you.

Hang panniers, change headlights and mirrors. The Alpha moped is from the series that will respond to any of your concerns with reliability in thousands of your future kilometers. But remember, installing a more powerful light bulb will put a strain on the battery. Install a powerful battery and the generator may not be able to charge it.

I have seen three types of generators on alphas - two-coil, three-coil and 6-coil. At the same time, the motors were completely of the same type and cost the same. The 6-coil battery is capable of charging a full 10 Ah motorcycle battery. The two-coil battery can hardly charge even the standard 3 Ah battery.

If the Alpha moped is not able to reach the required speed, despite the roar of the engine and solid revolutions, it is impossible to stop the spinning wheel, and gear shifting occurs intermittently, then the cause of the malfunction is clutch wear.

To fix the problem you need to:

- remove the engine;

- remove the plastic cover;

- unscrew the tightening screw;

- Unscrew the adjustment mechanism and tighten the screw tightly;

- start a moped;

- turn on first gear and drive a few meters.

Another cause of moped engine malfunction may be wear on the drive sprockets. If they are very worn, they must be replaced with new ones. Their cost is simply ridiculous, do this and you may feel like your moped has found a new life!

I don’t mean one drop a day dripping from under the engine, but actual oil leakage, indicating depressurization of the power unit.

In this case, it is necessary to drain the oil, disassemble the engine completely, find a leak (most often the problem is in the seals) and reassemble it taking into account repairs.

This is what an Alpha engine overheating looks like

It is necessary to disassemble the gearbox in order to replace used parts. As we have already mentioned, the Alpha gearbox is one of the weakest and most vulnerable parts.

Gearbox repair in progress

Motor repair is carried out as follows:

- Using a screwdriver or blade, remove the retaining ring and the transmission drive gear;

- Carefully unscrew the gear fixing bolt and remove the gear shift mechanism;

- remove the gear shift fork and shaft;

- remove the crankshaft and drum (including the core);

- After replacing the worn part with a new one, reassemble (in reverse order).

To assemble the gas distribution mechanism, pay attention to the following parts:

- You should definitely make sure that the chain vibration damper is working correctly (if you blow inside, it should let air through a little);

- When the damper contacts the tensioner, friction occurs (the rough surface of the tensioner should be polished).

To prevent the sprocket from jumping off the axle, it should be lubricated with grease. Then the cover is installed, pre-lubricated with sealant. After this procedure, install the starter star and chain guide.

KAWASAKI NINJA ZX-14R – 300 Km/H

He's absolutely amazing and we're sure you'll be wondering why he's in 7th place. Simply because there are faster motorcycles . However, the Kawasaki Ninja ZX-14R looks like a beast, let's be clear. Not many can match this in looks and form factor. However, appearance is not what interests us. This is a beast within a beast, an engine. The 1,441 cc of power from the inline-four engine gives the bike the zipper feel.

The three-level traction control system helps you quickly gain control of the motorcycle. However, the best part of the bike is that even in sixth gear at 50-60 speeds the bike rides smoothly. This motorcycle accelerates from 0-60 in just 2.6 seconds and produces a maximum power of 108 kW at 10,500 rpm.

If it doesn't start

When the Alpha moped does not start, the muffler fires and black smoke comes out of it, this means that you have a problem with the carburetor. Black smoke says a lot, a lot.

Firstly, since there is smoke, the fuel burns, and the piston throws it into the exhaust. This means the CPG is ok, and most likely the valves too.

Secondly, smoke indicates proper ignition, the candle gives a spark, otherwise smoke could not have formed.

Thirdly, smoke is almost a combustion process, which means the problem is in the carburetor, the fuel mixture is not supplied correctly.

To fix these problems, you need to clean the carburetor and air filter, also make carburetor adjustments and tighten the bolts thoroughly.

If your moped takes a long time to accelerate, it’s as if someone has “castrated” the engine and the power reserve seems to have disappeared – the problem is 100% in the valves, they should be replaced.

After a thousand kilometers, the engine needs to be checked for the first time, subsequent checks should be performed every four thousand kilometers. All checks should be performed only on a cold, already cooled engine.

Alpha has both pros and cons, for example, an undeniable plus is its low fuel consumption per hundred kilometers - only 2 liters of fuel.

The moped can be loaded with one hundred and twenty kilograms, while it itself weighs eighty-one kilograms. The Alpha moped is equipped with an air-cooled engine, two brakes: front and rear, four-speed manual transmission, 2 shock absorbers.

Additionally, the Alpha model is often equipped with mudguards on the rear and front wheels. They will help protect the driver and engine from water and dirt.

Alpha has a 4-stroke engine, which must be diagnosed and repaired according to the following parameters:

- Adjusting the valve clearances, such a need arises if characteristic knocking noises appear in the cylinder head, or violations in the clearances are found.

- Removal and subsequent installation of the cylinder head is necessary when the combustion chamber is clogged with carbon deposits, as well as for replacing and grinding in valves.

- Complete disassembly of the cylinder head - if the valves are no longer sealed, also to replace oil scraper valves and caps.

- Removal and installation of the entire cylinder, generator rotor and electric starter.

- Also removing and installing the piston and piston rings, chain.

- Disassembly and assembly of clutch, crankshaft, gearbox.

Now, in conclusion, I would like to give the most useful advice you can find on the Internet. When the engine is completely worn out, sometimes it makes sense to buy the entire engine, in which case you will also receive some spare parts from the original old engine, and, in principle, a new Alpha moped. Engine repair is almost always much more expensive than a new engine. Remember this.

There are situations when the driver has to change a moped tire himself. To do this correctly and quickly, below are instructions on how to perform tire mounting yourself.

Removing a tire (beading)

To remove a tire, follow these steps:

- Place the moped on the center stand and remove the wheel. Make sure that the moped does not fall after removing the wheel. Let me explain: after removing the wheel, the weight distribution will change and the moped will lose its support point.

- Remove the cap from the valve, then press the spool to relieve the pressure in the tire.

- Remove the tire beads from their seats.

- Carefully, so as not to damage the tube (if a tire with a tube is used) and the rim, insert the mounting blades on both sides of the valve and remove the tire beads from the rim.

- At the moment when the blades are spread approximately a third of the rim, bend the edge of the scooter tire along its entire length.

- Remove the valve from the hole in the rim (provided the tire is tubed).

- Carefully pull the tube out of the tire (provided the tire is tubed). Then you need to inspect the tire and tube for mechanical damage. To quickly determine the place where the camera is punctured, it is recommended to inflate it with air and immerse it in a container of water. In this case, the puncture site can be determined by the release of air bubbles. Cameras are repaired using vulcanization. If this method cannot be applied, then it is better to replace the camera with a new one.

- Remove the tire from the rim (in case it needs to be replaced).

If the wheel needs to be repaired on the road, and mounting blades are not at hand, then, for example, two slotted screwdrivers or just two steel strips will do. The main thing is that they do not have burrs or sharp corners.

Flange

To trim a moped wheel, follow these steps:

HONDA CBR 1100XX BLACKBIRD – 305 Km/H

The Blackbird is a renaissance motorcycle that leaves behind its glorious past to make it better. With some minor changes to the previous one released in 1996, it is back to its former glory, if not better. 1137 cc liquid-cooled inline-four engine.

The higher the rpm, the smoother this bike can ride. Accelerating from 0-60 in approximately 2.8 seconds, the Honda CBR 1100XX Blackbird is a precision instrument designed to measure speed. What it may lack in ride quality, it makes up for in build and reliability. It reaches a maximum power of 153 hp. at 10000 rpm.

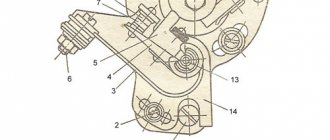

When to adjust the clutch

In general, there are two cases when you need to think about adjusting the scooter clutch:

Clutch leads

When you press the clutch lever and engage the gear, the moped starts moving (with the clutch depressed).

The clutch is slipping

When the gear is engaged and the clutch lever is completely released, the engine runs at high speeds, and the moped moves slowly or hardly moves at all.

All these problems are the result of a less than ideal design of the clutch release and engagement drive, as well as the fact that the parts of the clutch itself wear out after some mileage, which together leads to such troubles.