Motorcycle carburetors take air and mix it with fuel. Numerous factors can cause a motorcycle carburetor to fail. As a rule, motorcycle carburetors are upset by vibration. Manufacturers such as Mikuni, Keihin and S&S sell original equipment and aftermarket carburetors for numerous motorcycles. The details vary, but the setup principles are the same for all of these devices. Here, in particular, is how to adjust the carburetor that Harley-Davidson has used since 1989.

Mix but do not shake. Intake system

Part 1. Fuel system. Carburetor and electronic injection In previous articles, we figured out what the engine of a modern production motorcycle is. However, a bike is a complex system of devices that interact seamlessly with each other, and you can’t go far with just one engine. Therefore, for normal operation, the engine needs additional systems: an intake system and an exhaust system. The first serves to precisely control the air-fuel mixture entering the cylinders, the second removes exhaust gases after combustion. But before we take a closer look at these systems, it’s worth first understanding what our two-wheeled friends “eat”.

Fuel As soon as the very first motorcycle appeared, its fuel tank was filled with the same liquid that is used to this day. Gasoline is a generally accepted fuel for motorcycles. Of course, there are many alternative fuels, but they are either more expensive or less efficient. Like many other decisions in the motor industry, choosing gasoline as a fuel is a compromise. In this case, between two properties: evaporation (volatility) and calorific value. The volatility of a fuel is a measure of how easily it will evaporate at low temperatures. Calorific value is the amount of thermal energy, and therefore useful work, that can be obtained from a given amount of fuel. You've probably already guessed that, ideally, an internal combustion engine needs a fuel that evaporates easily and has a high calorific value. However, as the calorific value increases, the volatility of the fuel decreases, and the lower volatility of the fuel makes it more difficult to ignite. So, we have chosen the fuel. Now you need to figure out in what ratio to mix it with air in order to obtain the most complete and efficient combustion. If there is not enough air, the unburned fuel will literally “fly out of the chimney”; if there is a lot of air, the useful energy received from the cylinder will decrease. To ensure complete combustion, 14.7 parts of air must be 1 part of fuel. Chemists call this ratio stoichiometric. To extract maximum power from the engine, the mixture is made “rich” (lack of air up to 10%), to achieve maximum efficiency - the mixture is “lean” (excess air up to 10%). In addition to atmospheric parameters, engine design and combustion characteristics also influence the optimal mixture composition. In reality, the limits for successful combustion of the mixture are between 12:1 and 18:1. The only thing left is to install on the bike a reliable system for supplying this very mixture to the combustion chambers.

Intake System Before moving on to the key players in the “intake command” - carburetors or fuel injection systems, let's understand the path the air-fuel mixture takes to get into them. The fuel tank begins the winding path of gasoline to the engine. It is supplied from the tank by gravity (in most modern motorcycles, except perhaps the simplest ones, the supply occurs under pressure using a fuel pump) through a filter along the fuel line to the carburetors or injector nozzles. To control the flow of fuel, a manually or automatically controlled fuel valve is used, which opens or shuts off the fuel supply from the tank. On most fuel injection systems, there is no valve as such, and the function of controlling fuel flow is performed by the fuel pump. We will talk about how air is mixed with gasoline in the next article, and at the same time we will discuss supercharging and turbocharging systems. Gradually, under the pressure of increasingly stringent environmental standards and requirements for engine performance, the carburetor is giving way to fuel injection systems. Even ease of setup and low cost of production are no longer its strong suits. Living confirmation of this is that small-capacity scooters from the same Honda , like the SH 150 , at their moderate price, are equipped with an injector. The same applies to cross-country motorcycles - in 2008, Suzuki were the first to install injection on their off-road machine RM-Z450 . Other Japanese manufacturers soon followed suit. Nowadays, the carburetor is used only where ease of maintenance and unpretentiousness in the choice of gasoline still plays a role: small-capacity bikes for beginners (Kawasaki Ninja 250R is still equipped with carburetors, however, only in the version for the US market) and single-cylinder enduros like the Honda XR650L . Streetfighters, classics, sportbikes and cruisers have made a massive transition over the past few years from carburetors to more technologically advanced and efficient electronic fuel injection systems. However, we will still consider carburetors - after all, there are enough motorcycles of various ages traveling on the roads all over the world (and not just the hot new products of recent years), so you shouldn’t write off “carburetors” from accounts. First, let's understand the basic principles of operation of any carburetor.

Suzuki RM-Z450 - the first motocross bike with fuel injection system

The principle of operation of a carburetor The principle of operation of any type of carburetor is based on the atomizing effect of the diffuser. It is a specially shaped tube. Imagine - if air flows through an ordinary pipe with parallel walls, then the pressure and speed of air movement will be constant throughout the entire length of the pipe. If you make a narrowing in the pipe, the air flow characteristics will change: at the narrowing point, the air flow speed will increase and the pressure will drop. Thus, a vacuum is created at the point of greatest narrowing. In the minimum cross-section of the diffuser there is a hole through which the fuel enters the diffuser and, under the influence of the spraying effect, breaks up into tiny droplets. In the hole there is a jet (nozzle) of such a size that each part of the incoming fuel will correspond to 14 parts of air. That's all, the simplest carburetor is ready. It will cope with providing the engine with a fuel mixture at constant loads and at the same crankshaft speed. However, such engine operation is a utopia, and therefore we will need a more complex device. To ensure uninterrupted operation, the carburetor requires a constant supply of fuel, the level of which at a constant level is ensured by a float mechanism in float chamber . The principle of its operation is very simple, but it is better to see it once than to read my writings here. Therefore, I suggest you, dear readers, to go to... the toilet. However, not for the reason we usually go there, but in order to remove the lid from the toilet cistern. Before your eyes you will see the carburetor float mechanism, enlarged many times. If you flush water into the toilet, its level in the tank will drop, the float will drop and open the valve, through which the water will again enter the “toilet float chamber”. Everything is extremely simple. To control engine speed, you need to use some kind of device that will limit the amount of air-fuel mixture entering the engine. A round plate mounted in a diffuser on a moving axis can be used as such a device. By adjusting the opening angle of this plate, called the throttle valve , we control the amount of mixture entering the engine. This simple device is used on carburetors with a constant diffuser cross-section. Another way to limit the amount of incoming air is to use a movable throttle valve located in the vertical bore of the diffuser. The throttle can move up and down along the bore, changing the cross-section of the diffuser so that the flow of passing air is partially or completely blocked. This device is used on slide-type carburetors and is called a throttle valve . The combination of a throttle valve and a throttle valve is used on constant-vacuum carburetors, which, like the slide-type carburetor, are classified as carburetors with a variable diffuser cross-section. To start a cold engine, carburetors are equipped with a starting device . When the engine is cold, the fuel condenses on the metal parts of the engine and therefore no longer evaporates, making the engine very difficult to start. To compensate for this, you have to make the mixture richer than during normal engine operation. This can be achieved in three ways: increase the amount of fuel in the float chamber, close off the diffuser and supply more fuel through a separate starting system. The starting device is also called a “suction device”. Depending on the complexity of the system, its individual elements are controlled manually (float stopper on the carburetor, choke lever, etc.) or automatically. There is also an idle system, the name of which speaks for itself, but we will not dwell on its design. Many modern carburetors are equipped with a throttle position sensor . It serves to optimize the ignition timing and does not affect fuel dosing processes.

Carburetors We've figured out the basic parts of carburetors, now let's look at the types of carburetors. There are three types of carburetors that are used on motorcycles.

K-65 with constant diffuser cross-section

- Carburetor with constant diffuser cross-section. This type of carburetor is the least common, although for some time Harley-Davidson used them on its entire line of motorcycles. This name comes from the fact that the profile of the diffuser does not change, even though the throttle valve regulates the amount of air flowing through it. Due to the limited ability of the throttle valve to change the cross-section of the diffuser, a system of vias and more than one main system jet (additional jets are called secondary jets) are usually required. The placement and dimensions of the secondary jets ensure the supply of the required mixture at all engine speeds. Such a carburetor is most often additionally equipped with an accelerator pump, the task of which is to compensate for the leanness of the mixture when the throttle is sharply “unscrewed”. These are the least efficient of the three types of carburetors.

Slide carburetor battery, Kawasaki ZXR750R

- Slider type carburetor. In such carburetors, the problem of changing engine needs is solved by changing the effective size of the diffuser. This approach, together with the use of a metering needle, eliminates the need for a complex system of jets and channels, and allows the slide carburetor to be small and light - very important qualities when designing motorcycles. And careful tuning ensures fairly smooth performance over a wide range of engine speeds. This type of carburetor turned out to be so successful that it was used on motorcycles for half a century, somewhere until the mid-90s. However, slide-type carburetors have one significant drawback. If you open the throttle suddenly, a large volume of air enters the carburetor. The speed of air movement above the atomizer is insufficient for the flow of fuel in the proportion corresponding to the air. Therefore, the mixture entering the engine instantly becomes leaner. If there is a large mismatch between the throttle position and the speed, the engine will stall or start working intermittently; with a smaller mismatch, this will lead to significant deviations from the correct mixture composition. Therefore, those who like to sharply twist the throttle with or without reason will experience inefficient engine operation most of the time. A very striking example is the Kawasaki ZXR750R , a sportbike from the early nineties. If a rider has a “bike feel” and the ability to operate the throttle smoothly (and such a skill is in any case necessary if you want to ride a motorcycle for more than one season), the ZXR will reward him with excellent dynamics and show a real sporting character. Otherwise, jerks in the style of “I saddled a sick donkey” will be observed.

Keihin CVK30 CV carburetors for Kawasaki Ninja 250R

- Constant vacuum carburetor (CV – constant velocity). In general, a CV carburetor is very similar to a slide-type carburetor. The main difference is that the throttle is replaced by a piston, the position of which in the diffuser is determined not by turning the throttle knob, but by the difference in air pressure in the diffuser and the atmosphere. Air flow, and therefore engine speed, is controlled using a throttle valve, as on carburetors with a constant diffuser cross-section. The damper is installed after the carburetor piston and is connected to the gas handle using a cable. Operating principle. Imagine a tin cup placed tightly in a pipe, closed at one end. There is a spring between the top of the cup and the closed side of the cylinder. An air pipeline is connected to the pipe above the glass. When a vacuum is created in the pipeline, air will flow outward and the pressure above the glass will decrease. The air under the glass is at normal atmospheric pressure, so the glass will begin to move up the pipe, overcoming the resistance of the spring. When the vacuum is removed, the glass will lower under spring pressure, sucking air into the cavity below it. A constant vacuum carburetor easily bypasses the problem inherent in slide-type carburetors, even at full throttle. The rise of the piston in the carburetor is directly dependent on the air flow, at which the pressure decreases. Therefore, there is no sudden leaning of the mixture. This means that the metering of fuel relative to air is much more precise than in the other two types of carburetors, resulting in smoother, more linear engine operation. Simply put, the mixture composition is always close to optimal, regardless of the rider’s enthusiasm for controlling the trigger.

It is difficult to unambiguously determine which of the two types of carburetors with a variable diffuser cross-section is better. In practice, the choice of a specific type is determined by the purpose of the machine and its cost. Only one thing is clear - both types of carburetors with a variable diffuser cross-section are much better than those with a constant cross-section. Almost all modern cars that are equipped with carburetors, as a rule, use carburetors with constant vacuum - as the most technologically advanced and accurate in creating the optimal mixture. However, their accuracy cannot be compared with the most advanced method of supplying the air-fuel mixture that motorcycle manufacturers have in their arsenal. We are talking about fuel injection systems. Fuel injection Perhaps, having read the title of the title, you imagined a complex device with an electronic “brain” that, with precision, creates the optimal ratio of gasoline and air, and delivers the resulting mixture in a strictly defined amount to the combustion chambers of the engine. Modern injectors are just such “gadgets” - complex and intelligent. It is even more difficult to believe that fuel injection has existed since 1898, almost since the advent of internal combustion engines. Then these were mechanical systems (what kind of electronics were there at the beginning of the twentieth century!), and in the forties they were widely used in the automotive and aviation industries. The first fully electronic system appeared in 1950 through the efforts of the Bendix company, but there was no talk of installing such systems on motorcycles - carburetors quite coped with the requirements in terms of reliability and performance (fighters for the purity of nature were not at all rampant at that time, so there is no need to talk about them not worth it). The craftsmen from Kawasaki were the first to install an injector on a production motorcycle - in 1980, injection found its place on board the Z1000-H1 . Since the mid-80s, Honda, Kawasaki and Suzuki have used electronic injection on their turbocharged bikes, but they have not yet thought about switching to fuel injection en masse.

Kawasaki Z1000H1 - the first production motorcycle with electronic fuel injection

However, progress is inexorable, and under dual pressure from environmentalists and consumers, who demanded improved dynamic and performance indicators, in the mid-90s a gradual but inevitable transition began from carburetors to systems with electronic fuel injection. In the case of carburetors, there are many operating modes in which it is difficult to guarantee the supply of the mixture required for combustion to the engine cylinders. These modes include cold start and engine warm-up, when low temperatures impair fuel volatility; low idle speeds; sharp “unscrew” mode and operation at maximum load. It is not enough just to set the exact composition of the mixture; you also need to maintain precise control of it in all operating modes. Thanks to its operating principle and numerous sensors, electronic injection guarantees the achievement and maintenance of constant, precise control over the mixture composition. Environmentalists are not offended either - increased engine power is combined with efficiency and low exhaust emissions. Let's figure out how this electronic contraption works. Operating principle. The most important difference from carburetors is that the fuel is supplied under pressure for mixing with air. At the same time, the system must provide the engine with evaporated fuel in a volume corresponding to many parameters and taking into account any changes. This is achieved thanks to the rapid and accurate assessment of information by the electronic control unit (also called ECU ) coming from various sensors installed on the engine. These sensors collect information about engine speed, air flow, crankshaft angle, air temperature and density, throttle position and a host of other parameters. Having received the necessary data, the smart silicon “brain” determines the opening time of the fuel injectors, the amount of fuel supplied, and sends an electrical impulse to each injector. As soon as the injector opens, compressed gasoline is sprayed near the intake valve, mixed with air and entering the cylinder. All this is simple for an electronic piece of hardware, but it’s too much for a bearded old man with a carburetor, isn’t it? And now in more detail about the whole process. Fuel from the tank is supplied by an electric pump through a filter to the fuel rail , from which the individual injectors . The pump supplies more fuel than the engine requires, and therefore creates excess pressure in the fuel supply system. The ECU has a separate safety circuit that turns off the fuel pump if the engine is not running but the ignition is on (for example, after an accident or some kind of “jamb” in the engine). We will not dwell on the design of injectors; we will only say that based on the number of injectors per cylinder and their location, all injection systems are divided into single-point (“mono-injection”) and distributed.

Fuel rail assembly with throttle pipes and injectors. Suzuki Hayabusa 2008.

Motorcycles use indirect injection ( Indirect Injection ), in which nozzles are placed in the intake duct in front of the intake valves of each cylinder (multipoint injection). Thus, there is one, and on most sportbikes even two, injectors for each cylinder. One injector for all cylinders is used very rarely, as a rule, on the most budget models of bikes or scooters. There are also Direct Injection systems, in which fuel is supplied directly to the combustion chamber, but such systems are used mainly on canned diesel engines, so we won’t waste time on them.

Cards on the table!

The ECU controls fuel injection based on three-dimensional "maps". Maps are a way of graphically displaying data collected from various sensors. Whatever combination of indicators appears, the map will always indicate to the ECU exactly how much fuel should be injected under certain conditions. Most often, two maps are used - for low and high engine loads. At light loads, the duration of fuel injection is determined by the air pressure in the intake manifold and the engine speed. At heavy loads - by opening the throttle and engine speed. Changing maps is a popular means among tuners to increase engine power or reconfigure it for specific purposes. Of course, in conjunction with other activities, because just poking around with cards will bring nothing but problems.Program for setting injection maps, carried out using the Rapid-Bike module connected to the bike system

I hope that after reading this article, you have made some progress in your understanding of what happens to gasoline when you put it in the tank. In the next article we will talk about the path air takes before entering the combustion chamber. And of course, we will tell you about resonant air charging and turbocharging systems. Stay with us!

Operating principle of the main dosing system

The needle moves inside the calibrated part of the atomizer and at low throttle lifts the cross section through which fuel is sprayed is small. As a result, fuel consumption is also low, which is required to maintain the correct mixture composition at low elevations. At higher throttle lifts, the conical part of the needle with a smaller diameter appears in the fuel spray zone, thereby increasing the flow area of the nozzle. This allows you to increase the fuel supply, as is necessary for normal engine operation. This design and the corresponding operating principle of the main metering system makes it possible to maintain the desired mixture composition, so the engine is able to operate correctly at any throttle position.

Interaction of the needle with the sprayer

Now that the principle of operation has become clear, the principle of adjusting the main dosing system becomes clear. Adjustment is carried out using a needle and a calibrated nozzle hole.

Combustible mixtures

For the combustion of gasoline in the cylinders of a motorcycle, it is necessary that the fuel meets air, the meeting point of gasoline and air is the carburetor, and a mixture of these substances is formed here. For normal combustion of air, the mixture changes its composition depending on the time of year, engine load and other factors. Even small errors can lead to deviations in the operation of the carburetor and negatively affect engine performance.

Kinds:

- A “rich” type of mixture is formed when there is not enough air entering the carburetor, but there is too much gasoline. If there is not enough air, gasoline does not have time to burn out in the cylinder, it burns out in the exhaust system, forming carbon deposits, which reduces engine power, leads to excessive fuel consumption, and overheats the cylinder.

Signs: motorcycle revs and speed decrease, spark plug is black or dark brown;

- “lean” mixtures are formed if there is too much air and not enough fuel. It is worth looking for the cause in a loose connection of carburetor parts, the presence of places for additional air intake, etc. Signs: overheating and reduction in engine power, excessive fuel consumption, popping noises in the carburetor at idle, a light brown spark plug.

In addition to these types, there are 2 more intermediate ones, in which the manifestations of symptoms are weaker than in the extremes - these are “enriched” and “depleted” mixtures. In these options the excess is insignificant.

After purchasing the new motorcycle, there were a number of problems with the carburetor. 1. Unstable idle, the motorcycle could stall at a traffic light (increasing idle speed did not solve this problem) 2. Failure during acceleration 3. When releasing the gas, the speed “stuck” (there was no air leak) On the Internet, many give advice to raise the needle one notch and supposedly this will solve all the problems, I’ll say right away that this is nonsense and setting up the carburetor is a slightly more complicated process than just raising the needle. Also, many write that the PZ30 carburetor is, in principle, very bad and you can’t get normal operation from it, and if you want to remove dips, then only an accelerator pump will help, and this is also not true. I hope this post will help someone solve their problems with the carburetor and not waste money on another carburetor, which will also have to be adjusted anyway. In stock on the Racer Ranger 200 motorcycle, the carburetor is equipped with a GTZh (Main Fuel Jet) at 102 and an XX (Idling) jet at 40. For a 200 cc engine, 102 GTZh is not enough, so it should be immediately replaced with a 110 GTZh, the XX jet can be left 40. Before adjusting the carburetor, you should first adjust the valves and make sure that the air filter is not clogged and there is no air leakage where it should not be. Set the needle to the middle position. Now we warm up the engine to operating temperature and begin the adjustment itself. Tighten the quality screw until it stops and unscrew it 1 turn. Using the quantity screw, we set the minimum idle speed at which the engine does not stall, then unscrew the mixture quality screw until the speed increases, then reduce the speed with the quantity screw and again unscrew the mixture quality screw until the speed rises. You do this procedure until the motorcycle starts to stall due to the quality screw being unscrewed too much. Next, we tighten the quality screw to a state at which the speed is maximum (with the quantity screw unscrewed to the minimum).

When unscrewing the quality screw, do not pay attention to the fact that it dangles and is almost completely unscrewed; even if it falls out, it is not difficult to screw it back. If the optimal position is achieved when the quality screw is strongly unscrewed and the spring no longer fixes it, then unscrew it and place a spacer under the spring. A spacer for the spring can be made from an unnecessary jet; to do this, drill a hole in the jet so that the jet fits onto the adjusting screw; the jet also needs to be ground from the outside so that it fits into the carburetor. This will allow you to securely fix the mixture quality screw so that it does not unscrew or get lost. (If you managed to achieve optimal mixture quality in a position where the bolt is normally fixed and without a spacer, then, therefore, there is no need to make a spacer)

Now, using the quantity screw, we set the speed at which the motorcycle will operate stably. We try to ride, if when the gas is opened the motorcycle accelerates without a dip, then the adjustment can be completed at this point, if the dip remains, then we move on to the needle.

To begin with, lower the needle one notch and try to ride again. If it gets better, then lower it another notch and see at what position of the needle the motorcycle accelerates more pleasantly.

If lowering the needle did not help or even worsened the situation, then raise the needle one notch up (relative to the center); if it gets better, then raise it again and see in what position the motor works better.

We leave the position in which the failure will be least pronounced. I managed to remove the failure completely. My carburetor works with GTZ 107.5 (I bought it at the nearest AvtoVAZ store, otherwise it’s better to set it to 110), my XX jet is 38. I had to unscrew the mixture screw very tightly and put a spacer under the spring so that it is fixed. The needle is pubescent by one division. If it was not possible to remove the hole, then most likely the air filter does not provide enough air and you need to clean it up.

Link to jets (The seller needs to leave a comment to put the jets of the size you need)

In the mountains

Audi 80 Audi RED MATT Logbook FOR SALE Manifold for horizontal carburetors. VWAudi 8valve Dbilas

The composition of the mixture produced by the carburetor also depends on barometric pressure. This is well known to anyone who has driven in the mountains - engine power quickly decreases with ascent. Why? Firstly, due to a decrease in air density, the weight charge of the fresh mixture in the cylinder decreases; secondly, this mixture itself becomes too rich. According to data given in the literature, with increasing altitude the mixture is enriched by approximately 6 percent for every thousand meters. When driving up a mountain road, you need to change the carburetor adjustment from time to time. Most carburetors do not have special height correctors that allow the mixture to be properly leaned—only partial load modes (by lowering the metering needle) and idle modes (with the quality screw) can be adjusted. We are not considering the possibility of replacing the main jet, since for almost all carburetors this work is too labor-intensive. Thus, when the throttle valve is fully opened at high altitudes, the mixture will be over-rich - this must be remembered, especially when, due to a lack of power, every now and then you want to give more “gas”. Overloading the engine at low speeds is completely unacceptable, since an attempt to increase the speed by opening the throttle valve leads to an even greater drop in power, interruptions in operation, or even stopping of the engine. When starting a hot engine, you need to remember that the mixture is very rich, and in order to avoid serious troubles, it is better to forget about the existence of the quencher at this time. Don’t look for unnecessary adventures; there are already enough of them in the mountains.

Starting to move in conditions of a steep climb and lack of power is no less difficult. Sometimes you need to help the engine by pushing the motorcycle, and at the same time select the position of the spool at which the engine pulls satisfactorily and does not “choke.” It is better to get into the saddle while moving, without losing speed, which is already low.

Not all mountain roads run in the sky. Sometimes even at low altitudes they require certain skills from motorcyclists. Very often, motorcycle “aces” who come from lowland areas have a difficult time here. Miscalculation follows miscalculation. They often make mistakes in assessing the steepness of the ascent or descent on mountain passes; it happens that they do not catch the moment when the ascent ends and the descent begins. The high speed of movement and sharp closed turns only aggravate these errors, the reason for which, apparently, should be sought in the absence of the usual “horizon” before the driver’s eyes. It is not found in the mountains. For example, a mountain range rising like a giant wall in front sometimes gives the illusion of a steeper descent than it actually is. Moreover, in fact, at this moment the road may even be ascending. Hence the ridiculous mistakes in choosing the right gear: when the engine protests and, overloaded, begins to lose speed, the driver comes to his senses and... mechanically, out of habit, adds gas! Usually, immediately after this, interruptions in operation begin, because at excessively low speeds, increasing the gas does nothing. After all, if the engine is overloaded, but the throttle valve is partially open, then the air speed above the atomizer may still be sufficient for normal atomization of gasoline (the air passes through a relatively narrow gap). Although the power is small, this is not a “failure”. But if, instead of changing gear, they try to increase the traction force of the motorcycle by adding gas, the power quickly drops. What happens in the carburetor does not even remotely resemble its normal operation. On the one hand, the decreased vacuum worsens the operating conditions of the atomizer and the entire dosing system, on the other hand, low air speed worsens its mixing with fuel, which now enters the engine in a wide variety of forms - from vapors to large drops. Let the reader decide for himself what kind of mixture there actually is in the cylinder—whether it’s rich or lean. And is it even a mixture?

To avoid such puzzles, it is recommended to change gears in a timely manner, avoiding overloading the engine. And the carburetor will not let you down!

Setting up the float mechanism

The level of the fuel mixture in the float chamber is directly related to its quality. At an increased level, the mixture will turn out to be lean, which will negatively affect gasoline consumption and increase toxicity. Without adjusting the floats, the question of how to adjust the carburetor cannot be solved. The process of adjusting the floats includes the following operations:

- Adjusting the floats in relation to the lid and walls of the fuel chamber. If deformation of the float fixing bracket is noticed, it should be aligned manually;

- We adjust the bracket with the needle valve closed;

- We adjust with the float retracted and the valve open; the distance between the float and the valve should in this case be set to about 15 millimeters.

Adjusting and tuning the carburetor: main steps

Most modern gasoline cars are equipped with fuel injection systems, but before they gained dominance, all cars were equipped with carburetor systems. For this system to work correctly, the carburetor settings must be performed flawlessly. High-quality carburetor adjustment will reduce fuel consumption, make the engine run smoothly at idle, reduce the emission of harmful substances into the atmosphere and increase the overall engine life.

Most domestic cars have a carburetor system, and the question of how to adjust the carburetor will not lose its relevance for a long time. Many owners of rare old foreign cars also face the problem of how to adjust the carburetor. Since the principle of operation of carburetors around the world is no different, the algorithm of work will be the same.

The carburetor is the main component of the fuel system of any carburetor car. This is where air and fuel mix to form a fuel mixture that enters the engine's combustion chambers. A properly adjusted carburetor produces a fuel mixture in the required proportions. Such a mixture will not detonate in the cylinders, which will increase the life of your engine.

Adjusting the main carburetor systems in the Urals

Adjustment of carburetors on a Ural motorcycle is carried out after checking and adjusting the gaps between the spark plug electrodes, breaker contacts, valve stems, and the ends of the rocker arms. Each of the two carburetors is separately adjustable. It is necessary to begin adjusting the carburetor in the Urals after measuring the gap between the tip of the cable sheath and the fitting, which should be 2-3 mm.

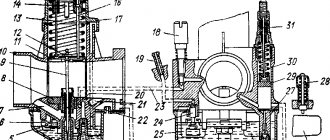

Rice. 3a. The main elements of the carburetor: 1 - main air path: 2 - throttle valve; 3 - subsidizing haze; 4 — air nozzle; 5 - sprayer; 6 — air channel; 7 - well; 8 — main fuel jet; 9 — float chamber (central location).

Rice. 3b. Fuel corrector: 1 — air inlet channel: 2 — spool; 3 — spool needle; 4 — fuel jet: 5 — sprayer; 6 — output emulsion channel; 7 — spool return spring; 8 — corrector control cable.

If the gap does not correspond to the specified size, the union locknut is loosened. Turn to the right or left to set the required gap. After this, the fitting is re-locked with a lock nut and the carburetor of the Ural motorcycle is adjusted. By turning off the warm engine at a minimum engine speed without load, the basic settings are made. The idle system is adjusted for each of the two mechanisms separately. The Ural carburetor is adjusted with the second cylinder turned off.

Idle adjustment

By rotating screw 28, the crankshaft speed is set to the minimum stable engine speed. Screw 29 is slowly unscrewed gradually until the motor begins to malfunction. It also gradually, slowly twists until a calm, stable speed is achieved. Once again, use screw 28 to reduce the opening angle of the throttle valve until the minimum speed is reached.

At the same time, screw 29 adjusts the saturation of the mixture. Such operations are repeated until the minimum stable engine crankshaft speed is obtained. The carburetor of the Ural motorcycle is adjusted in the same way for the second cylinder. The test is carried out by sharply opening and closing the throttle. In this case, you must sharply turn the throttle towards yourself and release it to its original position.

Operating modes

Modes of medium loads are characterized by the position of the needle relative to the throttle. Adjustment is carried out by choosing its most optimal position. The settings must be repeated when seasonal conditions change (winter-summer), during the running-in of new vehicles, in order to increase engine power. In this case, the dosing needle 25 moves along the thread relative to the bar 6. The locknut 5 is loosened.

When screwed into the bar, the needle rises in relation to the nozzle hole. The mixture becomes richer. When unscrewing, the mixture becomes leaner. One revolution of the needle moves 0.5 mm. The quality of the adjustment is checked by sharply turning the throttle knob. The loud pops that the carburetor makes on a Ural motorcycle indicate that the mixture needs to be enriched. To do this, the needle rises.

When operating motorcycles, owners often wonder which carburetors are best to install on a Ural motorcycle. Now Chinese carburetors are widespread in the Urals. There are some good examples among them. Foreign-made Solex and Weber models performed well in operation. However, their prices are higher than domestic ones.

What carburetors should I put on the Ural IMZ motorcycle? In my opinion, a Russian-made K63 carburetor would be good for the Urals. This is a trouble-free mechanism, the professional adjustment of which allows it to last for several decades. Every 5 thousand km it is recommended to clean it, blow it out, and rinse it.

The jets must be washed with acetone. The parts are wiped with rags or soft vinyl. The throttle should be installed after servicing with the cutout facing the air filter. Regular maintenance will ensure long-term trouble-free operation of the K63 model.

Adjusting the carburetor draft

Before you begin adjusting the rods, you should remove the air filter cover so that nothing interferes with the process. First, using a caliper, measure the distance between the rod tips. According to factory parameters, it should be 80 millimeters. To adjust the length of the rods, you need to loosen their clamps.

Checking the strainer should be carried out when there is fuel in the float chamber. This will help you see if the shutoff valve is closing completely. After examining the valve, you need to clean and dry it. Problems with loss of power and engine failures occur due to obstructed fuel supply. This is another reason to thoroughly flush the carburetor.

The tightness of the shut-off needle can be checked using a rubber bulb, while listening for air leaks. If they are present, it is time to change the needle.

How to adjust the carburetor on a motorcycle

If the synchronization of carburetors is carried out so that the amount of the combustible mixture is adjusted, then they are adjusted to improve the quality of this mixture supplied to the cylinders from the carburetors.

The Keihin carburetor for a motorcycle is adjusted in the same way for different models and brands of motorcycle. It is best to adjust carburetors at the same time as cleaning the carburetors. Because most often a poor-quality combustible mixture is formed when the jets are not clean enough.

The carburetor for the Ural motorcycle and other domestic motorcycles has been used from St. Petersburg since ancient times. It was constantly modernized and changed. And today this is a completely new device, which is called K-68. Today the Ural is the only motorcycle in the world that uses carburetors with variable vacuum.

To keep your motorcycle running properly, you need to know how to adjust the carburetor. And this needs to be done under certain weather and a specific road. Carburetors installed on motorcycles differ slightly from each other.

Attention: Motorcycle carburetors are designed specifically, and all its systems must work in parallel. The slightest mistake in this type of work will lead to other errors occurring. Care is required here.

To the question of how to properly set up a carburetor, we will answer this way, only in strict sequence.

- The float chamber contains fuel. Its level needs to be adjusted. Read the instructions carefully. The required float height is indicated there. The tongue is bent for adjustment. This adjustment is only necessary for precise adjustment.

- Idling. In this case, the carburetor operates when the throttle valve is closed. Idle speed is adjusted. To do this, you need to use the idle system jet and screws that regulate the quantity and quality of the mixture formed.

- Transitional mode. Here the throttle valve opens to a quarter. It is very important to choose the right jet and adjust the idle system.

- The throttle valve is partially open, up to seventy-five percent. Here you need to pay special attention to the gap that forms between the needle and the tunnel where the needle moves. The composition of the mixture depends on the diameter of the needle. To access this needle, on most motorcycles the carburetors will need to be removed.

- The throttle valve is fully open. The size of the fuel jet used is important here. The spark plug insulator, or rather its color, will help you find out whether you have adjusted the carburetors correctly or not. When properly adjusted, its color is dark brown.

This work is complex and small. But the reliable operation of your motorcycle engine is entirely dependent on this work. Constant practice and experience will lead you to success.

Adjusting the motorcycle carburetor video

HOW TO ADJUST THE CARBURETOR?

To adjust a motorcycle carburetor, it is necessary to take into account a number of factors characterizing the terrain in which the lightweight vehicle is used: temperature, humidity, altitude, etc.

- Determine the deviation in the composition of the mixture using indirect evidence. Pay attention to the engine's performance, look at the color of the spark plugs, or do a test. Cover one-fourth of the carburetor pipe with the plate and drive at low speed. An intense decrease in revolutions and speed will mean that the mixture is “rich”, a slight deviation - “rich”, a significant increase in speed - “poor”, a slight deviation - “lean”.

- Adjust the ratio of air and gasoline, turn the screws at the bottom of the part so that the air supply is optimal, taking into account the terrain, external and internal factors.

- Proceed to adjusting the motorcycle carburetor needle at the top of the motorcycle. The position of the needle is responsible for the amount of gasoline in the combustible mixture. Usually it is set to 5, but you can change it lower or higher if necessary.

- Adjust the top. Open the float chamber where the valve is located. This valve contains a movable needle, which can be used to adjust the flow of gasoline.

Parameters of carburetors of domestic motorcycles

Table. Parameters of carburetors used on domestic motorcycles and scooters.

| Carburetor designation | Make and model of motorcycle or scooter | Diffuser diameter, mm | Main jet flow capacity, cm3/min | Spray diameter, mm | Idle jet diameter, mm | Correction device |

| K-55 | K-55; K-58; M1M | 20 | 135 | 2,67 | — | VZ |

| K-55B | K-175; K-175A | 20 | 190 | 2,67 | — | VZ |

| K-55V | VP-150 | 22 | 165 | 2,67 | — | — |

| K-55D | M-103; M-104 | 22 | 145 | 2,67 | — | — |

| K-28B | -49 | 24 | 110 | 2,55 | 0,5 | VC |

| K-28G | T-200M; TG-200 | 25 | 182 | 2,55 | 0,6 | VC |

| K-28D | IZH-56 | 25 | 182 | 2,7 | 0,5 | VC |

| K-28Zh | IZH-Yu | 25 | 270 | 2,7 | 0,5 | VC |

| K-28I | IZH-P | 25 | 215 | 2,7 | 0,5 | VC |

| K-36R | V-150M | 22 | 155 | 2,6 | 0,6 | — |

| K-36M | M-105; M-106 | 22 | 155 | 2,65 | 0,5 | — |

| K-36 | K-175V; K-175V; "Sunrise", "Tourist" | 24 | 180 | 2,65 | 0,6 | TK |

| K-36Zh | IZH-Yu2; IZH-Yu3 | 24 | 240 | 2,65 | 0,5 | TK |

| K-36I | IZH-P2 | 27 | 250 | 2,6 | 0,5 | TK |

| K-36D | IZH-P3 | 27 | 260 | 2,6 | 0,5 | TK |

| K-37 | M-72; K-750 | 24 | 160 | 2,7 | 0,5 | VZ |

| K-37A | K-750M | 24 | 160 | 2,7 | 0,5 | VZ |

| K-38 | M-61; M-62 | 24 | 150 | 2,7 | 0,5 | VZ |

| K-302 | K-750; K-750M | 24 | 185 | 2,66 | 0,4 | VZ |

| K-301 | M-62; M-63 | 24 | 185 | 2,66 | 0,4 | VZ |

| K-301V | K-650 | 24 | 200 | 2,66 | 0,4 | VZ |