Design features of the fuel valve

The principle of operation of the fuel tap of a scooter is similar to the operation of the simplest locking devices. The membrane located inside the housing, thanks to the force of the return spring, is pressed against the fuel channel and blocks it.

When the engine is running, a vacuum is formed in the intake manifold, which passes to the membrane through a rubber tube. Under the influence of vacuum, the membrane, compressing the return spring, moves back and opens the fuel channel. Gasoline begins to flow freely into the carburetor through a special fuel line.

If the engine stops running, the process occurs in the reverse order. Due to the drop in vacuum in the intake manifold, only the return spring acts on the membrane. The partition is pressed tightly against the fuel channel and shuts off the fuel supply. Gasoline does not enter the carburetor.

Thus, three tubes fit to the fuel tap:

- — one hose is designed to supply fuel from the tank;

- — another tube leads to the carburetor;

- — the third hose (air) serves to transmit vacuum from the intake manifold under the membrane.

The fuel valve is mounted directly on the scooter frame and is covered by the side fairing.

Other answers in this thread

#2 GGarry

- Participant

#3 DmxOd

- Participant

#4 gor

- Active participant

#5 DmxOd

- Participant

Two tubes connect to the carburetor!

Say that the pressure in the carb is below atmospheric pressure. And one more thing, which of these inputs is for gasoline and which is for air??

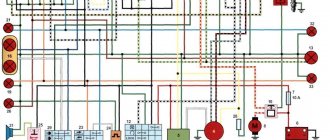

Attached images

#6 (DiMoN)

- Old timer

Two tubes connect to the carburetor! Say that the pressure in the carb is below atmospheric pressure.

And one more thing, which of these inputs is for gasoline and which is for air??

#7 DmxOd

- Participant

Thank you, you have given me confidence!

#8 gor

- Active participant

#9 DmxOd

- Participant

Manifold in English!! No, my tube is not located there, two are connected directly to the carb. Carb Del'orto 12 PHBN

Source

Checking the fuel tap

The simplicity of the crane design significantly increases its reliability. However, you need to remember that the fuel taps of the scooter cannot be repaired. This is due to the integrity of the product body, which cannot be disassembled.

To check the functionality of the faucet, you need to disconnect the hose from the carburetor and place it in any container that is at hand. Unscrew the air tube from the engine through which vacuum should be supplied. You can simply draw in air through it, and gasoline should begin to flow out of the fuel hose.

If fuel does not flow from the carburetor hose, it means the valve is clogged or faulty. It is imperative to clean the fuel filter installed on the tap. It is not recommended to blow the product with a compressor or pump; this will not give an effective result and will only increase the likelihood of serious damage to the membrane.

Fuel valve on a scooter - purpose and device

The fuel valve is a structurally simple, but much-needed part for the correct operation of the scooter engine. It should be immediately noted that for the most part, the fuel valve is non-separable and unregulated. If it fails, it simply needs to be replaced. Fortunately, it is inexpensive, and replacing it will only take a few minutes, even for an inexperienced scooter rider.

Location of the fuel valve under the tank

Not every scooter model is equipped with such valves; many engines with the tank located under the floor are equipped only with a fuel pump.

Operating principle of the fuel valve

So let's get to the point. Everyone knows that after starting the engine, a vacuum forms in the intake duct. Under the influence of negative pressure, the diaphragm compresses the spring supporting it, as a result of which a hole opens, through which, in fact, fuel enters the carburetor.

The vacuum from the intake manifold is transmitted to the tap through a separate rubber tube, the outlet of which goes under the membrane. Under the influence of vacuum, the membrane compresses the spring and opens the channel, after which fuel flows freely through the rubber tube from the fuel tank into the carburetor float chamber.

After stopping the engine, the vacuum disappears and the spring returns the diaphragm (valve) to its original position, the hole closes tightly and the fuel supply to the carburetor is completely stopped.

Fuel valve device

At its core, the fuel valve is an automatic replacement for the mechanical valve that is installed under the fuel tank (for example, on mopeds), where the valve must be manually opened before each ride.

The device is very simple. Only a diaphragm and a spring are installed inside. There is a rubber valve (protrusion) on the diaphragm in the center, which closes the fuel channel.

Outside, the fuel valve has 3 fittings:

A variety of fuel valves. 1 - with three fittings, installed on the frame. 2 - with two fittings, installed directly into the tank.

It should be noted that there are also fuel valves that are installed directly under the tank (rigid clutch), therefore, there is no fuel supply hose there, because the fuel comes to it directly from the tank. Often such valves are also equipped with a fine filter for fuel. The filter is a tube of filter material at the inlet. The tube goes inside the fuel tank.

How to check the fuel pump on a scooter?

Summer. Time for the sensations of driving both cars, motorcycles and scooters. A scooter, according to reviews from travelers, is a convenient and fun technology. On it, if systems and parts are checked and adjusted, movements are made along asphalt roads over vast distances. One of the parts that plays a role in the proper functioning of gasoline in the engine operating system is the scooter's fuel pump. Let's take a closer look at the purpose for which a fuel pump on a scooter is used, and how this part works.

Malfunction of the vacuum tap on the scooter

Any equipment, be it a Chinese or Japanese scooter, can malfunction. And many owners are not able to immediately recognize the cause of the breakdown. Why does the scooter stall and is difficult to start? Often the cause is a very minor problem, such as a malfunction of the vacuum tap. After all, equipment does not tolerate low-quality, dirty or diluted gasoline. Therefore, after a certain time, the scooter begins to stall and cannot be started.

Causes of vacuum valve malfunction

Such a seemingly simple problem can actually cause a lot of trouble for the scooter owner. After all, if you do not fix the problem in time, you can have serious consequences. For example, fuel cannot pass to the carburetor because the membrane is stuck along the way. It does not allow gasoline to pass through and of course does not open. Or another common problem - when you turn off the engine, the tap does not close. You can drive with an open tap, but it is better to replace it in time, because sooner or later you will notice a puddle of gasoline under the scooter, as the carburetor shut-off needle will begin to let it through. Therefore, it is better to replace it with a new one.

How to check the serviceability of a vacuum tap

If you doubt the reason for the breakdown of the scooter, you can immediately check the serviceability of the faucet. This is done quite simply: you need to disconnect the gasoline supply pipe and the vacuum tube from the carburetor, place a container and observe - if the tap is working properly, gasoline will not flow from it. Next, you need to draw air from the tube with your mouth, and if gasoline flows into the substituted container from the gasoline supply tube, then everything is in order. If not, you need to change the faucet, since it cannot be repaired, because the body is rolled.

You can buy a vacuum faucet of good quality and at an affordable price on the website begemoto.com.

Consequences of a malfunctioning vacuum valve

The vacuum tap plays an important role in the operation of scooters. And they can lead to complex consequences. It is necessary to pay attention to the fact that if the valve malfunction is not corrected in time, the tire may suffer, because it will become limp from constant contact with fuel. There is also a high risk of fire because there are electrical wires nearby. Therefore, the problem cannot be neglected; it must be eliminated urgently.

Another cause of scooter malfunction may be “hibernation”. It stood in the garage for a long time, the membrane stuck and could not come off, which prevents fuel from passing through. Motorcycle repairs must be carried out on time, so as not to regret later that you will have to invest a lot more money and time.

Any equipment requires constant care and timely repairs. And Chinese and Japanese scooters especially need preventative maintenance and replacement of parts that have worn out or have some kind of malfunction. The main thing is not to ignore signals from technology that a problem has occurred, but to immediately look for it and fix it.

www.0342.ua

On what models is it installed?

The fuel pump is installed on various models of scooters. The most common ones are presented below.

The scooter's fuel pump plays a role in the proper functioning of gasoline in the engine operating system.

On Japanese models:

- Honda Dio - easy to use, with a glove compartment that allows you to store a helmet and other things on the go, tank capacity is 4-6 liters;

- Vamaha Jog – has great maneuverability, the volume of the power unit is 49 cubic centimeters.

On Chinese scooters:

- Suzuki Address V110 is a two-stroke with a medium speed engine, its wheelbase is designed for movement around the city and beyond;

- Viper Storm 150 is a two-seater, reliable, comfortable model.

Gasoline pumps are installed on equipment from Russia - a manufacturer in Yoshkar-Ola, an official dealer of Polaris and the Russian brand of several companies Irbis:

- Lifan LF 125T-27 - it has a four-stroke engine, 125 cubic centimeters, speed 80 kilometers per hour, gas tank capacity 5 liters;

- Irbis Z50R is a high-speed scooter for driving outside the city with wide tires.

A fuel pump is installed on various scooter models

Supply system

The power supply system for scooter engines includes: fuel tank, fuel tap, fuel filter, carburetor and air filter. Fuel tanks are made of high-strength plastic and can hold, depending on the model, 4.5-6 liters of gasoline.

The fuel taps for all models are automatic, requiring no action from the driver. Such valves open only when the engine starts, and when it stops they close immediately. The operation of the valve is controlled by the vacuum that occurs in the inlet pipeline. A fuel filter is inserted into the line between the tap and the carburetor, which prevents dirt from entering the carburetor.

An important detail that extends the “life” of the engine is the air filter, which also plays the role of an intake noise muffler. It consists of a housing with a cover and a foam air filter that allows repeated cleaning.

Air filter (Nexus Viper)

Air filter design:

- lid;

- foam filter element;

- partition;

- frame;

The main device of the power system is the carburetor; it prepares and accurately doses the air-fuel mixture entering the cylinder. Its design is quite complex; it includes several fuel dosing systems. Without going into details, the carburetor must supply enough gasoline to maintain an optimal ratio in all modes, approximately one part by weight of gasoline to 15 parts by weight of air. When the proportion of fuel is higher, the mixture is called rich, less - lean. Running the engine on rich mixtures increases power, while running on lean mixtures increases efficiency. However, too rich mixtures do not burn completely in the cylinder and worsen efficiency, while poor ones lead to engine overheating, flashes and pops in the carburetor, and a drop in power. In addition to the fuel metering systems, the carburetor contains a float chamber in which the float maintains the fuel level at a constant level. Otherwise, the dosage by the carburetor is violated.

Main parts of the carburetor:

- starting enrichment;

- throttle valve;

- frame;

- idle jets;

- float;

- float chamber cover;

- float chamber cover;

- main fuel jet;

Another automatic device included in the carburetor that allows the driver not to think about what to do when starting a cold engine is a starting enricher with a heating element. When starting a cold engine, the enricher shut-off needle is retracted, the fuel nozzle cross-section is completely open, and the fuel-air mixture is enriched. After starting the engine, current from the generator flows to the heating thermoelement; after a certain time, sufficient to warm up the engine, its working fluid expands and, acting on the enrichment needle, closes the fuel channel.

Features of operation and spare parts

Gasoline is poured into one of the holes in the tank. The fuel pump automatically opens when the engine starts, and closes its second hole when it stops. In this case, a vacuum occurs, affecting the opening of the gas tap to supply fuel to the pipeline. Then, through the gasoline filter, the fuel enters the carburetor, where it is mixed with the air that has passed through the air filter. At the same time, the filters clean gasoline and air from foreign impurities, respectively, protecting scooter parts from damage.

How do they use a fuel pump on Chinese scooters? On Chinese technology, instead of a pump, there is a vacuum valve. Here, fuel is supplied from the tank by gravity, since the tank is located above the carburetor. When servicing and repairing, it is necessary to pay attention to breakdowns and contamination of hoses from the carburetor and filters in the tap.

Vacuum tap

Appearance of the vacuum valve

The vacuum valve is attached to the bottom of the gas tank. Gasoline exits through the bottom fitting, and through the side vacuum supply (Fig. 1). In normal condition, the valve is closed, but if a vacuum is applied to the side fitting, it will open.

The vacuum is supplied by a hose from the pipe between the carburetor and the cylinder head. If the valve does not allow gasoline to pass through when the crankshaft rotates, either there is something wrong with the vacuum hose, or the valve itself is clogged. Diagnostics of the operation of an automatic gas tap can be done by drawing in air in a vacuum hose. Gasoline should flow from the fuel hose. The unit is non-separable and must be replaced if faulty. However, you should remove it from the tank and make sure that the inlet is not clogged with sand

When to check your work?

Let's figure out in what cases it is necessary to check the operation of the scooter. For this you need:

- periodic checks, cleaning, replacement of parts. With them, attention is directed to brittle, fragile parts;

- regular – parts sensitive to blockages. Dirt on them can lead to engine failure, overheating or jamming;

Maintenance leads to an extension of the life of motorcycle equipment

- current - when a violation is detected: rupture of connecting tubes, leakage of oil and the presence of stains from it, as well as cracks due to the influence of precipitation and temperature on the plastic;

- Preventive checks when changing oil, refueling, cleaning from dirt. Ignition and braking systems are also checked.

Maintenance extends the life of motorcycle equipment. You should pay attention to regular cleaning of dirt and dust.

Preventive inspections and measures taken to replace unsuitable parts are important:

- fuel pump,

- gas tank,

- gasoline tap,

- fuel filter,

- air filter,

- carburetor,

- connecting tubes.

You can check the functionality of the fuel pump yourself.

How to properly check?

How to check the fuel pump on a scooter? This question worries many fans of this vehicle when the vehicle does not start. There could be several reasons for this, one of them is that there is something wrong with this part. You can carefully check the performance of the fuel pump yourself.

First, let's try to configure the fuel pump:

- It has two screws: the first is for idle speed, the second is responsible for the quality of the fuel mixture. We tighten both screws, then release the second screw two turns, the first two and a half turns. We start the scooter, listen to the engine: smooth - no adjustment required, intermittent - continue.

- We fix the equipment with a step, slowly tighten the idle screw until the clutch engages - the wheel begins to rotate. Unscrew it a quarter turn. We check while driving: if acceleration is difficult, then tighten the screw a quarter turn. Acceleration is normal - the screw should be turned a quarter counterclockwise. Then we adjust the idle speed screw again.

Let's take a closer look at how to check the vacuum fuel pump on a scooter if the adjustment fails:

- Unscrew the four screws using the hexagonal star handle;

- carefully pull out the fuel pump cover, remove the rubber gasket, membrane, see the valve;

Features of the gas pump on a 4T scooter

In a four-stroke Chinese scooter, the fuel pump consists of a cap, a spring, a valve with a membrane, a fuel needle, and a vacuum chamber. If the membrane or needle is damaged, the elements must be replaced.

This technique uses an original mixture. There are starting enrichment agents. The dosing needle releases the trigger channel. A passage opens to increase the dose of fuel. The system disables the idle option under load.

Adjustment when the engine is warm with a special screw, when tightening it, makes the air flow less. The fuel becomes richer, the number of revolutions increases. When unscrewing it, the process occurs in reverse.

Fuel flows proportionally due to the adjustment screw or throttle valve. Enrichment occurs when the screw is turned clockwise or the needle is raised, and vice versa if a regular mixture is needed.

The fuel pump is one of the important parts, know it, study others and travel on a scooter, drive around the city and enjoy the world around you!

Source of the article: https://topkarting.ru/kak-proverit-benzonasos-na-skutere.html

How does a scooter carburetor solenoid valve work?

The starting enrichment on a 2t scooter and on a four-stroke moped works according to a fairly simple algorithm. On a cold power unit, the spool needle occupies the upper position. It is responsible for opening the fuel channel, and the position of the damper affects the volume of supplied air. The first revolutions when starting the engine cause a vacuum inside the emulsion channel, and gasoline is sucked into the engine.

The result is a highly enriched mixture, making it easier to start a cold engine. Before reaching operating temperature, the power unit needs to be fed with an enriched mixture.

The enricher in this mode performs the function of a parallel carburetor - fuel entering through the nozzle is mixed with air and directed to the engine.

The current generated by the generator of the running engine is supplied to the contacts of the heater that controls the thermoelectric valve of the intake system. Due to heating, the temperature of the powder drive increases, which causes the rod to gradually extend up to 4 mm. The force is transmitted to the pusher, which ensures the movement of the damper.

The starter enricher on a scooter works according to a fairly simple algorithm.

As the engine warms up, the spool with the needle lowers, followed by the air-fuel channel closing. After five minutes, the damper closes completely and the mixture becomes lean. Now the gasoline enrichment system on a warm engine is regulated by the carburetor.

After stopping the engine, the valve stops heating, and as a result of powder compression, the damper drive using a pusher and rod returns it to its original position. The system is ready for subsequent startup. The cooling and return process takes no more than two minutes. The enricher has a drawback - it works separately from the motor.

As a result, in the warm season, on a hot engine that does not need a rich mixture, the engine, when the thermoelement has cooled, is powered by a rich mixture.