Brand popularity

Although Ural is found everywhere in the Russian Federation, a large number of manufactured mopeds are sold to other countries. Only three percent of the total volume remains in Russia. This is due to the considerable cost of the motorcycle. For the same price it is possible to purchase a used car of excellent quality.

Realizing that this bike was very popular abroad, I decided to reconstruct it, started buying spare parts abroad, and carrying out the assembly in the Russian Federation. About a thousand bikes are produced annually and are already sold in advance. It’s hard to imagine which countries they drive on.

"Ural" is made on the basis of military bikes "BMW R71". They were produced by the Germans in the forties of the last century. The first “Ural” was manufactured during the Second World War and had additional devices that distinguished it from German motorcycles. To make the army more maneuverable and mobile, Iraq purchased many bikes from the Russian Federation. They were equipped with additional channels, machine guns and flamethrowers. It was after the Iraq war that America began to become interested in these bikes.

content .. 41 42 46 ..Front fork of Ural motorcycle

IMZ-8.103-10

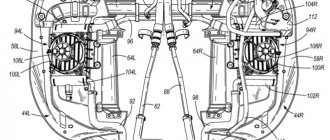

The telescopic front fork with internal springs and a double-acting hydraulic shock absorber (Fig. 22) consists of a steering column rod 8 with a bridge 16, a yoke 3, two stays with shock absorbers and a steering shock absorber (damper).

The steering column rod serves to attach the fork to the frame head on two support ball bearings. The lower end of the rod is pressed into the bridge, and its upper end is clamped in the frame head with a nut that tightens the bearings.

The crossbar is placed on top of the conical ends of the pipes of 24 fork legs and is attached to the rod with a nut. The fork leg tubes are inserted into the two side split holes of the bridge and secured with coupling bolts.

The fork spring softens shocks transmitted from the wheel to the frame. The lower end of the spring is screwed onto the nut 35 of the shock absorber tube, the upper end is screwed onto the upper tip 12 of the spring, placed on the rod, between the limit nuts. The spring connects the movable part of the fork (tip 25 of the fork leg) and the fixed pipe 24 of the fork leg and can work in both compression and tension.

An oil shock absorber is installed in each front fork leg to dampen vibrations. It consists of a tube 27, a rod 34, a tube nut 35 and a lower shock absorber guide 31. The tip 25 of the pen is filled with oil, the level of which should be above the lower guide. .

The shock absorber body is secured with a bolt 29 to the base of the fork leg tip. There are holes at the bottom of the shock absorber housing to allow oil to pass into the shock absorber.

The upper end of the rod is screwed into the tightening nut 11 of the feather tube. The lower shock absorber guide 31, which has the shape of a square with rounded corners, is attached to the rod from below with a nut. Above the guide there is a shock absorber piston 32, made in the form of a plate with a hole in the center. The edges of the piston fit tightly to the inner surface of the shock absorber tubes. The upward movement of the piston is limited by pin 26. At the moment when the piston rests against the pin, oil passes freely from bottom to top through the gap between the piston hole and the rod.

Nut 35 of the shock absorber tube serves as the upper guide of the rod and is a glass with a calibrated hole. The shock absorber body moves with the wheel axle.

135 cm3 of engine oil is poured into each fork leg through unscrewed tightening nuts 11. To remove oil and wash the fork legs, you need to unscrew and remove the tips (see section 9, page 89).

When assembling the front fork, it is necessary to ensure that there is a gap of 0.2-0.5 mm between the tips of the spring and the nut that locks the tightening nut of the airfoil tube, ensuring free rotation of the tightening nut with the rod.

Steering shock absorber. The motorcycle is equipped with a friction-type shock absorber (see Fig. 22). It consists of two steel washers, movable 37 and fixed 39, two friction washers 17 and a tightening bolt 7 with a head. Friction between the steel and friction washers makes the front fork difficult to turn.

The degree of tightening of the steering damper is selected depending on the road condition and driving speed. When driving at high speed, especially on uneven roads, the tightening bolt must be tightened; When driving slowly or with frequent turns, the bolt is released, since a tightly tightened shock absorber makes it difficult to turn the steering wheel.

The bearing tightening must be adjusted in the following sequence:

hang the front part of the motorcycle so that the front wheel does not touch the ground;

Unscrew the tightening bolt of the steering shock absorber, remove the spring and support washer, supporting the shock absorber washers with your hand;

by rocking the front fork (up and down) by the handlebars or by the tips of the stays, determine the presence of play.

If there is play in the bearings, you need to loosen the nut 4 of the steering column rod, move up the yoke 3 with the nut, having first loosened the tightening nuts of the fork legs, tighten the nut 9 of the bearings until it stops, and then loosen 1/6-1/8 of a turn. Check again for play in the bearings.

Rice. 22. Front fork: 1 — protective washer; 2 - oil seal;. 3 - traverse; 4 — steering column rod nut; 5 — support washer; 6 — spring washer; 7 — long bolt; 8 — steering column rod; 9 — bearing nut; 10 — upper angular contact ball bearing; 11 — tightening nut; 12 — upper spring tip; 13 — casing sealing ring; 14 — feather casing with headlight bracket; 15 — coupling bolt; 16 — steering column bridge; 17 — friction washers; 18— spring; 19— oil seal cuff; 20 — oil seal cuff; 21 — oil seal spring; 22 — opera ring; 23 — upper bushing; 24 — fork leg pipe; 25 — tip of the fork; 26 - pin; 27 — shock absorber body tube; 28 — shock absorber housing cone; 29 — shock absorber mounting bolt; 30— lower bushing; 31 — lower shock absorber guide; 32 — shock absorber piston; 33 — spring ring; 34 — shock absorber rod; 35 — shock absorber tube nut; 36 — oil seal housing; 37 — movable washer; 38 — lower angular contact ball bearing; 39— stationary washer of the steering shock absorber; 40 — head frame pipe; A - sub-piston cavity; B - supra-piston cavity

content .. 41 42 46 ..

Replacement procedure

Before changing the oil, be sure to look where the lower plug on the fork is located - the principle of performing the entire procedure depends on this. The following options are available:

- Down at the end;

- On the side at the bottom;

- The bottom plug is missing.

If the drain hole is located at the end of the fork, lift the motorcycle onto a support, remove the front wheel and install the rods strictly vertically. The lateral location of the plug allows you to repair the hydraulic system without removing the wheel, although you will have to lift the motorcycle in this case as well. If there is no bottom plug, you will need to remove the fork.

Having decided which oil to pour into the fork, first unscrew the upper plug, and then the lower one, after placing a vessel with a volume of at least 0.5 liters under each shock absorber. If you have to work on a motorcycle without a bottom plug, the removed fork will have to be turned over so that the oil comes out of it through a single hole. After draining the technical fluid, the fork must be washed - a special fluid or regular low-viscosity motor oil is suitable for this. Having done all this, blow the inside of the part with compressed air from a compressor or a special can.

A very important question is how much fluid to add to achieve ideal damping characteristics? The most common recommendations on the Internet suggest using 500 ml of liquid for each shock absorber. However, this is a very rough assumption that can make the motorcycle completely uncontrollable. To optimize the controllability of two-wheeled vehicles, it is worth focusing on such a parameter as the oil level from the top edge of the pipe. You can find it in the vehicle’s operating instructions or in specialized technical literature.

It is worth understanding that an oil pump with a measuring needle that prevents fluid from overflowing costs about $100 - not every motorcyclist is willing to pay such an expense. Therefore, a much better solution would be to build the necessary tool yourself, spending no more than 100 rubles on it. At the pharmacy, buy a 10-cc syringe and a catheter, which is a transparent tube that fits over the nose of the syringe. You will need a length of catheter equal to the distance found in the instructions. It will need to be tightly placed on the syringe spout to prevent oil leakage during operation.

First, you need to pour 500 ml of oil into the fork, or a little more if the catheter does not reach the top edge of the liquid. Then the syringe is applied to the pipe so that the base of its nose coincides with the cut line. All you have to do is pump out the excess oil that will interfere with the suspension adjustment. Remember that this procedure must be performed with the fork compressed in order to be able to accurately determine the required oil level. The cartridge should be installed at this point, but the spring does not need to be installed.

What oils are poured into a Dnepr motorcycle?

MOTORCYCLE DNEPR-11. ENGINE LUBRICATION SYSTEM

The engine lubrication system is combined (pressure and splash). The lubrication diagram is shown in Fig. 12.

Oil is poured into the engine crankcase through the filler hole and closed with plug 2 with an oil measuring rod. From here, the oil is sucked through a strainer 3 by a gear pump installed in the front bearing housing, which is driven by a gear meshed with the drive gear of the timing mechanism. The oil pump has two gears that are installed in the housing and pump oil into the main line 7. To prevent the oil pressure in the system from increasing above the permissible level, a pressure reducing valve 5 is installed in the oil pump housing.

Oil change intervals

Most manufacturers recommend changing the oil in the front suspension of a motorcycle every 12-15 thousand kilometers to ensure that the two-wheeled vehicle maintains good handling. However, experienced owners prefer to replace them simultaneously with scheduled repairs, which include installing new oil seals. This allows you to obtain optimal fork stiffness parameters without having to deal with time-consuming, labor-intensive adjustments.

It is recommended to change the oil after the motorcycle has been idle for the winter, since low temperatures may cause it to partially or completely lose its properties. If the motorcycle participates in sports competitions and the demands on its handling are very high, the frequency of replacing technical fluid should be reduced to 5 thousand kilometers. Experienced drivers recommend changing the fluid when the fork wear becomes noticeable. This is expressed in deep “dive” when braking, as well as in destabilization of the motorcycle at high speed. In such a situation, it is recommended to buy oil of higher viscosity in order to stiffen the suspension and also improve the handling of the two-wheeled vehicle.