The clutch of Izh motorcycles , as well as all other models, is designed to smoothly connect the crankshaft to the engine power transmission. Without it, it is impossible for the motorcycle to start moving smoothly. It is used in all cases where short-term disconnection of the rotating engine shaft from the power transmission is required: when starting, changing gears, braking.

Izh motorcycles have a mechanical clutch based on the use of friction between the drive and driven discs. It is multi-disc, operating in an oil bath. With this type, a small-diameter coupling can be used due to the large friction area of many discs. The clutch requires maintenance and proper adjustment. Now we will look at the procedure for disassembling and adjusting the clutch, for example we will take the Izh Planet 5 motorcycle; on most other Izh models this is done in a similar way.

Disassembly:

- Remove the carburetor guards, shift lever and kickstarter lever.

- Place the motorcycle on its right side or drain the engine crankcase.

- If the motorcycle is equipped with a separate lubrication system, disconnect the oil line from the intake manifold and the wire from the sensor contact on the left engine cover.

- Remove the left crankcase cover.

- Unscrew the clutch basket nuts and remove all discs.

Assembly:

- Tighten the nut securing the basket to the input shaft. To do this, engage fourth gear. Keep in mind that the threads on it are left-handed.

- Reassemble all discs in reverse order into the bin. Pay special attention to evenly tightening the nuts.

- Install the crankcase cover, having previously aligned the oil pump drive shank with the groove in its drive coupling on the primary drive gear.

Purpose of the clutch IZ Planet and IZ Jupiter

Clutch - the name speaks volumes about the job it does. In our case, the crankshaft engages the gearbox of the IZH Planet and IZH Jupiter engines. The connection should occur smoothly without jerking, this is necessary to start moving and smoothly change gears. In case of heavy loads, it protects engine parts from damage.

The clutch is located in the left half of the crankcase, under the left engine cover.

To get to the clutch, you need to drain the oil and remove the cover with the gasket, first remove the levers and unscrew the mounting bolts.

The basket is constantly in working condition, the discs are tightly compressed by springs.

The motor transmission consists of two sprockets. The small drive is located on the crankshaft. A large star driven on a drum. The connection is made by a motor chain.

The engine gear ratio is 2.17 for all single-cylinder IZh models. For IZ Jupiter, the gear ratio is 2.57.

When assembling the motor transmission, the planar arrangement of the stars is controlled. No more than 0.4 millimeters are allowed.

Switching off occurs using a special device. The shutdown mechanism is installed in the right engine cover. This mechanism is used to make adjustments.

Tips for increasing the life of the Izh motorcycle clutch

The clutch is not intended for long-term operation in the disengaged position, as in this case increased wear of the mechanisms occurs. The control lever must not be released abruptly or very slowly. When turned on abruptly, the power transmission receives maximum load; when turned off slowly, the parts wear out even more than when turned off completely, due to slipping of the disks. If you have a habit of keeping your fingers on the lever, make sure that there is not even the slightest pressure on it. Even with a slight pressure that does not cause the discs to slip, the clutch mechanisms experience significant load. Do not use the clutch to disconnect the engine from the gear when stopping or coasting for a long time. In all these cases, use the gearbox, putting it in neutral. Also, never try to make the engine work easier on climbs and in other difficult situations, causing the discs to slip and, as a result, increase engine speed. In such cases, it is better to switch to a lower gear in advance.

Clutch adjustment IZH Planet

To adjust the clutch control mechanism of motorcycles IZH Planet 5, IZH Planet 4, IZH-56, IZH-49, use adjusting screw 1 and locknut 2. By loosening the locknut by turning the screw clockwise, reduce the free play of the control lever. When turning the screw counterclockwise, the free play increases. After completing the adjustment, tighten the locknut. The normal free play value is determined by the free movement of the end of the clutch lever by 5..10 mm.

The normal amount of free play is determined by the free movement of the end of the clutch lever by 5..10 mm.

Clutch adjustment IZ Jupiter

On motorcycles IZH Yu and IZH Yu K, adjustment of the clutch release mechanism begins with the release mechanism, for which the adjusting screw is screwed in all the way and released 1/4 -1/2 turn, after which the lock nut is tightened.

The correct installation is checked by pressing the shift pedal in one direction or another. Moving the front end of the shift pedal 5-5.5 mm from the neutral position should not lead to movement of the pressure plate. After this, the manual release is adjusted using the adjusting screw located in the left post of the clutch lever on the steering wheel (the free play is 5-10 mm).

MY MOTORCYCLE

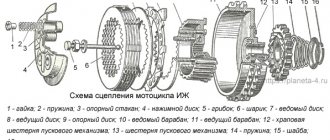

The clutch ensures the transmission of torque from the large gear of the motor transmission to the input shaft of the gearbox, short-term separation and smooth connection between them. IZh motorcycles use a friction multi-plate clutch operating in an oil bath. Let's consider the operation of the clutch using the example of the IZH Planet power unit. The large driven gear of the motor transmission is made integral with the drive drum 8 of the clutch (Fig. 2).

The driving plastic disks

6 fit with their protrusions into the grooves of the large drum 8 . Between the drive disks, driven steel 5 , which are connected in the same way to a small, driven clutch drum 7 , mounted on the splines of the gearbox input shaft. The disk pack in working condition is compressed by five cylindrical springs 2 , which rest on cups 3 fixed in the outer steel pressure disk 4 . The force of the springs can be changed using shaped nuts 1 : during operation, this has to be done when replacing the package in order to move it evenly in the grooves of the drums. The normal position of the clutch is constantly closed, the discs are pressed tightly and with great force against each other. To disengage the clutch, you need to separate the discs and move them away from each other. This is accomplished by a shutdown mechanism mounted on the right engine crankcase cover and a drive. The clutch release lever is located on the left side of the steering wheel. 14 is fixed in it . When you press the lever, the force is transmitted through the cable to the worm 13 ; the latter turns, moves along the three-start thread and presses on the ball 11 , the thrust rod 10 and the pusher 9 and moves the pressure disk 4 , overcoming the force of the springs. At the same time, the clutch discs are released from the force compressing them and are separated, the clutch is disengaged. As soon as you release the lever on the steering wheel, the shutdown mechanism returns to its original position under the action of springs 2 and 12 . Normal operation of the clutch mechanism is ensured only if there is sufficient clearance in the drive (free play on the release lever), and the springs are preloaded so that the discs move without distortion and over a sufficient distance. Approximately, the spring force can be considered normal if the nuts protrude above the caps by approximately 4.5-5 mm. The clearance in the clutch release mechanism is primarily ensured by the adjusting screw 17 . First, this screw must be screwed in until there is a noticeable stop (without, however, allowing the discs to move), and then loosened 1/2-3/4 of a turn and secured with nut 16. Then, use the adjusting screw on the steering wheel to set the free play of the clutch cable: it is at the end of the lever should be 5 mm.

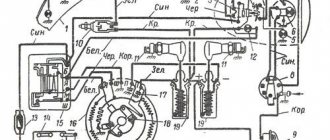

IZH Jupiter engine: clutch and release mechanism The clutch release mechanism of the IZH Jupiter engine (Fig. 3) differs significantly from that described above, primarily in that it is interlocked with the gear shift mechanism. This allows you to disengage the clutch using both the lever on the steering wheel and the pedal, and gear shifting occurs more smoothly and quickly. The shutdown mechanism is also mounted on the right engine crankcase cover. As in the previous case, it is connected to the lever on the steering wheel by a cable drive, the operation of which requires no explanation. As for semi-automatic clutch release, we need to talk about it in more detail. The gear shift pedal is mounted on the left end of the shift shaft; At the right end of this shaft 14 there is a cam 15 of the automatic clutch release. The cam has a complex shape; in constant contact with its working surface there is a roller attached to the end of the double-armed lever 19. In the normal position of the shift lever, the roller is located in the cavity of the cam 15 . When the lever moves down or up (one or another gear is engaged), the cam 15 with its protrusion runs onto the roller, through it presses on the lever arm 19 ; the second arm acts on the pusher 13, the ball 12 and the thrust rod 11 and moves the pressure plate 6. The springs 2 are compressed and release the disks, the clutch is disengaged. The working surface of the cam 15 is designed so that the clutch disengages before one or another gear is engaged; It turns on only after the transmission is detected. You have to pay for convenience - in this case, with more complex adjustments. If in the IZh Planeta clutch release mechanism it was necessary to adjust only the free play of the lever on the steering wheel, then on the Jupiter it is also necessary to adjust the free play of the shift pedal. Moreover, the sequence of adjustments is also important. Start, as in the first case, with the clutch springs. They should protrude above the cups by approximately 3.5-4 mm and ensure uniform, distortion-free movement of the discs when the clutch is disengaged. After this, screw 4 must be screwed into the pressure plate until it stops and unscrew it 1/4-1/2 turn. This may not work right away; for insurance purposes, it is better to perform this operation several times to be absolutely sure of the result. Then lock screw 4 with nut 5 . Only now can you adjust the free play of the lever on the steering wheel. As in the previous case, it should not exceed 5-8 mm at the end of the lever. If the gearbox works perfectly, automatic clutch release is very convenient and significantly makes the life of a motorcyclist easier: if the clutch cable breaks, it is sometimes possible to ride for quite a long time, even in city conditions, using only the foot-operated semi-automatic release. True, starting from a standstill requires a certain skill. When the box “fools”, and this, alas, happens often, it is better to use manual clutch release - this only prolongs the life of the mechanisms.

Disturbances in the operation of the clutch that appear during operation are most often associated with a natural change in the gaps in the drive or loosening of the fastening of its parts. It is not difficult to restore both. Typical clutch failures boil down to essentially two things: the clutch either “drives” or “slips.” The first term means that the disks do not separate completely and torque transmission occurs to one degree or another all the time. This means that the gear cams in the gearbox are constantly pressed against each other and their separation requires considerable effort. The most likely cause is disk misalignment; less likely - a large gap in the shutdown drive. The clutch “slips” if the springs do not create the required force or there is no clearance in the release drive. Both can be eliminated by adjustments. The composition of clutches and drive mechanisms for different models of IZH power units, as well as the applicability of parts, are indicated in the table.

Adjusting the clutch springs

Adjusting the springs is not difficult, the main thing is to get it right. We start by placing the motorcycle on the center stand. Then remove the lid, draining the oil in advance. We squeeze the lever on the steering wheel to the limit and make sure to fix it. Next we turn on the speed, preferably the first one. We take the wheel and begin to rotate. We try to determine by touch how much effort we are applying. We look at the coupling as it rotates and determine which springs are loosely tightened. We mark them with chalk, then tighten them. We begin to rotate the wheel again and if you feel that the wheel has become easier to spin, then everything has been done correctly. The process must be repeated to achieve a better result. After this, we check the result obtained while moving. If, as the load increases, the clutch begins to slip. All springs must be tightened using nuts. In this case, all nuts must be turned the same number of turns.