Purpose of the clutch IZ Planet and IZ Jupiter

Clutch - the name speaks volumes about the job it does.

In our case, the crankshaft engages the gearbox of the IZH Planet and IZH Jupiter engines. The connection should occur smoothly without jerking, this is necessary to start moving and smoothly change gears. In case of heavy loads, it protects engine parts from damage. The clutch is located in the left half of the crankcase, under the left engine cover.

To get to the clutch, you need to drain the oil and remove the cover with the gasket, first remove the levers and unscrew the mounting bolts.

The basket is constantly in working condition, the discs are tightly compressed by springs.

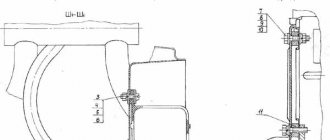

The motor transmission consists of two sprockets. The small drive is located on the crankshaft. A large star driven on a drum. The connection is made by a motor chain.

The engine gear ratio is 2.17 for all single-cylinder IZh models. For IZ Jupiter, the gear ratio is 2.57.

When assembling the motor transmission, the planar arrangement of the stars is controlled. No more than 0.4 millimeters are allowed.

Switching off occurs using a special device. The shutdown mechanism is installed in the right engine cover. This mechanism is used to make adjustments.

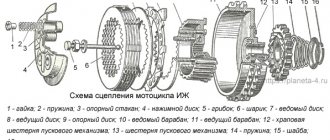

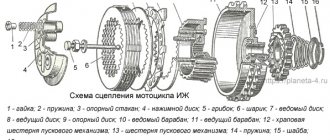

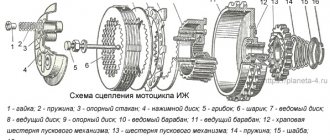

Clutch device of the IZH Planet 5 motorcycle

For those who are not good at technology, it is worth recalling that the clutch acts as a connecting element between the crankshaft and the gearbox. The large clutch gear is connected to the small crankshaft sprocket by a chain transmission, which is how torque is transmitted. In the normal state, the system ensures constant communication between the gearbox and the crankshaft and only when the clutch lever is pressed, the drive mechanisms increase the gaps between the elements in the multi-disc clutch system, thereby disconnecting the box from the crankshaft.

Owners of the IZH Planet 5 motorcycle are lucky; their clutch release system is simpler in comparison with the similar 5th Jupiter, which means it is unpretentious and easier to set up with your own hands. It looks like this:

- Shaped nuts;

- Springs;

- Cups;

- Pressure disk;

- Driven (steel) disk;

- Drive (plastic) disk;

- Driven drum;

- Large drum with large gear motor transmission;

- Clutch release pusher;

- Kernel;

- Ball;

- Spring;

- Worm;

- Cable;

- Washer;

- Screw;

- Screw.

Clutch adjustment IZH Planet

To adjust the clutch control mechanism of motorcycles IZH Planet 5, IZH Planet 4, IZH-56, IZH-49, use adjusting screw 1 and locknut 2. By loosening the locknut by turning the screw clockwise, reduce the free play of the control lever. When turning the screw counterclockwise, the free play increases. After completing the adjustment, tighten the locknut. The normal free play value is determined by the free movement of the end of the clutch lever by 5..10 mm.

The normal amount of free play is determined by the free movement of the end of the clutch lever by 5..10 mm.

Features of clutch settings

It is possible to check the correctness of the clutch settings by pressing the pedal in any direction. Moving the first end of the lever 3-5 mm from the neutral position should not affect the pressure plate, that is, it should not move. After completing this procedure, it is possible to adjust the manual squeeze using a specialized screw to make the adjustment. After this, the IZ Jupiter 5 clutch is assembled, during which it is necessary to strictly adhere to the sequence of all necessary actions.

- Photo report: Repair of the clutch of the motorcycle “Izh-Planet”, “Izh-Jupiter”

Clutch adjustment IZ Jupiter

On motorcycles IZH Yu and IZH Yu K, adjustment of the clutch release mechanism begins with the release mechanism, for which the adjusting screw is screwed in all the way and released 1/4 -1/2 turn, after which the lock nut is tightened.

The correct installation is checked by pressing the shift pedal in one direction or another. Moving the front end of the shift pedal 5-5.5 mm from the neutral position should not lead to movement of the pressure plate. After this, the manual release is adjusted using the adjusting screw located in the left post of the clutch lever on the steering wheel (the free play is 5-10 mm).

The clutch is driven by the Izh Jupiter. Adjusting the clutch of the Izh Planet motorcycle

Adjusting the clutch on motorcycles of the “Jupiter” series is complicated by the fact that here the clutch release must be synchronized in a certain way with the gear shift.

This is not at all difficult to achieve if you follow the established procedure and do not perform these actions thoughtlessly. First of all, you need to remove the left engine cover (after draining the oil, of course!) and, pressing the lever on the steering wheel, watch how the disks move in the grooves of the drive drum. In itself, this movement is insignificant, about 2 mm, so any, even the smallest, misalignment of the disks will lead to incomplete shutdown of the mechanism. By tightening or loosening the corresponding clutch spring nuts, achieve uniform movement of the entire disc pack. After this, tighten the clutch adjustment screw on the steering wheel until it stops so that it does not interfere with the free movement of the lever. And begin to carefully screw the clutch adjustment screw (Fig. 26) into the pressure plate until a noticeable stop appears. This is where you need to show special sensitivity with your fingers: not just turn the screw, but screw it in until it comes into contact with the pusher passing through the input shaft. (Try turning the screw in and out several times - and you will learn to determine this moment!) After contact, unscrew the screw 1/4. 1/3 turn and secure with lock nut.

Rice. 26. Adjusting the clutch of the Izh-Yu motorcycle

It remains to unscrew the screw on the steering wheel so that the free play of the lever, measured at its end, is 5.8 mm, and the adjustment is complete.

AutoNews / Reviews / Tests

How to Adjust the Clutch on Izh Planet 5

Adjust the grip of the IZH Planeta motorcycle

Adjusting the clutch springs

Adjusting the springs is not difficult, the main thing is to get it right. We start by placing the motorcycle on the center stand. Then remove the lid, draining the oil in advance. We squeeze the lever on the steering wheel to the limit and make sure to fix it. Next we turn on the speed, preferably the first one. We take the wheel and begin to rotate. We try to determine by touch how much effort we are applying. We look at the coupling as it rotates and determine which springs are loosely tightened. We mark them with chalk, then tighten them. We begin to rotate the wheel again and if you feel that the wheel has become easier to spin, then everything has been done correctly. The process must be repeated to achieve a better result. After this, we check the result obtained while moving. If, as the load increases, the clutch begins to slip. All springs must be tightened using nuts. In this case, all nuts must be turned the same number of turns.

Clutch setting

Adjusting the springs usually does not take much time and is not considered a complicated procedure. To carry out these actions, the motorcycle is placed on the stand, the oil is drained, and then the installed cover can be removed. After this, the special lever will need to be squeezed to the maximum and securely fixed. Then it is recommended to turn on the first or second speed, take the wheel and start rotating. Based on the load, we determine which springs are more tense and which are looser.

Then, when we have figured out which springs need to be tightened, we rotate the wheel to check the result. It is necessary to pay special attention to such a fairly important point that when the load increases, the clutch will not slip. After all of the above steps are completed, the IZH Jupiter 5 clutch basket is assembled. Adjusting the IZH Jupiter 5 clutch is important for stable and safe riding on this popular motor vehicle. Therefore, when you feel that it is necessary to carry out these actions, then you should not delay it.

Clutch faults

Possible malfunctions that may appear during operation of IZ motorcycles.

The clutch of IZH Jupiter IZH Planet is slipping reasons

The malfunction is noticeable during sudden acceleration. We increase the speed, but the motorcycle does not accelerate. The same thing happens when driving on a steep hill as the load increases. The motorcycle cannot overcome the obstacle and stops, although the crankshaft speed does not drop. The discs get very hot and wear out quickly. It is impossible to operate the equipment in this condition; the cause must be found and eliminated.

This malfunction indicates that the disks are poorly pressed against each other.

There may be several reasons:

- The adjustment was not carried out correctly

- The springs have lost their former elasticity

- The discs have worn out and become thinner.

- Wear of drive parts

A serious problem could be a jammed control cable. The reason is damage to the shell and the resulting rust underneath. Gentle cleaning and lubrication, better replacement.

Check and wash the adjustment mechanism itself located in the right engine cover. Small particles of road sand that get into the mechanism with water can slow down the operation. After squeezing the lever, the parts do not return to their original position.

Malfunctions and clutch adjustment of Izh motorcycles

There are two possible types of clutch malfunction: incomplete disengagement of the discs and slipping. If the motorcycle is slipping, it will not develop speed as the crankshaft speed increases. The reasons for this malfunction may include: wear of the discs, insufficient spring pressure due to loss of elasticity or loose adjusting nuts, incorrect adjustment of the clutch mechanism. When the clutch is not fully disengaged, the motorcycle wheel continues to rotate while the control lever is fully pressed. This may also be due to incorrect adjustment, or this malfunction may occur when thick oil is used, especially in cold weather. First of all, if you discover one of the clutch malfunctions, try to eliminate it by correct adjustment. First, you need to adjust the gap in the shutdown mechanism; this is done using the adjusting screw located on the right engine cover. To do this you will need a screwdriver and a 13 mm wrench. Using a wrench, loosen the locknut and use a screwdriver to tighten the screw until it stops, and then turn it in the opposite direction half a turn - one turn. Tighten the locknut with a wrench. Secondly, after this, adjust the free play of the lever using the cable adjusting screw on the left handlebar handle. It should be within 5-10 millimeters. The correct clutch adjustment can be checked in this way: place the motorcycle on a stand, engage first gear and try to manually turn the rear wheel with force. If the adjustment is correct, you will not be able to do this. Now you need to perform one more check: to completely disengage the clutch. To do this, in the same position (motorcycle on a stand, rear wheel not touching the ground), start the engine and engage first gear. Then fully depress the clutch control lever and apply the rear brake, the wheel should stop. Release the brake, the clutch is depressed, and the wheel should remain stationary if adjusted correctly. If it starts to rotate when the lever is pressed, you need to loosen the adjusting bolt on the right side of the engine.

To check the ease of movement of the clutch cable in the sheath, press the lever and release sharply. The lever should spring back to its original position. It may be worth lubricating the cable with a few drops of liquid oil, such as Autol.

"Sores"

“Planet” was good in its time, except for the ill-conceived launch mechanism. For those who have “Planet”, I think there is no need to explain what “return” means. Personally, once it gave so much that it tore the kickstarter shaft in half, bent the gearshift shaft and tore the ratchet on the clutch basket. Those whose slippers fly into the sky are lucky compared to my version...

Checking the clutch drum

The first step is to check the foot start ratchet mechanism. This is where the main load falls. Turn the clutch basket over with the ratchet facing you, remove the retaining ring and disassemble the ratchet.

We inspect the teeth of the ratchet: they should be sharp without chips or other damage. If the teeth are wrinkled or broken, the winding foot will slip 100%. Many suffer from this problem due to thick oil or a weak spring - in fact, the reason for the foot slipping lies in the ratchet.

If the teeth on the basket are not worn out, it is advisable to rivet the ratchet: buy a new one in the store or remove it from another basket and rivet it. I riveted several baskets and they went without any problems until the “victory”...

An example of ideal ratchet teeth.

Often and thickly, the rivets on the ratchet weaken and if you don’t notice this in time, they are cut off. To prevent this trouble from happening to you, move the ratchet with your fingers. If it wobbles, drill out the old rivets and rivet them again. Pulling old rivets usually does nothing.

If you are making a clutch “for yourself” and for a long time, be sure to check the condition of the teeth for the motor chain.

If the teeth have already begun to turn back, then such a basket should be immediately thrown into the trash. It will no longer be of any use: the operating noise will increase, it will 100% eat up the motor chain, and there’s never an hour when one “fine” day it will lick your teeth and you will then be forced to push your jalopy for a long time and tediously...

An example of worn teeth.

It is not uncommon for the basket body to burst. Unfortunately, the body is made of cast iron and welding it will be problematic. If you find cracks on the body, try to find a welder who welds non-ferrous metals, the so-called “argon welder”; they usually take on welding cast iron.

An example of cracks in the basket body. By and large, this basket can still be saved: chamfer the cracks, weld and turn the seams on a lathe. But the teeth under the motor chain were worn out and I threw it away.

Checking the clutch basket inner drum

The inner drum is eternal by definition. The only problem that arises with it is that it breaks and sometimes cuts off the splines and the fit of the bolts under the pressure springs becomes loose.

Place the drum on the shaft and swing it:

- If the drum dangles too much on the shaft, inspect the splines and if they are broken, replace the drum with a new one.

Loosen the bolts under the compression spring one by one:

- If the bolts wobble, knock them out of the drum, anchor the seats and hammer them back into the drum.

Checking clutch discs

The main clutch problems occur due to the fault of the discs. If the discs are crooked or worn out, then no amount of even a super couture adjustment will correct the poor performance of the clutch.

Wear is determined visually and only on plastic discs: we inspect the disc and if we find a crack or a broken hook on it, with which it enters the outer drum, or we see that the round protrusions on the working surface have long been worn out, we throw such a disc in the trash.

The curvature of the disks is determined as follows: place all the disks on the glass one by one and try to swing them

- If the disk wobbles, it means it is 100% crooked and should be in the trash.

- If the disk lies flat, leave it.

Adjusting the alignment of the motor transmission teeth

We put an adjusting washer on the input shaft of the gearbox, then we put the spacer sleeve of the outer clutch drum there. We put a spring washer on the crankshaft journal. We install the outer drum and the drive sprocket of the motor transmission on the engine, tighten the bolt on the sprocket. We apply a ruler to the sprockets and look at the alignment of the teeth under the motor transmission.

- If the teeth do not converge, we adjust their convergence by placing or removing adjusting washers under the clutch basket

In my case, the teeth of the basket and drive sprocket are aligned.

After adjusting the alignment of the teeth, remove the drum and sprocket from the engine and leave the adjusting washers and spacer sleeve.

We put the thrust washer of the kickstarter return spring on the gearshift shaft.

We put the kickstarter shaft on the shaft of the gear shift mechanism and insert the return spring hook into a special groove.

To avoid injury to your hand, tension the kickstarter spring only with the crank!

We put the claw on the shaft, tighten the bolt and, depending on personal preference, tension the spring. Personally, I tensioned the spring two turns. It turned out a little tight, but the paw didn’t dangle like snot and always returned to its place.

We install a basket with a sprocket and a motor chain on the shafts. We place a tin rod or stick under the chain and tighten the bolt on the sprocket with the maximum possible force.

We install the inner clutch drum on the shaft, put a special lock washer on it, screw on the nut, fix the drum with a puller and tighten the nut with the maximum possible force (left-hand thread, pull counterclockwise).

We look for the thickest one in the set of metal clutch discs - this is the thrust disc, it still has a groove on the inside - you can’t go wrong. We place the thrust disc with the groove towards the engine on the inner drum of the clutch basket, then we put a plastic disc and alternating the discs with each other we assemble the basket.

There can be 7 pieces of plastic disks on the “Jupiter” baskets. There are only 6 at Planetovskie.

We install the clutch rod into the input shaft of the gearbox: on “Jupiters” the rod is normal, on “Planets” it has a fungus. We put the pressure disk on the basket, insert the cups under the pressure springs into the holes of the pressure disk, then insert the springs into them and clamp the springs with special nuts.

Before installing the nuts, they need to be hammered: lay the nut on its side and hammer it into the flange with a chisel. Where to put it at risk, you will see: there are factory ones. There is no need to tighten the nuts tightly - screw them so that their ends are 5-6 mm higher than the bolts, this will be quite enough.

After final assembly of the clutch, we carefully adjust it.

Not all motorcycle enthusiasts can afford a BMW 1200 , and some simply ignore all the technological innovations of the “West,” preferring Soviet classics. The only thing is that the owners of such motorcycles experience not only a lack of spare parts, but also a hunger for information. This fully concerns the adjustment of the gear control mechanism, on which the efficiency of using the vehicle depends.

Functional purpose of the gearshift clutch

Before you adjust the clutch on the Izh-Jupiter 5 motorcycle, it’s a good idea to understand its purpose and principle of operation. The essence of the transmission clutch:

- Ensuring the transmission of torque from the large gear of the motor transmission to the gearbox input shaft.

- Short-term separation and smooth connection of transmission elements to each other.

Izh motorcycles were equipped with a mechanical clutch, the operation of which is based on the friction force between the driven and driving disks. It is a multi-disc design operating in an oil bath - a classic arrangement that the Izhevsk Machine Plant used until 2008. Working in tandem, the main chain drive and four-speed gearbox are reliable and proven by many generations of motorcyclists.

Motorcycle IZH-Planet.

Operation, maintenance and repair. >> Motor transmission, clutch, trigger mechanism. Clutch - disc replacement LLC "World of Autobooks"

Clutch - disc replacement

Before replacing the clutch discs, motor chain or drive sprocket, it is necessary to remove the left muffler from the left driver's footrest (with a two-pipe exhaust system), drain the oil from the power unit crankcase, or (for repairs on the road) place the motorcycle on its right side. If the fuel tank is full, the fuel must be drained or the tank removed.

The work is shown on a removed power unit.

Removing the clutch discs

1. Using a 12 mm wrench, loosen the pinch bolt of the gear shift lever.

2. Remove the lever.

3. Remove the washer.

4. Remove the O-ring.

4. Use a 14 mm wrench to loosen the pinch bolt of the kick starter lever.

5. Remove the lever.

6. Using a slotted screwdriver, unscrew the eight screws securing the left crankcase cover. If necessary, you can use an impact screwdriver.

Please note that the screws vary in length and some have aluminum sealing washers underneath.

7. Remove the cover along with the paronite gasket. Be careful not to tear the gasket.

8. Using a large slotted screwdriver, unscrew the five nuts of the clutch pressure springs.

9. Remove the five springs along with the caps from the inner clutch drum.

10. Remove the pressure plate.

11. We take out the driven and driving disks.

12. We lay out the disks in the order of removal, so that (in case of assembly without replacement) install them in their original places.

13. Inspect the clutch discs. The driven (steel) discs must not be deformed as a result of overheating, and the driving (plastic) discs must be free of cracks, burns and visible wear of the contact surfaces. The outer protrusions of the discs must not be damaged. If defective disks are found, we replace the entire set.

Installing clutch discs

We install the clutch discs in the reverse order.

Uniform compression of the springs is ensured by equal protrusion of the ends of the nuts above the ends of the studs. It should be equal to 4.0-4.5 mm (for new disks) and is measured with a caliper depth gauge.

The pressure plate should move without distortion or jamming. Otherwise, it is necessary to eliminate the distortions by additional adjustment with nuts.

Before installing the crankcase cover, it is recommended to degrease its seating surface and the crankcase seating surface, and apply a thin layer of sealant to them or to the oil-free gasket (on both sides).

The holes in the cover for the screws should also be degreased, and sealant should also be applied to the back of the screw heads.

Attention!

After installing all the removed parts, you should adjust the clutch drive (see below), and, in addition, repeat this adjustment after several hundred kilometers of the motorcycle, when the clutch discs have become accustomed to each other.

Contents :: Next >>

When is it necessary to repair and adjust the gear clutch on an Izh motorcycle?

Regardless of the amount of experience the motorcyclist has, the feelings regarding gearbox malfunctions are almost the same:

- At first it seems that the clutch is slipping slightly. After two or three days, confidence appears - yes, it is slipping, because as soon as you add speed, the acceleration rate lags behind the engine speed level. The breakdown is especially obvious when moving uphill.

- The clutch “leads” or the clutch is incompletely disengaged when the control lever is depressed. In such a situation, the disks of the assembly remain pressed against each other and do not stop transmitting torque to the gearbox. You can finally verify such a breakdown after lifting the rear wheel - it continues to rotate in this situation.

If you want to know how to adjust the clutch on a motorcycle Izh-Jupiter 5 , then information about the reasons causing the listed factors would be useful:

- Use thicker oil in winter.

- Weakening of pressure springs.

- Worn clutch discs.

- Wear of clutch control mechanism elements.

In most cases, if signs of slipping or incomplete disengagement of the clutch are detected, a simple adjustment of the mechanism is required. To do this, it is enough to have a “13” key and a slotted screwdriver.

Basic clutch malfunctions

One of the most common problems that occurs with the IZH Jupiter 5 motorcycle is clutch slipping. Almost all owners who use this model for quite a long time face this problem. This kind of malfunction indicates that the discs are not pressed together well enough and the IZ Jupiter 5 clutch needs to be adjusted.

The main reasons why this can happen:

- The IZ Jupiter 5 clutch was adjusted incorrectly.

- The installed springs have lost the required elasticity.

- The discs have lost their thickness due to significant wear.

- The drive elements are significantly worn.

Sometimes it feels like the clutch is dragging . A similar problem usually occurs when the lever is clamped to the maximum, but the clutch is not disengaged. In this case, the installed disks in some places touch slightly, and in others they fit tightly to each other. Adjustment of the clutch basket on IZ Jupiter 5 must be carried out in full compliance with the specified recommendations.

Life hack: how to adjust the clutch on an Izh-Jupiter 5 motorcycle yourself?

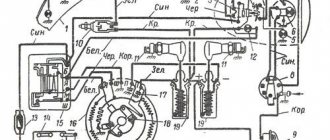

The adjustment procedure depends on the design features of Izhevsk motorcycles. The fifth generation is equipped with a shutdown mechanism, which is combined with a gear shift device. Adjusting the clutch control should begin by centering the machine's cam relative to the roller with the lever, which are mounted on the body of the right crankcase cover.

First of all, the distortions of the pressure plate (No. 1 in the photo) are removed, for which the lever on the steering wheel is secured with wire or rope in the squeezed position. Next, turn on 1st speed and rotate the rear wheel, while observing the axial runout between the pressure plates and the end of the drum. The nuts (No. 2 in the photo) that are closer to the point of maximum deflection need to be tightened, and the tightening force should be determined experimentally. Repeat the operation until the runout becomes minimal.

The following operation is performed when the gear shift unit has been disassembled for repair, or after replacing the right crankcase cover. Motorcycle owners interested in how to properly adjust the clutch on an Izh-Jupiter 5 should definitely familiarize themselves with the work technology:

- Disconnect the cable end from the clutch control lever on the steering wheel.

- Between the end of the weakened fastening of the machine cam and its cotter pin, install such a number of washers so that the gap between them and the cotter pin is no more than 0.4 mm.

- Tighten the cam bolt with enough force to prevent the cam from turning.

- Place the right crankcase cover in its original place and secure it with screws.

- Remove the hatch on the left crankcase cover, loosen the locknut and tighten the adjusting screw until it touches the thrust rod, then tighten it another 2-3 turns.

- Move the gear selector pedal up and down by 20-25 mm, then carefully remove the right crankcase cover.

- Without changing the position of the cam on the shaft, tighten the bolt securing it with a force of 2-2.5 kgm .

- Replace the right crankcase cover and remove the adjustment screw.

- Screw the adjusting bolt until it touches the thrust rod, then unscrew it half a turn and secure it with a locknut.

You can check the correct setting by pressing the foot switch pedal. In this case, moving the front end of the pedal 5-6 mm from the neutral point should not lead to movement of the pressure disk; as you continue pressing, the disk should move without distortions. The final adjustment is made with a special screw on the steering wheel bracket; the free play of the end of the lever should be within 3-5 mm .

Experienced motorcyclists who know how to properly adjust the clutch on an Izh-Jupiter 5 motorcycle note the following points:

- A properly adjusted clutch begins the shifting process at the moment when the lever is released by half or a third of its full travel.

- If the upper rule is not followed, then slippage should be expected under severe loads.

- If there is no free play of the lever, then the force of the clutch springs is spent on stretching the cable rather than compressing the discs. In difficult conditions, when maximum traction is needed, the clutch may not work.

Adjusting the IZH Jupiter clutch

On IZH-Yu and IZH-YUK motorcycles, adjusting the clutch release mechanism begins with adjusting the machine, for which the adjusting screw is screwed in all the way and released 1/4.1/2 turn, then tighten the lock nut. Correct adjustment is checked by pressing the switch pedal in any direction. Moving the front end of the shift pedal 5-5.5 mm from the neutral position should not lead to movement of the pressure plate. Then adjust by manually pressing the adjustment screw located in the left column of the clutch lever

on the steering wheel (free play 5-10 mm)

An important detail - the cable

Owners of used motorcycles do not always take into account the essential role of the cable in the clutch control system. The cable itself is practically not subject to stretching, but the sheath loses its qualities. Its frame is a spiral under a layer of PVC.

After prolonged use, the frame becomes pliable and excessively springy, which affects the useful stroke of the lever. If the cable sheath is worn out, the clutch will not operate normally, so it is important not to miss the moment and replace the cable in a timely manner.