Frame in a winter bike

The cyclist is lucky in this matter, since he can choose the frame according to the material from which it is composed. We will look at all frame options for winter skiing so that you can make the right choice and skate for several seasons without any problems.

Aluminum

This is the most common option, which is also inexpensive. Aluminum frames withstand aggressive influences. A chemical film quickly forms at the site of damage, which serves as protection. Therefore, if small chips of the paintwork occur, you don’t have to worry about the frame; it will withstand such a nuisance.

A winter bicycle requires its user to periodically check the aluminum frame for damage. The most attention should be paid to the right chainstay and dropouts, because these are the places that are most exposed to mechanical stress. To reduce the negative impact and extend the life of the frame, special linings or neoprene covers are put on these places. But first you need to treat and paint over the chipped areas.

Another nuance concerns welds, which also require increased attention. Due to the insufficient ductility of aluminum, fatigue stress can accumulate in the welding area. If in summer a small crack does not cause any particular trouble, then in winter, due to a sharp change in temperature and water ingress in this place, a big problem can arise. Therefore, all cracks will need to be treated before the onset of frost.

Steel

Steel, no matter how high quality it is, can rust. This is not a contraindication, you just need to inspect the frame more carefully and carefully prepare the bike for winter riding. Any chipped paint coating must be thoroughly cleaned, treated with a primer and paint applied.

Dropouts suffer the most from winter driving. It is possible to put them in order, but it is a complex and lengthy process. If before winter it was not possible to properly treat the rear part of the frame, then it must at least be lubricated. Litol, grease, anticorrosive, Movil are suitable for this. The latter option can also be used to process a bicycle frame from the inside.

Magnesium in alloys

A bicycle with such a frame should absolutely not be used for winter riding. Magnesium is a very active element, so it quickly reacts with many elements. If you regularly ride on snowy city streets that are liberally sprinkled with salt, the frame will be completely damaged.

Bicycles with magnesium frames are most often used for racing or at least for high-speed riding, they cost a lot, and it would be a shame to lose such cross-country transport in one winter season.

Titanium

A bicycle with a titanium frame can be considered an ideal option for winter riding. This material is characterized by chemical resistance, which does not change even when exposed to aggressive factors and sudden temperature changes. Titanium does not even need to be painted, since it does not need such protection, and its natural color and texture already look noble.

Even corrosion is not a problem for this material, with the exception of welding areas. In general, working with titanium is very difficult. Welding a high-quality titanium frame can only be done in a professional workshop that has the equipment suitable for this.

Finding a high-quality titanium frame for a bicycle is a great success that smiles only on a few. And a frame with poorly executed welds in Russian winter conditions can collapse even faster than an inexpensive aluminum model. So now think about whether it’s worth tempting fate and hoping that a titanium specimen that was welded by professionals in the proper way will fall into your hands.

Carbon

On the one hand, carbon fiber is not susceptible to the effects of salts, dirt and other aggressive elements. But, on the other hand, at sub-zero temperatures carbon becomes brittle. No one is immune from falling on a bicycle, especially in the winter. The only thing left to add is the high cost of carbon frames.

What can a snowmobile be made from?

In the first stages of developing a homemade snowmobile, you need to decide on the choice of the so-called donor, that is, the vehicle on the basis of which the process of building the snowmobile will take place. There are not many options here, but there are quite enough of them to choose the most suitable one for you. Basically, homemade snowmobiles are built on the basis of the following power units:

- Motorbike

- Chainsaw

- Walk-behind tractor

You can choose the option that suits you best from this list. The only thing worth remembering is the output power of the snowmobile. It is quite logical to assume that a snowmobile made on the basis of even the simplest motorcycle will be much faster than a snowmobile with a chainsaw engine

A walk-behind tractor will also be more powerful than a chainsaw, but a motorcycle still remains the best option if you take into account the power of the resulting vehicle. In our review we will analyze the designs of a motorcycle and walk-behind tractor

So, how to make a snowmobile with your own hands?

How to make a snowmobile bike with your own hands

For a long time, cyclists have been thinking about how to convert a bicycle into a snowmobile, so that in the summer they can again use it for its intended purpose. So that the bicycle has the ability to transform into a snowmobile and back. Anyone can do it. A do-it-yourself design has the following advantages:

- a mechanical drive with wheels made from large car inner tubes will not get stuck in snowdrifts:

- the control located in front of the structure will make it easy to control the snowmobile;

- the low price of components for a homemade device will save money.

What can you take from your bike?

To make a snowmobile bicycle at home, you will need almost all the parts of the bicycle - frame, fork, seat. It is best to make a snowmobile from a mountain bike or other bike with a frame made of titanium, aluminum, stainless steel - light and durable, with several speeds. It is better to install a motorcycle power unit on a snowmobile as an engine because it is lightweight, but has great power and good speed.

A self-made snowmobile can reach speeds of up to 30-50 km/h on a flat road. A snowmobile derived from a bicycle can carry only one person with a body weight of up to 80-100 kg and take with it a small load. When manufacturing a snowmobile, only strong and durable parts are used.

Chainsaw parts

The chainsaw engine has great power, so it is widely used in various modifications, including when converting a bicycle into a snowmobile. The engine installed on a snowmobile covers a distance of up to 15 km and does not use much fuel. A homemade design with a chainsaw engine has the following advantages:

- good adaptation to different weather conditions;

- low fuel consumption for internal combustion engines;

- ease of care and maintenance of the engine - all that is required is the use of high-quality gasoline and regular lubrication of the gearbox.

Kamaz cameras

On a slippery or covered with loose snow road, the assembled snowmobile will slip. To increase wheel grip, it is better to use large-diameter tubes. For a homemade device, cameras from KAMAZ are suitable - this will ensure good stability of the snowmobile bike. The truck tires are wide and sink less into the snow. It is better to buy cameras in special stores or markets selling special equipment.

Use cameras that have been used only after checking for ruptures, cracks, and other damage. To avoid an emergency.

Working with the drive part of vehicles

First, remove the rear wheel from the bike. Instead, a tracked chassis will be installed. If you couldn’t buy ready-made tracks, then we make them from rubber with our own hands. You should cut a strip about 40×50 cm wide. We stuff metal, plastic or wooden strips onto one side of the prepared piece of rubber. These small elements for the snowmobile will serve as snow hooks, so it is best to make them higher. We connect the edges of the rubber to each other to form a closed piece with snow hooks on the surface.

We assemble the wheels in pairs on the axle. Taking into account the diameter of the wheels and the length of the assembled track, it is necessary to make a frame that will serve as a common platform for all three pairs of rollers. We mount two pairs of wheels tightly to the frame, and the third outer pair is movable in a horizontal plane. Its mobility will ensure good rubber tension, and as a result, prevent the tracks from slipping. We attach the sprocket from the rear wheel of the motorcycle to the axle of the first pair of wheels.

The assembled frame with track must be installed at the rear of the bicycle. This can be done by welding the drive frame to the bike frame with plates. However, if the frame is large, made of titanium or aluminum, then the drive should be secured with bolts, since at home it is unlikely to be able to weld to non-ferrous metal. The distance from the caterpillar to the frame must be at least 5×10 cm.

Let's start installing the power unit on the snowmobile. The best place for the motor is the horns behind the seat. There the engine will not interfere with your legs and there will be no fear of getting burned on it. However, you can place it in the center of the frame, but only with the top trim. It is worth noting that it is best to place the engine with the shift paw in the middle of the frame, and it is advisable to place the motor with the gear shift on the steering handle at the rear.

The engine is placed on the snowmobile so that its sprocket is above the track drive sprocket. When installing the power unit, additional welding of the plates and channel will be required to fix it on the bicycle frame. You should know how to weld them on site. After this, you need to make a chain of the required length and connect the sprockets. We mount the tank as close to the engine as possible.

Thus, the snowmobile is almost assembled. We install all the power unit controls and the brake bar. For comfort, select a more comfortable seat.

So, it’s not difficult, you can assemble a snowmobile without major investments, which uses a bicycle as a base. You can modify the snowmobile with your own hands at your discretion, but the above diagram will be quite sufficient for driving through snow-covered fields.

A snowmobile is a good means of transportation in winter. It is capable of reaching speeds of up to 70 km/h, is highly maneuverable and quite economical. Unfortunately, the cost of branded products is quite high, and not everyone can purchase them. However, homemade snowmobiles can be a way out of this situation. They can be made from scrap materials and their price will be relatively low.

What can you take from your bike?

It would seem that there is nothing to remove from a bicycle to make a snowmobile. However, to make a snowmobile with your own hands you will need almost the entire bike. In particular, for a bike, you will need the entire frame, fork, and seat.

In order to make a snowmobile, it is best to use a mountain version or any other with a reinforced, lightweight frame and a wide range of speeds. It is advisable to use a motorcycle engine as a power unit. It has a small mass, but at the same time produces quite good torque and speed. In particular, you can take the engine from the Minsk motorcycle. or ?Izh?.

With your own hands you can make a snowmobile that can accelerate to a speed of 30–50 km/h on a flat track. Winter transport from a bicycle is designed for one person, whose weight is up to 80–100 kg. At the same time, the snowmobile can also move a small additional load.

In addition to spare parts for the bike, you will need the following parts and products:

- a ski with a length of 60 to 80 cm and the wider the better;

- two pieces of iron pipe with a diameter of up to 50 mm (it is best to use a lightweight aluminum pipe, but with a thick wall);

- a piece of channel or U-shaped bracket;

- metal plate 25×50 mm wide and 4×5 mm thick;

- square profile;

- thick rubber or ready-made tracks. Finished products for the chassis can be found on the construction equipment market. For example, the tracks needed for a snowmobile will fit from a mini-excavator;

- three pairs of metal (preferably) wheels from a small cart.

Tools you will need:

- set of wrenches;

- pliers;

- hammer;

- welding machine;

- drill.

[ads-pc-1]

Snowmobiles

Snowmobiles are not cheap machines, especially new ones, and even from the world’s leading manufacturers. What about those who, being keen on fishing, hunting, tourism, sports, see a snowmobile, as they say, in a dream or in reality, but do not have sufficient funds to purchase a new car? Of course, you can “stick your head in the credit loop” by paying, albeit in installments, for a new snowmobile an amount that is almost double its actual and already high cost. However, there is another and, perhaps, the most optimal way out of this situation, namely: buy a used snowmobile. And if, after thinking and once again carefully assessing your capabilities, you nevertheless make just such a decision, be careful and do not act rashly.

A used snowmobile is the same as a used car: you can buy it, but carefully and with great care, observing a number of certain conditions in order to buy, as they say in Odessa, “a thing, not junk”

The sale of used snowmobiles is carried out mainly by quite decent people who will openly tell the buyer about all the weak points of the machine and advise what needs to be paid attention to during operation. However, unfortunately, there are those who like to deceive, and just for this case - a few tips for novice buyers

Today, shops and markets sell snowmobiles, both new and used, for a variety of purposes and from a variety of manufacturers. YAMAHA snowmobiles. ARCTIC CAT snowmobiles, POLARIS snowmobiles, domestic snowmobiles - it’s simply impossible to list the entire range. At the same time, Yamaha snowmobiles and other snowmobiles from leading foreign manufacturers, as a rule, are quite reliable even after several years of operation. However, having chosen a specific machine, you should contact a competent specialist before making a final decision. If for some reason this is not possible, perform an inspection yourself, but keep in mind: it must be extremely attentive and meticulous.

First of all, make sure that the geometry of the body is correct and that there are no dents or other external damage on it.

It is very important that there are no chips, gaps, cracks on the plastic surfaces of the body and its mating parts - the consequences of a possible accident

Also pay primary attention to the condition of the track: it should not be worn out or torn. Remember that a new caterpillar will cost you no less than a thousand conventional units

Next, of course, is the engine. Determining its condition visually is very difficult, if not impossible. It is good to have a compression gauge with you and measure the compression in each of the cylinders, making sure that it is present and that there are no discrepancies in the values.

The next point is the condition of the variator, oil, and suspension elements. After checking everything and making sure that it is in working order, ask the seller to start the car and evaluate the rhythm of the engine by ear. It is necessary to try the snowmobile on the move: there should be no knocking, grinding or other extraneous sounds. The car should move smoothly, without jerking, “diving” or jumping.

And in conclusion, one more piece of advice. Today, many localities offer snowmobile rentals. Before you shell out a considerable amount of money to buy a snowmobile, even a used one, think: doesn’t it make sense for you to use this type of service at least initially to gain experience?

: A homemade bicycle with a screw-pull motor or an aero bike.

How to make a snowmobile from a bicycle

Every boy and adult who loves nature and rides on any type of transport, at least once, has dreamed of his own snowmobile, on which any snowdrifts can be overcome and any distance can be overcome in order to drive through the snow for fishing or just for fun, to see to new places where you have never been before.

However, snowmobiles are not a cheap pleasure, and all dreams are shattered by the sad reality of the majority of not very rich people.

What should an ordinary average person do in this situation, when he really needs to be able to go fishing in the snow, etc.?

Puzzled by such a problem, one talented craftsman thought about it and came up with a new means of transportation through the snowdrifts.

Calculation and assembly of caterpillars

The caterpillar is a tape, on the outer surface of which tracks are attached. Tracks are rigid lugs installed along the entire length of the tracks. Track options:

- Made from 3mm thick transport tape.

- From a car tire.

- From V-belts.

- Ready-made factory-made tracks.

The conveyor belt must be looped. Its strength is only sufficient for light snowmobiles with engines no more powerful than 10 liters. With. Car tires are stronger than tape and are suitable for powerful engines. Solid tires do not need to be looped, so the likelihood of a rupture is minimal. It is more difficult to choose a tire of the required length than a tape.

Finished tracks are removed from other similar equipment (snowmobiles “Buran”, “Sherkhan”). They are equipped with lugs from the factory. The products are not suitable for use with low-power motors from walk-behind tractors. Homemade snowmobiles made from Buranovsky tracks must have gears from the same “donor”.

The size of the caterpillar is selected according to the required driving characteristics: the larger the width, the lower the handling, but the higher the maneuverability. The minimum area of the contact patch from the snowmobile (skis and tracks) must be such that the pressure from the equipped vehicle does not exceed 0.4 kg/cm2 of surface. Light snowmobiles use a 300 mm wide conveyor belt, cut lengthwise into 2 strips of 150 mm each.

Preparing the Tape

The tracks are attached to homemade tracks with M6 bolts with a wide head. The bolts are fixed with a nut, a washer and a groover are used. Before fastening, leading holes with a diameter of 6 mm are drilled in the tape and tracks. When drilling, use a jig and wood drills with special sharpening.

The conveyor belt is also looped with M6 bolts. To do this, the edges of the tapes are overlapped with an overlap of 3-5 cm, the connection contains 1-2 rows of bolts. For a 150 mm wide track, the following distances are maintained:

- From the edge of the tape 15-20 mm.

- Between bolts on tracks 100-120 mm.

- Between the bolts when banding 25-30 mm.

In total, one track requires 2 bolts, and one belt connection requires 5-10 bolts, depending on the number of rows. When using car tires, only the tread is left, and the sidewalls are removed with a shoe knife.

Homemade lugs

The tracks are made of polyethylene pipe with a diameter of 40 mm with a wall thickness of 5 mm, sawn in half in the longitudinal direction. The entire section of the lug is adjacent to the tape. In light snowmobiles, one track connects the tracked pair. With a track width of 150 mm, the track length is 450-500 mm.

The lugs are cut using a wood circular saw. They use a special machine with two guides (metal and wood), rigidly fixed on a fixed tabletop. The walls of the pipes are sawed one by one.

The distance between the tracks depends on the parameters of the gears on the drive shaft. Typically 5−7 cm. The specified distance is maintained with an error of no more than 3 mm. Otherwise, the operation of the drive is disrupted: the lugs “run” onto the teeth of the drive wheels, the caterpillar begins to slip and fly off the rollers.

Assembling the front part of the snowmobile

The pipes are attached symmetrically to each other. To give additional rigidity to the extensions constructed on the fork, we drill through holes in the middle of the length of the tubes and tighten them together with a long bolt or pin. After this, we cut the fixed tubes to length so that they are 20–30 cm longer than the bottom of the bicycle.

Let's return to the ski with the bracket. It is necessary to make holes symmetrically to each other on both sides of the channel/bracket. At the edges of the tubes (near the ground) on the fork we drill holes of the same diameter as in the channel. The holes must be at least 11–13 mm. Now we connect the extended fork to the ski through the holes. To do this, we use a long bolt M10-M12. Thus, the ski is installed on the snowmobile. At the same time, it remains movable in the vertical plane, which allows descent/ascent at different angles. You can control the vehicle by turning the steering wheel, just like on a bicycle.

Step-by-step instruction

Before starting work, calculations are made of all design parameters, draw a diagram of the snowmobile on a sheet of paper, prepare all the parts and tools:

- wide ski up to 80 cm long;

- two small metal pipes with a cross section of 50 mm;

- a small piece of channel;

- a metal plate measuring 25x50 mm, thickness 4-5 mm;

- cameras from a KAMAZ vehicle;

- wrenches of different sizes;

- hammer;

- pliers;

- electric drill;

- welding machine.

Assembling the front part of the snowmobile

It’s best to start by replacing the front wheel with a ski to reduce friction with the snow. Making your own skis is not difficult. To improve the quality of the structure, it is recommended to make skis from duralumin or chipboard.

- To do this, take 4 pieces of plywood with a thickness of 5 mm. Pieces of plywood are glued together and attached to the steering base.

- Then a spring made of high-strength steel is well secured to the structure. Instead of a homemade ski, an old skateboard or out-of-use factory skis are also used.

- The next step is to remove the front wheel of the bicycle. Then fasten the piece of channel in the center to the prepared ski - this is done using four M8 or M10 bolts.

- Then cut two pieces of pipe of the same size, attach them to the bicycle fork - one pipe for each arch of the bicycle. To make the structure strong, it is better to secure the pipes to the bicycle fork using clamps or clamps - use at least two fasteners for each fork arc.

- The pipes must be fastened symmetrically relative to each other. To make the structure durable, rigidity is added. To do this, through holes are drilled in the middle of the tubes, which are tightened together with bolts.

- The tubes attached to the bicycle fork bars are cut to be 20-30 cm longer than the bottom of the bicycle.

- The ski is mounted with a bracket. To do this, symmetrical holes are drilled on both sides of the channel. At the edges of the fork tubes, holes are made the same size as in the channel - no less than 11-13 mm. The structural element is connected with long M10-M12 bolts.

- To strengthen the frame at the joints of the parts, weld a transverse pipe to the bottom of the steering wheel. You need to attach the ski attachment to the transverse pipe using hinges.

- Using a washer, bushing, steel pin, and two nuts, assemble the hinge joint.

Working with the drive part

Work begins with dismantling the rear wheel. Then the wheels, made by yourself, are installed. It is recommended to install wheels with low pressure - they are elastic, have a small mass, and do not put pressure on the ground. Wheels with large chambers have good qualities - increased maneuverability and efficiency. If car inner tubes are filled with polystyrene foam, this will save them from the accumulation of snow, dirt, and ice. The design of the chassis and rear drive is simple and does not cause difficulties in making a vehicle yourself.

Snowmobile with a walk-behind tractor engine and inner tubes

The walk-behind tractor practically does not have to be redone if you upgrade the original wheels. You will need lowered tubes from the truck. Five of them are pulled onto each wheel and secured with chains. The cameras are pumping. Due to the fixation with chains, their shape becomes like a daisy with segments in the form of an ellipse. The new wheels will handle deep snow well.

Another wheeled snowmobile can be built from a walk-behind tractor by putting steel hoops on the inner tubes instead of chains. They are equipped with tracks on the outside. The jumpers are welded from metal plates. The height of the track is about 2-3 cm. After inflating the chambers, the metal hoops will be securely fixed to the wheels.

Homemade snowmobiles from a walk-behind tractor

Not every walk-behind tractor is converted into a snowmobile, so before purchasing a power unit, pay attention to the following technical features:

- Availability of rear towbar.

- The engine is not lower than middle class.

- Manual control is required.

- Air-cooled motor.

When the power unit has been purchased, proceed to its conversion. The main tools and parts that will be needed for this are a small list:

- welding machine;

- pipe bender;

- tracks, two wide skis or wheels;

- auxiliary details.

The main thing is to select all the parts necessary for the transformation. Some of them are made independently. Design begins with choosing a snowmobile model. Snowmobiles are divided into two main classes: wheeled snowmobiles and tracked snowmobiles. It is advisable to first make a layout.

Converting a walk-behind tractor into a snowmobile

The first and second stages consist of manufacturing the frame and mounting the power unit:

- The frame is made from old motorcycle or car pipes. A pipe bender will help to shape it.

- The joints are processed by spot welding.

- We move the engine to the center of the housing structure.

- We place the engine on a specially made platform with fasteners for fixing the motor itself.

The installation of the steering wheel and seat is chosen by the master independently - the main thing is that it is comfortable to operate the device. Depending on the engine power, the snowmobile can accommodate several passengers.

The third stage is to install the skids. Most often these are two wide skis that are attached to the steering column using hinges. The front part, which secures the runners, must be equipped with shock absorbers.

Instead of skis, you can use tracks or wheels (pneumatics). Each option has its pros and cons.

Drawing of a simple snowmobile

DIY mini snowmobile

Mini snowmobiles are very popular means of transportation in the winter season. Such a unit is found in the suburbs, but in the village it is simply irreplaceable. At the same time, mini snowmobiles have many advantages over standard snowmobiles:

- High cross-country ability and maneuverability.

- Economical fuel consumption.

- The method for making a mini-snowmobile does not pose any difficulties.

- Available materials for manufacturing.

- Takes up little space in the garage.

Thanks to its compact dimensions and minimal weight, the unit passes through the most inaccessible places and practically does not fall into loose snow. If you carefully think through all the manufacturing nuances, you can get by with minimal financial costs for re-equipping the unit.

DIY snowmobile: photo of step-by-step assembly

1. Disassembled snowmobile. 2. Assembling the snowmobile begins with installing the engine on the track motor.

3. Two rods are attached to the caterpillar mover, connecting it to the transverse beam on which the rotary skis and steering column are mounted.

4-5. The front pillar and the seat support arch are inserted between the rods.

6. The beam with swivel skis and steering wheel is connected to the caterpillar drive.

7. The parts of the snowmobile are connected to each other using pins and bolts with wing nuts.

Below are other entries on the topic “How to do it yourself - for a homeowner!”

Self-propelled children's snow scooter with a gasoline mower engine

Every fisherman, hunter, and just a lover of extreme sports, of course, dreams of a snowmobile. To go fishing or in the forest or just take walks and admire nature. But all snowmobiles, even at the lowest price, are beyond the means of the common man, and this type of transport is very necessary. What should a common person do in this situation? So the author spent a long time racking his brains about what to do, where to get so much money, it’s unrealistic. But a little later he was struck by the idea of creating a snowmobile from a bicycle, a kind of recreational snowmobile. There was an old broken bicycle lying in the garage, and it became the donor for the creation of an all-terrain bicycle. And so, what is this design - the rear wheel is a pneumatic roller or mono-wheel, in the front part is a ski, which was made from an old skateboard. The rear fork has been converted to a mono-wheel, which is essentially the whole point of this design. Now let’s take a closer look at how the author carried out the work of creating a snowmobile from a bicycle and what he needed for this.

Materials:

old bicycle, inner tube from a Niva car, tarpaulin, aluminum sheet, old skate board, pipe.

Tools:

welding machine, grinder, hammer, set of wrenches, lathe, sandpaper, glue.

Next, he made the wheel; he made no design changes; he simply made an extension from an aluminum sheet.

Then I put a tube from a Niva car on the wheel and made a canvas cover for the wheel. On the front part I installed this ski track from an old skate board.

Other devices

You can easily and quickly make an angle grinder from a saw that can work autonomously and have high power. For such a transformation, you need to buy the necessary attachments at a building materials store that will help transform one tool into another. To reduce the likelihood of blade breakage, the saw can be equipped with a protective casing, and the number of revolutions can be reduced with a high-speed gearbox.

A good solution is to make a portable generator set from a saw. It will come in handy in a summer cottage where there is no electricity. A power of twelve volts will be enough to provide illumination as from a normal flashlight.

By connecting the inventor, you can convert the energy to 220 volts.

Among the useful homemade products you can add a motor to an inflatable boat, a motorcycle (you will need more than one saw for it), and a light aircraft.

Classification of children's snowmobiles

The electric children's snowmobile runs on rechargeable batteries. Such power supplies do not require any maintenance other than periodic recharging. Self-discharge is completely eliminated due to the special design of the batteries.

Some children's vehicles use gasoline engines as their power source. Different types of motors are installed on such vehicles. Children's snowmobiles with two-stroke gasoline engines are lightweight, easy to maintain, warm up quickly, and can run on cheap fuel. Four-stroke engines make less noise during operation. They have lower fuel consumption and a much longer working life.

Some motors have an air cooling system. It must be used correctly to prevent overheating. The hydraulic cooling system uses ordinary snow.

Injection engines have a number of advantages: stable operation, environmental friendliness and efficiency. They are not reliable and are not recommended for use in field conditions. It is advisable to refuel the engines in children's snowmobiles with unleaded gasoline to reduce harmful emissions and increase engine life.

Working with the drive part of vehicles

We assemble the wheels in pairs on the axle. Taking into account the diameter of the wheels and the length of the assembled track, it is necessary to make a frame that will serve as a common platform for all three pairs of rollers. We mount two pairs of wheels tightly to the frame, and the third outer pair is movable in a horizontal plane. Its mobility will ensure good rubber tension, and as a result, prevent the tracks from slipping. We attach the sprocket from the rear wheel of the motorcycle to the axle of the first pair of wheels.

The assembled frame with track must be installed at the rear of the bicycle. This can be done by welding the drive frame to the bike frame with plates. However, if the frame is large, made of titanium or aluminum, then the drive should be secured with bolts, since at home it is unlikely to be able to weld to non-ferrous metal. The distance from the caterpillar to the frame must be at least 5×10 cm.

The engine is placed on the snowmobile so that its sprocket is above the track drive sprocket. When installing the power unit, additional welding of the plates and channel will be required to fix it on the bicycle frame. You should know how to weld them on site. After this, you need to make a chain of the required length and connect the sprockets. We mount the tank as close to the engine as possible.

Thus, the snowmobile is almost assembled. We install all the power unit controls and the brake bar. For comfort, select a more comfortable seat.

So, it’s not difficult, you can assemble a snowmobile without major investments, which uses a bicycle as a base. You can modify the snowmobile with your own hands at your discretion, but the above diagram will be quite sufficient for driving through snow-covered fields.

Powerful snowmobile bike

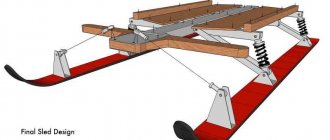

Inspired by the Discovery Channel show “American Chopper” and seeing my neighbors riding around in their snowmobiles, I decided to create a crazy combination of one and a pedal-powered snowmobile. I designed and built this bike in three weeks using parts from three broken bikes, steel tubing and corner extrusion, and a track from an old 1990 Polaris snowmobile.

Step 1: Thinking through the insides

Once you've got the right tools, parts, and as many bikes as possible in one place, start thinking about how you'll assemble your track and bike frame. Children's mountain bikes with 20-inch rims fit perfectly into the snowmobile truck, and the textured tires fit snugly in the gap where the sprocket should be. I have found that the limited space inside the crawler is better suited to a 3 wheel configuration than a 4 wheel configuration.

Start by disassembling two bicycles to assemble the interior of the future snowmobile. Disassemble the bike down to the frame with pedals. trim the frames so that they fit well inside the crawler and do not interfere with rotation. The frames will be located parallel to each other inside the crawler track.

You need to connect the two frames together by welding the chainstays and top stays of the additional frame to the inside of the two-wheel frame. The third wheel should also fit snugly into the gap in the track. When welding frames, you need to remove the paint from the metal surface. *Make sure that the assembled structure of the frames and wheels fits tightly to the track surface, so that when inflating the wheels, the tires adhere well to the track without additional equipment.

Step 2: Making the drive

I originally wanted the pedals to be in front of the crawler. But for convenience and simplicity of design, I decided to use a traditional pedal design, placing it inside the caterpillar track. Of course, the pedals will have to be turned on both sides of the wide track, which can create inconvenience. But in reality it turns out better than it seems: in a vertical position, the pedals extend beyond the top edge of the track, so pedaling is quite comfortable. Since we have two frames, both pairs of pedals must be positioned perfectly evenly in relation to each other, since when the pedals are twisted, one single axis will rotate. Also, the distance from the system to the axle of the drive wheels must be the same so that both wheels rotate the track together.

My two frames didn't fit together perfectly, so I needed to cut new dropouts into one of the frames to properly connect them together. If you, like me, use two different frames, you will have to tinker with the connection. The most convenient way to do this is with dropouts.

When everything is adjusted, you need to remove the two inner pedals and cut off the levers, leaving a small fragment for welding. You can connect two cut internal arms by welding a piece of metal corner. This connection synchronizes the two frames when pedaling. The connection must be secure, so firmly weld the corner to both arms. The gear ratio in both frames must be the same so that both drive wheels rotate synchronously.

Now we have something like a tank unicycle :)

Now we need to construct the final outer frame to attach the seat and handlebars. I simply welded angle steel segments to the frames where the pipes were attached. Steel pipes will extend from them to the seat mounting axis. Then you need to attach the pipe sections to the front and back, as shown in the photo. Cross pipes are needed to attach the seat and steering rails. They are connected by a long transverse pipe. This design allows you to drill holes in the profile and pipes, and find the optimal position for the frame parts. You can bolt it together and adjust the position of the pipes. When everything is debugged, it is enough to simply weld the bolts so that the frame becomes solid.

I left a few of the fasteners unwelded so that the top frame could be unscrewed and stowed away as a separate modular unit in case the track had to be removed for repairs.

The mountings of vertical tubes to bicycle frames must be strong enough not to break under the weight of the rider. They should also not touch the chain or other moving components inside the track. The most convenient way to secure the frame seat tube is at the intersection of the horizontal beam and the long cross tube.

Step 4: Steering Gear

The movement of the bike is complicated by the presence of a heavy track with strong friction on the ground, as well as the combination of the track with a regular front wheel. And if you make it heavier and thereby increase the friction of the wheel on the ground, this will make the bike even more difficult to control. The bike is very heavy, so don't expect any windy rides from it. I decided to use the front frames from disassembled bikes to make the steering gear as lightweight as possible.

I arranged the two head tubes so that the handlebars could be rotated in a traditional way to change direction, but also on a horizontal axis to allow the front wheel to be freely raised and lowered. This steering allows weight to be redirected from the track to the front wheel for better control of the bike. I extended the frame by adding a handlebar mount made from two steel angles (see photo). This moved the front wheel away from the track and the bike was over 2m long.

The addition of long angle bars and Ghost Rider style handlebars allows for better control of the bike from the back of the seat and gives enough leverage to lift the bike (front wheel) while sitting on it. This unconventional way of transferring weight during steering takes some getting used to, especially when cornering, but you can get used to it.

Let's move on to practice

The frame, made of pipes or angles, is primarily equipped with a steering mechanism. Having chosen the height and angle of inclination, spot weld the element

Install and secure the motor according to the drawing, taking care not to tilt too much. The snowmobile should not have a long fuel line, so try to position the tank close to the carburetor

The next step is to install the track. Mount the driven axle with the canvas on at the back of the frame (on the fork, suspension, shock absorber, etc., depending on the type of structure), the drive axle - in the middle part of the snowmobile (most often under the driver's seat), in the shortest possible connection with the engine. The gears of both axles are pre-engaged.