Winter is that time of year when everything around is covered with a “fluffy blanket” in the form of snow. Our country is located in a climate zone where we must be prepared for heavy rainfall every winter. Often snow falls completely unexpectedly and then traffic throughout the city stops.

Fortunately, in big cities there are metro stations where underground trains constantly run, on which you can easily get to anywhere in the city.

The situation is completely different in small towns and villages, where the movement of any transport is not possible during heavy snowfalls.

But even from such a difficult situation you can find a way out, namely, move on a snowmobile. Today we will talk to you about how to make a homemade snowmobile with your own hands.

Frame construction

Before you begin building a snowmobile, you will first need to select a material. The easiest way is to make a homemade frame from wooden blocks. The result is a very light and fairly durable structure, which is considered the cheapest and easiest to manufacture. For this you will need:

- Wooden bars.

- Sheet iron.

- Metal scissors.

- Drill and drill bits.

- Hand saw.

- Bolts and nuts.

The advantages of building such a structure are undeniable. In the event of a breakdown, the wooden model will not be difficult to repair far from a populated area. In the forest it is easy to find scrap materials that can be used for repairs. But the main advantage is that this snowmobile rarely falls through the ice and does not sink in water.

Wooden structure

It is known that bars and boards made of wood do not have particular strength in their places

connections. Therefore, before starting construction, it is necessary to make additional metal corners. To do this, take sheet iron and cut square plates with scissors along the width of the bars. The places for the bolts are marked in them with a tape measure, and then four holes are drilled with a drill. After this, the plates are bent in half exactly 90 degrees. These will be excellent devices for firmly fastening wooden blocks in the corners of a homemade frame.

Usually they start construction after making a drawing with exact dimensions. And four bars are cut along them with a hacksaw, and holes for bolts are drilled in the corners with a drill. Then they are placed on a flat floor surface in the form of a regular rectangle. Metal corners are applied to the connection points, bolts are inserted and tightened tightly with nuts.

To mount the engine and track, two additional crossbars made of bars with holes for bolts at the ends are installed on the frame. But before that, the corners for fastening are first made. They are cut out of triangular shaped iron sheets and holes are drilled in the corners .

It’s better to make eight pieces at once and place them on top and bottom. Then the fastenings will be more durable and reliable in operation.

When they are ready, the crossbars are inserted inside the frame and the triangles are placed on top. Holes are drilled into them exactly to size using a drill through the bars. Then long bolts are inserted there and tightened tightly with nuts. At this point, a strong wooden frame will be ready, which will serve for a long time on a homemade device.

Metal frame for snowmobile

It is much more difficult to build homemade metal products. This requires special tools and devices that not everyone may have. Significant costs will be required to purchase or rent them. However, this building will be much stronger and more durable than a wooden structure . Here you will need:

- Welding machine.

- Electrodes.

- Mask.

- Bulgarian.

- Spanners.

- Pliers.

- Hammer.

In addition, to build a metal frame you will need more durable materials. You will definitely have to buy them in the store, since today they are not found anywhere else. And I don’t really want to build a new homemade snowmobile from old parts due to poor reliability. Therefore, only good materials will be used here:

- Metal pipes.

- Iron corner.

- Sheet steel.

- Channel.

As a rule, before you start building a frame, you need to make a simple drawing. Using a grinder, cut the pipes according to its parameters and use a welding machine to connect them into a rectangle. Inside the frame, insert a couple more partitions from the corner to install the engine and track. If you make them from channel bars, the structure will be much stronger and more reliable in operation.

After this, you just need to cut off two small bushings from the metal pipe.

And then weld them to the corners of the front part, where the swivel ski supports will be inserted. The metal frame is ready and you can begin construction, as well as installation of the main units and components.

Hanging equipment

To make a snowmobile fast and strong, you need to put a good engine on the frame. If you install a low-power motor, then such a structure will move poorly. You also need to correctly calculate the caterpillar. If the area is too small, it will drown in large snow and will not pull even on flat terrain. Particular attention should be paid to skis, which should create good stability and safety when moving at high speed.

DIY rubber caterpillar

To easily move through the snow, it is very important to give your homemade snowmobile a good rubber track. It is not easy to make such a device with your own hands and it is better to purchase it in a store completely with rollers. Installing a standard factory track on a homemade structure is not difficult. To do this, you just have to secure the drive shaft and rollers with bearings to the frame. If your financial situation does not allow you to buy the entire device, then the most expensive parts can be easily made yourself. For this you will need:

- Conveyer belt.

- Plastic pipe.

- Bolts, washers and nuts.

A cheap homemade snowmobile track is usually made using a thin conveyor belt. To do this, plastic pipe blanks are sawed off to fit the width of the rollers. Then they are cut lengthwise into two equal parts and holes are drilled for small bolts. After this, the halves of the plastic pipes are secured to the conveyor belt with bolts, washers and nuts. The caterpillar is ready and further construction needs to begin .

Read also: How to glue iron to glass

Homemade skis

It's no secret that in winter it is much more convenient to travel on deep snow on skis. They also serve well as a control device on a snowmobile. It is not difficult to make a wooden structure, but only strong boards made of birch or oak are suitable for this. They need to be well dried, planed, and then heated and the ends bent. It's no more difficult to make metal skis. To do this, you will need to cut two plates from sheet steel and weld a thin corner on the sides.

In order for the skis to turn freely, metal pipe stands are welded to them. In working condition, they are held in the front bushings of the frame, where they rotate easily .

Washers or large nuts are welded to the top of the racks, into which rods are inserted to control the snowmobile.

The steering wheel itself is easy to make with your own hands, or it’s easier to remove it from an old motorcycle. Thus, all that remains is to install the motor, as well as the driver’s seat, and you can hit the road.

With the arrival of winter, some people successfully replace two-wheeled vehicles with homemade snowmobiles. This equipment is capable of overcoming large snowdrifts and is convenient for moving on snow-covered roads. It is expensive and not everyone can afford to buy it, so many assemble snowmobiles on their own using scrap materials.

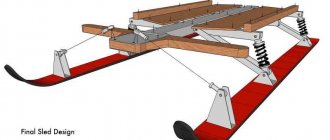

General structure of the snowmobile

A snowmobile is a sled that is powered by an engine. They are agile, agile and capable of speeds in excess of 85 mph. Middle-class equipment can overcome inclines of 20°. Steep slopes up to 65° can be passed by snowmobiles with a higher class. General structure of the snowmobile:

- The equipment is controlled via steering handles. The handles are connected to the skis that stand in front.

- The steering wheel is equipped with drives: gas and brake. These levers control the speed and braking of the snowmobile.

- There are no rear wheels, but instead a solid rubber band (track) is installed that moves the snowmobile. It is connected to the engine through a chain and belt.

- Some models can be made using inner tubes from tractor wheels.

Thanks to their design, snowmobiles overcome difficult places that cars cannot pass. With their help, food is delivered to snowy areas where there are no roads. But most people are used to using them for entertainment.

Drive system

A small diameter drive sprocket is installed on the engine output shaft. From it, torque is transmitted through a chain to the driven shaft, located under the engine seat. On the driven shaft there are:

- Large diameter driven sprocket.

- Gear wheels that drive the tracks.

- Guides for tracks.

The driven shaft is mounted on the frame using bearings. Gear wheels push the tracks, causing the tracks to move. The chain and sprockets are removed from one device. Old motorcycles and snowmobiles (Buran) are suitable donors. Gear wheels for tracks can only be removed from other tracked vehicles.

The guide rollers rotate with the shaft, are attached next to the gears and serve to tension the belt. They are made of wood or plastic and have a layer of soft rubber at the ends. Rubber prevents damage to the track. It is easy to make such rollers yourself by securing the edging with a furniture stapler.

Manufacturing of structural elements

Before starting to manufacture structural elements, prepare a drawing, required materials and tools. You can take ready-made drawings based on the Bullfinch or Vepr snowmobiles. Tools you will need:

- welding machine;

- pipe bender or finished frame;

- hammer;

- screwdrivers.

Since the design of the mini snowmobile is low, the seat is made of durable waterproof material. The fuel tank is made of metal. Its volume should be from 10 to 15 liters. You can use a motorcycle chain as a drive.

How to make a snowmobile track

A snowmobile track is created from tires or conveyor belt. The work will be difficult and time-consuming if tires are used as the basis. The sides are cut out of them, so the work requires a sharp shoe knife or an electric jigsaw. To facilitate the process, tires are selected with a suitable tread pattern. Making a homemade caterpillar:

- The sides of the tire are cut out with a knife. If the knife blade is periodically moistened in a soapy solution, the cutting process will become easier. When using an electric jigsaw, install a blade with small teeth and moisten it with water.

- If, when cutting, the track turns out to be hard or extra layers have formed on the wrong side, they are also cut off.

- Cutting a new structure is done when there is a mismatch in the tread pattern. The structure made must cling to the soil, so the structure of the pattern must be correct.

A caterpillar made according to this design is quite reliable due to the fact that it has a closed loop. Its disadvantage is its narrow width. To make a larger size, it is doubled. If the caterpillar is made from a conveyor belt, then it is combined into a single ring. This can be done in 2 ways:

- like a piano hinge (with a hinge);

- ribbon stripes.

You need to choose the appropriate thickness of the tape if it is sewn on. Its thickness should be suitable for the engine power. A homemade snowmobile from an IZH motorcycle requires the use of a 10 mm thick tape. To increase the service life of the snowmobile, the edges of the conveyor belt are stitched with fishing line. The seams are made according to the method of overcasting the edges with an interval of 1 cm.

Tackles

A trolley is a movable platform that protects the chassis of equipment from unnecessary mechanical loads. The platform is used when it is necessary to drive a snowmobile into a garage. For its manufacture, a metal pipe of medium diameter (6×6 mm), rollers and a bearing system are used. The wheels are installed with rubber coating and metal discs. Their diameter must correspond to the weight of the equipment.

Snowmobile skis consist of a base, a shock-absorbing part, a rod, a fork and bipod, and a link leg. Skis can be made in different designs from different materials. If plastic linings are used for the base, they are supplemented with expanders. The extensions are mounted with fastenings to the snowmobile chassis. The plastic design is suitable for small equipment. For large and medium-sized snowmobiles, you will need metal skis.

- To give the skis a shape, cut out the base from a cardboard stencil. At the same time, a bend is formed in front. The amount of bending is done at your own discretion. A ski track with a large bend glides poorly and collects snow. And this creates unnecessary braking. Therefore, you should not make it too large. The approximate size of the ski track is 2.5 cm wide and 100 cm long.

- A pipe is welded along the edges of each part. This gives additional rigidity to the product and protects it from stones that come along the way.

- Where the bend passes, the pipe is welded along the contour.

- Shock-absorbing parts are fixed to the skis. Bolts are used as fastening elements.

- The platform and the nose of the skis are connected by a hydraulic pipe. The top part is ready.

- For the lower part, the hydraulic pipe is fixed at 4 points and compressed.

- Then the polyethylene pipe is attached with self-tapping screws, having previously cut it. Instead of a polyethylene pipe, you can use polypropylene.

Read also: What to make rivets from

Finished skis must be painted.

Slimes

Slides are removable guides along which the snowmobile track slides. They prevent the track from sagging between the wheels and protect it from abrasion. Snowmobile slicks can be purchased at a store or made from a water pipe. The thickness of the pipe should be about 10 mm. Strips are made from it and mounted to the runners.

Rollers

Rollers are the supporting elements of the tracked undercarriage system. They create tight contact between the track and the surface of the ground support. Steel sheets are used as supports.

Variable speed drive

A variator is a special mechanism that allows you to smoothly regulate speed in mini snowmobiles. Safari is the most popular CVT. It consists of 2 pulleys: driven and driving, therefore it is capable of adjusting 2 parameters. These are revolutions and movement resistance. The pulley will operate like a clutch if the engine speed reaches 2200 rpm. In this case, the engine and the reverse shaft are disconnected.

Engine

To make a snowmobile powerful, you need to choose a powerful engine. The best engines for assembling a snowmobile are Lifan type engines with a power of 15 hp. With. This model is equipped with a reduction gearbox and has a centrifugal automatic clutch.

Chassis and suspension

The rear and front suspensions are the shock-absorbing system of the snowmobile. The front suspension creates smooth movement for the chassis. At the same time, the driver does not feel any vibrations on uneven roads.

If you choose a suspension based on the principle of operation, then the telescopic one is the most popular.

It consists of a shock absorber and a spring. These parts are located in the rack and eliminate shock loads. Snowmobiles equipped with this suspension are agile in conditions with dense vegetation and trees.

Each snowmobile is equipped with a frame. This part can be borrowed from a moped, scooter or ATV, or welded from pipes. The pipe diameter must be more than 40 mm.

General rules of constructions

Self-made snowmobiles are often completely different. But they are all united by the desire to give the snowmobile the following properties:

- do not fall into the snow;

- move in the right direction and at the right speed.

In order for a snowmobile to satisfy these conditions, its design must contain several mandatory elements:

- supports (wheels, tracks, runners);

- engine;

- steering wheel that changes the direction of the snowmobile;

- frame.

When making a homemade snowmobile, you can use a wide variety of elements and parts from other devices, which greatly simplifies the process.

Simple children's snowmobiles

If you want to make a snowmobile for a child, then you should not use a powerful engine. Homemade products must be created in accordance with the age, weight and height of the child.

It’s worth starting with the support - installing the skis under the frame. To make the process easier, you can use a snow scooter. Then you should install a motor with low power (about 2 horsepower). It can be removed from a chainsaw.

If you are planning a children's snowmobile, then there is no need to further strengthen the frame, but for transporting adults this procedure is required.

Ice motor sleigh

Movement in winter, especially on ice, is very difficult. Therefore, many fishermen who do not have the budget to purchase expensive equipment are thinking about making ice snowmobiles themselves.

Unlike a children's snowmobile, an adult's snowmobile uses a sled instead of a snowmobile.

Next, attach a chainsaw motor with a power of 4-5 horsepower (you can use a “Friendship” chainsaw). This design is well suited for icy surfaces, but is not suitable for moving on snow (especially loose snow).

Inflatable wheels

You can also make a snowmobile on inflatable wheels. To do this, take rims from a motorcycle or bicycle and wide inflatable chambers from the wheels of a truck or tractor. Chains or crossbars are attached around their circumference to increase traction. To give the cameras strength, liquid rubber should be applied to their surface or some kind of waterproof material should be glued. For such snowmobiles, you can take frames with engines from motorcycles (Ural or Dnepr).

On caterpillar tracks

Homemade snowmobiles on tracks have high speed and reliability, which is why they are popular.

Tracks can be made in several ways, for example, from truck tires or from conveyor belts.

Plastic tubes less than an inch in diameter, cut lengthwise, are screwed across the tape. Conveyor belt tracks can be reinforced with a chain.

If you cut the sidewalls from truck tires with winter tread, they can also be used as tracks. To do this, you need to sweep the edges with fishing line in centimeter increments.

Upgrading homemade snowmobiles

After using a homemade snowmobile for the first time, people notice some shortcomings that they want to correct.

To begin with, it is worth making it possible to use a snowmobile not only in the daytime, but also in the dark. You will need a lamp and a generator (you can take a bicycle one).

To prevent the wind from sweeping snow into your eyes, you can install ready-made windshields on your homemade vehicle or come up with something of your own.

Snowmobile assembly

You can make your own snowmobile from a moped, chainsaw or motorcycle. The circuit for a homemade snowmobile made from a chainsaw needs to be developed independently, since each part has its own characteristics. The equipment is assembled in stages, adhering to the drawings:

- First, the frame is assembled. The middle part of the structure is made from steel corners measuring 50x36 cm. The front and rear parts are assembled from steel sheets with a thickness of 2 mm or more.

- To install the track mechanism and guides, 2 holes are made. They must be end-to-end. Tensioners for track wheels are mounted on both sides of the side members. The tensioner helps adjust the track and creates tension in the second stage tensioner.

- To install track rollers, special brackets are required. They are welded to the side members, on the bottom side at the same distance from each other.

- The rollers are installed in the open slots of the brackets. Installation is carried out from the bottom. The rollers are positioned on 5 axes.

- Bushings are made from pipes of suitable diameter and installed between each roller.

- The bracket axes are secured with nuts and locknuts. This fastening will allow you to maintain the required distance between the side members and strengthen the frame.

- Mounting stands are made for the chainsaw gearbox. They are made from 3 metal corners. Then the intermediate shaft of the chain drive is mounted.

- The frame is ready. A seat is installed between the rear and middle parts. You can use a car seat or a simple box as a seat.

- Control handles are welded to the pipe - this will be the steering wheel. It is installed on the front of the frame, after drilling a hole.

- To create additional strength, the area where the racks are attached is equipped with metal gussets.

- The drive shaft is made from a pipe. To attach the gears, a round flange is inserted into it.

- A steering mechanism for a snowmobile is created from an old motorcycle that has a three-lever control.

The finished snowmobile has simple controls and can be used for children's parties. This is a lightweight and compact equipment that can be transported in the trunk of a car. If snowmobiles are made on the basis of a walk-behind tractor, then they are divided according to the material of the snow hooks: “pipe bugs” and “stick bugs”. Here, simple plastic water pipes are used for the tracked structure. This protects it from deformation, but at the same time reduces the level of adhesion between the tracks and snow.

During cold weather, transport on two wheels becomes irrelevant, and sometimes it is impossible to drive through snowy expanses even by car. What to do in a situation where there is no money to buy a vehicle more adapted to the harsh winter?

In this case, you can make a homemade snowmobile. Winter vehicles are most often equipped with a tracked drive and steering skis are installed at the front. The snowmobile has high cross-country ability, light weight (70-80 kg), which allows it to drive both on valuable snow and on hard-packed snow-covered roads. Driving this vehicle is easy and the speed is low. So riding a snowmobile in the countryside in winter is not only convenient, but also safe.

Children's

And the last type of snowmobiles is for children. Models of this type are designed for teenage children aged 9-12 years. Single-seat models attract with their compact size and well-thought-out design. An effective security system is implemented here. This is an ideal solution for those cases when you want to teach your child to ride a snowmobile. The features of children's snowmobiles include low weight, ergonomic design, and excellent functionality.

Features of homemade snowmobiles

A huge number of companies sell snowmobiles in the CIS. But their prices are high even for families with decent incomes. If you don’t want to overpay for advertising and are a hardworking and creative person, then try making a homemade snowmobile.

Read also: Parallel connection of LED strip

A self-propelled gun made by yourself costs 7-10 times less than the cheapest factory-made models.

The success of making a snowmobile yourself depends on several factors:

- your personal skill;

- your engineering and design thinking;

- availability of parts and assemblies from other snowmobiles, motorcycles and other things.

It should be kept in mind that riding a snowmobile, like riding any vehicle, is associated with increased danger. Despite the fact that homemade devices, as a rule, are not capable of reaching speeds of more than 15 km/h, the quality of parts, welding, and bolting of elements should be approached with the utmost seriousness. The issue of operational safety and reliability of the final unit should be the main one for any person who intends to make a snowmobile with his own hands.

Short story

The first functioning snow sled engine was developed and put into operation by the famous French polar explorer J.-B. Charcot, French automobile pioneer, Marquis Jules-Albert de Dion and engineer Georges Bouton. The drive had to be driven by an internal combustion engine, a drum on the snow surface with numerous crossbars and teeth. At the same time, Briton Robert Scott, preparing for an expedition to the South Pole, also turned to De Dion Bouton to develop a motor sleigh based on the design of a Norwegian sleigh called the “Nansen sleigh.” Testing of these vehicles took place in the spring of 1908 in the area of the Lautaret Pass in the Dolphin Alps.

The first Soviet snowmobile

Probably the first motor sleds equipped with an aerosan (special propeller) were built by the Russian scientist A.S. Kuzin in 1908. Almost at the same time, the aerosan was built by the young I. Sikorsky in 1909-1910. In parallel, attempts were made by the United States to adapt the famous FordModelT car for winter driving, but it was not until 1924 that the American inventor and designer Carl Eliason made his first functional prototype of a snow car. In 1927, Alison's scooter was patented - this design is used today virtually unchanged, only for economic reasons, changing the parameters of the vehicles. os.

Preparation

Before you start making a snowmobile, you need to calculate the basic parameters of the device. If you are a bit of a design engineer, then it is appropriate to make a drawing of the unit. In principle, all snowmobiles are designed the same and simply. Your task is to make a reliable device modeled after all other variants of this class of vehicle.

What you will need for production:

- Pipe for the frame, for pendants and other frame elements.

It was experimentally found that the optimal pipe diameter is 40 mm. If you are using a profile, then 25 x 25 mm will be enough. Wall thickness – 2 mm. With smaller parameters, the resistance of the device to deformation will be reduced. If they are large, the car will become heavier, which, accordingly, will affect the already not brilliant driving characteristics.

- Wheels with rubber on the axle.

Wheels from ATVs (small models with a wheel diameter of 30-40 cm), some carts, etc. are suitable. A total of 2 axles with 2 wheels on each are required.

- V-belts or conveyor belt.

The main element of the "caterpillars". The optimal thickness is 3 mm. This is enough for stability and wear resistance.

They are used to make lugs - the second element of the “caterpillars”. The optimal diameter is 40 mm with a wall thickness of 5 mm.

- Propulsion system.

As a rule, they use an engine, a carburetor, or a fuel tank from a motorcycle.

- Transmission mechanism.

As a rule, they use sprockets and a chain from a motorcycle, and sprockets from snowmobiles. Drive shaft from any unit, suitable in size.

- Guide skis.

It is optimal to take skis from another snowmobile. Since this element must be as reliable as possible, designed for the load of the unit itself, plus the driver and possible passengers.

As a rule, they use a motorcycle handlebar, respectively, with a gas handle and a cable.

- Platform, seat, body.

In principle, you can do without a platform by attaching the seat(s) and the body (optional) directly to the frame. But sometimes an additional platform is constructed on the frame, for example, from wooden boards, which provide slight cushioning, allow you to place several seats, and at the same time lightly weight the structure.

This element adds additional complexity to the design. Therefore, they often do without it, especially if they plan to drive on uncompacted snow. Shock absorption is installed on the front suspension and driver's seat. You can take it from an old snowmobile or motorcycle.

In addition to those listed above, other standard parts will be required to make a snowmobile: bolts, studs, nuts, hinges.

Price

The design and narrow purpose of snowmobiles make a snowmobile an expensive pleasure. Prices vary significantly depending on the brand, country of manufacture, age of the unit and the presence of additional functions. Thus, a domestic snowmobile, which has been “out” for several seasons, will cost $500–1,500; a new Russian model, for example, “Buran” or “Lynx,” will cost around $5,000. Prices for used equipment of foreign brands start from $2,000 for those options that have been “on the road” for 3–4 seasons and from $2,500 for those that have been in use for 1–2 winters. New children's snowmobiles can be purchased for $3,000 to $3,500. To purchase “adult” models, you should be prepared to spend from $4,500 for a simple package. Maximum additional features and parts, of course, along with the snowmobile itself, will cost between $7,000 and $10,000.

Choosing and purchasing a snowmobile is a responsible matter, so it is better to seek advice from specialists, for example, representatives of a equipment distributor. If you want to buy a good snowmobile, pay attention to the leading brands on the market.