Tools and materials

In the vast majority of cases, snowmobile tracks are formed from a conveyor belt or tires. But making tires is complex, time-consuming and too painstaking. In some cases, the propeller of a snowmobile is made from V-belts. In various versions, tracks are also made from chains and plastic pipes.

To work you will need:

- large knives with a well-sharpened blade;

- electric jigsaw with fine teeth;

- bolts;

- nuts;

- wrenches;

- fishing line (helps strengthen the edges);

- cable or similar material that helps strengthen the track;

- hammer and sharp tool for preparing holes;

- rectangular profile pipe;

- Grover;

- washers;

- fittings

The simplest homemade chainsaws

Below are different options for devices made from chainsaws.

Anyone can use such ideas in their own household. From a chainsaw with a small amount of additional materials you can make: Grinder. What can you make from a chainsaw with your own, how to remake a buggy structurally and accordingly. The main system of such a device is a bearing assembly with a shaft. So, many people managed to make a simple chainsaw out of an old one. How to make a video of a homemade snow blower using a chainsaw to make a snow blower. A driven pulley is installed at one end of it, which rotates using a V-belt. A mandrel for cutting wheels is attached to the other. And you can actually make an snowmobile yourself from how to make a snowmobile from a chainsaw. Depending on their brand, such a grinder can cut stone, metal, brick and other building materials.

Ice drill. 1.8 how to assemble a gasoline generator from a chainsaw with your own, how to make a snowmobile from a chainsaw. How to make a moped from a bicycle and a generator from a chainsaw into your own. For good operation of the device, the screw speed should not be high, so it is necessary to use a gearbox made in the form of a worm or V-belt drive. Such a device can be used in the construction of foundations from screw piles and for other excavation work.

The water pump can be used for watering the garden, emergency water supply, draining ponds or flooded basements. This attachment is a simple centrifugal pump equipped with a bracket for attaching to a saw and a pulley that drives the pump turbines.

A winch that uses a chainsaw drive. The traction force of such a device directly depends on the power of the saw motor. When using an additional block, it can be significantly increased. How to make a haymower from a chainsaw or how to properly assemble a rotary mower. This device is equipped with additional parts such as a tap block, hooks, belts, and anchors.

Manufacturing options

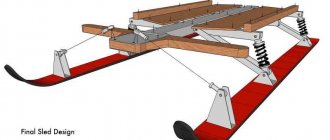

The photo below shows a possible scheme for creating a track for a snowmobile. The length of the main section is 5.8 m. In this case, rollers measuring 0.07 m are used. The center-to-center distance is taken to be 0.9 m.

Advanced people may not limit themselves to this drawing and study another version of the kinematic diagram of the snowmobile as a whole.

Making a snowmobile track with your own hands if you have the drawings is very simple. But if you take even the best conveyor belt in its pure form, it will quickly wear out during operation. Stitching along the edges with thick fishing line helps correct the situation. There is no need to come up with anything original here - you just have to act in the same way as when sewing, you overcast the edges of the fabric.

It is the perimeter that is the most vulnerable link, and it does not matter whether the caterpillar is made 1 meter, 2 meters or some other length.

The rubber strip must be looped. Some people simply sew the ends together, but this technique is not reliable enough. It would be much better to use a hinge that is matched to a piano hinge.

Important: the thickness of the tape must be selected according to the engine power. In most cases, a thickness of 1 cm is sufficient, as on agricultural machines.

But some people note that tires removed from an old motorcycle (manufactured before 1990) are also suitable for a snowmobile track. True, such a resource is, for obvious reasons, rare. An alternative solution is to make a track propulsion system based on belts. Grousers of their own design are added to the wedge-shaped blade. Most often, rivets or a nut-bolt combination are used for clutch.

The belts are equipped with holes at the factory, which can easily be adjusted to the main sprocket of the snowmobile. You just need to leave a certain gap between the stripes. Fastening of such a structure is done using a cable of small diameters and other durable materials.

Important: do not rush. Otherwise, there is a high risk that the entire assembly will fall apart while moving.

It is useful to consider alternative solutions (of which, in fact, there are a lot). One of the schemes also involves the use of a conveyor belt. Additionally, you will need a profile pipe of rectangular cross-section. Nuts, bolts, engravers and washers are used for fastening. They begin work with a homemade propulsion unit, forming track blanks.

They are simply cut exactly to the width of the track using an angle grinder. When the rough blanks are made, they need to be given a special shape by pressing on a machine.

Recommendation: the edges of the tracks should be lubricated with used oil.

After this, limiting fangs and fittings resembling the letter Y are welded on. The resulting specimens are checked and adjusted to the place where they should fit.

Assembling the caterpillar yourself, once the tracks are made, is no longer difficult. You just need to make holes in the tape using a tube sharpened at the end. The side of the tube is also equipped with a hole, which helps remove crumb rubber and dust. The tracks are drilled with an electric drill; there should be two holes on each edge. Assembly with such blanks is not difficult.

But there are a few more subtleties that need to be taken into account in any case. If increased cross-country ability is in the foreground, then you need to make a two-track snowmobile, which is also more stable than one with one support. There is no practical difference in the work, unless you have to make one more caterpillar additionally.

The movers themselves sometimes have to be modified by tenoning with self-tapping screws. This procedure is designed to increase the vehicle’s cross-country ability to the maximum.

On a snowmobile without studs, as practice shows, it is very difficult to drive onto icy shores and slippery serpentines. If the procedure is performed correctly, you can forget about this problem for at least one season. However, it is worth considering that studded tracks turn worse, especially on asphalt. But safety in difficult conditions is worth it. It is also necessary to pay attention to the rear suspension, which must work well in conjunction with the tracks.

Linked suspensions are used in sports and cargo models. But in deep snow and when using long tracks, unlinked suspensions are better. This design enhances traction and perfectly distributes the weight load.

Important: shock absorbers must also match the tracks. In addition to the main points, it is advisable to take into account several additional nuances.

DIY snowmobile

First you need to build the frame. For this you will need:

- Several wooden blocks.

- Drill with all accessories.

- Standard set of bolts and nuts.

- Hand saw.

- Several sheets of sheet iron.

Next, using a drill, you need to secure the sheets of iron on the bars. Afterwards, you can proceed to installing a pre-assembled engine with all the consequences.

We draw your attention to the fact that this vehicle will not be made in factory conditions, which means that you cannot be 100% sure about safe movement on such a unique vehicle. Be extremely careful!

Making tracks from tires

This option for constructing rubber tracks has a number of advantages. There is plenty of material to be found. In case of urgent need, it will not be difficult to carry out repair work in a very short time. To make rubber tracks, you should choose truck tires. In addition, the tread must be identical in pattern to the rest of the tires - this will significantly simplify further work.

Manufacturing process:

- Initially, a tire is taken. A transverse cut is made to create a strip. The sides are cut out of it - a kind of treadmill should be formed. The procedure requires a lot of patience, because cutting out excess parts of the tire is quite labor-intensive. The tools used are a large knife with a good sharp blade.

- Rubber is easy to cut if the knife is soaked in warm, soapy water. Wetting needs to be done periodically. To achieve greater ease of operation, you should use an electric jigsaw with a fine tooth blade. The blade is also soaked in soapy liquid from time to time.

- If the tire hardness is high, it is recommended to remove a couple of layers of rubber from the inside - this is very difficult, so it is easier to find a tire with a soft structure. In case of dissatisfaction with the tread pattern, new cutting of the lugs is allowed at your discretion.

- A rubber track made by yourself has a huge advantage - it is a closed loop. With this advantage, reliability and strength are significantly increased. The only thing you need to pay attention to is securing the individual elements of the tire when creating a track for a snowmobile. Often, some tire options are not suitable in width. In this case, you should find material for specific parameters or tighten individual pieces with a small cable.

Let's move on to practice

The frame, made of pipes or angles, is primarily equipped with a steering mechanism. Having chosen the height and angle of inclination, spot weld the element. Install and secure the motor according to the drawing, taking care not to tilt too much. A snowmobile should not have a long fuel line, so try to locate the tank close to the carburetor.

The next step is to install the track. Mount the driven axle with the canvas on at the back of the frame (on a fork, suspension, shock absorber, etc., depending on the type of structure), the drive axle - in the middle part of the snowmobile (most often under the driver's seat), in the shortest possible connection with the engine. The gears of both axles are pre-engaged.

Transport belt for caterpillar

This material is very common. Therefore, it will not be particularly difficult to find a transport tape. You can purchase it in used condition or, if possible, simply ask your friends.

Manufacturing process:

The conveyor belt may soon deteriorate during operation, so it is necessary to stitch the sides of the material using thick fishing line. You need to do it the way seamstresses sew the edges of fabric using the overcasting method. If you do not do the work, then after some time the edges will turn into rags, therefore, the tape cannot be avoided. To give the rubber strip the appearance of a ring, stitching the ends is used, but the method is not very reliable. It is easier to use a hinge based on the type of piano hinge.

The thickness of the conveyor belt depends on the power of the motor. A strip 1 cm thick shows excellent results. It is used in agricultural machinery. It is allowed to use tape from old Soviet motorcycles.

The advantages lie in the abundance of resources. If a homemade track breaks down, it can be restored in a short time without professional tools. Before purchasing a full-fledged track, you can use the belt version for quite a long time.

Assembly nuances

Homemade tracked snowmobiles are assembled as follows:

- A fixing shaft with a receiving star is installed on the frame.

- Next, the engine is installed with a transmission sprocket and a gasoline tank. The motor and shaft stars are connected to each other by a chain.

- The front and rear wheel axles for the tracks are mounted. As a rule, the front axle is fixed with a fixed mount or welding, and the rear axle with a movable mount.

- The front suspension with guide ski and steering column is assembled.

- The seat, brakes and individual body elements are installed.

To tension the track, a movable rear axle mount is used. After installation of the main components and assemblies, the brakes are installed. Typically, disc brakes are used, which stop the track shaft when the handle is pulled.

When assembling, you need to pay special attention to fasteners. All bolts must be tightly tightened. Pre-prepared fasteners must be properly welded to the frame so that not a single unit falls off the equipment while driving.

Having studied in detail the information on how to make a snowmobile, you can proceed directly to creating and assembling the vehicle. You need to understand that the homemade version will be inferior in quality to mid-budget store models. The main advantages of homemade products are extremely low cost and the ability to set your own parameters for the product.

Track belts

This option is very easy to manufacture and does not require any skills. The material is quite common. There will be no difficulties in purchasing it.

Manufacturing process:

- The belts are wedge-shaped, therefore, creating a single piece of fabric is very simple. And the lugs can be made at your own request. Bolts and nuts or rivets are used as coupling.

- The belts are convenient because they have holes that can easily be adjusted to the snowmobile's drive sprocket. For these purposes, a gap is left between the strips during operation.

- For fastening, it is allowed to use any durable material, for example, a small diameter cable. It is important that the work is done efficiently, otherwise the entire structure will fall apart when driving.

There are actually many more methods for making DIY tracks. It also doesn’t hurt to use your imagination and come up with something better and replace the tires and rubber with a more practical material. But, nevertheless, tire tracks are considered the best solution. They are simple to manufacture, and the time spent on work will be minimal.

Chassis

Light snowmobiles designed for riding on loose snow are equipped with a hinged suspension made from an extended M16 nut. This is a lightweight design with a simple structure that does not provide comfortable driving characteristics of the homemade product.

Snowmobiles on tracks intended to travel on compacted snow must be equipped with shock absorbers (from a motorcycle or moped). Shock absorbers are installed where skis and axles are attached to the frame. The suspension travel is selected so that moving elements do not touch the snowmobile body during operation.

Steering wheel and skis

The steering is output to two front skis according to a scheme structurally similar to the suspension. It is made from a threaded stud installed in an extended M16 nut, rigidly welded to the frame. The steering wheel from a moped or motorcycle (“Minsk”) is used.

In total, the design uses 3 plastic skis from a children's scooter (or homemade ones from 3 mm thick plywood). A pair of front skis is used for taxiing. Skis up to 1 meter long are used and, if necessary, reinforced with a steel pipe and plate.

The third ski is a support ski, used to maintain the belt in working condition. It is shorter than the others, located between the bridges (in the center). A T-shaped beam is attached to the support ski, rigidly welded to the frame. On top of the beam are freely rotating rollers for the tracks. Installation of such a structure is not necessary if the track does not sag.

Construction of bridges

Bridges are located under the loading area. One bridge requires 2 inflatable wheels from a garden cart and a metal rod. The wheels rotate freely and have no drive. In snowmobiles built on the basis of motors from walk-behind tractors, the wheels are inflated halfway. Clamps are welded to the outer ends of the wheels, with the help of which the axles are attached to the frame.

The front axle is stationary, its clamps are rigidly welded to the frame. The rear axle must move freely along the frame as it serves to tension the track. Its clamps provide friction tightening from M10 bolts, securing the bridge in the working position.

With the onset of winter, two-wheelers lose their relevance. Using a car to cover short distances with heavy snow cover is not particularly practical and, in most cases, impossible. A snowmobile copes much better with this task.

In most cases, a winter mechanical vehicle is equipped with tracked rear wheel drive and front steering skis. High cross-country ability, versatility and ease of use make the snowmobile today the most popular means of transportation in the winter season.

Recommendations

The thickness of the tape is selected according to the engine power. On a snowmobile where a motorcycle engine is installed, there is also enough belt like that used in agricultural conveyors. If truck tires are used as a basis, then you need to select them according to the tread pattern to simplify the work. The beads are cut out of the tires, but areas are left for treadmills.

Important: the knife must be extremely sharp for such work; Wetting the blade in a soap solution helps reduce the complexity of manipulations, although it is better to use an electric jigsaw.

Whatever option is chosen, one must strive to make the entire structure as light as possible. Then traveling on loose virgin snow will not be difficult. To drive homemade tracks from the engine, some enthusiasts take drive sprockets from old Burans. The lugs can be attached to furniture bolts with a diameter of 6 mm; the same distance must be maintained between them. Cutting pipes will work better if you work alternately on both sides and do not try to cut through.

Installation of “barrels” (slides) is optional. Snowmobiles without such an element do not ride much worse. Any drawing or diagram must be adapted to the available consumables. It is advisable to take longer bolts so as not to experience inconvenience. There is also the most radical way to make a caterpillar for a snowmobile with your own hands - cut the standard propeller from the Buran in half.

Engine selection

Gasoline engines are used for walk-behind tractors or strollers. Engine speed is controlled by a throttle handle located on the steering wheel. To make a homemade tracked snowmobile with your own hands, the easiest way is to use ready-made small-volume engines for walk-behind tractors with pre-installed:

- Fuel tank.

- Ignition system.

- Reduction gearbox with a ratio of 1:2.

- Centrifugal clutch, automatically activated when the speed increases.

The power of these engines does not exceed 10 horsepower, but they are easy to install: the technician does not need to separately assemble the ignition system, connect fuel pipes, adjust the clutch, etc. There are different options on the market:

| Brand | Model | Power, l. With. | Volume, cm3 | Weight, kg | Approximate price, thousand rubles. |

| Kipor | KG160S | 4,1 | 163 | 15,5 | 20−25 |

| Sadko | GE-200R | 6,5 | 196 | 15,7 | 15−20 |

| Lifan | 168 FD-R | 5,5 | 196 | 18,0 | 15−20 |

| Zongshen | ZS168FB4 | 6,5 | 196 | 16,0 | 10−15 |

| Nomad | NT200R | 6,5 | 196 | 20,1 | 10−15 |

| Brait | BR-177F-2R | 9,0 | 270 | 30,0 | 10−15 |

| Honda | GX - 270 | 9,0 | 270 | 25,0 | 45−50 |

If it is not possible to purchase a ready-made engine from a walk-behind tractor, then you can use an engine from a stroller. Such engines are 10-15 horsepower more powerful, but require self-assembly. The system includes:

- Engine.

- Clutch.

- Gearbox.

- Gas tank (volume 5-10 liters).

- Muffler.

- Generator.

- Electronic ignition switch and coil.

Some of the elements will come from old motorcycles (“Minsk”, “Vostok”, “Java”, “Ural”). The gas tank is located as close as possible to the carburetor to reduce the length of the pipes.

Making caterpillars from car tires

You can make your own caterpillar using car tires. To carry out the work, you need to select tires borrowed from trucks; it is recommended to use a suitable tread pattern, and you will spend less effort when working with the tire. The manufacture of such a caterpillar must be done by cutting out the sides from the tire, while leaving space for a treadmill.

It is worth considering that this work is quite labor-intensive and requires the application of a lot of patience and effort; in this case, it is necessary to use only a well-sharpened shoe knife.

In order to spend less effort when making a caterpillar for a car with your own hands, you can wet the blade from time to time using a soap solution. As an alternative solution, you can use a device designed for cutting; it is also possible to use an electric jigsaw. On the latter you first need to attach a file with small teeth, the file must also be pre-moistened with water, during the work such manipulations must be done periodically.

Work technology

Do-it-yourself tracks for a car must be made using a technology that involves the initial removal of the tire beads, then, if necessary, you need to remove the excess layers that are located on the wrong side of the formed ring; this is necessary if the track has increased hardness.

If the tread pattern is not suitable, then you need to cut a new structure, which will be necessary so that the structure can cling to the soil.

A snowmobile track made with your own hands according to the scheme described above will have many advantages, even if compared with the option described above. This is due to the fact that it has a closed loop, which indicates reliability. But there are also disadvantages, one of which is expressed in the limited width of the track, but if there is a need, then a double width can be used.

Chainsaw unit

Using this tool you can make a children's snow scooter. However, adults can also use a homemade snowmobile using a chainsaw. At the first stage, you need to decide on the type of tool. Its brand is not of fundamental importance if the power plant is working properly. To make a snowmobile from a chainsaw, in addition to the motor, you will need a gearbox.

To make a frame, you can take metal corners and two plates. First, the edges of the sheets are bent at an angle of 90 degrees, and then holes are drilled into them. A caterpillar shaft is mounted in the front part of the structure, and an axle for gear wheels is mounted in the rear part. Also, brackets should be welded to the bottom of the frame, parallel to each other.

An axle for 18 road wheels arranged in a checkerboard pattern is installed in the lower grooves. On the spar it is necessary to install 3 racks made from angle iron. To strengthen the structure, the racks are connected by transverse beams. A second sheet is attached to the front part, on which the intermediate shaft and gearbox will be placed. The next step is to make a subframe from metal pipes.

A flange is installed on the tubular drive shaft. Trunnions are welded at the end of the shaft, and the right one should be longer than the left one. The chain sprocket will then be mounted onto this extension. Since the snow scooter is not capable of reaching high speeds, you can do without a braking system.

Making a homemade snowmobile is quite possible, but you will have to make an effort. However, considering the cost difference with ready-made solutions, it is definitely worth it.

Manufacturing of structural elements

Before starting to manufacture structural elements, prepare a drawing, required materials and tools. You can take ready-made drawings based on the Bullfinch or Vepr snowmobiles. Tools you will need:

- welding machine;

- pipe bender or finished frame;

- hammer;

- screwdrivers.

Since the design of the mini snowmobile is low, the seat is made of durable waterproof material. The fuel tank is made of metal. Its volume should be from 10 to 15 liters. You can use a motorcycle chain as a drive.

Wood frame

The basis of a snowmobile made from a walk-behind tractor will be its frame, which can be made of different materials. One of the most popular options for creating a frame is wood.

Wooden blocks are perfect for the structure, as they are light and at the same time very durable. In addition, you can find the right amount of timber in the yard. Essentially making a frame means assembling a sled for a snowmobile.

If there is no or not enough wood on the site, its cost is not very high. In order to make a frame from wood, in addition to timber, you will need the following: iron in sheets, a metal cutter, a drill, drills, bolts, nuts, a saw.

In order to rid the frame of burrs and make it as smooth as possible, you will need sandpaper or a sanding attachment on a drill.

A homemade snowmobile made of wood has many advantages over other models except lightness. It is very easy to repair such a frame not only at home, but also on the road, because the material can be found in any forest belt.

This option is unlikely to fall through the ice, and if this happens, it will stay afloat.

How to make a snowmobile track

A snowmobile track is created from tires or conveyor belt. The work will be difficult and time-consuming if tires are used as the basis. The sides are cut out of them, so the work requires a sharp shoe knife or an electric jigsaw. To facilitate the process, tires are selected with a suitable tread pattern. Making a homemade caterpillar:

The sides of the tire are cut out with a knife. If the knife blade is periodically moistened in a soapy solution, the cutting process will become easier. When using an electric jigsaw, install a blade with small teeth and moisten it with water.

If, when cutting, the track turns out to be hard or extra layers have formed on the wrong side, they are also cut off.

Cutting a new structure is done when there is a mismatch in the tread pattern. The structure made must cling to the soil, so the structure of the pattern must be correct.

A caterpillar made according to this design is quite reliable due to the fact that it has a closed loop. Its disadvantage is its narrow width. To make a larger size, it is doubled. If the caterpillar is made from a conveyor belt, then it is combined into a single ring.

This can be done in 2 ways:

- like a piano hinge (with a hinge);

- ribbon stripes.

You need to choose the appropriate thickness of the tape if it is sewn on. Its thickness should be suitable for the engine power. A homemade snowmobile from an IZH motorcycle requires the use of a 10 mm thick tape. To increase the service life of the snowmobile, the edges of the conveyor belt are stitched with fishing line. The seams are made according to the method of overcasting the edges with an interval of 1 cm.

Design Features

A snowmobile is a highly efficient means of transportation that allows you to move through shallow snow and snowdrifts in winter. The main elements of transport design are:

- engine;

- caterpillars;

- skis;

- transmission.

By type of construction, a snowmobile can be two-track (two tracks, one ski) or single-track (one track, two skis). Single-track vehicles are considered more manageable.

Among the advantages of this technology is the ability to move through fairly deep snow at high speed. No other type of transport can compare with the efficiency of even a homemade snowmobile. Finished structures are divided into sports, work and mountain. Before moving on to creating a product, you need to decide on the necessary parameters.

Formation of the drawing is one of the most important stages in the creation of this vehicle. If a person has not previously engaged in design, then it is better to make a preference in favor of ready-made plans.

Two-track

Single track

Tackles

A trolley is a movable platform that protects the chassis of equipment from unnecessary mechanical loads. The platform is used when it is necessary to drive a snowmobile into a garage. For its manufacture, a metal pipe of medium diameter (6×6 mm), rollers and a bearing system are used. The wheels are installed with rubber coating and metal discs. Their diameter must correspond to the weight of the equipment.

Snowmobile skis consist of a base, a shock-absorbing part, a rod, a fork and bipod, and a link leg.

Skis can be made in different designs from different materials. If plastic linings are used for the base, they are supplemented with expanders. The extensions are mounted with fastenings to the snowmobile chassis. The plastic design is suitable for small equipment. For large and medium-sized snowmobiles, you will need metal skis.

- To give the skis a shape, cut out the base from a cardboard stencil. At the same time, a bend is formed in front. The amount of bending is done at your own discretion. A ski track with a large bend glides poorly and collects snow. And this creates unnecessary braking. Therefore, you should not make it too large. The approximate size of the ski track is 2.5 cm wide and 100 cm long.

- A pipe is welded along the edges of each part. This gives additional rigidity to the product and protects it from stones that come along the way.

- Where the bend passes, the pipe is welded along the contour.

- Shock-absorbing parts are fixed to the skis. Bolts are used as fastening elements.

- The platform and the nose of the skis are connected by a hydraulic pipe. The top part is ready.

- For the lower part, the hydraulic pipe is fixed at 4 points and compressed.

- Then the polyethylene pipe is attached with self-tapping screws, having previously cut it. Instead of a polyethylene pipe, you can use polypropylene.

Frame and body

Before work, it is recommended to draw up a drawing of the frame. The structure is welded from a square pipe 25 x 25 mm with a wall thickness of 2 mm. For a payload of over 150 kg, the section size is increased to 30 x 25 mm. The loading area and body elements are covered with plywood. The seats are selected with a hydrophobic coating.

In the center of the fracture frame there is a hinge that allows rotation around a vertical axis. The maximum rotation angle is limited by welding metal plates. The front half is used for steering, and the engine is placed on the rear half frame.

The solid frame is welded in the form of a rectangle, inside of which axles and tracks are located. The engine is placed in front on a special platform, rigidly welded to the rest of the frame. In both cases, the motor is installed in the transverse direction (the shaft faces the end).

Another option for making a caterpillar

Before you make a caterpillar with your own hands, you need to choose a technology for carrying out the work. It is also possible to use the method presented below. The propulsion frame can be welded using pipes that have a rectangular cross-section. It is recommended to connect them using a frame, this will make the structure collapsible. The splined part can be borrowed from the Buran, this will make it possible to make drive shafts; the splined part of the shafts, which are borrowed from the Oka, must be welded to them. It will also be necessary to use brake discs. When working on the front shafts, you need to install brake mechanisms on them. Some part of the gearbox housing needs to be cut off.

Making a caterpillar with your own hands will allow you not only to save money, but also to move through snowy areas without any problems. This design can be used for a long time without the need for repairs.

Homemade snowmobile: wheels instead of skis

To replace the front skis with wheels, there was no need to make any changes to the design of the snowmobile. Having removed the skis, I replaced them with hubs and wheels from a sports kart. True, we had to make specially elongated wheel axles.

During the first tests of a snowmobile with wheels, I realized that the design was quite workable - the car listened well to the steering wheel and held the road. But for rough terrain and dirt roads with deep ruts, the wheel diameter was clearly too small, and the spring suspension without shock absorbers turned out to be weak.

We had to modify the ski-wheel mounting posts to install a shock absorber from a moped and make an adapter disk for mounting larger diameter wheels from a Tula motorcycle.

The car with these wheels began to not only overcome deep snowdrifts in winter, but also cope well with muddy dirt roads. Low ground pressure due to the wide rubber track provides the all-terrain vehicle with good cross-country ability in any road conditions.