Advantage of Geon motorcycles

Geon motorcycles are of high quality. They are suitable for both professionals and beginners. They can be purchased for travel, for daily trips to work, for walks with friends, for sports. Reliable technology has a number of advantages.

- Technically, the motorcycle is in no way inferior to expensive models. It has a single-cylinder engine with two valves, a five-speed gearbox, and a multi-plate clutch. The equipment can reach a maximum speed of up to 140 km/h and withstand 150 kilograms of weight. The motorcycle has a spacious fuel tank of 14 liters.

- This model range is one of the most popular, since with excellent technical characteristics it has an acceptable price, allowing it to be purchased by customers of different incomes.

- Economical fuel consumption allows you to cover a distance of 600 kilometers with a full tank. One hundred kilometers takes only three liters of gasoline. You can significantly reduce your refueling costs.

- You will not have any problems when repairing or replacing spare parts. They can be purchased at any car service center or store. They are always in stock.

- The quiet operation of the engine and smooth ride make riding a motorcycle comfortable and unforgettable.

Selecting the Geon model range in the Mototek online store

A specialized online store offers a large selection of Geon brand models with delivery to any city in Ukraine. You can purchase budget options, equipment for professional bikers or motorcycle racers. The range of products includes all-terrain vehicles and ATVs, children's motorcycles. The website describes all models in detail, highlights their advantages, and indicates their cost. Online you can easily get acquainted with each product card, choosing the model you like. Store managers are ready to provide professional assistance to each customer and advise in choosing a product. If you are buying motorcycle equipment for the first time, contact specialists, they will help you choose a motorcycle for a beginner. By purchasing a model based on price or specifications, you will be purchasing the best product.

You can pay for it in any convenient way. Before payment, you can order a test drive service, which will help check the technical condition of the motorcycle. Regional customers receive goods with prepayment. It is acceptable to obtain a loan for the purchase of goods.

Geon equipment will not disappoint the buyer. The combination of high quality and low price will allow you to purchase one of the popular brands of motorcycle equipment.

Report on the condition of the Geon X-Road 250 CB for a year of operation

As winter draws to a close, it’s time to prepare for the new motorcycle season. This means that there is even less time to write reports on the operation of this motorcycle. Therefore - here.

We purchased the X-Road in mid-summer 2015. This is the third motorcycle that I bought new, so I have a coherent concept for how to approach the break-in. I do this (testing new equipment) very “long and tediously”, but the result is invariably pleasing. I make a note about the break-in so that it becomes clear that almost the entire second half of the summer was spent on this process. No, I made several trips into nature, I even visited the Kitsevskaya desert, but, due to the extremely gentle operating regime, these trips were boring and had no consequences. At that stage, maintenance was reduced to banal adjustments to the chain slack and changing the oil. By the way, about oil. The Sweetmoto company, the official representative of the Geon brand , generously gives two liters of Motul engine oil (10w-40 and 15w-50) upon sale. I spoiled my previous motorcycle with Motul. This time, due to the high dollar exchange rate, and, consequently, the high price, it was not affordable to use the pleasantly smelling Motul. I chose the synthetic XADO 10w-40 4t MA. Looking ahead, I’ll say that, on the recommendation of a friend, I tried Hadov’s 10w-60 oil, which seems to be more suitable for loaded endurik cycles, but, according to subjective sensations, it seemed too “liquid”. The box worked with a more expressive noise, the gears were engaged more harshly. In a word, I “returned” to 10w-40.

During the break-in period, I got used to the considerable height of the motorcycle and adjusted the “working place” to myself. The motorcycle fits perfectly for my height (1.78m), but at first it seemed tall off-road. I adjusted the handlebar height and removed the rubber pads on the footpegs. This made it possible to achieve the classic “standing position” - slightly bent knees, straight back and head above the instrument panel. In general, with my build, I am very comfortable driving the Geon. The only thing that cannot be easily corrected is the considerable weight of the motorcycle.

In the fall of 2015, I met a group of endurist travelers and, from that moment, the process of professional degradation for my motorcycle accelerated noticeably). In October, I was lucky to take part in a two-day interception at Grunivska Sich. After this raid, I had certain thoughts on the topic of light modifications to the moto. It was decided to postpone this work until spring. The end of that season was a one-day ride along the banks of Vorskla. The 2015 motor year was completed with 2500 km on the odometer.

At the beginning of March 2016, the garage doors opened! I started the long-awaited improvements. They consisted of installing additional light - an LED lens, a socket for a compressor, a navigator and a telephone in the form of a car cigarette lighter, and, most importantly, manufacturing a luggage system. An additional headlight was ordered from China for a ridiculous 170 UAH. It was turned on by a hastily attached emergency button. “Kolkhoz” was justified by lack of time and by the fact that this is a test version and will soon be replaced with a digestible analogue. Yeah, that’s how I skated the season))). The headlight, by the way, showed only its best side; the only thing we can complain about is the narrow “sheaf” of light. I would like it to be wider. There’s not much to say about the cigarette lighter: it worked, sometimes the contacts oxidized, it shorted out a couple of times, burning the fuses I had provided for such a case. The luggage system was suffered through pain)). The Kharkov craftsmen from MMoto did not respond to my letter of inquiry. This is a workshop that is famous for its luggage racks far beyond the borders of Ukraine; their work is both beautiful and reliable. Despite the considerable cost, I was ready to order a luggage system from the guys. Especially for this, I disassembled the tail section of the motorcycle down to the bare frame, photographed all the joints and mounting points, and described my wishes in detail in a letter. I don’t know whether they didn’t like my requests, or whether the photos were uninformative, but the questions remained unanswered. I had to get out on my own. On occasion, a pipe of the required diameter was purchased (which I conveniently forgot to bring on the day of welding), and a sketch of the product was ready. Having finally persuaded my always busy brother to help me with welding, I came to Akhtyrka and discovered that the main material, namely the pipe, remained in Kharkov. At the metal depots in Okhtyrka there was nothing similar to the required pipe, there was no way to transfer the work to “someday later”, so I had to buy a smooth rod with a diameter of 8 mm. A system made from such a rod does not look very good, but it will perform its functions perfectly. My fears about the excess weight of the trunk were not justified - the finished product weighs just over 3 kg. The rod was bent using heating with a propane cutter, and cooked using a conventional inverter. Four hours later, the finished luggage system was primed, and we drank beer with satisfaction.

In field conditions, our design showed its best side - neither repeated falls nor overloads affected it in any way. The first difficult off-road climb was the “Izyumskaya Cherta”, followed, a month and a half later, by the “Burluk Raid”. The first losses occurred. In the mud of the spring fields, the rear pads simply evaporated. The front brake began to work with micro-seizing, but after washing and lubricating the caliper, the binding disappeared. The wheel bearings urgently required attention: the front bearings “buzzed”, the same thing happened with the left rear bearing, but the situation with the right one was worse. The fact is that the developers did not consider it necessary to close the rear right bearing with an oil seal, therefore, despite the closed design of the bearing itself, it dies first. This flaw led to the fact that in 12,000 km I had to change the bearing three times.

Maybe when using a motorcycle on civilized roads, it takes some acceptable time, but in the conditions in which our specimen found itself, it is not guaranteed. Having discovered the problem, I began to inspect this unit on other motorcycles: on the old “Japanese” and on the new “Chinese” - nowhere had they thought of this. Even an almost exact copy of the X-Road from Shineray has an oil seal. There were no answers to this question on the very specific forum of geonovods. One user agreed that yes, there was a problem, but he was going to solve it radically - by replacing the entire wheel. The rest, apparently, are not bothered by such a trifle. I wasn’t ready to buy a new wheel, so I decided to bother modifying the existing one. Upon closer examination of the unit, I came to the conclusion that the bearing seat should be “deepened”, and thus we will get the necessary space for installing the oil seal. Naturally, bearing displacement along the wheel axis leads to the need to replace the bushings. It’s easier with an internal spacer sleeve - you just need to shorten it by the 4mm that will deepen the bearing fit. The outer one needs to be made new, 4mm longer. Before ordering turning and boring work, I was concerned about finding a suitable oil seal. The outer size of the oil seal is set by the bearing (6203 bearing - 40mm), but the inner size varied. The factory spacer sleeve has an outer diameter of 27mm, I couldn’t find such an oil seal, so I ordered a new sleeve with a diameter of 25mm - for the 25-40-7 oil seal

The work to bring the hub to perfection was completed within a few days and cost 450 UAH.

This modification was not the only one. The neighboring node, the progressive pendulum, also deserves close attention. The pendulum axis has needle bearings, and this joint is also susceptible to abrasive attacks. In addition, from the factory these bearings, like wheel bearings and progression units, are very conditionally lubricated, that is, to say that they are dry is to lie, but to consider them sufficiently lubricated would be an exaggeration. I was aware of this feature of the Chinese approach thanks to the above-mentioned forum, so immediately, during assembly, I applied lubricant to problem areas. Today, the needle bearings and bushings of the pendulum axle have noticeable wear, but they will still ride. I decided to replace the progression bearings with caprolon bushings. The work on manufacturing and installing bushings cost me 200 UAH.

The last two rides brought little joy - at the intersection the rear of the motorcycle seemed to be thrown and carried around on its own. I even sinned on the bursting frame. It turned out that it was a “leaked” shock absorber - driving on one spring is terrible. This is probably the most annoying breakdown - a shock absorber that is unable to go 10k is downright frustrating. The stock price is 1156 UAH, the price of the tuned one from GN Motosport is 3200 UAH. I saved money and bought stock.

Before the start of the new season, the rear brake line was also replaced. The mechanism worked flawlessly, but quite frightening cracks were visually visible.

To complete the description of the motorcycle chassis, we also need to say something about the chain/sprockets and the consequences of a broken chain. Due to a cracked link, the chain tore the trap from the pendulum. The plate on which the chain catcher is attached is attached to the pendulum with two bolts screwed into barely welded nuts. All this was turned out with “meat”. The trap broke off the fastening ear of the star on the hub and knocked out the spoke. All of the above did not prevent me from skating for another five months.

The drive sprocket had to be replaced along with the second chain. The star had a pronounced “saber tooth” and I didn’t want to kill the new chain with it.

At the moment, there is a third chain on the motorcycle. All three were sealless: the first was factory, looked impressive and was declared as “reinforced,” but it burst without traveling even 5 thousand km; the second, bought on the road, a Chinese knockoff of the Kovrov one, lasted 4 thousand km; the third one still stands today, but it will soon be time for it to retire. The driven sprocket, once in contact with them, looks decent with barely noticeable wear. But, if I still decide to fork out money for DID VT2, I will have to replace it.

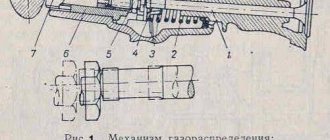

Over the entire mileage of the moto, which is more than 12,000 km, I replaced the air filter and spark plug once. Checking the thermal clearances of the valve drive gave acceptable readings. The carburetor did not bother me; during the entire period of operation I did not disassemble it.

Of the plastic tails, only the front wing had any adventures - I fell apart on a wet chalk road and broke the wing at the attachment point, under the lower yoke. With Andrey's hands, the wing was restored and installed in place. Thanks to the well-soldered plastic, the process was easy and quick. The soldering was reinforced with metal mesh.

From the unknown. Left remote control. Probably karma. First, the plastic part of the turn signal switch lever was lost, as a result of which it is normal to use it with gloves, but without gloves it digs into your finger painfully. Then the side/low/high light switch started to malfunction. Disassembling and cleaning the contact group did not yield anything. The remote control has been replaced with a new one.

A set of tires was purchased in the off-season. The original tires were worn out to the point of “driving to the mountains and throwing them away there.” The Carpathians are too close, the Caucasus is just right. I bought my favorite Mitas, the front one is S-19, the rear one is S-02. She looks angry and scary, just like in life - we'll see.

I hope it is clear that everything that happened specifically with this motorcycle is an individual case. Neither a broken fender nor a broken chain trap can judge a motorcycle. Also, stories with bearings and shock absorbers cannot objectively reflect the overall quality of the build - a picky critic will accuse me of misusing this moto. But the unique design of the rear hub, on the contrary, is very characteristic.

But, be that as it may, the article does not intend to discredit the manufacturer or glorify him. This is just a usage report and an attempt to show that IT IS WORTH IT! Don’t be afraid of the “Chinese” - all routine repairs and replacement of consumables over 12,000 km and a year and a half of operation cost ~$300. And then, decide for yourself))).

(c)doctus