When servicing suspension components, users often ask the question of what oil to pour into shock absorbers. This problem is relevant due to the small amount of information about collapsible structures. According to statistics, 80% of car repair shops do not reassemble struts. Our editors present an article containing information useful for solving the problem.

see also

Comments 17

modern forks were filled into the rear shock absorbers RFY. There is no effect, but I filled in two-stroke Lukoil, and the shock absorbers started working))) What am I talking about? And you'll have to choose. The fork wears out in all sorts of ways, and the boxer is much heavier than the PS...

The stiffness of the fork is determined by the spring; only the degree of damping can be adjusted with oil. You may have to grind out inserts for the springs to preload them.

I poured 20-50 in Yu-3, it was hard, I went back to the spindle - it was ok

In reality, I filled in synthetic for the steering hydraulics Golf 3 (Phoebe 061062) and I am pleased with the result! The fork does not leak and works well. But I don’t know how rigid the PS’s fork is and the load from the opposed one will be greater, we need to think through everything!

For the boxer, the PS fork is a little soft, but to tighten it up with 46 hydraulics, it will be just right.

I want to try dextron, it is recommended as the oil that gives the smoothest running

Now I’m putting the third Jupiter on its feet, I came across the instruction manual for the 1993 Izh-Jupiter. This is what it says about fork oil: ATF oil or for hydraulic boosters, in extreme cases a spindle, but ATF is preferable, since it contains anti-foaming additives. I filled it with ATF - experiment)

I drained the factory fluid, filled it with ATF, and didn't notice any difference.

Dextron is fine

what the heck is a motor with a transmission?! as an option, a hydraulic I-20 or something close to it if a modern one is difficult to acquire.

modern is not difficult, if it fits an ancient plug, I am only FOR modern

the fork is a classic monotube design of a non-inverted type, the old one may only have tired oil seals and anthers. Feel free to apply modern oil, it’s difficult to say by viscosity which one it needs. 10W is an option

modern is not difficult, if it fits an ancient plug, I am only FOR modern

If the ATF is like “snot”, then pour Motul 10-15-20w, select it yourself, or better yet, immediately try different options for the viscosity of the fork Motul. In my case, 500 re was simply thrown out for dextron, since it turned out to be too liquid (even worse than drain) and was drained. Stopped at 20w.✊

Working conditions of a motorcycle shock absorber fork

The front fork is two long tubular pieces that hold the front wheel to the motorcycle. These parts move up and down to compensate for unevenness in the road surface.

Unlike a car shock absorber, the spring assembly allows the fork leg to compress and then spring back, resulting in a better ride and improved traction. Each of the front fork tubes for most motorcycles contains a spring and oil. Back in the middle of the last century, fork legs were just a spring inside a pipe. When the spring was compressed by the impacts, the front of the motorcycle bounced.

After the development of the damping system, this bouncing motion became much smoother. However, to soften shock impacts, the system must contain an incompressible fluid that can easily withstand shock loads - fork oil. The most common design is one where inside each shock absorber fork leg there is a tube with holes and chambers that control the movement of oil.

What to put in shock absorbers?

I'm rebuilding the shock absorbers. I checked it on the motorboat and it works correctly. I know the volumes - 135 in telescopes, 105 in rear ones. There are 2 candidate fluids - AZh-12T and motorka 10w40. Single, no use in winter. Which one should you prefer?

I would like someone with experience to roll it out - what will be the difference, and will there be any?

in 3 rear AZh12 in plug 10W

In shock absorbers - shock absorber fluid definitely. Judging by the volume... this is Uralovskoye. means pouring what is written above!

I always used hydraulic oil after repairs (I have access to it) and there were no problems.

In the front transmission, in the rear and the stroller there is 10w, but the flow varies

The question is more theoretical. As I understand it, the main characteristic of shock absorber fluid is viscosity. As I understand it, the AF was invented so that the viscosity in the cold would not be cosmic and the suspension would not turn into a stool. Isn’t it possible that if we drive only at a comfortable above-zero temperature, then we can pour in anything with the appropriate viscosity, as long as it doesn’t eat up the rubber and lubricates properly? And why is there such discrimination - in the rear AF, and in the fork of a motorbike of the same viscosity?

I'm not fighting for the rights of the fork on the AJ) I'm just really interested.

The shock absorbers in the fork, due to the precision of manufacturing of the parts and design, work quite conditionally, there is of course a difference in years and acceptance, but on the most popular models everything is very sad, so thick oil makes it possible to get at least some performance, hydraulics in the rear shock absorbers it copes with its task well, but requires an individual approach, again due to the precision of manufacturing of parts and the wear of these same parts; it is possible to select a liquid only empirically. As for seasonality, naturally synthetics are stable over a wider range, and hydraulic fluids differ from motor fluids, in our case, primarily by the presence of antifoaming additives.

Oh, thank you, the meaning becomes clearer. In general, the experiment will save the stepson of Russian hydraulics)

In the front, at least you can change the oil without removing it, but in the rear it’s not so simple (

There was a container of TNK synthetics 0-30, I rushed to pour it into the Priora, left it for morters. I filled the front orion fork and the rear shock absorbers on the single, and all the morters on the sidecar. It’s very oaky at the moment, especially in the front, maybe it will be softer in the summer, it’s oaky at the back, but tolerable. On my own, I decided to pour AJ into the orion and pump it up to taste, and try mixing it in the ass. But on the stroller I filled all 5 ammorts with 0-30, there were no suspensions yet, but I like the way the front suspension works by hand.

I have been pouring dextron into the rear shock absorbers for a long time (the car has a coupling, so there is no need to buy it specially), the only thing is that the rubber bands there (acting as seals) have been replaced with normal seals (by the way, they are suitable from Uralokpp, only they are single-collar, but two would be desirable). They are used with a bang in the summer. Well, first of all, you need to select the oil according to viscosity, like that of the eight, and the quality, like in normal oil, because the eight has the property of turning into G over time. And how correctly they wrote here: “The shock absorbers in the fork, due to the precision of manufacturing of the parts and design, work rather conditionally,” but you couldn’t be more precise. ;)))

Functions and Features

Despite the wide range of products offered, there are many discrepancies and uncertainties in their designation and parameters. Thus, the operational requirements for fork oils include:

- Ensuring optimal fork damping and stable performance over a wide temperature range.

- Independence of oil performance from fork design.

- Prevents foaming.

- Elimination of corrosive effects on metal parts of the shock absorber and fork.

- Chemical inertness of the composition.

Motorcycle suspension care.

Another short and obvious article, this time about caring for motorcycle suspension. There are a lot of well-known points, but overall it’s a good read.

Typically, suspension maintenance, in addition to basic things like cleanliness and periodic visual inspections, is not available to the average motorcycle owner in a garage environment, however, it is necessary to understand that shock absorbers, progression and other suspension components are the same motorcycle parts that require periodic maintenance . For adequate operation of a motorcycle suspension, it is still necessary to sometimes turn to professionals for its maintenance.

How to choose fork oil?

First of all, by its viscosity. As is known, kinematic viscosity is measured in centistokes (cSt), and represents the speed of fluid flow through a conventional tube of a certain cross-section. In practice, the dimension mm 2 /s is more often used. In relation to fork oils, the standards of the American Society of Automotive Engineering (SAE) apply, which relate viscosity values at a certain temperature (usually 40 ° C) to the density and weight of the product. Weight in English weight; From the initial letter of this word the designations of fork oil brands are formed. So, when considering fork oils for motorcycles of brands 5W, 10W, 15 W, 20W and so on, you should remember that, for example, 10W class oil corresponds to a product with a nominal viscosity of about 10 mm 2 /s.

Fork oil weight is determined by an industry standard for hydraulic systems called Saybolt Seconds Universal (SSU). Unfortunately, the voluntarism of the main manufacturers often leads to confusion among the labeling of fork oils. The following correspondence of viscosity parameters was experimentally established:

| Marking | Actual viscosity value, mm 2 /s at 40 ° C, according to ASTM D 445 for brand products | |||

| RockShox | Liqui Moly | Motul | Motorex Racing Fork Oil | |

| 5W | 16,1 | 17,2 | 18 | 15,2 |

| 10W | 33 | 29,6 | 36 | 32 |

| 15W | 43,8 | 43,9 | 57 | 46 |

| 20W | — | — | 77,9 | 68 |

Weaknesses of the IZH-P5 engine

- Air filter;

- Cylinder-piston group;

- Transmission.

More details about the weak points of the IZH-P5 power unit...

Air filter. To prevent dust from entering the engine, frequent washing and oiling of the filter element is required. Installing a paper filter would reduce the time spent on engine maintenance during maintenance and would improve the quality of cleaning the air supplying the carburetor.

The CPG wears out after 20,000-25,000 km due to the lack of water cooling.

Transmission . Over the years, due to wear and tear, the gears switch off on their own and adjustment does not eliminate the problem. In this case, it is necessary to overhaul the gearbox and replace worn out parts.

Izh 2.673 Cornet

Izh Cornet is a mini-motorcycle with a ground clearance of 195 mm. Characteristic features of this model are a high steering wheel, disc brakes and chrome parts. The lining is plastic, the footrests are moved forward. Thanks to its compact dimensions, the motorcycle is maneuverable and economical. It is equipped with a two-stroke 2-cylinder engine with a carburetor power supply system and air cooling. The lubrication system is combined (oil mixed with fuel). The estimated speed of the Izh Cornet motorcycle does not exceed 50 km/h.

Year of manufacture: 2001

Two-stroke 2-cylinder, carburetor, 50 cc. cm, 2.21 l. pp., oil volume – 20:1, approval: API-TC

Izh 6.113-020-05 Junker

Izh Junker is a recreational motorcycle with a ground clearance of 175 mm. It is made in the American style, and its distinctive features (compared to its predecessors) are a high steering wheel and a streamlined teardrop-shaped tank. The instrument panel is mounted on the tank.

The developers managed to ensure the comfort of passengers by installing a two-level saddle, which can accommodate just two. In addition, the Junker is equipped with a front disc brake, and a “drum” is installed at the rear.

An updated intake and exhaust system is installed, which is relatively quiet and provides higher thrust at low speeds than previous models. The total production volume of the Izh Junker motorcycle was 6,000 copies, including modifications for special services.

Years of production – 2000-2005

Two-stroke 2-barrel, carburetor, 347 cc. cm, power – 24 l. pp., oil volume – 20:1, approval – API-TC

Izh Planet 7

Izh Planet 7 is a middle-class motorcycle, the successor to the successful Planet 5 model. Owners positively evaluate Planet 7, which has a rather interesting original design, a powerful and economical engine and has high maintainability.

However, there are also disadvantages: low reliability of rear wheel bearings, insufficiently efficient air cooling (especially in hot weather), poor quality assembly and weak traction in versions with a trailer. The Izh Planet 7.107 modification periodically experiences strong engine vibrations.

Next, we note the main improvements compared to its predecessor (Planet-5): a lightweight 4-stroke engine of smaller volume but similar power, an electric starter for starting, a narrower gas tank, new instrument panel and optics with turn signals, electronic non-contact ignition, improved clutch, separate lubrication and five-speed gearbox. The improvements made had a positive effect on the dynamic qualities.

Years of production – 1987-2008

4-stroke, 2-cylinder, 250cc cm, 20 l. pp., oil volume – 2 liters, tolerance and viscosity: API-SG, SH, SJ; SAE 10W-40

How to replace fork oil?

To calibrate the oil, a much more sensitive viscosity calibration scale is used, so in practice you can get a conditional 7.5W or 8W “for yourself” by mixing ordinary industrial oils in the required proportions. For the performance of a product under specific operating conditions, it is not the viscosity value itself that is important, but the so-called viscosity index. It is usually indicated on the Saybolt Seconds Universal (SSU) scale at 100°C. Let's assume that the numbers on the container read 85/150. This means that the SSU value of the oil at 100ºC is 85. The oil's viscosity is then measured at 40ºC. The second number - 150 - is the value indicating the difference in flow between the two temperatures, which determines the stated viscosity index.

What does this have to do with motorcycle forks? The friction created by sliding metal parts and oil moving back and forth increases the temperature inside the assembly. The more constant the oil weight remains, the less likely it is that the fork damping will change.

Thus, it is quite possible to replace fork oil with industrial oil, combining its brands according to the operating conditions of your motorcycle.

With certain reservations, this principle can be used for other vehicles (with the exception of racing motorcycles).

A procedure such as changing the oil in a motorcycle fork frightens not only beginners, but also experienced drivers. Even professional mechanics often spend a lot of time doing this job because they have to deal with so many details. In addition, it is necessary to choose the right oil, which will allow you to obtain the necessary parameters of suspension rigidity. Therefore, it is necessary to approach such a procedure only after careful preliminary preparation.

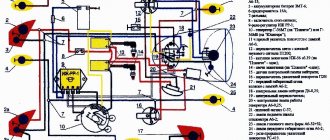

Izh Planet-5 gearbox diagram

In order to properly handle the device, you need to know not only the principles of its operation and operating rules, but also the circuit diagram of the unit. This is especially true when you need to independently repair any component of the motorcycle. This is also true for the gearbox. The Izh Planet-5 checkpoint diagram looks like this:

Each part will be described according to its number.

- Primary shaft of the gearbox of the Izh Planet motorcycle.

- Gear (gear) required for 2nd gear.

- Stop washer.

- Ring for installing elements.

- Gear (gear) for 2nd and 3rd gears.

- Primary shaft assembly.

- Washers.

- Additional shaft with bearing.

- Sprocket for secondary shaft.

- Lock washer.

- Nut for secondary shaft.

- Nut cap for secondary shaft.

- Ring.

- Intermediate shaft.

- Gear (gear) for 3rd gear.

- Installation ring.

- Gear (gear) for 1st and 4th gears.

- View of the gear (gear) of the 1st gear in a complete assembled set.

- Intermediate shaft with gears.

After studying the diagram and its components, you can begin to analyze the checkpoint itself.

Important! Although the diagram looks simple, for effective repairs you need to know the rules and instructions for assembly and disassembly. This is the only way to ensure the quality of the work performed.

Oil change intervals

Most manufacturers recommend changing the oil in the front suspension of a motorcycle every 12-15 thousand kilometers to ensure that the two-wheeled vehicle maintains good handling. However, experienced owners prefer to replace them simultaneously with scheduled repairs, which include installing new oil seals. This allows you to obtain optimal fork stiffness parameters without having to deal with time-consuming, labor-intensive adjustments.

It is recommended to change the oil after the motorcycle has been idle for the winter, since low temperatures may cause it to partially or completely lose its properties. If the motorcycle participates in sports competitions and the demands on its handling are very high, the frequency of replacing technical fluid should be reduced to 5 thousand kilometers. Experienced drivers recommend changing the fluid when the fork wear becomes noticeable. This is expressed in deep “dive” when braking, as well as in destabilization of the motorcycle at high speed. In such a situation, it is recommended to buy oil of higher viscosity in order to stiffen the suspension and also improve the handling of the two-wheeled vehicle.

Planet-5 gearbox repair

The gearbox is repaired after disassembling the gearbox. At this stage, the cause of the malfunction is identified and the necessary parts are replaced. At the same time, it is best to buy parts as a set, so there will be no discrepancies in size during assembly of the unit. If you follow the instructions given above, you can easily repair the gearbox yourself. For convenience, parts can be signed during disassembly. They should be laid out on a clean surface to prevent foreign bodies from getting into the structure in the future.

The result depends on the quality of the work performed. Therefore, it is important to carefully monitor the implementation of all points for assembling the gearbox with new parts, with the help of which the old ones were replaced.

Oil selection

Choosing fork oil is very difficult, despite the recommendations of motorcycle manufacturers. The problem is that motorcycle manufacturers often specify ideal viscosity parameters at operating oil temperatures that are many times higher than the temperature at which the fluid is poured into the fork. Therefore, it is necessary to pay attention not only to the standard designation of viscosity, but also to the coefficient of its change with increasing temperature. Such information is often indicated on the canister of liquid, and if it is missing, you will need to pay attention to the manufacturer’s website or to specialized materials published by technical experts.

Since the characteristics of oils from different manufacturers with the same SAE designation can vary significantly, it is better to choose one brand and remain faithful to it in the future. The first change is always made with oil with the same viscosity as specified in the vehicle’s operating instructions. With a significant reduction in fork stiffness, you will need to gradually increase the viscosity - by 2.5W or 5W with each subsequent replacement, depending on your personal preference. Most touring motorcycles recommend 10W oil, while sport and high-performance city bikes recommend 2.5-5W oil.

It is prohibited to use regular motor oil in the fork as it will help achieve the desired damping characteristics. On a canister with a special material you can find the inscription Fork Oil or Suspension Oil. You should beware of fakes, because with low-quality oil in the fork, the motorcycle can become uncontrollable, which will lead to a serious accident.

When choosing fork stiffness, you need to be guided by the type of roads on which the motorcycle will be used. By adding a thicker oil, you will get better damping characteristics and your vehicle will be more stable at high speeds. However, with an increase in rigidity, comfort will significantly decrease - on any major unevenness the driver will feel a “breakdown”, which can even throw the motorcycle off course. On the contrary, insufficiently viscous fork oil will cause significant vibrations, twitching, or even steering pull when cornering.

If the bike will only be used on quality intercity trails and race tracks, there is nothing wrong with significantly increasing the fork stiffness. However, for driving on country roads and city streets with poor quality coverage, such settings are no longer suitable. A special case is replacing technical fluid in a motocross motorcycle. For it you will have to buy a special technical fluid marked “Off-Road” on the canister. Using regular oil for road motorcycles can significantly reduce the energy capacity of the suspension or even lead to its failure.

Frequent malfunctions of the Izh Planet-5 gearbox

The most common problem is random knocking out of second gear. There are also cases when fourth gear disappears. Failures in the work of others also occur, but much less frequently. Another malfunction is related to the difficulty of switching speeds from high to low, jamming. This occurs due to a breakdown in the springs of the switching mechanism.

Its one fairly common malfunction is difficult gear shifting. This failure indicates that the problem occurred due to wear on the adjusting washers. But, as a rule, all problems with gear shifting on Izh Planet-5 can be corrected on your own.

Replacement procedure

Before changing the oil, be sure to look where the lower plug on the fork is located - the principle of performing the entire procedure depends on this. The following options are available:

- Down at the end;

- On the side at the bottom;

- The bottom plug is missing.

If the drain hole is located at the end of the fork, lift the motorcycle onto a support, remove the front wheel and install the rods strictly vertically. The lateral location of the plug allows you to repair the hydraulic system without removing the wheel, although you will have to lift the motorcycle in this case as well. If there is no bottom plug, you will need to remove the fork.

Having decided which oil to pour into the fork, first unscrew the upper plug, and then the lower one, after placing a vessel with a volume of at least 0.5 liters under each shock absorber. If you have to work on a motorcycle without a bottom plug, the removed fork will have to be turned over so that the oil comes out of it through a single hole. After draining the technical fluid, the fork must be washed - a special fluid or regular low-viscosity motor oil is suitable for this. Having done all this, blow the inside of the part with compressed air from a compressor or a special can.

A very important question is how much fluid to add to achieve ideal damping characteristics? The most common recommendations on the Internet suggest using 500 ml of liquid for each shock absorber. However, this is a very rough assumption that can make the motorcycle completely uncontrollable. To optimize the controllability of two-wheeled vehicles, it is worth focusing on such a parameter as the oil level from the top edge of the pipe. You can find it in the vehicle’s operating instructions or in specialized technical literature.

It is worth understanding that an oil pump with a measuring needle that prevents fluid from overflowing costs about $100 - not every motorcyclist is willing to pay such an expense. Therefore, a much better solution would be to build the necessary tool yourself, spending no more than 100 rubles on it. At the pharmacy, buy a 10-cc syringe and a catheter, which is a transparent tube that fits over the nose of the syringe. You will need a length of catheter equal to the distance found in the instructions. It will need to be tightly placed on the syringe spout to prevent oil leakage during operation.

First, you need to pour 500 ml of oil into the fork, or a little more if the catheter does not reach the top edge of the liquid. Then the syringe is applied to the pipe so that the base of its nose coincides with the cut line. All you have to do is pump out the excess oil that will interfere with the suspension adjustment. Remember that this procedure must be performed with the fork compressed in order to be able to accurately determine the required oil level. The cartridge should be installed at this point, but the spring does not need to be installed.

Preparing for assembly

Preparation for assembly can be divided into two main stages: measuring and, if necessary, eliminating the axial play of the tracer shaft and checking the suitability of the secondary shaft bearing for further operation.

The first stage is measuring and eliminating the axial play of the copy shaft

We put adjusting washers on the tracking shaft from the locking side. In my case, there were four adjusting washers, but you may have more or less, or maybe not... We move the locking bar to the side and install the copy shaft in its place. We put a standard thrust washer on the second end of the tracing shaft.

We place a new gasket (required) on the plane of the gearbox cover connector, on which you will later finally assemble the gearbox, and tighten the gearbox cover fastening screws with the required force.

We turn the engine over and measure the axial play of the copy shaft, the norm is 0.2-0.4 mm, but it will be better if you can ensure the axial play at a level of no more than 0.2 mm. Adjustment of axial play is accomplished by simply adding or removing shims.

I measure the play with an indicator. If you don’t have one, try measuring the backlash with a caliper; if you don’t have a caliper, so be it - measure by eye...

Second stage: checking the suitability of the secondary shaft for further use

Under normal operating conditions, the secondary shaft bearing runs for quite a long time. But no matter how much we want and try, it wears out. It would be nothing if it weren’t for safety: if your secondary shaft bearing falls apart while driving, and it will certainly fly apart if you don’t change it in time, the gearbox sticks together with the rear wheel, and it’s tight and you’re grinding the asphalt with your butt...

Carefully, take out the secondary shaft over some tray and carefully inspect the shaft bearing raceway, the races and the rollers themselves. The working surfaces of the bearing and rollers should be free of holes, edges, signs of wear or overheating. The path must have a perfectly flat working surface.

Example of a secondary shaft race and race in perfect condition.

To facilitate reassembly, apply some kind of lubricant, such as lithol, to the treadmill and carefully place the rollers on the track and, turning it a little, insert the shaft into the cage. As soon as the sprocket splines rest against the edge of the oil seal, use a thin screwdriver in a circle to straighten the edge of the oil seal and push the shaft until it stops. And immediately, so that the shaft does not fall out, put the sprocket on it and secure it with a nut.

Responsible process

The controllability of the motorcycle, and, consequently, the safety of the driver and others depends on the correct selection of oil for the fork. It is best to follow the recommendations of the motorcycle manufacturer, but increase the viscosity of the technical fluid when components wear in order to achieve good damping characteristics. It is also worth paying attention to the oil change procedure - the ability to adjust the suspension and obtain optimal rigidity depends on its correct implementation. We must not forget about flushing the fork after draining the old oil - drops of technical fluid remaining inside and chips obtained from friction between the components can significantly affect the characteristics of the shock absorbers. If you are not sure that you can perform an oil change and suspension adjustment yourself, contact professional mechanics, since your interventions can only cause harm.

Most common problems

Most often, the motorcycle in question loses or shifts poorly in second gear. This may be due to careless turning on of speeds. For example, when picking up high speeds in first gear without neutral, when engaging the second speed gear, an impact occurs, which contributes to intensive wear of the unit. Therefore, it is not recommended to “spin” the first speed too much. If, nevertheless, problems with the second position continue, there are several options for resolving them.

In some cases, the simplest method will help, without completely disassembling and then reassembling the Izh-Planet 5 box. It is necessary to place the motorcycle on the right side, and then remove the kick starter and gear shift foot along with the shaft. Next, the crankcase cover and clutch basket along with the discs are dismantled.

When the gears of the box wear out, the meshing of the teeth deteriorates. In turn, this leads to slipping, jerking and failure of the second gear. Another reason could be wear on the input shaft bearings. Since it moves slightly to the left due to vibration, it is necessary to move it into place with light blows using a mallet. The installation of washers of suitable diameter will allow you to fix the element in the desired position. Then the bearing stopper and other dismantled parts are reassembled in the reverse order.

It happens that disassembling/assembling the Izh-Planet 5 box may be necessary if the fourth speed disappears. This is often due to broken bearings on the output shaft. Such a nuisance occurs due to the presence of axial play, displacement of the bearing assembly, or its failure. You can try to fix the problem in the same way as repairing the second gear. If this does not help, you will need to completely disassemble the unit.

When the speed switch jams from a high range to a low mode, the spring system of the switching mechanism has failed. It needs to be replaced. Strained operation of the unit after assembling the Izh-Planet 5 gearbox indicates incorrect installation of the adjusting washers. To avoid this, it is necessary to mark and record the previous placement of these elements during the process.