Scooters today are relevant, popular and practical vehicles. People of various age categories can successfully move on them. For most owners, a scooter is their only means of transportation. Other owners use this technique as entertainment. During the operation of Chinese and Japanese mopeds, various malfunctions may occur. One of the common problems that many have encountered is the lack of spark on the scooter. Let's consider possible causes and ways to eliminate this problem.

Specifications

| Model | Today BA-AF61 FI/E (Honda Today AF 61) |

| Length | 1.695 m |

| Width | 0.630 m |

| Height | 1,030 m |

| Weight, kg | 75 (dry weight 71 kg) |

| Capacity | 1 person |

| Fuel consumption | 65 km/l (at 30 km/h) |

| Minimum turning radius | 1.8 m |

| Engine | 4-stroke air-cooled, single cylinder |

| engine's type | AF61E |

| The full amount | 49 cm3 |

| Bore × stroke | 37.8 × 44.0 mm |

| Compression ratio | 10,1 |

| Maximum output power | 2.8 kW (3.8 hp) at 8000 rpm |

| Torque | 3.6 N*m (0.37 kg*m) at 6500 rpm |

| Fuel supply form | Carburetor VK00A |

| Starting system | Electric starter and kick starter |

| Ignition | CDI |

| Lubrication | Separation by lubricant |

| Fuel tank volume | 5.0 l |

| Clutch | Dry multiplates |

| Transmission type | CVT (V-Matic belt) |

| Tires (front and rear) | 80/100-10 46J |

| Brakes (front and rear) | Mechanical drum |

| Suspension type (front) | Telescopic |

| Suspension type (rear) | Spring |

Honda Gyro Scooter with Roof

Recently, a new modification of the Honda Giro scooter was released, and unlike the initial version, it received a comfortable driver’s seat, the possibility of a closed cargo compartment and a roof. Also, the new Honda Gyro comes in two versions. The first version TA-01 received a simple 2-stroke engine, and in the second version TA-03 the scooter has a 4-stroke engine with liquid cooling capability.

Dealing with the candle

If the dio 34 does not start, then first of all we check the serviceability of the spark plug.

We unscrew the candle, insert it into the candlestick and connect the ground to it using an additional wire. We pull the kickstarter leg. Let's see if there is a spark. If it is not there, then disconnect the battery. And again we check with kickstarter for its availability.

If it does not appear, then you can determine the performance of the spark plug on another scooter or using a test gun.

In order not to waste time checking the old spark plug, it is better to immediately take a new one and continue working with it. I always take branded NGK or Denso from the catalogue, it is guaranteed to last for a year, or 5 - 6 thousand km.

When checking, with the battery disconnected, a weak spark may appear. The scooter will even start, but will not develop speed and will not move. The first impression is that the switch is faulty, but there is no need to rush to conclusions.

Check by appearance

A serviceable part must be clean. Only slight soot on it is allowed. However, if the electrodes are melted or black, then the spark will not occur. Spark plugs deteriorate if the fuel mixture is too rich. If the insulator is white, but there are small black spots on it and signs of erosion on the electrode, this indicates overheating. This is also evidenced by melted electrodes and insulator in bubbles. If there are oil deposits on the part, it can be considered faulty and it is better to replace it with a new one. This simple DIY scooter repair will help you use this vehicle again.

Various switches

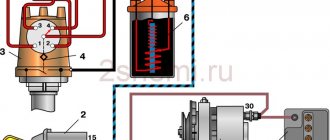

For example, on dio 35 there are 4 wires on the switch:

— s/w – the control pulse comes from the Hall sensor

- kr/h - with the engine running, an alternating voltage of 16.5 volts comes in, as well as + 12 volts of direct voltage from the battery. If the engine is not started, only + 12 volts come from the battery when the ignition is on

— z – ground (minus) or scooter body

— b/w – pulse voltage output to the ignition coil

And on the Honda Dio 34, another 5th wire with a reduced voltage of 9.3 V is connected to the switch. It is pink and goes from the ignition switch to the switch.

In the absence of reduced voltage, the scooter does not develop speed and does not accelerate. And when you increase the voltage on the pink wire to 12 V, the switch stops working altogether and the spark disappears.

The pink wire is provided as an anti-theft system so that it is impossible to start the scooter without a key by connecting the wires directly using a jumper.

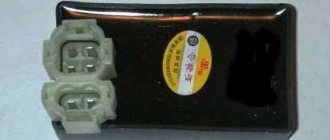

Pinout

If you have a 4T motor installed on your scooter, the pinout of the switch will depend on what type the scooter requires. For DC it will be as follows:

The leftmost terminal on top should connect to the generator sensor. Ground is connected to the terminal located under it.

You can tie the negative wire, for example, to the body of a moped; it is important that the part is metal. The upper terminal, located in the center, is connected to the wire leading to the ignition coil drive

The one located under it is also connected to the negative wire (ground). The wire from the ignition switch is connected to the upper rightmost terminal, which is needed to turn off the engine. The power wire is connected to the terminal located under it; it also comes from the ignition switch. If you have an AC type, the location of the terminals is the same, but they are connected differently:

If you have an AC type, the location of the terminals is the same, but they are connected differently:

- We move from left to right, first the top row, then the bottom.

- Here the wire from the generator sensor goes, as in the previous version.

- Next comes the ignition coil wire.

- And at the end there is a “silencer” for the ignition switch.

Bottom row:

- The first two terminals are the negative wire, “ground”.

- To the last remaining terminal we connect the power wire from the high-voltage winding of the generator. This point is the main difference when connecting an AC switch from a DC one.

Scooter Honda Dio AF 18 27

The Honda Dio AF 18 has a slightly different switch, made in Japan, which is why the pinout of the scooter is a little unique, and the mounts on the switch are different. It is connected as follows: from left to right, first the upper, then the lower terminals. Location:

- Hall Sensor.

- Ignition coil.

- Weight.

- Ignition lock.

- Power wire from a high voltage coil.

Yamaha Jog Scooter

Several types of generator can be installed on this type of motor vehicle. The most common option has 5 contacts, with wires already coming out of it. Therefore, if you have original wiring, you need to connect as follows:

- Orange should lead to the ignition coil and alternator.

- Black - to the ignition switch.

- Purple – Hall sensor.

- The remaining two wires are connected to the ignition coil.

Chinese scooters

Typically, such vehicles have standard switches, which were described above. The connection diagram depends on whether the AC or DC device is installed on your vehicle. It is worth remembering that different types of switches are not interchangeable.

Failure of ignition system components

This is not a common reason. But if the spark on the scooter disappears and there are no visible reasons, then it is necessary to test the switch, coil, and generator winding. You can check all these devices with the same multimeter. To make sure that the winding and pulse sensor are working properly, you need to connect one tester probe to the wire from the sensor, and the second to the engine crankcase.

A normally operating pulse sensor has a resistance of about 500 ohms. The generator winding resistance is two to three times less. If the multimeter shows infinity, then one of the components has failed. It should be replaced with a new one. If the value is less than 150-200 ohms, then the problem is in the supply coil, and therefore the spark is lost on the scooter. What to do in this situation? Buy a new generator. Such a device can be repaired, but if there is no time, it is better to simply replace it. Fortunately, the cost of the generator is low.

Checking the regulator-rectifier and voltage generator

Disconnect the battery. Switch the device to 10 A.

We put the red probe on the c/h wire, and the second probe on the minus wire - the green wire. Turn on the ignition. We pull the kickstarter leg. The device can show 5 - 10 A. This means that the voltage generator, regulator-rectifier, electrical wiring and fuses in the circuit from the generator to the battery are working.

If all this works, but there is no spark, then all that remains is to check the switch. It cannot be disassembled and has a complex electronic circuit inside. Therefore, it can only be tested on another similar working scooter. Finding a Japanese switch can be difficult. But there are many Chinese analogues, they work no worse than the original ones.

This troubleshooting sequence - no spark on dio 34, can be used on any 2t or 4t scooter or moped. All you need is an electrical circuit for the scooter, a universal set of screwdrivers and wrenches, and a multimeter (tseshka).

That's all.

Those who are interested will be able to find the problem with the spark on their scooter or moped and fix it with their own hands.

Do not be afraid. Try it.

If you have any questions, write. We'll figure out.

Bye everyone!

Cleaning the elements correctly

Every owner of motorcycle and automobile equipment should know how to properly clean spark plugs from carbon deposits. Most beginners try to restore parts themselves and then wonder why they don't work.

The main mistake is that the spark escapes to the spark plug body along the soot - it is not a conductor of electricity. The engine cannot be started. Plaque forms not only on the electrodes, but also on the ceramic insulator. Therefore, it is necessary to clean not only the side and central electrodes, but also the insulator.

A better effect can be achieved if you use a sandblaster. If there is none, you can try cleaning with just sand. To do this, you should purchase an electric drill and sand in a bucket. Next, take the candle and clamp it in the drill chuck by the thread on the top. Large threads are wrapped with tape. The part is then lowered into the bucket and the tool is started. After some time, the electrodes and insulator will be cleaned. If the spark is lost for this reason, the scooter spark plug will work properly again.

Checking the Zener diode

Before moving further, you need to once again verify that the zener diode is faulty.

To do this, remove the connector from the lock and use a meter (2 kOhm included) to measure the conductivity at the two outermost contacts. It should be like on a diode: if you swap the probes, then in one direction it will show 0, and in the other it will show resistance. If this is not the case, then the zener diode is definitely faulty.

Feel free to disassemble the ignition switch.

You will need the following tools: a T10N bit, a small key for a 6.5 mm bit, a soldering iron.

With the zener diode unsoldered, go to radio stores and buy a couple just in case. They are available everywhere and cost around 10 rubles.

We solder the zener diode, assemble the ignition switch, and connect the connectors. We connect the battery, turn on the ignition and again measure the voltage on the pink wire. It should be 8 - 9 V.

We look at the spark on the candle. If it is, then screw the spark plug into place, start the engine and ride all summer.

And if there is still no spark, then we look further and check: the ignition coil, Hall sensor, voltage regulator - rectifier, generator, switch. But more on that in the next article.

Subscribe.

Write how it works out for you, we’ll discuss it together.

Bye everyone.

How not to break the ignition

Someday you will have to cook something on a scooter.

There is no spark on the scooter or it disappears at the most inopportune moment, saddening the driver with a stalled engine. Not a common, but quite possible malfunction, especially on Chinese scooters. In this article, more aimed at beginners, we will look in detail at the reasons for the loss of spark and consider methods for eliminating this malfunction (return the spark).

When your scooter's engine stalls, you should first find out why it stalled. After all, there are only two main reasons why the engine stalls somewhere along the way, or does not start at all: either there is nothing to burn in the combustion chamber of a scooter engine (no fuel is supplied), or there is nothing to ignite (no spark).

I hope that everything is in order with the power system of your scooter, there is gasoline in the tank and fuel enters the combustion chamber due to the discharge from the piston (this is the topic of a separate article, but in this article we are looking at the lack of a spark). And the reason that the engine stalled is precisely because there is no spark on the scooter.

It is, of course, very easy to verify this, just unscrew the spark plug from the spark plug hole in the head and insert the spark plug into the spark plug cap, all that remains is to attach the spark plug body to the engine body, pull the kickstarter and look at the electrodes.

By the way, I advise you to pay attention to the spark plug electrodes not only for the presence or absence of a spark, but also whether the electrodes are wet or dry. If the electrodes are wet, this means that most likely everything is in order with the power system (carburetor) of your scooter and the motor has stalled (or will not start) precisely because of the lack of a spark at the spark plug electrodes.

If there is no spark, there may be several reasons and specific reasons will be described below. And let's start looking at the simplest ones and move on to more complex reasons for the lack of spark. Well, of course, it will be described how to troubleshoot and return the spark.

There is no spark on the scooter - reasons and methods for doing it yourself.

1. The first and most common reason for the lack of a spark at the spark plug electrodes is the failure of the spark plug itself. This happens often, since our gasoline, to put it mildly, is not very good in quality (we find out how to check gasoline yourself here) and due to the presence of all sorts of nasty things in gasoline, spark plugs often fail (read more about why spark plugs fail here ).

You can verify that the spark plug is to blame for the lack of spark by replacing it with a new or known good spark plug. But if suddenly you do not have a new spark plug at the moment, then you can check the normal operation of the ignition system using a regular piece of wire or a nail of suitable diameter (so that it fits into the hole of the cap and does not fall out).

It is inserted into the hole of the spark plug cap, then a wire pin or nail inserted into the cap is brought to the engine crankcase at a distance of approximately 5 - 7 mm and then we crank the engine crankshaft using the kickstarter. A spark jumping between the pin and the engine crankcase (ground) will confirm that the ignition system itself is in perfect order and there is no spark on the scooter just because of a faulty spark plug.

By the way, the spark plug can be cleaned and brought back to life (at least to get a new spark plug to the auto parts store). But many beginners do not clean the spark plugs correctly, and as a result, if a spark appears on the spark plug after improper cleaning, it does not last long. I recommend reading about how to properly clean candles here. Well, those interested can find out how to determine the state of the power system, or the engine of your scooter, by the color of the spark plug electrodes here.

2. The next common reason for the lack of a spark is a break in the wire (or oxidation of its terminal) that connects the engine to the frame (after all, the motor hangs on silent blocks and must be connected to the frame). This means that after checking the spark plug, we check the integrity of this wire and the reliability (cleanliness) of connecting the terminal to the motor and the frame of the scooter.

3. Another simple reason for the lack of a spark is a break (burnout) in the high-voltage cap of the noise suppression resistor. We remove it from the spark plug and test it with a tester turned on in resistance measurement mode (ohmmeter).

We disconnect the cap from the wire and insert the probe into the hole for the spark plug, and connect the second probe to a sharp pin (the one on which the wire is put) or to the wire, and measure the resistance. A working cap with a intact resistor should have a resistance of 5 kilo-ohms.

On modern scooters (unlike older mopeds), the high-voltage wire, cap and ignition coil are integral parts, as they are filled with rubber or compound. This means you should check the cap, wire and coil at the same time.

To do this, we again insert one ohmmeter probe into the hole in the cap intended for the spark plug, and alternately connect the second probe to the ignition coil terminals to determine the resistance of the primary and secondary windings, along with the cap and the high-voltage wire.

The resistance of the primary winding of the ignition coil (we check by connecting the probes to the coil terminals as in the photo) is approximately from 0.1 to 0.4 Ohms (for example, on a Honda Dio it is 0.2 - 0.3 Ohms).

Well, we check the resistance of the secondary winding of the ignition coil (we connect one probe to one of the coil terminals - green - see photo below), and the second probe to the hole for the spark plug in the cap) is 6.35 - 9.7 kOhm on most mopeds , but you can check the manual of your scooter (Honda Dio has approximately 8.2 - 9.3 kOhm). This is the total resistance of both the secondary winding of the ignition coil and the resistor in the cap (after all, the resistance of the noise suppression resistor is 5 kOhm).

Without the spark plug cap (if it is removed), the resistance of the secondary winding of the ignition coil will be approximately 2.7 - 3.4 kOhm. Well, if the ohmmeter shows infinity (break), then of course we replace the ignition coil with a new one, but do not forget that the resistor in the cap can also burn out, so to make sure that the ignition coil is correct, I advise you to measure the resistance of the secondary winding without the spark plug cap.

4. Another simple reason that there is no spark on the scooter is a break in some wire in the ignition system, disconnection of some terminal (rarely, but it happens), but most often it is oxidation of the contacts (terminals) of the wires coming to the system components ignition and, as a result, loss of contact and lack of spark (or there is a spark, or there is not). When the contacts oxidize, a transition resistance occurs at the terminals and, because of this, insufficient voltage.

Generator

Owners of 50cc who are familiar with the design of the scooter will immediately understand the purpose of this device. It produces an alternating electric current that powers the moped when the engine is running. But the second main task is to charge the battery while working. That is, the battery ensures the operation of the devices when the engine is turned off, and then the generator takes on this task.

The connection is made according to the following principle. There are several wires coming from the generator. The negative tire is attached to the frame of the scooter. There is alternating voltage on the white wire, which is immediately sent for rectification and stabilization.

In the electrical circuit, the yellow wire powers the low and high beam lights. Additionally, a Hall sensor is located in the generator housing. Its task is to generate impulses to control sparking. It is not electrically connected to the generator; it is connected to a white-green and red-black wire. The sensor is connected to the CDI block.

Let's continue to figure it out

We remove the beak. It is secured with three bolts at the front, four self-tapping screws on the other side under the steering wheel, and two clips at the bottom, on the wheel side.

We get to the switch (with a 5-pin connector), the ignition switch (with three wires - two red, one pink) and the voltage regulator - rectifier.

We measure the voltage. Connect a charged battery to the scooter. We take a multimeter (tseshka) and set it to “V -” 20 V. Normally, when the ignition is turned on, the two red wires are closed together, +12 V on them,

and on the third pink one it goes through a zener diode to the switch 8 - 9.3V.

If the pink one shows 12 V or 0 V, then the fault is in the ignition switch, namely the zener diode has failed. And not a switch, as it seemed at first glance.

We adjust the contactless ignition system

The contactless system operates through a sensor, switch, primary and secondary ignition windings. When the rotor with magnet closes the sensor, it sends a signal to the commutator, which, in turn, begins to accumulate current from the generator and transmit it to the primary winding. At this moment, high voltage appears in the secondary ignition winding. Its purpose is to ignite the spark. If there are any malfunctions listed above, adjustment is carried out by simply aligning the crankcase and ignition marks; to do this, remove the valve cover. The next steps are:

- We disassemble the crankcase in accordance with the technical description for your car.

- A mark is made on the rotor and crankcase at the dead center position of the engine in a place convenient for viewing.

- By rotating the crankshaft, we achieve a spark, make a mark on the crankcase relative to the mark made on it in the MTD. The difference between these marks on the crankcase is the ignition timing.

- Unclench the stator mounting bolts and set the advance angle corresponding to the technical documentation.

It is important to ensure that two of the three holes in the gear for the chain are at the level of the cylinder, and the remaining one is above the plane in which the cylinder and the mentioned holes are located. The Alpha moped has a reliable ignition system, but it can also break; you should not put off this breakdown and ride on a faulty moped. You just need to try setting the ignition

You can set the ignition yourself if you have special tools and minimal skills. If this is not the case, then it is best to contact a specialist.

You just need to try setting the ignition. You can set the ignition yourself if you have special tools and minimal skills. If this is not the case, then it is best to contact a specialist.

The Alpha moped has a reliable ignition system, but it can also break; you should not put off this breakdown and ride on a faulty moped. You just need to try setting the ignition. You can set the ignition yourself if you have special tools and minimal skills. If this is not the case, then it is best to contact specialists.

What does the ignition system consist of?

Such a system on a scooter includes the following devices:

- battery

- starter

- current generator

- switch

- coil

- lock

- candle

- wiring.

Although all these elements have different sizes, costs and complexity of the device, their importance in the proper operation of motorcycle equipment is almost equal. The malfunction of just one of the above elements leads to a malfunction of the entire scooter.

Each of these devices has its own possible malfunctions. Let's discuss each device in order in which repairs should be made.

Spark plug

The most common breakdown in the ignition system (including why there is no spark on a scooter) is a faulty spark plug. The reasons are completely different: carbon deposits due to poor fuel quality (or oil); overheat; lean or enriched air-fuel mixture and others.

You can assess its condition visually by unscrewing it from the cylinder. The working color of the candle is brick. But white and black indicate problems in her work. The best way to solve the problem is to replace it with a new one. If this is not possible, then clean it with a brush, rags or heat it on a gas burner.

The spark test is carried out in the following order:

- The spark plug is unscrewed from the cylinder along with the tip.

- The spark plug body is leaned against a metal “mass”.

- The engine rotates with the crank or starter, and sparks should jump between the electrodes of the spark plug.

Remember! If a spark appears during replacement, then the ignition system is in order and you should move on to diagnosing other parts of the scooter.

Ignition coil

If the spark plug is replaced with a new one, but the scooter (moped) still does not start, we diagnose the coil. The coil is a device with two windings - primary and secondary. Visually, it is a barrel with two contacts and a high-voltage wire coming out.

The role of the coil is to increase the incoming voltage hundreds of times. The primary winding has two contacts as outputs. The secondary winding is located between the positive contact and the end of the high-voltage wire. Violation of the integrity of one of the windings leads to failure of the main task and, as a result, the absence of a spark.

It is better to start diagnosing the coil with the spark plug cap. Inside the cap there is an interference suppression resistor, which also fails. You can check it with a multimeter in resistance measurement mode. You need to connect probes to the unscrewed cap - one to the spark plug seat, the other to the end for the armor wire. The resistance is considered normal - within 5 kOhm. If not correct, replace the cap.

On modern ignition systems, the coil is made of a monolith with a wire and a tip. In this case, you need to test everything together. We connect one probe of the multimeter to the cap, the other probe - alternately to the two contacts of the coil. Determine the resistance on the primary and secondary windings of the coil.

Remember! The resistance of the primary winding should be in the range of 0.1 to 0.4 Ohm; secondary winding –6.35 to 9.7 kOhm. The values are the average for most scooters made in China. Therefore, for each model they need to be clarified in the reference book.

If the instrument readings do not correspond to the reference values, change the coil or spark plug cap, if removed.

Electrical wiring

Another useful principle - if you don’t know why the spark on the scooter disappeared, then check the wiring. The reason that the spark has disappeared is trivial - a broken wire, oxidation of contacts, connections, or broken terminals. This problem is typical for any scooter - be it China or Italy.

By removing the decorative plastic trim, you can fully inspect the condition of the wiring. Pay attention to the ground wire from the coil to the body. Wire contacts often oxidize, and this leads to a decrease in voltage in the ignition system. The same problem exists in the contacts of the wire connecting the engine and the moped frame.

Carefully inspect the sensor and switch contact terminals. The wires may not be in contact or have weak contact, as a result, current is lost. To eliminate it, clean each terminal from oxidation and carbon deposits, crimp the contacts and make sure that everything is firmly in their sockets.

Another unlikely problem (but quite possible) is a break in the ground wire from the ignition switch. The wire is used to stop the engine and switch the lock to the off state. If the wire breaks and shorts to the frame, even with the key turned, the spark disappears.

Switch

A switch is a complex electronic device that combines several elements. The main elements are a capacitor and a thyristor. A thyristor is an electronic device that interrupts the current flowing to the ignition coil. Reducing the voltage allows the thyristor to open a current path for the capacitor.

The capacitor serves to accumulate electrical charge and short-term release of charge at the required time. Like the ignition coil, the switch cannot be disassembled, so it is impossible to check the functionality of individual elements without special equipment. Therefore, all diagnostics boil down to replacing the device. If replacing the switch helped, that was the problem.

Advice! Since switch failure is a common reason when the spark is lost on a 4t scooter, it is recommended that everyone carry a spare switch in the glove compartment. This will allow you to get home if the switch breaks down on the road.

Generator

An expensive part in a scooter is the generator, even if it is China, or even Japan. It rarely fails, but it still happens. You can also diagnose the device using a multimeter by measuring the resistance on the generator winding.

Near the generator, locate two wires coming out of the engine crankcase. One of the wires is red and black (comes from the pulse sensor), the second is blue and white (the main winding on the generator). Test both of these devices.

To diagnose the pulse sensor, connect the multimeter probe to the red-black wire, and the second probe to ground. The nominal circuit resistance is 500 Ohms. Checking the generator winding is carried out according to the same principle, but the probe must be connected to another wire - blue and white. In this circuit the resistance is 150-200 Ohms. If the values shown by the multimeter do not correspond to the specified ranges, change the cause of the breakdown. Poor resistance means failure of the pulse sensor or generator winding.

Checking the Pulse Generator

We measure the resistance of the Hall sensor coil at the switch connector. We set the device to 2 kOhm. We connect one probe to the green wire, and the second to the s/w. Should be 114 ohms. This means the wiring and Hall sensor are working properly.

If the circuit does not show resistance, then this indicates a break in the coil or electrical wiring from the pulse generator to the switch.

Next, we check the functionality of the entire pulse generator along with the mechanical part. Switch the device to 2 mA, leaving the probes in place.

We pull the leg of the kickstar. From the Hall sensor, for one rotation of the magneto, one pulse with a small current is supplied to the commutator. The meter should show approximately 0.6 mA. This means that all elements of the pulse generator are working properly and the reason for the lack of spark is not in the Hall sensor.

If the device does not show current, then you need to remove the air cooling casing. Look at the gap in the mechanical part of the generator, between the magneto and the Hall sensor. Check to see if the crankshaft bearings are loose or if the wire from the sensor is broken.

Breaks in the spark plug cap

This reason can also be considered simple. If there is no spark on the scooter, you should remove the cap and then check its resistance level. After disconnecting the cap from the wire, take measurements. The multimeter probe is inserted into the spark plug hole. The other is attached to the pin that the wires go to. If the cap is working properly, the multimeter will show about 5 kOhm. On most modern scooters, the high-voltage wires, spark plug cap and ignition coil are made one-piece.

My account

You should monitor the tread height of your tires and replace them as necessary. Riding a scooter with worn tire tread is extremely unsafe.

The turn should be done “pull”, controlling the gas or releasing it in advance. Always turn on low beam headlights when riding a scooter.

Float chamber It is important that the fuel in the float chamber is always within certain limits and does not drop below the permissible norm. It is also important that gasoline does not rise above permissible standards - this will help avoid overfilling

Actually, the float, which on the opposite side has a shut-off needle at its disposal, is responsible for the optimal level of fuel in the float chamber. Gasoline filling the chamber raises the float as it enters, which is constantly afloat.

cleaning the carburetor Honda Dio 27

When it reaches its maximum fulcrum, it closes the channel through which gasoline is directed from the gas tank to the carburetor. This is how the stable presence of a small amount of gasoline in the float chamber is regulated.

These are probably all the main systems of the Honda Dio 27 carburetor, so once you understand the operation of this device, it will not be difficult for you to put your scooter in order using the instructions in the manual.

Tags: accent, rear, replacement, stabilizer, struts, Hyundai

« Previous entry

Tuning switch for scooter - feasibility of use

Let's take a closer look at why you need a tuning switch on a scooter and what you will ultimately get after installing it.

What is a switch

First, let's remember what a switch is. In simple terms, this is the main controller for controlling the operation of the scooter engine. It transmits impulses to the ignition coil, which subsequently produces a spark at the spark plug. Most stock (those installed from the factory) switches are programmed to limit engine speed, for example at around 6500 or 7000 rpm. The engine does not spin above these values, and the entire transmission is adjusted by the factory in such a way that, for example, a speed of 60 km is achieved by a value of 7000 rpm. at one o'clock.

There is a reasonable question - what if we increase the engine speed? Will the scooter go faster? Why did the manufacturer set the cutoff at this value? Not so simple.

To get started, read the material:

What is a tuning switch

The tuning switch is manufactured by third-party companies and is a kind of modification of the stock “brains” of the scooter. It performs exactly the same tasks as the stock one, but lacks a cutoff. Or, more often, it has a cut-off around 8500 rpm, which can sometimes be critical for the engine.

Also, some switches have the ability to adjust the ignition timing.

Will the scooter go faster when using a tuning switch?

As practice shows, without other modifications, the scooter will increase speed by only 5-10 km per hour. Let's say your scooter currently accelerates to 60 km per hour at 7000 rpm. At this value, the cutoff in the switch is triggered. After installing the tuning switch, at 8500 rpm the scooter will have a maximum speed of 70 km per hour.

With many Chinese 50cc scooters, the story is a little different - they themselves cannot reach a good maximum speed, so sometimes it doesn’t even reach the cutoff. Here, of course, there is no point in installing a tuning switch at all. In general, in the case of Chinese scooters, each case is individual. There are also more or less passable specimens, with which you can even work and achieve something.

Consequences of tuning the switch on a scooter

As always, for this extra 10 km per hour increase in maximum speed you will need to pay for a decrease in engine life. This is in addition to the switch itself, which will cost from $40.

In the article about main bearing wear, we already wrote about the consequences of installing a tuning switch, and this is its main disadvantage. In a nutshell - at high speeds, the main bearings stop being lubricated properly and at some point they simply run dry, overheating and becoming deformed.

Hence the simple conclusion - it is advisable to use a tuning switch in the following cases:

- When tuning a scooter for racing, when the engine life is considered within one or more races.

- If you like to constantly tinker with your scooter and halve the engine every year, this is your hobby.

- The main goal is to achieve new heights at maximum speed at any cost.

- You have an extra 40-50 dollars and you don’t know where to throw it.

- Unclear reasons.

In other cases, using a tuning switch on a scooter is not practical.

You can also read other articles on the topic:

source

conclusions

From the article you learned why there is no spark on a 4t scooter and the reasons for such a malfunction. The cost of repair work may vary depending on the cost of the parts, but it is always more profitable to do the work yourself. And now you know what to do if the spark suddenly disappears; what to pay attention to. Be careful when troubleshooting, pay attention to details, refer to reference books for accurate data. Only if all conditions are met will you succeed!

Scooters today are relevant, popular and practical vehicles. People of various age categories can successfully move on them. For most owners, a scooter is their only means of transportation. Other owners use this technique as entertainment. During the operation of Chinese and Japanese mopeds, various malfunctions may occur. One of the common problems that many have encountered is the lack of spark on the scooter. Let's consider possible causes and ways to eliminate this problem.

Types of scooter switches

Before connecting the switch, it is important to know what type your scooter requires. If you connect the wrong device or do it incorrectly, the switch will immediately fail

The problem is that the part has the same plugs, but you can tell them apart. It's worth starting with the fact that DC is much larger in size.

AC CDI is much more common. It is installed on most Chinese and some Japanese vehicle models. Most often, such a switch is found on those scooters that have a 139QMB or 157QMJ engine.

A slightly different AC switch is installed on “Alpha”, “Delta” mopeds, and other equipment with a 1P39FMB motor. Such a switch operates from a generator coil and requires alternating voltage

DC has a different type of power supply - from a battery, so it has

12V, and if you connect it to a generator, the switch will break. AC is more durable in this regard; most likely, it simply will not work until you connect it correctly.

Faulty spark plug

This is the simplest reason why there is no spark at the electrodes. Such a nuisance often happens due to the quality of the fuel, as well as due to the presence of various harmful impurities in domestic gasoline. Because of this, many owners of Chinese equipment lost spark on their 4T (4 stroke) scooters. How to check its availability?

To make sure that the spark plug has failed, you need to install a new or exactly serviceable part in its place. But there are times when a new one is not available and there is nowhere to purchase it. Then a nail or a piece of wire will help. It is necessary to select devices whose diameter will be sufficient so that the wire or nail does not fall out of the cap. The element must be inserted into the spark plug cap, and then it is brought to the engine housing. The approximate distance from the nail to the crankcase should be 7 millimeters.

Next, the starter turns the crankshaft. If the scooter's electrical wiring is completely intact, a white spark will appear between the nail and the metal body of the motor. This means that the ignition system is operating normally, and it is worth replacing the spark plug. You can try to clean it of carbon deposits. This way it will work again. But most beginners do it wrong. After such cleanings, if the spark returns, it is for a very short period of time.

Operation, maintenance and repair

manual

Replacing consumables

During operation, metal dust settles in the engine oil, which affects the structure and properties of the oil. That is why it must be replaced regularly. The first change is carried out immediately after purchase. The second is recommended after 1000 km, and after break-in - 3-4 thousand km.

Oils typically used range from SAE 5W-20 to 10W-40. A worn engine will accept SAE 20W-50 grade oil.

Before replacing, warm up your moped. This will thin the oil and mix it with any dirt that may have accumulated in it. To warm up a moped in summer, 5 minutes is enough, in winter – 10 minutes.

Ignition installation

The Honda af61 uses a CR7HSA spark plug with a resistor. To install the ignition, follow the instructions:

- Disconnect the spark plug cable;

- Connect two strobe wires to the battery and the third to the spark plug cap;

- Find the ignition timing timing marks (usually one mark on the generator flywheel, the second on the scooter body);

- Crank the engine and fix the strobe flash and markers. If the response time of the device coincides with the marks on the power unit, then the ignition is set correctly.

Removing the rev limiter in the Honda dio af 34/35 switch

This article is suitable for Honda Dio AF 34, 35/35 SR/35 ZX scooters

ATTENTION! The speed limiter can be removed only for switches marked: CI649 and CI649A. For switches with other markings, it will not be possible to remove the limiter, and if you try, you will simply ruin the switch, and your scooter won’t even start...

If you don’t know how to solder, then contact a friend who knows how to do it and show him this article, and if you don’t know such a friend, then contact any electronics specialist or auto/motorcycle specialist and also show him the article, he He will do everything for you.

How to remove the switch and where is it located?

The switch is located at the front of the scooter under the beak (the largest part of the plastic is at the front). The beak is attached to 3 large bolts in front, and 4 under the dashboard (two on each side), unscrew 3 large and 4 small bolts. Now you can remove the beak! Removed? Now we are looking for a metal platform:

Honda Gyro Review

Modern cargo scooters are great for the city, therefore, due to their convenience and the presence of all the necessary characteristics, the Honda Gyro is in great demand among online stores and fast delivery services.

If you've heard a lot about the quality of Japanese technology, then most likely you will be confident in the Honda Gyro Canony. Repairing a cargo scooter is quite simple; no special innovations have been noticed in terms of design. But new cargo scooters have one big disadvantage - they are overpriced. Of course, new Japanese equipment today costs a lot, but the price of the Honda Gyro today is about $9,000, which is quite a lot for small companies. But this does not greatly discourage the owners of courier services, because most companies buy a moped because of its efficiency, small dimensions and, accordingly, fast delivery of the necessary cargo.

To solve the price problem, sellers bring used tricycles from Japan, which subsequently undergo major repairs (replacement of tires, batteries, filters, etc.). In Japan, such equipment is used carefully, so other countries receive excellent specimens even 10 years old. As a result, the seller puts the price at approximately $3,000, which is much lower than a new scooter.

Conclusion

After we have examined the main advantages of a cargo scooter and its approximate cost, we can draw certain conclusions. Japanese quality and practicality are confirmed in any manufactured equipment, so the modern Honda Gyro Canony cargo scooter is an ideal option for transporting small and compact cargo. Also, if you are interested in modern technology with three wheels, check out this interesting review about the new Ural motorcycles of the 2015 model year.

Scooter electronic ignition device

The modern ignition system of a 4t scooter is designed as follows: the switch and coil, which are its main elements, supply high voltage to the spark plug, which generates an electrical discharge that can ignite the fuel. The coil generates high voltage due to electromagnetic induction. The switch is needed to distribute its interruption voltage at the right time. Inside there is an electronic circuit, a thyristor and three outputs for wires. At the right moment, the switch supplies voltage or turns it off.

The principle of operation of the scooter ignition system is as follows: the battery supplies voltage to the coil, which is often connected to a switch in one unit, the switch supplies voltage to the spark plug, and decides when to interrupt it. The mixture in the cylinders lights up at the right time. The correct operation of the engine and whether it will start at all depends on how the ignition is configured and set.

Switch

In many scooter models, the commutator is combined with a coil, so if one of the devices fails, the entire unit has to be replaced. Such spare parts are inexpensive.

Externally, the switch looks like a plastic box. Inside there is a microcircuit, a variety of electronics that cannot be repaired. In addition, there is a thyristor. The task of this element is to interrupt the electrical impulse at the right moment; for this purpose it has three outputs. When current enters one of them, the thyristor turns into a conductor, and the current moves from the input contact to the output. When a certain voltage is reached and the current drops, the pulse is interrupted, after which the Hall sensor returns the thyristor to its original position so that the signal arrives again at the third output. The process is repeated every time the voltage is applied again.

Spark plug gap

Spark plug gap is an important factor for proper engine operation. This parameter plays an important role in the process of spark formation, ignition of the fuel mixture, and efficient operation of the scooter throughout the entire speed range. The gap should be specified in the documentation for the specific scooter - this parameter may vary among manufacturers. Generally speaking, for most modern four-stroke Chinese and Japanese mopeds, the gap on the spark plugs is from 0.5 to 0.8 millimeters. It is necessary to monitor this parameter. For this reason, the spark may disappear. She leaves because the gap is too big.