The time to work in gardens and vegetable gardens is approaching, and it’s time for summer residents to think about how their equipment will cope with the tasks assigned to it. For example, a conventional walk-behind tractor is not always able to pull attachments - it begins to slip even despite the lugs on the wheels. And this is not the only problem. Often it is simply impossible to get to summer cottages in the spring due to mud, which means that such an issue requires an urgent solution, for which the Homius editors suggest making tracks for various wheels with your own hands.

Making your own tracks for walk-behind tractors

A walk-behind tractor can become an indispensable assistant in the garden if it does not stand exactly in the center of the plot as a monument that will take a long time to dig up. But if you prepare in advance for spring work, this option can be easily avoided. So what should you use to make homemade tracks for a walk-behind tractor?

There are various ways here. For such work, you can use a conveyor belt, car drive belts with chains, or even ordinary tires. Today we will talk about each of these options in detail, and we will leave it to the dear reader to decide which tracks are better.

Module for walk-behind tractor: tracks made of conveyor belt and chains

If we talk about a crawler walk-behind tractor, then this option can be called the most optimal for use. Manufacturing the module is not particularly difficult and does not require a large number of tools or expensive materials. Of course, such tracks are not suitable for an all-terrain vehicle due to their low strength, but for a walk-behind tractor they are just right.

In order to increase the service life of such a caterpillar, the conveyor belt is stitched along the edge with thick fishing line. This will help prevent the tape cord from fraying. It is better to use a piano loop to connect the ends of the strips. Conventional stitching, even with the most durable materials, is very short-lived.

Related article:

Which walk-behind tractor is better: prices, reviews. In the article, we will find out which device is better after familiarizing ourselves with the design, types of devices, potential capabilities of modern models, owner reviews, average prices and additional recommendations.

Do-it-yourself caterpillars for a walk-behind tractor from large-radius car tires

If an additional pair of wheels has not yet been installed, then the master has the opportunity to use a tire from a tractor or loader as a gooseneck. The convenience of this option is that you don’t need to sew anything together. After all, the tire already has a closed shape. Let's consider the order in which such work is carried out.

First you need to prepare the tire. Using a sharp knife, periodically moistened with soapy water, it is necessary to cut out the inner parts of the tire, leaving only the “running” strip. In this case, special attention should be paid to the tread height. The larger it is, the better. After all, it is the tractor tread that will play the role of a lug.

PHOTO: drive2.ru Tires make good tracks

When the strip is cut, you can begin measuring and installing the driven pair of wheels. Subsequently, all that remains is to pull the finished goose onto the wheels if necessary.

Belts and chains for making tracks for walk-behind tractors

For the manufacture of such tracks, drive motor belts are used, which are connected to each other using steel lugs. In this case, a chain is fixed along the track. It serves as a driven element that will rotate the sprocket.

The result should be a ring with one or two rows of chains along the inner circumference.

PHOTO: qpprosto.ru An interesting option from an internal combustion engine timing belt

Related article:

The most reliable and popular cultivators and walk-behind tractors : varieties and average prices, a review of popular brands, the secrets of choosing the right device for a summer house and garden - in our publication.

An example of manufacturing and installing tracks on a walk-behind tractor: step-by-step instructions

Surely many novice craftsmen have a question about how to install a homemade crawler drive on a walk-behind tractor. In step-by-step instructions we will try to figure out this issue using photographic examples.

In fact, with little effort and time, you can create with your own hands an all-terrain vehicle on rubber tracks, the maneuverability of which will be determined only by the width of the wheels used for the base.

You can learn more about the master class on the manufacture and installation of a tracked attachment to a walk-behind tractor, be it a Neva or another unit, in this video.

How to make a homemade snowmobile with your own hands: diagram, photo and device

This homemade snowmobile was made in a few weeks with my own hands in my own garage. As we can see, its device is very simple, and will be quite within the capabilities of many home craftsmen.

Several years ago I built a snowmobile for my nine-year-old daughter with a homemade track made from conveyor belts and plastic water pipes as lugs. At first I had doubts about the reliability of such a track and how the plastic parts would behave in the cold. But during two years of winter operation, no breakdowns or severe wear of the pipes occurred. This inspired me to create a light snowmobile for myself with the same homemade track.

In the photo above is a homemade tracked snowmobile - at the top is a single-seater version and at the bottom is a two-seater version.

Understanding full well that the smaller the mass of the snowmobile and the larger the supporting area of the caterpillar, the better its cross-country ability in loose and deep snow, I tried to make the design as light as possible.

TOOLS FOR HOME AND GARDEN, HANDCRAFTS, ETC. PRICES VERY LOW

The operating principle of the snowmobile is very simple (Fig. 1). There are four wheels installed inside the caterpillar, which, when moving, roll along a conveyor belt on which lugs are attached. And the caterpillar drive from the motor is carried out by a chain through the driven shaft using special drive sprockets. I took them from the Buran snowmobile.

With an engine from a conventional walk-behind tractor with an automatic clutch with a power of only 6 horsepower, you will not accelerate quickly. I planned to ride the snowmobile not on compacted paths, but on loose snow, so I abandoned the soft track suspension and skis to reduce the weight of the snowmobile and simplify the entire design.

Other equipment equipped with tracks instead of wheels

If you look at it, you can put any equipment on tracks, regardless of its purpose. And if previously only garage craftsmen, of whom there are a great many in Russia, were engaged in such “experiments”, today you can see similar factory-produced equipment.

Not only snowmobiles and swamp vehicles are equipped with tracks, but also mini-tractors, which were not originally intended for these purposes. But production vehicles mounted on caterpillar tracks are of particular interest.

PHOTO: rosvezdehod.ru Swamp vehicles are very popular among hunters and rangers

What kind of homemade caterpillars can there be?

- 1 Methods for making homemade caterpillars

- 2 Home-made caterpillars based on a walk-behind tractor

- 3 Features of the development of a caterpillar mini tractor

- 4 Conclusion

Using a caterpillar is the most common way to increase the maneuverability of any equipment working on unpaved soil. Homemade caterpillars are very popular among the population. There are many developments in this direction. Craftsmen implement various approaches: from well-known, classic solutions, using factory parts, ready-made drawings, and ending with the implementation of their own, non-standard ideas using what is at hand.

A homemade mini caterpillar tractor, compared to its wheeled counterpart, has significantly greater cross-country ability and moving power. This allows you to use mini tractors in any weather conditions, types of terrain, and reliefs.

Work technology

Do-it-yourself tracks for a car must be made using a technology that involves the initial removal of the tire beads, then, if necessary, you need to remove the excess layers that are located on the wrong side of the formed ring; this is necessary if the track has increased hardness. If the tread pattern is not suitable, then you need to cut a new structure, which will be necessary so that the structure can cling to the soil.

A snowmobile track made with your own hands according to the scheme described above will have many advantages, even if compared with the option described above. This is due to the fact that it has a closed loop, which indicates reliability. But there are also disadvantages, one of which is expressed in the limited width of the track, but if there is a need, then a double width can be used.

Methods for making homemade caterpillars

After deciding that the equipment will be tracked, you should choose the type of homemade caterpillar. It is important to take into account not only the available material, but also the engine power. It also takes into account what the homemade product on tracks will mainly do. Usually two options are considered:

- All-terrain vehicle for transportation only;

- Equipment for cultivating land plots: tractor, mini tractor, walk-behind tractor.

The most popular method is to use a conveyor or conveyor belt. It is relatively inexpensive. All additional parts can be made independently. This type of caterpillar is effective when moving on snow. The caterpillar track uses an important element - the lug. To make it you need a steel sheet with a thickness of 2 millimeters.

It is important to use high-strength steel when creating rivets. The strips of the conveyor belt on the tracks are connected by hand using U-shaped lugs. It is advisable to sew the tape along the edges, for example with fishing line, to increase the duration of use. To create lugs and caterpillar tracks in general, it is recommended to use ready-made drawings.

The cheapest way is to make a caterpillar from a car tire. The length of the tape will depend on the tire size. This is a good option to make mini tracked ones. Typically worn tires are used. The better the tread is preserved, the better. The most labor-intensive stage of this approach is cutting out the track with treads. During this process, the side surface of the tire is separated. In this case, it is advisable to have a tool such as a jigsaw, but you can get by with an ordinary sharp knife. The advantage of this approach is that the cut tape is immediately a closed loop.

An interesting way is to use flat drive belts. An important advantage of this approach is that when connecting the belts using lugs, ready-made holes for the sprocket are obtained. It is better to buy drive belts in a store. Finding this material is not difficult, and the cost, as in the case of conveyor belts, is quite reasonable.

Making tracks from tires

This option for constructing rubber tracks has a number of advantages. There is plenty of material to be found. In case of urgent need, it will not be difficult to carry out repair work in a very short time. To make rubber tracks, you should choose truck tires. In addition, the tread must be identical in pattern to the rest of the tires - this will significantly simplify further work.

Manufacturing process:

- Initially, a tire is taken. A transverse cut is made to create a strip. The sides are cut out of it - a kind of treadmill should be formed. The procedure requires a lot of patience, because cutting out excess parts of the tire is quite labor-intensive. The tools used are a large knife with a good sharp blade.

- Rubber is easy to cut if the knife is soaked in warm, soapy water. Wetting needs to be done periodically. To achieve greater ease of operation, you should use an electric jigsaw with a fine tooth blade. The blade is also soaked in soapy liquid from time to time.

- If the tire hardness is high, it is recommended to remove a couple of layers of rubber from the inside - this is very difficult, so it is easier to find a tire with a soft structure. In case of dissatisfaction with the tread pattern, new cutting of the lugs is allowed at your discretion.

A rubber track made by yourself has a huge advantage - it is a closed loop. With this advantage, reliability and strength are significantly increased. The only thing that needs to be paid attention to is securing the individual elements of the tire when creating a track for a snowmobile . Often, some tire options are not suitable in width. In this case, you should find material for specific parameters or tighten individual pieces with a small cable.

Home-made caterpillars based on a walk-behind tractor

If the task is to make a walk-behind tractor on tracks with your own hands, first of all you need to decide on the purpose of the future equipment. It is necessary to take into account the number of seats, the weight of the cargo being transported, and the operating conditions in which the tracked walk-behind tractor will be located. All this is necessary in order to correctly calculate the load on the engine. After understanding the general concept, the type of crawler track is selected.

Creating a full-fledged tracked module for a walk-behind tractor requires the presence of a frame, the frame of which can be constructed from rectangular metal pipes. To fasten them you will need a welding machine. It is better to borrow elements such as the splined part and drive shafts from factory units, for example, from Buran, Oka. Ready-made drawings will significantly reduce the development time of a home-made device.

Basic recommendations for tracked homemade products based on a walk-behind tractor:

- In order for a walk-behind tractor on tracks to be maneuverable, you need to install brake mechanisms on the front shafts.

- The track module should not be made too high. Excessive height shifts the center of gravity, which increases the likelihood of capsizing. The balanced height of the tracks will allow you to confidently drive through difficult sections of the road and sharp turns.

- An increase in the second driven axle, ranging from 1 to 2 centimeters, significantly increases the stability of the tracked walk-behind tractor.

- If the walk-behind tractor does not have a differential, you should use a rotary extension. This approach increases the ability to maneuver equipment.

- A walk-behind tractor on tracks will last longer if you use water cooling for the engine. The air-cooled option may not withstand heavy loads.

- The homemade part of the caterpillar track should not be heavy, otherwise the point of creating mini caterpillar tracks is lost. There is no point in using massive parts, for example from a bulldozer. There is always a way to make a part by hand from lighter materials.

- Widening the wheelbase certainly wouldn't hurt. This can be solved by inserting a bushing on the drive shaft. It is better to purchase a ready-made bushing at a car dealership or, if you wish, grind it yourself.

- The caterpillar is considered a more complex mechanism than the wheel drive. Therefore, it is very important to first calculate everything and sketch out a diagram of the future unit.

- In addition to the above-mentioned advantages, transferring equipment to caterpillar tracks has its disadvantages, the main ones being: reduced speed and increased fuel consumption.

Is it necessary to go to a workshop?

When deciding to replace a track on your own, you should soberly evaluate the combination of your capabilities with the design features of the snowmobile, since the list of work may differ slightly. The typical procedure for replacing a track using the Arctic Cat 580Z snowmobile as an example looks like this:

- The rear part of the snowmobile is hung on a special lift or using improvised means.

- The track tension is released, after which the cart is unscrewed.

- The driven pulley of the variator (often mistakenly called by many as the “rear variator?”) is removed, and the speedometer cable is removed. A special puller may be required.

- The oil is drained from the gearbox, after which its cover is removed.

- The drive chain tensioner springs, gears and the chain itself are dismantled.

- The bearing cover of the track drive shaft is unscrewed.

Only after this can you pull the drive shaft of the caterpillar inward and remove it, and then, putting the new caterpillar in place, assemble everything in the reverse order. It is important to remember that before installation, the inner surface of the track must be moistened with water? it acts as a lubricant for mucous membranes.

Tensioning the new track should be done after the engine has been cranking it for a while with the snowmobile suspended.

The list of necessary operations can be increased by the presence of a disc brake on the drive shaft, as well as by poor layout of other components. So, on a Ski-Doo TNT you will have to dismantle not only the brake mechanism, but also the battery and muffler. This kind of work can already be difficult for many snowmobile owners, so making the decision to take the machine to a workshop will be a very smart one. For most devices of the highest price category, the cost of tracks for which is measured in tens of thousands of rubles, the answer will be obvious, because the price of the master’s work will be an insignificant part of the costs. Self-replacement in such cases is more of a whim than a necessity.

Features of the development of a caterpillar mini tractor

A homemade crawler mini tractor used for domestic purposes primarily has wheels. But during operation, situations arise when the wheeled version does not cope with the assigned tasks. Then you have to create a new version of the mini tractor or modernize what you have.

A homemade tractor on tracks can give the impression of being a clumsy, crude piece of equipment.

But if you assemble the tractor correctly and do it rationally, then you will get a fairly powerful, efficient mechanism capable of performing almost any task.

Homemade mini tractors are the result of certain design stages. Sequence is important for fitting one part to another. A homemade tractor on tracks is manufactured in the following sequence:

- The frame is being assembled.

- The drive wheels and road wheels are attached to the frame.

- The power unit and gearbox are installed.

- Onboard brakes and differential are attached.

- The necessary components are connected to the gearbox.

- Installation of the control system.

- The driver's seat is being arranged.

- Assembly of caterpillar tracks.

- Fastening the tracks.

- A homemade crawler tractor on tracks is tested, and if necessary, certain components are modified.

To assemble the frame, it is enough to have two spars and traverses. It should be taken into account that the rear traverse must be larger than the front. This is adjustable using channels of different sizes.

To assemble a crawler tractor with your own hands, you need an engine. There are no special restrictions when choosing a motor. The main thing is to select the required power. If a homemade crawler tractor requires a bridge, then it can be taken from any domestically produced truck. All other components (gearbox, control system, brakes, etc.) are installed in the order described above.

The caterpillar is selected based on preliminary calculations. It is highly recommended to make detailed drawings. A homemade crawler tractor is very difficult to create without accurate technical data.

A mini tractor on tracks is not much different from large tractors. The organization of their main working units is the same. The only difference is that the mini tractor on caterpillar tracks has a simplified design of the turning system. This must be taken into account when assembling a mini tractor with your own hands. The turning process can be briefly described as follows:

- One axle shaft is braked, and the second receives torque;

- The second one rotates around the stopped first caterpillar.

It turns out that a mini tractor on tracks does not have a single drive. Mini tractor tracks do not turn in one direction at the same time.

In the simplest design, wheeled rollers with tires from a trolley can be used. Typically, wheels are selected to match the size of the mini tractor. The track itself can be cut from a large tire. It’s easier to assemble a homemade mini caterpillar tractor if you have at least the most necessary large tools: a welding machine, a jigsaw, a lathe, an angle grinder.

Snowmobile assembly.

Engines of the Lifan type are very suitable for building snowmobiles; the author decided to use a similar 200 cc engine with 6.5 horsepower, the Sadko GE 200 R.

This engine already comes with a reduction gear (½) and a centrifugal automatic clutch, which is activated when the engine speed increases, which is ideal for homemade snowmobiles, walk-behind tractors, go-karts and other equipment.

The photo shows a Chinese-made Sadko engine.

The snowmobile frame is made of a 25 x 25 profile pipe with a wall thickness of 2 mm.

The caterpillar is made of a conveyor belt 3 mm thick, the width of the belt is 300 mm, the belt itself was cut in half lengthwise at 150 mm.

The tracks are made of plastic water pipe with a diameter of 40 mm and a wall thickness of 5 mm. The pipe is cut lengthwise.

The tracks are screwed to the conveyor belt with M6 bolts with a wide head, the bolts are tightened with a nut through a washer and a screw. The edges of the tape are connected with the same bolts.

Track drive axle.

Guided star from Minsk.

Stars for the caterpillar track from the Buran snowmobile, homemade guide drums.

The support ski removes part of the load from the track; there are guide rollers at the top.

The rear axle moves along the frame along a guide, which allows you to tension the snowmobile track.

The front axle is stationary.

Driven and driven sprockets, as well as a chain from a Minsk motorcycle. Chain drive with a gear ratio of 1 to 3.

Steering rack.

The hinges are made using a threaded connection, nut and stud on M16.

The skis are taken from a children's snowmobile and reinforced with a profile pipe.

The photo shows how the star engages the track track.

Read also: How to make a 4 wheel cart

The seat is made of plywood in the form of a box, in front there is room for a child, in the back for two adults.

Middle support ski.

The equipment is ready for testing.

The snowmobile moves confidently when fully loaded.

In the photo is the author of the homemade product: Evgeniy Venglovsky.

I recommend the author’s interesting video about assembling a tracked snowmobile and testing it.

Do-it-yourself mini tractor on caterpillar tracks

A mini tractor is a necessary agricultural equipment for those who are actively involved in farming work. Buying a tractor is not affordable for everyone, but many craftsmen can assemble a caterpillar mini tractor with their own hands.

In addition, all the parts for assembly may have been gathering dust somewhere in your backyard for years.

- Design features of the mini tractor

- Frame

- Power unit

- Bridge

- Caterpillar

- Other mechanisms

- Build process

- Principle of operation

- Assembly Tips

Design features of the mini tractor

A homemade mini tractor may seem unsightly and disproportionate only at first glance. In fact, a well-assembled mechanism is a rational arrangement of all key components and assemblies of the chassis (suspension, transmission, engine). The main components of the frame are two spars and two cross members.

Homemade mini tractors on caterpillar tracks have a spar of three successive stages: the outer ones are made of a channel, the inner ones are made of a square steel pipe. And the front traverse must be smaller than the rear one (for example, if a 12-size channel is selected at the front, then a 16-size channel must be installed at the rear).

DIY tracked all-terrain vehicle: description, manufacturing plan, tools, video.

How to make a vibrating plate with your own hands is described here.

Power unit

Any motor that matches the required power and torque will do. The optimal solution is a 4-cylinder water-cooled diesel engine with a power of 40 hp.

It can be installed without making any adjustments to the design. That is, to make a crawler tractor with your own hands, you just need to remove the bridge from any suitable domestic truck and integrate it into homemade equipment.

Caterpillar

It is necessary to select the design that will be used and the track itself. The simplest option is designs with rollers made of wheels and tires taken from carts, for example. The wheel size is selected depending on the size of the mini tractor. The caterpillar can be made from a large tire, cut off on the sides.

Other mechanisms

As a gearbox, you can choose, for example, a unit with a GAZ-53 or its alternatives. A device with a GAZ-52 is suitable for clutching.

Tracks for a homemade snowmobile

First I made the caterpillar. A plastic water pipe with a cross-section of 40 mm was cut into blanks for lugs 470 mm long. Then I sawed each piece lengthwise with a circular saw into two equal parts.

Using the device shown in Fig. 2, I used a wood circular saw to cut plastic pipes for lugs lengthwise.

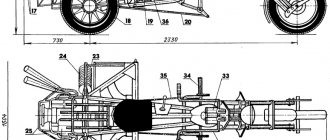

Figure 1. Drawing diagram of a homemade snowmobile

I attached the lugs to the conveyor belt with two 6 mm furniture bolts with a large semicircular head. When making a caterpillar, it is very important to maintain the same distance between the lugs, otherwise they will “run” onto the teeth of the drive sprockets and the caterpillar will begin to slip and slide off the rollers.

Figure 2. Device for cutting plastic pipes: 1. wooden block; 2. plastic pipe; 3. metal corner.

To drill holes in the conveyor belt for 6 mm mounting bolts, a jig was made. The holes in the tape were drilled using a wood drill with a special sharpening.

Using such a jig, you can drill 6 holes in the conveyor belt at once to attach three caterpillar lugs.

At the store I purchased four inflatable rubber wheels from a garden cart, two drive sprockets from a Buran snowmobile and two sealed bearings No. 205 for the caterpillar drive shaft.

I asked a turner to make the drive shaft of the caterpillar and supports for the bearings. I made the snowmobile frame myself from 25x25 mm square pipes.

Since the axes of the ski and steering hinges are on the same line and in the same plane, you can use a continuous tie rod without ball ends.

Ski turning bushings are easy to make. I welded 3/4″ female plumbing couplers to the front cross member of the frame. I screwed pipes with external threads into them, to which I welded the bipod of the steering rod and ski racks.

I recommend using skis from the Argomak children's snow scooter. They are lighter and more flexible, but they need to be equipped with corners for attaching to the snowmobile's rotating stand and a metal undercut at the bottom - for better control of the snowmobile when moving on crusty or compacted snow.

Read also: Direct acting pressure reducing valve

The chain tension is adjusted by moving the motor.

Driving a snowmobile is very easy. When you increase engine speed with the throttle handle located on the steering wheel, the automatic centrifugal clutch is activated and the snowmobile begins to move. Since the estimated speed of the snowmobile is low (only about 10-15 km/h) and depends on the density of the snow, the snowmobile is not equipped with brakes. It is enough to reduce the engine speed and the snowmobile stops.

Build process

The order is something like this:

- Assembling the frame, attaching road wheels and drive wheels to it;

- Installation of the power unit, gearbox;

- Installation of onboard brakes and differential, connection of components to the gearbox;

- Assembling controls, arranging the driver's seat;

- Installation of tracks, additional parts;

- Checking the performance of the mini tractor and modifying individual components (if necessary).

Principle of operation

Homemade mini tractors with caterpillar tracks are not much different from their large-sized counterparts. All key operating moments are organized in the same way as in a conventional tractor. The only difference is that the minitractor has a simplified turning system:

- The engine sends torque to the gearbox, where it is adjusted;

- Next, the rotation is directed to the differential, where the torque is distributed among the axle shafts;

- The wheels begin to move, followed by the tracks, and the entire minitractor begins to move;

- During a turn, one of the axle shafts is braked, and torque is sent to the second. The second caterpillar moves around the stopped first one - this is how the turn is performed.

In other words, the tracks do not have a single drive, and they cannot turn in the same direction at the same time.

IFA car: general information, characteristics, prices, reviews.

Technical characteristics of the KamAZ 43114 truck.

Assembly Tips

- Having decided to make a mini tracked tractor with your own hands, make all the calculations on paper and create a detailed drawing. Without accurate technical data, it is impossible to create a working machine.

- Before starting work, you should check the availability of such necessary devices as a welding machine, drill and grinder. They may be needed at any stage of the assembly. You should also not forget about protective equipment.

- Despite its visual massiveness and angularity, the mini tractor requires a careful approach. Hammer and chisel is not that story. Therefore, be patient, often carefully tightening a bolt with a wrench is much more effective than tightening it “with meat”.

A homemade mini tractor is an effective solution for any agricultural work. And here's an example: