How long does a motorcycle clutch last?

Its correct adjustment and appropriate operation increases the service life of the clutch

long enough.

For careful drivers, it can travel about 40 thousand km or more. However, in any case, there comes a time when the motorcycle clutch

requires replacement.

Interesting materials:

How to remove fill in text in Word? How to remove text replacement when typing? How to remove notes from a slide in PowerPoint 2007? How to remove notes from a slide in Powerpoint? How to clear a paper jam in the printer? How to remove a comma in Excel? How to remove entries in a search engine? How to remove scheduled reboot from Windows 10? How to remove password memorization? How to remove a remembered password in mail?

MY MOTORCYCLE

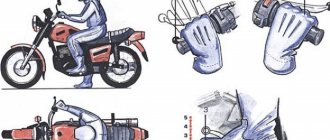

A properly functioning clutch gives the driver the opportunity to accurately dose the engine torque when transmitting it to the gearbox shaft and further to the wheels. On road motorcycles this is important at the start, when turning on a narrow road and, especially, when driving in city traffic jams.

On enduro, the work of the clutch is absolutely invaluable when driving through difficult obstacles.

Clutch wear may be indicated by noise in the crankcase, tight lever squeezing, or vibrations. But none of these symptoms alone is a death sentence. For example, noise may be normal for a given model of motorcycle; moreover, as a rule, it is produced by gearbox gears rotating without load. Vibrations at the moment of start are more common on completely new motorcycles, when the clutch discs have not yet gotten used to it.

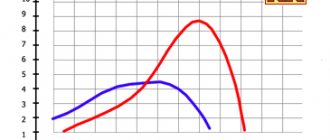

A more serious symptom is clutch slipping: the lever is released, but there is no rigid connection between the engine and the wheels. The motorcycle can move, but as soon as you add gas, the engine speed begins to increase faster than the speed, as if instead of a manual gearbox you have a hydromechanical “automatic”. In the initial stage, slipping appears only in higher gears, but after half a day of active driving the clutch comes to an end. Therefore, at the first sign of slipping, you need to stop. If the drive is cable, check the free play and ease of movement of the cable. Is the cable tension when the lever is released? Tighten the adjusting nut to loosen the cable. It is better to check the free play of the lever on the drive shaft (1-2 mm at the end of the lever) - this way we will simultaneously make sure that the cable is not overtightened and does not get stuck in the sheath. The cable cannot go out of adjustment on its own; there must be some reason. If it gets caught on something, such as in the woods, the shell stop may pop out of its recess, creating tension. Therefore, pay attention to how the cable is installed.

If after adjustment the signs of slipping disappear, consider yourself lucky: the motorcycle can be ridden. But this rarely happens. If the clutch slips even when the cable is adjusted correctly, then it’s time to change it. Slowly, preferably in low gears, head to the repair site, trying to keep slipping to a minimum. Many modern bikes use a hydraulic clutch drive.

It does not involve any adjustments and, in principle, cannot cause the clutch to slip. Therefore, slipping on such motorcycles is almost always a sign of serious wear on the unit.

There is another picture - the clutch “leads”: the lever is squeezed all the way, and the motorcycle tries to move forward. Gears are difficult to shift, and neutral is almost impossible to catch. In cold weather this is normal; When the frozen oil warms up, everything will be fixed. But if the motorcycle has spent the winter in “hibernation”, the discs can “stick” tightly to each other. To separate them, sometimes you have to drive several kilometers (it is advisable to play with the gas and brake, squeezing the left lever all the way). In especially severe cases, the discs are seized so that it is impossible to even move. Then the following scheme works: two friends push your motorcycle back and forth, and you, as the owner, sit on it, loading the rear wheel and squeezing the clutch lever. On the third or fourth, their disks usually turn. Otherwise you will have to disassemble the assembly.

If the clutch begins to “drive” during operation, we again turn to the cable adjustments. Perhaps its free play is too big. Reduce it, but remember that a slight play at the end of the lever should remain. The hydraulic drive can also become a problem, since air in the system or a torn cuff will not allow you to fully press the clutch. But if everything is fine with the cable and hydraulics, you will have to look for the fault inside.

On domestic motorcycles, it happened that unevenly adjusted clutch springs distorted the disk pack and they continued to rub on one side, preventing the drive from completely disengaging. This is not difficult to determine: we look at how the discs move in the basket when the lever is pressed. If it is uneven, rotate one or more screws securing the springs. In modern systems this is basically impossible (the screws are tightened all the way), and it is only extremely rare that the disks themselves become bent.

When opening the crankcase of the power unit for diagnostics and repair (replacement) of the clutch, you need to imagine what you are getting into. Firstly, most likely (especially on an older motorcycle) you will need a new crankcase cover gasket (the old one delaminates and breaks). Secondly, on some motorcycles, to access the body, you will have to remove the exhaust pipe of the muffler (it makes it difficult to pull out the cover), and this is not always easy and may lead to the need to look for the pipe gasket, studs, nuts, etc.. The problem with unexpectedly Scarce spare parts also apply to the fastening of the cover - on some motorcycles the screws are disposable. Thirdly, if the clutch is slipping, flushing the engine and changing the oil and filter is a mandatory procedure. Finally, you will need a good tool and a clutch kit itself, preferably a complete one (clutches, steel discs and springs). Let me note that field repair involves much fewer conventions. Thus, the cover gasket can be cut from any flat material of suitable thickness - from cardboard to linoleum, and installing washers under sagging springs will help to temporarily tighten the disks.

Doesn't that stop you? Then we will assume that the preparation has been completed: the clutch cover has been removed, the gasket is torn, and the disposable screws are neatly lying around, awaiting reuse. It's okay, we'll worry about that after we repair the clutch itself.

8. Remove the cover and carefully inspect its gasket (as a rule, it has to be replaced).

9. Unscrew the fasteners of the basket pressure disk. Be careful not to lose the springs. Let's check if they are the same length.

10. Remove the pressure disk, remember the features and location of the disks in the basket (in the photo, the farthest disk is different from the rest in color).

11. Assess wear. It is better to change the discs as a set.

12. On sale there are separate sets of friction discs (in the photo), and steel ones (they last longer), and springs (their cost-effectiveness sometimes leads to rapid failure of the new set of discs).

13. Before assembly, it is useful to wash the assembly with a universal cleaner and wipe dry. But “wet” friction discs need to be soaked in oil before installation.

14. Before installation, apply blue (weak fixation) thread sealant to the threads of the pressure disk screws (and the cover fastening).

15. Tighten the screws evenly to the prescribed torque.

16. It remains to install the clutch release parts. The main thing is that the cover should easily fall into place, you cannot force it down - it’s so easy to break the teeth on the clutch drive shaft. It doesn’t matter that the lever does not get into the desired position, it’s easy to rearrange it on the splines. A shaft with a pair of chipped teeth can be temporarily used by simply turning it 180°.

We unscrew the screws (often with internal hexagons) securing the clutch springs and the pressure disk, but we are in no hurry to remove the disks themselves. It is necessary to note the peculiarities of the location of the disks in the basket. Multi-disc systems suffer from increased noise when the clutch is fully depressed and when the gearbox is in neutral. The noise is created by the disc crowns lightly hitting the edges of the slots in the clutch basket. The noise could be reduced by reducing the gap between the rims and the basket, but then the risk of the disks jamming when heated increases. Therefore, usually one friction disk, usually the upper one, is placed in special grooves that are slightly smaller in width. This disk practically does not move along the grooves and, accordingly, does not jam, but at the same time, being pressed against the other disks, it restrains their looseness inside the basket. Sometimes for the same purpose they make one crown narrower than the others on all the disks, and a narrower groove on the basket. It happens that some clutches have a smaller working surface width or other differences. It’s impossible to list them all, and that’s why when disassembling a new unit for the first time, pay attention to the nuances. After removing the disks, it is easy to determine what happened to them. Clutches (those with paper, plastic or cork sectors around the entire circumference) are usually brownish or greenish in color. Blackening and a burning smell are a death sentence for them. The same problem as for intermediate metal discs is deformation or tarnishing.

It is quite difficult to wear out the clutch while driving the motorcycle correctly. As a rule, this takes about 40 thousand km. But it also happens that a worn clutch does not smell like burning. It’s just that the overall thickness of the disk package decreases, as does the friction between them. With high mileage of the motorcycle, the basket itself wears out. A groove appears on the edges of its longitudinal slots, impeding the movement of the discs and the smooth release of the clutch. A shallow hole can be carefully leveled with a file, although, of course, this is an extreme measure and it is better to replace the basket with a new one. (To unscrew the nut securing it, just put the gearbox in high gear, press the brake pedal with your foot, and pull the key with your hand. With a certain skill, neither special tools nor even an assistant are needed.) Before installing new discs, be sure to soak them in engine oil and carefully watch for the correct sequence of their installation in the basket. It is very important not to exceed the tightening torque of the clutch spring screws. It is small, and the threads in the duralumin drum are easy to break.

LONG RIDING WITH A STRONGLY SLIPPING CLUTCH CAN KILL THE ENGINE OF YOUR MOTORCYCLE: PARTICLES OF BURNED FRICTION DISCS WILL INEVITABLY GET INTO THE OIL, AND WITH IT, INTO THE PRECISION JOINTS OF THE INSERTS, CONNECTING ROD, PISTONS

Springs are another important element of the unit. For road motorcycles, springs that are not too stiff are used so that the hand does not get tired when frequently pressing the clutch. But if you are using the bike for racing, it is better to set it harder. After all, the clutch will actively work only once - during the start. By the way, racing clutch kits can only withstand two fast starts in a row. What can we say about ordinary road ones. Keep this in mind if you decide to participate in street drag racing.

All of the above applies to the most common type of clutch on motorcycles - multi-plate, in an oil bath.

But there are others. Ducati, for example, is famous for its multi-disc dry clutch. Very noisy, it nevertheless creates less resistance to rotation.

From time immemorial, BMW has been using a convenient, from the point of view of layout, dry single-plate automotive-type clutch on its boxer cars. A dry clutch does not like long slips and from this point of view is inferior to a “wet” one. But he also has a serious advantage - he absolutely does not care what kind of oil is poured into the engine. That is why it is not recommended to fill motorcycles with a conventional (wet) clutch with automotive oils with antifriction additives, as well as any friction modifiers and other automotive dietary supplements. Slipping will not be long in coming. Finally, advice to novice motorcyclists: take the time to train your skills in operating the clutch lever. This is a vital governing body. You need to master the skill of a smooth start and be able to take off quickly, be able to turn around in a limited space and shift gears “down” during emergency braking. Without this, it is impossible to drive a motorcycle efficiently and get real pleasure from riding.

Based on materials from MOTO Magazine 2011 No. 5.

Adjusting the tightening of nuts

We tighten the adjusting nuts to approximately the same limit as in the photo. I delay all my clients in approximately the same way - no more and no less. After tightening the nuts, press the lever and watch how the pressure plate comes off.

- If the disk comes off skewed, tighten the required nut half a turn and check with a new one

- If half a turn is not enough, turn the nut another half turn until the disc comes off perfectly straight.

- If you are transporting large loads and the clutch cannot cope with the increased load and slips, tighten the nuts a few turns

- If the force on the lever is high for you and you operate the scooter without a load or alone, for example, “Tula” - loosen the nuts

Checking the clutch drum

The first step is to check the foot start ratchet mechanism. This is where the main load falls. Turn the clutch basket over with the ratchet facing you, remove the retaining ring and disassemble the ratchet.

We inspect the teeth of the ratchet: they should be sharp without chips or other damage. If the teeth are wrinkled or broken, the winding foot will slip 100%. Many suffer from this problem due to thick oil or a weak spring - in fact, the reason for the foot slipping lies in the ratchet.

If the teeth on the basket are not worn out, it is advisable to rivet the ratchet: buy a new one in the store or remove it from another basket and rivet it. I riveted several baskets and they went without any problems until the “victory”...

An example of ideal ratchet teeth.

Often and thickly, the rivets on the ratchet weaken and if you don’t notice this in time, they are cut off. To prevent this trouble from happening to you, move the ratchet with your fingers. If it wobbles, drill out the old rivets and rivet them again. Pulling old rivets usually does nothing.

If you are making a clutch “for yourself” and for a long time, be sure to check the condition of the teeth for the motor chain.

If the teeth have already begun to turn back, then such a basket should be immediately thrown into the trash. It will no longer be of any use: the operating noise will increase, it will 100% eat up the motor chain, and there’s never an hour when one “fine” day it will lick your teeth and you will then be forced to push your jalopy for a long time and tediously...

An example of worn teeth.

It is not uncommon for the basket body to burst. Unfortunately, the body is made of cast iron and welding it will be problematic. If you find cracks on the body, try to find a welder who welds non-ferrous metals, the so-called “argon welder”; they usually take on welding cast iron.

An example of cracks in the basket body. By and large, this basket can still be saved: chamfer the cracks, weld and turn the seams on a lathe. But the teeth under the motor chain were worn out and I threw it away.

Adviсe

To know for sure whether the clutch is worn out or not, you need to engage 3rd or 4th gear and at a speed of 50-60 km/h with the clutch depressed, press the gas pedal hard. If the engine starts to gain speed, but the vehicle speed does not match, then the clutch is worn out. The engine will produce excessive speed as a result of slippage - weak contact of the clutch with the flywheel.

Do not drive a car with a worn clutch. A worn clutch will result in significant loss of power and increased fuel consumption. A worn-out clutch can completely break at any moment, in which case the possibility of being left somewhere on the side of the road is not excluded.

Replacing the clutch is a matter of time, since it is necessary to remove the transmission. Replacing the clutch of a car with rear-wheel drive is considered simpler than that of cars with front-wheel drive or all-wheel drive.

In this case, with the transmission already removed, it is very good to be able to practice replacing the clutch. This can save you money in the long run.

Help your friends - share these incredibly practical recommendations with them!

Checking the clutch basket inner drum

The inner drum is eternal by definition. The only problem that arises with it is that it breaks and sometimes cuts off the splines and the fit of the bolts under the pressure springs becomes loose.

Place the drum on the shaft and swing it:

- If the drum dangles too much on the shaft, inspect the splines and if they are broken, replace the drum with a new one.

Loosen the bolts under the compression spring one by one:

- If the bolts wobble, knock them out of the drum, anchor the seats and hammer them back into the drum.

Driving with the clutch depressed

Driving with the clutch depressed

#1 Post by azzon » Wed Jan 18, 2012 22:12

Re: Driving with clutch depressed

#2 Message to Nike » Wed Jan 18, 2012 22:15

Re: Driving with clutch depressed

#3 Post by Lu4Nik » Wed Jan 18, 2012 22:17

Re: Driving with clutch depressed

#4 Post by azzon » Wed Jan 18, 2012 22:21

Re: Driving with clutch depressed

#5 Post by Rekrut » Wed Jan 18, 2012 22:28

Re: Driving with clutch depressed

#6 Post by kabanchik » Wed Jan 18, 2012 22:32

Re: Driving with clutch depressed

#7 Post by SaSh'ok » Wed Jan 18, 2012 22:45

Re: Driving with clutch depressed

#8 Post by azzon » Wed Jan 18, 2012 22:47

Re: Driving with clutch depressed

#9 Post by DontKillMePLZ » Wed Jan 18, 2012 10:52 pm

Re: Driving with clutch depressed

#10 Post by azzon » Wed Jan 18, 2012 22:56

Yes, no one travels at a disadvantage. I drove around the garage parking lot.

By the way, I’ve been riding on a 10w50 handcar all winter (and last winter at -20) - no problems.