When to adjust the clutch

In general, there are two cases when you need to think about adjusting the scooter clutch:

Clutch leads

When you press the clutch lever and engage the gear, the moped starts moving (with the clutch depressed).

The clutch is slipping

When the gear is engaged and the clutch lever is completely released, the engine runs at high speeds, and the moped moves slowly or hardly moves at all.

All these problems are the result of a less than ideal design of the clutch release and engagement drive, as well as the fact that the parts of the clutch itself wear out after some mileage, which together leads to such troubles.

How to adjust the clutch on an Alpha

In order to eliminate all these problems, we need a minimum amount of tools, time and experience, that is, virtually any beginner can perform the adjustment of the moped clutch.

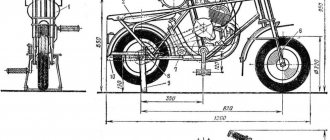

You need to place the moped on the central stand and unscrew the chrome cover on the right side of the motor (marked with an arrow), behind which the clutch adjustment mechanism .

When the lining was thrown off, the clutch device appeared in front of us. We see the adjusting screw and the locking nut. Insert a screwdriver into the screw slot and use a 10mm wrench to unscrew the fixing nut (lock nut).

After unscrewing the locknut, you need to unscrew the adjusting screw a few turns. Then we tighten the adjusting screw back until you feel that the screw has rested somewhere and then turns with some tension, this will be the position of the adjusting screw we need. After you have found the required position of the adjusting screw, secure it from turning with a screwdriver and tighten the locknut.

We screw the tire into place, find the adjustment bolt on the clutch cable, loosen the lock nut and tighten and unscrew the adjusting bolt until the free play on the clutch lever is 5 ... 10 mm .

Many moped drivers are familiar with the situation when a fully serviceable clutch on a moped does not work entirely correctly. For example: you press the clutch lever, engage the gear, and meanwhile the moped begins to move slowly (the clutch is moving), or vice versa, when the gear is engaged and the clutch lever is completely released, the engine runs at high speeds and the moped drives slowly, as if someone is holding it rear (clutch slips).

Sometimes it drives, sometimes it slips, in general it’s a complete torment and not a ride... All these troubles are a consequence of the not very perfect design of the clutch disengagement and engagement drive, plus the parts of the clutch itself wear out after a certain mileage, which together leads to such troubles.

In order to fix all these problems, we need a minimum of tools, time and experience, that is, almost any beginner can do the work of adjusting the moped clutch.

So, we put the moped on the central stand and on the right side of the engine we unscrew the chrome cover (marked with an arrow) behind which the clutch adjustment mechanism is hidden.

alpha moped clutch cover

We insert a screwdriver into the slot of the adjusting screw, and with the other hand, use a ten key to unscrew the lock nut.

After unscrewing the lock nut, unscrew the adjusting screw a few turns, after that: tighten the adjusting screw back until you feel that the screw has rested on something and then turns with some force, this will be the position of the adjusting screw we need. Once you have found the desired position of the adjusting screw, secure it from turning with a screwdriver and tighten the locknut.

Half the job is done, only a little remains...

We screw the cover into place, look for the adjusting bolt on the clutch cable, loosen the lock nut and tighten and unscrew the adjusting bolt until the free play on the clutch lever is: 5-10mm.

Checking the presence of a spark and the condition of the spark plug

This is the simplest check that every moped owner can carry out, having only a spark plug wrench or a spare spark plug on hand. Moreover, if you unscrew the spark plug from the engine, you can at the same time assess its condition and understand by the color of the carbon deposits how correct the working mixture is being prepared by the carburetor.

So, if you unscrew the spark plug from the engine, pay attention to the carbon deposits that cover the central electrode. The carbon deposits should be brown or light brown in color. If the carbon deposits are black, this indicates that the mixture is too rich, or the spark plug is faulty, or the engine is “eating” oil. Perhaps this is the reason for poor engine performance.

Also pay attention to the presence of liquid on the candle. If the spark plug is “wet”, that is, there is gasoline on the spark plug, then gasoline still enters the combustion chamber, but does not ignite. There are at least three reasons why a spark plug may be wet:

- trying to start the engine with the ignition turned off - if you turn the engine with the kick starter for a long time, the spark plug will simply flood with fuel and it will not be able to work normally. To solve the problem, the candle needs to be dried, for example, heated with a lighter.

- The spark plug is faulty - if the spark plug insulation is broken or the gap is broken, the spark plug will not work normally. Only replacing the spark plug with a known good one will help here.

- ignition system faulty

Now we put the tip on the spark plug and press it to a metal surface, for example, to the engine head, turn on the ignition and turn the engine with the kickstarter. It is more convenient to check the spark together, so that one person holds the spark plug and the other turns the engine. But in principle, one person can handle it. Be careful - there is high voltage at the center electrode of the spark plug.

If there is no spark, then the ignition system is at fault. Check all wires for breaks or shorts to ground. All electrical wiring connectors must be connected. If possible, replace the ignition coil with a known good one. Check if the generator coils are damaged. You can read more in the article “The moped has lost its spark, what should I do?”

If you can’t figure out the wiring, contact someone who knows how to do it.

If there is a spark, then most likely the problem is in the power system. Screw the candle into place and continue.

Clutch faults

So, what clutch malfunctions can happen is when the clutch slips, or when the clutch drives.

Let's look at situations when the clutch slips:

- The kickstarter foot slips and the moped does not start;

- When you engage first gear and the moped does not move. It starts to grab at the very end of the clutch handle being depressed;

- When you are riding a moped and give it a sharp gas, the engine speed increases, but the moped does not pick up speed.

Now let's look at the situation when the clutch drives:

The moped starts well, but when the clutch handle is depressed and first gear is engaged, the moped jerks and starts to move;

Gears are difficult to engage and disengage. While driving, there are difficulties with switching to another gear.

Adjusting the clutch on an alpha moped

The clutch adjustment mechanism is located on the right side of the engine, where the kickstarter is. To get to it, you need to unscrew the two screws of the round clutch cover with a Phillips screwdriver.

Unscrew the clutch cover

The clutch release mechanism must always be lubricated! Otherwise, the parts of the mechanism will quickly wear out and become unusable.

If you do not have lubricant on the clutch mechanism parts, then lubricate them. Suitable for lubrication: lithol, solid oil, automobile engine oil. I lubricated them with automotive brake caliper grease. Because this lubricant is heat-resistant.

The clutch mechanism is adjusted by an adjusting bolt, which is locked with a lock nut. To start adjusting, you need to loosen the locknut with a 10mm wrench. It is better to use a socket wrench.

Now take a simple screwdriver and unscrew the adjusting bolt until the clutch release parts loosen and begin to dangle, and the adjusting bolt rotates freely.

Unscrew the adjusting screw

At this stage the clutch discs are fully engaged.

Then we begin to slowly tighten the adjusting bolt until it rests against the release bearing bushing. You should feel this as the force increases as you tighten the bolt.

As the force applied to the bolt, it means it rested on the release bearing. Next, unscrew the adjusting bolt a quarter turn so that there is a small gap. This completes the primary adjustment of the clutch mechanism.

Now you need to adjust the stroke of the clutch release handle, which is adjusted by the tensioner on the clutch cable.

Adjusting the travel of the clutch release handle

Adjusting the clutch handle release on the Alpha moped is adjusted by the tensioner on the clutch cable.

Tensioner on the clutch cable of the Alpha RX moped

We need to start the moped and engage first gear, but before starting the moped, it must be placed on the service stand.

We achieve a point where the rear wheel can be stopped with a little effort. For example, take the same screwdriver or wrench in your hands and bring it to the rear tire.

We check the clutch adjustment by applying slight force to the rear wheel.

We adjust by turning the tension bolt and checking the clutch. Before adjusting, the tensioner must be unlocked with a lock nut.

After we have achieved the desired adjustment, we tighten the tension bolt with a locknut and screw on the clutch cover.

After this adjustment, we check again how the rear wheel rotates when the clutch is depressed. We make sure that the settings are correct.

The clutch adjustment on the Alpha moped is completed.

Gearbox disassembly

It is necessary to disassemble the gearbox in order to replace used parts. This is done after the following parts have been dismantled:

Repair of this part of the engine is carried out as follows:

- Using a screwdriver or blade, remove the retaining ring and the drive gear;

- Carefully unscrew the gear fixing bolt and remove the gear shift mechanism;

- remove the gear shift fork and shaft;

- remove the crankshaft and drum (including the core);

- After replacing the worn part with a new one, reassemble (in reverse order).

Alpha moped engine repair

Let's take it slowly, in order:

- first remove the cylinder, then the rotor and clutch block;

- carefully remove the retaining ring (you need a screwdriver and a thin knife or blade) and the drive gear;

- To remove the speed unit, unscrew the fastener - the bolt on the back side.

- remove the gear shift fork;

- remove the crankshaft and drum.

When the repair of the Alpha moped box is completed, assemble the gearbox using the reverse algorithm.

Recently, on the repair forum, Alf found an article from the manufacturer with recommendations. The article began with the words “Repair of an Alpha moped for many begins almost immediately after purchase.” Alas, this is the bitter truth. If you are choosing between a used Alfa with a mileage of 10 thousand and a new Alfa three times more expensive, then it is better to buy a used one, since many problems will begin in the new one, in time you will not “win” even one season.

And the problem is not that the alpha moped is a bad transport, but that it is cheap, which means many of the components in it are assembled from slightly more fragile materials. This means that it needs to be closely monitored, serviced on time, and the driving style should be calm.

There are three types of simple upgrades that can be made on the first day of purchase:

- Replace the seat with a more comfortable one.

- Install a 110 or 125 cylinder instead of the standard 49 or 72.

- Replace sprockets from 14 to 16 to increase speed or, conversely, from 14 to 13 to increase traction. The standard 14 teeth are no good at all.

Increase in cylinder volume - replacement from 50 cc. at 125 cc., will add power, which is never enough. To do this, in addition to the cylinder head, you will have to change the pistons and carburetor. You can carry out such maintenance of the Alpha moped yourself. The author of this article saw with his own eyes how a man bought only a 110 cylinder and installed it right next to the store instead of the standard one. Nothing else was changed - neither the carburetor nor the head.

Did the moped go after that? Yes. How long? No. Everything jammed, right down to the connecting rod and crankshaft.

Once you have disassembled the timing belt and CPG, put the parts in separate boxes. Sketch the position of the gears and forks on paper before removal or take a high-quality photograph on your smartphone.

Do not hurry. Think more, do less. Don’t be afraid and don’t be lazy to study the hardware, watch a lot of video tutorials until the structure of the motor is completely clear to you.

Engine Features

The engine of the Chinese Alpha moped has characteristic features, thanks to which fans of motorcycle technology prefer this particular model.

Engine capacity - 72 cc. With the right approach, it can be upgraded to 110 cc. Also, if desired, you can increase the speed by 10 kilometers.

The weak point of the engine is the gearbox, which requires close attention and a delicate approach . When repairing the “heart” of a moped, you need to know how to correctly disassemble and reassemble this part of the motorcycle “organism”.

Alpha is equipped with a powerful engine, the circuit of which is complex. If you can’t figure it out on your own, it is recommended to contact an experienced specialist. The price of repairs is quite affordable.