Weaknesses and shortcomings of the IZH-P5 engine of the IZH Planet 5 motorcycle

Why did they stop producing the IZH Planet motorcycle in Russia?

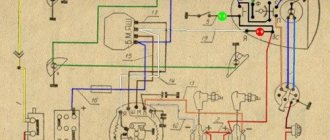

Oddly enough, the Kovrov Machine-Building Plant named after Dektyarev (ZID), as well as the former Soviet, now Belarusian Minsk Motorcycle Plant, still supply their motorcycles to the market. As for the Izhevsk Machine-Building Plant, which produces IZH motorcycles (Planet, Planet-Sport, Jupiter), the last production batch of motorcycles was produced in 2008, then, due to difficulties arising from the economic crisis, the production of IZH motorcycles was curtailed. It’s a pity, because the state could have provided assistance to the plant. At that time, Izhmash had a lot of experimental design work on promising motorcycles, both with two-stroke and four-stroke engines. I have a lot of positive memories associated with the IZh “Planet-3” and “Planet-5” motorcycles. Any motorcycle model starting from Planet-2 gave a head start to Jupiters in terms of cross-country ability, old or new, it doesn’t matter. He didn’t sail on it, even in the taiga or in the forest, fishing or hunting. A very reliable “workhorse” with traction like a tractor, and my father and I never transported anything on it. We bought it in 1989 and to this day my father drives it, but it looks like new and makes my heart happy with its proper operation. Planet motorcycles, even its oldest models, continue to serve their owners regularly and reliably, despite the stoppage of production, there are no problems with spare parts for repairs on the market, and there is no limit to the maintainability stock. In this article, we will look at the IZH-P5 power unit of the IZH Planet 5 motorcycle, or more precisely, its technical characteristics, weaknesses and disadvantages. The IZH-P5 power unit differs from the IZH-P4 20 hp. the previous model of the motorcycle “IZH Planety-4” increased by 2 hp. power, a higher compression ratio and an engine head, the 4th model has two exhaust pipes, the 5th has one. Gearboxes differ in the number of teeth on the gears and, accordingly, in the gear ratios. Gearboxes are interchangeable.

Strange sound when the engine is running.

- Just come

- 35 messages

- City: Tyumen

- Motorcycle: HONDA TRANSALP XL 650 V6

Dear forum users, tell me what could be knocking like that, video is attached.

The power and speed do not drop, if it were not for the sound, then there is nothing else to worry about.

- Quote highlighted

- City: Matveev Kurgan

- Motorcycle: XL650 Elephant, XR 250 Pig, super sherpa, pw 80, k-750

- Quote highlighted

- City: Ulyanovsk

- Motorcycle: Honda Transalp-650

- Quote highlighted

been sitting here for a long time

- City: Vladimir region

- Motorcycle: Izh Jupiter 5. transalp 650

- Quote highlighted

- Moscow city

- Motorcycle: 11 years on XL650VY => R 1200GS

Depress the clutch, shift into gear. Has the sound disappeared? if yes, then the basket is normal for runs over 60t.

- Quote highlighted

has been living here for a long time

- City: Crimea

- Motorcycle: alpha

who makes a video less than 1 minute. that radish.

he has a camera with a soap dish

- Quote highlighted

- Honda Transalp Owners Club

- → REPAIR AREA

- → Engine

- Change style Main style

- Mobile style

- Deflection (light)

- Forums

Disadvantages of the IZH-P5 engine

Loud operation has a negative impact on people around (interferes with rest), which causes corresponding reactions towards the motorcyclist.

Increased engine vibration is felt throughout the motorcycle, especially with your hands on the handlebars.

The resource is limited to an interval of 20-25 thousand km

PS. Dear “Planetovod” motorcyclists! You can ask a question or add reviews and information on the weak points and shortcomings of the IZH-P5 motor in the comments.

Source

Izh Planet 5 engine jammed

1. Cause of malfunction 2. Remedy

Kickstart lever skips or does not return (slowly returns) to its original position

1. Rotating the kickstarter lever on the shaft. 2. Tighten the lever mounting bolt; if the splines are severely damaged, replace the lever or shaft. 1. In cold weather, too viscous oil is poured into the gearbox. 2. Replace the oil corresponding to the ambient temperature (viscosity according to SAE 5W30, 10W30) or, as a temporary measure, you can slightly dilute the oil in the gearbox by pouring 100-150 cc into it. cm gasoline or kerosene. Remember to replace this mixture with “normal” oil as soon as possible. 1. Chips or severe wear of the sector teeth, ratchet or trigger gears. 2. Replace damaged parts, be sure to flush the gearbox. 1. The gear sticks on the clutch drum hub. 2. Eliminate jamming, dull the sharp edges of the gear hole. 1. The trigger spring has burst or weakened. 2. Replace the spring. 1. The retaining ring has come off the clutch drum hub. 2. Replace the ring or drum.

Engine won't start

1. The ignition is turned off by the emergency switch. There is no spark at the spark plug. 2. Turn on the ignition. 1. There is no fuel in the tank. 2. Fill the tank. 1. On a cold engine, the starting device (fuel corrector) is not turned on. 2. Turn the fuel corrector lever and, if necessary, eliminate the drive malfunction (sticking cable or corrector plunger). After starting and warming up the engine, return the corrector lever to its original position. 1. Fuel does not enter the carburetor due to clogged filters or valve channels (there is no stream of fuel from the hose removed from the carburetor and the fuel valve is open). 2. Remove the valve, disassemble and wash all parts in solvent, blow out the channels and the fuel hose with compressed air. After installing the valve and connecting the hose to the carburetor, press the float reducer to fill the carburetor float chamber with fuel. 1. There is no spark on the spark plug due to it being oiled with the fuel mixture, poor contact between the tip of the spark plug and the high-voltage wire, or another malfunction of the spark plug. Fuel condensate has accumulated in the crank chamber of the engine, which leads to over-enrichment of the combustible mixture and the impossibility of its ignition. 2. Turning off the fuel supply and opening the decompressor valve, blow out the crank chamber and cylinder with several slow movements of the kick starter lever. If this does not help, remove, clean or replace the spark plug. Ensure reliable contact in the connection of the high-voltage wire with the tip of the spark plug. 1. Other elements of the ignition system are faulty or the connections between them are in poor contact (no spark on the spark plug). 2. Check one by one the high-voltage wire, ignition coil, capacitor, operation of the breaker contacts, ignition timing, fuse and battery charge, ignition switch. Replace faulty elements, ensure reliable electrical contact between them. If necessary, adjust the ignition timing, check the level and density of the electrolyte, clean the surface, terminals and terminals of the battery, charge or replace the battery. 1. The throttle valve (its drive) or the carburetor needle valve is stuck, the fuel jets and carburetor channels are clogged, in particular the starting device channels. 2. Wash the carburetor parts in a solvent and blow out the channels with compressed air, repair and adjust the carburetor, as well as the throttle valve drive.

What is knocking in the engine on Jupiter 5

When I press the clutch, either with my hand or with my foot, all the sounds disappear. Only a slight clunking sound from the gearbox when shifting. But I’ve just finished rebuilding the engine, so pah-pah everything is in order so far, and last year, when I got it, mom, don’t worry, it rattled, when the speed dropped below idle it generally made a sound like a PAZ when engaging first gear - the ring came off retaining basket and tore the crankcase at the bearing.

And the idea came because the Jupiter also had a liquid-fuel system, at idle I drowned it out with a metallic clatter, but from the start it drowned me out. and flew away. “40kg is still not extra”

Although right now I’m finishing the post and taking your idea into account.. The sixth Jupiter doesn’t actually exist in nature, just like the 7th Planet.. Although regarding the planet, 7 seems to have appeared like a concept with a 4-stroke engine, but this is a trifle. When they talk about the 7th Planet ala 6 Yupak, they are not expressing themselves quite correctly, I agree.

In general, Yupak with dropsy actually works quieter, we agreed with you. I don’t quite understand what a slight clattering noise when switching means. Do you think that Izhevsk gearboxes switch silently? You're wrong... Maybe there are examples that work absolutely silently when switching, softly, etc. .. Actually, I was just amazed at the softness of the Yunko box.. While I have the same Izh7 Planet 5 produced in 2004, its box did not work correctly from the factory. This was expressed in the fact that when the second gear was engaged, it slipped and ended up between the second and third.. I took it for maintenance under warranty.. They couldn’t do anything.. Then I gave up, took it apart with the folder myself, the problem turned out to be that the spring The latch (the one that rests on the worm) has almost fallen off, firstly. and secondly, it was very weak .. Well, I bought a new shift shaft itself, then everything worked perfectly, albeit harshly; It is difficult to switch speeds at high speeds, and, as a rule, this is accompanied by a crunching sound)) But I drove more than 8 mowers on it and there is no wear on the gears! At the same time, I bought a new engine for another Planet, assembled on a hike, somewhere near the plant... So I came across this awesome box on it. Actually in the gallery it is a Black planet.

Regarding the 6th Jupiter, that’s right, not out of the blue. The designers did everything right. They labeled the model as a modification rather than a new model. If we give a new figure for each modification, then now we would already be driving the 600th Jupiter. Structurally, the motor is absolutely identical to the previous Jupiter, there are only some MODIFICATIONS. That's what we're talking about

Izh Planet 5 troubleshooting

Izh Planet 5 malfunctions and ways to eliminate them:

1. Cause of malfunction 2. Remedy

Kickstart lever skips or does not return (slowly returns) to its original position

1. Rotating the kickstarter lever on the shaft. 2. Tighten the lever mounting bolt; if the splines are severely damaged, replace the lever or shaft.

1. In cold weather, too viscous oil is poured into the gearbox. 2. Replace the oil corresponding to the ambient temperature (viscosity according to SAE 5W30; 10W30) or, as a temporary measure, you can slightly dilute the oil in the gearbox by pouring 100-150 cc into it. cm gasoline or kerosene. Remember to replace this mixture with “normal” oil as soon as possible.

1. Chips or severe wear of the sector teeth, ratchet or trigger gears. 2. Replace damaged parts, be sure to flush the gearbox.

1. The gear sticks on the clutch drum hub. 2. Eliminate jamming, dull the sharp edges of the gear hole.

1. The trigger spring has burst or weakened. 2. Replace the spring.

1. The retaining ring has come off the clutch drum hub. 2. Replace the ring or drum.

Engine won't start

1. The ignition is turned off by the emergency switch. There is no spark at the spark plug. 2. Turn on the ignition.

1. There is no fuel in the tank. 2. Fill the tank.

1. On a cold engine, the starting device (fuel corrector) is not turned on. 2. Turn the fuel corrector lever and, if necessary, eliminate the drive malfunction (sticking cable or corrector plunger). After starting and warming up the engine, return the corrector lever to its original position.

1. Fuel does not enter the carburetor due to clogged filters or valve channels (there is no stream of fuel from the hose removed from the carburetor and the fuel valve is open). 2. Remove the valve, disassemble and wash all parts in solvent, blow out the channels and the fuel hose with compressed air. After installing the valve and connecting the hose to the carburetor, press the float reducer to fill the carburetor float chamber with fuel.

1. There is no spark on the spark plug due to it being oiled with the fuel mixture, poor contact between the tip of the spark plug and the high-voltage wire, or another malfunction of the spark plug. Fuel condensate has accumulated in the crank chamber of the engine, which leads to over-enrichment of the combustible mixture and the impossibility of its ignition. 2. Turning off the fuel supply and opening the decompressor valve, blow out the crank chamber and cylinder with several slow movements of the kick starter lever. If this does not help, remove, clean or replace the spark plug. Ensure reliable contact in the connection of the high-voltage wire with the tip of the spark plug.

1. Other elements of the ignition system are faulty or the connections between them are in poor contact (no spark on the spark plug). 2. Check one by one the high-voltage wire, ignition coil, capacitor, operation of the breaker contacts, ignition timing, fuse and battery charge, ignition switch. Replace faulty elements, ensure reliable electrical contact between them. If necessary, adjust the ignition timing, check the level and density of the electrolyte, clean the surface, terminals and terminals of the battery, charge or replace the battery.

1. The throttle valve (its drive) or the carburetor needle valve is stuck, the fuel jets and carburetor channels are clogged, in particular the starting device channels. 2. Wash the carburetor parts in a solvent and blow out the channels with compressed air, repair and adjust the carburetor, as well as the throttle valve drive.

The engine does not start immediately, is unstable, does not respond well to turning the throttle, and stalls spontaneously

1. The carburetor needle valve is dirty or damaged; the position of the float in the float chamber is not adjusted. 2. Clean and repair the valve, adjust the position of the float.

1. Over-leaning of the combustible mixture due to the float or valve needle sticking in the upper position, float leakage, clogging of the carburetor jets and channels. 2. Wash, repair and adjust the carburetor.

3. Over-leaning of the combustible mixture due to the suction of additional air into the crank chamber through various leaks. For example: the gasket between the cylinder and the crankcase, the gasket of the suction pipe or leaks in its connection, the gasket of the right crankshaft oil seal cover, the gaskets of the purge channel plugs. “Extra” air can also get into the combustible mixture through worn right or left crankshaft oil seals, as well as a loose joint between the crankcase halves. In the last two cases, oil quickly “leaves” from the gearbox, and with worn seals, the engine smokes more than usual, although visible oil leaks may not be noticeable. 2. Tighten the fastenings of all specified parts, if necessary, replace damaged gaskets, hardened and worn oil seals. Eliminate leaks in the suction pipe connection. If necessary, disassemble and reassemble the engine, reliably sealing the joint between the crankcase halves.

1. Contamination, burning, moisture on the breaker contacts, incorrect adjustment of the gap between the breaker contacts, the ignition is installed incorrectly, the hammer spring touches the engine ground.

2. Clean the contacts, set the correct gap and ignition timing, eliminate contact of the spring with ground.

1. Capacitor malfunction (manifests itself in the form of strong sparking between the breaker contacts). 2. Replace the capacitor, check the condition of the contacts, and clean them if necessary.

1. Malfunction of the ignition coil. 2. Replace the ignition coil.

1. Severe carbon deposits, wear, burning of electrodes (increased gap) or other malfunction of the spark plug, contamination of the high voltage wire cap and the outer surface of the spark plug insulator, use of a spark plug with an inappropriate heat rating. 2. Clean or replace the spark plug. Keep the wire connection to the spark plug clean, use only recommended spark plugs.

1. There is too much oil in the fuel mixture. Thick bluish smoke comes out of the mufflers. It is possible that the gasoline evaporated when the mixture was stored for a long time in a plastic canister or some other leaky container. 2. Replace the fuel mixture, turn it out and rinse in clean gasoline or solvent (or replace) the spark plug.

When starting the engine, the kickstarter lever “gives” to the leg

1. Early ignition. 2. Adjust the ignition timing.

Assembly and disassembly

Before you think about power, you need to understand motorcycle maintenance. Often, chasing speed and appearance, owners forget about the basic rules for operating their pet. Due to negligence, and not only, various types of breakdowns occur. You can troubleshoot problems yourself. Considering that disassembling and assembling the IZH Planet 5 engine is very simple, they can be done at home. However, it is recommended that you consult the factory-produced motorcycle operation and maintenance book.

There are cases when the maintenance book was lost long ago, or was not received at all upon purchase. In this case, here is a simple procedure for disassembling the engine:

It should be noted that the cleaner your workplace is, the better the repair will be done, since dirt that gets inside the engine can make it difficult to operate and even cause another breakdown. Don't be too lazy to wash the engine well before work .

Write down or mark the progress of your actions. This will help with assembly. Group the parts in the order they are disassembled and assemble them by location. The more organized the disassembly process is, the faster you will assemble the IZH Planet 5 engine, the technical characteristics of which will once again delight you.

- So, the first thing you need to do is remove the exhaust tube. It will be most convenient not to unscrew it completely, but only from the engine side and tie it to a stable part.

- Now proceed to remove the cylinder cover, which is secured to four bolts and the cylinders themselves, being careful not to damage the gaskets. Damage to the gaskets will lead to loss of engine pressure and compression.

- Remove the tube from the chain boot.

- Knock out the front pin strengthening the engine. Knock it out carefully; the bent part will not fit back in.

- Now proceed to the engine mounts. Remove all nuts and bolts from the rear of the engine.

- When the engine is not secured, move it to the side on a stable surface. There are seven bolts on the pallet that need to be unscrewed. Then carefully remove the tray. Remove the outboard flywheel plate and gasket and secure the engine. It is better to fix the engine on a workbench; if you don’t have one, then a massive table will do.

- Let's move on to the take-out flywheel. To loosen the bolt holding the flywheel in place, you will need a socket wrench and a long, sturdy pry bar. The carving on the cap is quite soft; if you overdo it, you can tear it off.

- Then we separate the halves of the pallet. They will still be needed, so we don’t put them away in the “far corner”.

- Now we move on to the take-out flywheel and veneer. They are easy to remove and do not require any special skills.

- Having remembered the locations of the adjusting washers, remove the front, rear and follower shafts in sequence.

- Let's move on to the crank chamber covers. After unscrewing the pins, carefully remove the covers and rings.

- Then you need to return to the pallet again. Remove the crankshafts from its halves.

- Next, remove the bearings of the crankcase halves. Unscrew the race and screws with the crankshaft oil seal.

- And the last step. Remove the installation rings and knock out the seals. Assembly is carried out in the reverse order, but it is necessary to tighten the bolts and studs with certain efforts. Otherwise, there should be no questions about how to assemble the IZH Planet 5 engine.