The first production Voskhod motorcycle was equipped with a K-36B type carburetor, which had two metering systems - main and idle, as well as an enrichment device.

To rinse and clean it is necessary to disassemble in the following order: 1 - close the gasoline tap and disconnect the gasoline hose; 2 — unfasten the latches and remove the housing cover along with the cables, spool and fuel corrector; 3 - remove the rubber coupling; 4 — unscrew the two fastening nuts and remove the carburetor; 5 — remove the sealing gaskets; 6 - perform a complete disassembly.

Wash the removed parts with clean gasoline, inspect and reassemble in the reverse order. The factory settings ensure maximum and optimal engine efficiency.

Adjusting the Voskhod motorcycle carburetor

The first production Voskhod motorcycle was equipped with a K-36B type carburetor, which had two metering systems - main and idle, as well as an enrichment device.

To rinse and clean it is necessary to disassemble in the following order: 1 - close the gasoline tap and disconnect the gasoline hose; 2 — unfasten the latches and remove the housing cover along with the cables, spool and fuel corrector; 3 - remove the rubber coupling; 4 — unscrew the two fastening nuts and remove the carburetor; 5 — remove the sealing gaskets; 6 - perform a complete disassembly.

Wash the removed parts with clean gasoline, inspect and reassemble in the reverse order. The factory settings ensure maximum and optimal engine efficiency.

Kovrovets (all carburetor topics from Vladislav)

From the factory instructions

Removing and installing the carburetor

The motorcycle “Voskhod-3M”, “Voskhod-3M-01” is equipped with a K65V type carburetor with a starting device (Fig. 7).

To flush and clean the carburetor, do the following:

— close the gas tap and disconnect the gas hose;

— unscrew the two screws securing the carburetor body cover and remove it together with the throttle;

— remove the rubber carburetor coupling;

— unscrew the two nuts securing the carburetor and remove it;

— disassemble the carburetor.

Wash the removed parts in clean gasoline, inspect and reassemble in reverse order.

It is strictly forbidden to wash carburetor parts in acetone or solvents, or to clean jets with metal objects.

To adjust the fuel level in the carburetor float chamber, remove the float chamber body, turn the carburetor up with the floats and bend the brass adjusting element so that the longitudinal mark from the mold connector on the floats is parallel to the plane of the carburetor body. With the indicated position of the floats, the fuel level in the float chamber required for normal engine operation is equal to 12.14 mm.

Adjusting carburetor idle speed

Adjust the idle speed only on a well-warmed engine in the following sequence:

- screw in the idle speed adjusting screw 18 until it stops, then unscrew it 0.5 - 1 turn:

— turn the throttle handle 20-30° towards you:

— start the engine, warm it up, then use adjusting screw 16 for throttle lift to achieve a minimum stable engine speed. After this, turn it out using the idle speed screw 18. achieve maximum engine speed: then use screw 16, tightening it, again achieve the minimum stable speed.

Check the correct idle speed adjustment by sharply opening the throttle (by sharply turning the throttle control handle toward you).

If the engine stalls, screw 18 should be turned a quarter to half a turn (the mixture will become richer).

If necessary, repeat the adjustment operations.

Ignition installation.

The ignition timing is set by turning the generator stator after first loosening the three screws securing the stator to the crankcase.

For normal engine operation, it is necessary that the moment of spark formation at the generator - (Fig. 22) (this moment is determined by the coincidence of the rotor edge E with the groove G in the stator cover) coincides with the moment when the piston does not reach TDC 2.5 - 3.0 mm.

The piston position is set with the spark plug turned out.

Generator maintenance mainly comes down to tightening the threaded fasteners of the generator stator, as well as checking the condition of the passages and plugs in the block. All wires must be securely fastened and insulated from each other. The serviceability of the generator is determined by checking it in operation and checking its characteristics in special areas.

do you have drawings of the cylinder, or better yet, the engine? and what is TDC

Why do you need drawings? Smoke the manual! TDC - Top dead center.

«

Adjusting the K-36B carburetor

Adjustment at idle speed is carried out as follows: 1 - before starting the adjustment, you need to start and warm up the engine. 2 — set the fuel corrector coin to the farthest position from you; 3 — by turning out or screwing in screw 14, set the minimum possible engine speed; 4 - tighten screw 13 until it stops, gradually unscrew it, achieve clear, stable operation of the engine; 5 - set screw 14, lower or raise the throttle to the minimum stable idle speed.

The quality of the mixture is adjusted in operating modes by moving the metering needle 6 in the throttle valve to one of the five annular grooves, while raising the metering needle ensures enrichment of the working mixture, lowering ensures depletion.

Adjustment recommendations

Impeccable operation of the unit is the key to the reliability and endurance of the motor. Before adjustment, the operation of the ignition system, the integrity of the pistons and cylinder are checked. It is also necessary to clean the spark plugs or replace them with others.

What is not recommended to do:

- clean the jets with iron rods or wire;

- wash parts with acetone or other solvents, and use only purified gasoline.

Adjustment process:

- The presence of gaps and worn-out gaskets is checked, as they allow air to pass through.

- The flange of the device must be completely adjacent to the engine cylinder.

- All adjacent parts of the assembly are checked with a surface plate and ground in if necessary.

- The fuel level in the float chamber is assessed.

- It is important to check the parallel placement of the floats. An error of no more than 0.5 mm is allowed.

- The gap from the float to the body should not be more than 26.5 mm. This is important for maintaining a normal fuel level in the chamber at average atmospheric pressure.

Carburetor adjustment to 62

- The device has two screws (the first is a quality screw that closes the channel and provides increased air flow; the second screw adjusts the position of the damper. Both elements are designed to regulate the idle speed and the needle, which is responsible for the quality of the working mixture. When it rises, the mixture is enriched, with lowering - it becomes leaner.

- First of all, you need to tighten the quality screw until it stops, and then turn it once. Then the engine should be started and warmed up. The screw is unscrewed until the sounds of interruptions occur in the engine. The adjustment is carried out until the engine is in stable operation mode.

This sets the average mixture composition for low idle speeds. If the speed is high, then use the damper screw to lower it. If malfunctions occur in the engine, stop lowering the damper.

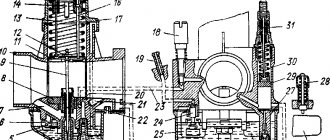

K-36B carburetor diagram

1. Fitting. 2. Fuel corrector. 3.Fuel corrector spring. 4. Locking needle. 5. Throttle valve spring. 6. Dosing needle. 7. Mixing chamber housing. 8. Air intake channel. 9. Sprayer. 10. Main jet. 11. Fuel corrector jet. 12. Float. 13. Idle speed adjustment screw. 14. Throttle set screw. 15. Throttle valve. 16. Cover of the mixing chamber housing. 17. Cable guide. 18. Leaf spring. 19. Float release button. 20. Float chamber cover. 21. Float chamber housing.

Adjusting the K-62V and K65P carburetor

Adjust the idle speed in the following sequence: 1 – screw screw 18 until it stops, which regulates the air supply for idle speed. Then unscrew one turn. 2 – Open the throttle slightly using the throttle. 3 – Start the engine and warm it up. 4 – Using bolt 16, lowering the throttle valve, achieve minimal stable engine operation. 5 – Unscrew screw 18 to set the maximum speed. 6 – Using bolt 16, lower the damper again to minimum speed. 7 – Check the adjustment. Sharply open the throttle with the throttle. If the engine stalls or there is a failure in operation. When switching from idle to main working. The adjustment is incorrect. Screw 18 needs to be used to enrich the fuel mixture - tighten it by a quarter. Or repeat the entire adjustment. 8 – Adjusted correctly, if there is no dip and the motor does not stall. And it continues to gain momentum.

Adjustment with dosing needle

The dosing needle for adjustment has five positions and is fixed with a special lock. Raise the needle one notch and increase the fuel supply. We lower it and reduce the fuel supply.

Under normal conditions, the needle is installed in the central groove.

When operating a motorcycle at high temperatures of plus 35 degrees and above, as well as in rarefied air at an altitude of 2000 and above above sea level. The needle should be released one division.

And vice versa at low temperatures of minus 15 degrees and below. The needle should be raised one notch

Main functions

In the last century, when developing any type of equipment, manufacturers sought to reduce the number of components and assemblies. The carburetor for 62 was first released in 1970, it replaced the old series for 36. The advanced model significantly increased engine performance. This required expanding the air channels to increase the volume of the mixture. Old devices did not allow this. The new version has a float chamber and at the same time the design of the float and flat-type throttle valve have changed. Innovations led to the fact that the components decreased in size, and with sudden changes in the motorcycle's riding mode, the engines operated smoothly.

Adjusting the fuel level

For this purpose, there is a brass adjusting element on the float, as shown by the white arrow in the photo.

The entire adjustment process comes down to setting the float in a certain position. Remove the bottom carburetor cover and turn it upside down with the float.

We look from the side so that the mark on the float from the mold (black arrow shows) is parallel to the carburetor plane (red arrow shows).

In this position of the float, the fuel level will be within 12 ... 14 mm. This level is necessary for normal engine operation.

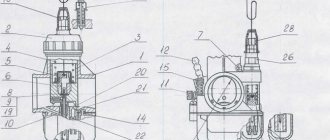

Scheme of the carburetor K-62V motorcycle Voskhod

1. Idle fuel jet. 2. Main fuel jet. 3. Float chamber. 4. Sprayer. 5. Float axis. 6. Float lever bushing. 7. Air channel. 8. Nozzles. 9. Dosing needle. 10. Body. 11. Throttle. 12. Needle lock. 13 Throttle spring. 14. Throttle lift limiter (removed after engine break-in). 15. Throttle control cable. 16. Throttle lift adjusting screw. 17. Cover. 18. Idle speed adjustment screw. 19. Fitting for fuel intake. 20. Transition hole. 21. Idle air channel. 22. Drainage hole. 23. Idle air channel. 24. Locking needle with washer. 25. Float. 26. Float sink.

How to adjust the carburetor on a motorcycle sunrise

For many years, domestic motorcycles and scooters, as well as Buran snowmobiles, were equipped with carburetors of the K62 family or their varieties. Operation revealed a number of design flaws. Their elimination required a major modernization of carburetors and led to the emergence of an essentially new device, which was designated K65. Its implementation began at the end of last year and will be completed this year. Since the carburetor has a long life ahead of it, we asked the engineers of the Leningrad Carburetor Plant to tell us more about it.

At first glance, the K65 carburetor is not much different from the usual K62. But this is precisely at first glance, since modernization affected not the form, but the content. And you will be convinced of this when, together with us, you examine the structure, principles of operation and adjustment of the new device shown in the figure.

First, let's talk about the design and operating principles. It all starts with a system for supplying and maintaining a constant fuel level. Through fitting 20 it reaches the fuel valve 15, which is equipped with an elastic lock washer. The valve rests on a tongue 18 connected to plastic floats 17, which are interconnected and rotate freely on an axis 16. If for some reason the fuel level rises, its excess is drained from the float chamber through the drain hole 32. So that when heated, the pressure in the float chamber the chamber did not increase, it is connected to the atmosphere by an unbalancing channel 31. The main metering system consists of a sprayer 5, a main fuel jet 6, a throttle needle 7 and an air supply channel 8. Fuel from the float chamber through the main fuel jet 6 enters the sprayer 5, rising under by the action of vacuum in the gap between the nozzle and the throttle needle 7. At the outlet of the nozzle, it is mixed with air entering through channel 8 through the hole in the nozzle body. The throttle needle ensures engine operation at medium speeds and can be set to one of five positions. At maximum power modes, fuel consumption is determined mainly by the throughput of the main fuel nozzle. Reliable fastening of the atomizer is ensured by a lock washer 14 installed under the fuel pipe 9. The idle system consists, in turn, of a fuel pipe 9, an air channel 10, mixture quality screws 11 and mixture quantity 27, idle hole 12 and transition hole 13. When the engine is idling, under the influence of vacuum in the mixing chamber behind the throttle, the fuel rises through tube 9 and mixes with air entering through channel 10. The resulting emulsion, with a slight opening of the throttle (at low speeds), exits only through hole 12. With further lifting of the throttle and increasing revolutions, the vacuum in the area of hole 13 increases and the liquid also begins to flow through it. Thus, the fuel supply increases as the speed increases. Main system for starting and warming up the engine . Carburetors of different modifications use different systems of enrichment devices; on K65S and K65V - a starting device with an autonomous drive; on K65G and K65Zh - with cable drive; on K65I and K65D - corrector-enrichment. Let's look at them in that order. The starting device with an autonomous drive consists of a plunger 37, a guide 35, a return spring 36, a starting device needle 39, a sealing rubber 38, a protective cap 29, a control rod 40, as well as channels 33 and 34, a fuel well A and hole 41. Normal position devices are closed. In this case, the needle 39 with the sealing rubber 38 blocks the fuel channel, and the side surface of the plunger 37 blocks the channels 33 and 34. To turn on the starting device, you need to lift the rod 40 up and turn it approximately 90°. In this case, the extrusions on the rod will come out of the grooves of the guide 35 and will be fixed on its upper end. The plunger will rise, opening channels 33 and 34 and fuel channel 48. Under the influence of vacuum, fuel from well A will enter the cavity under the plunger, mix with air and be fed into the mixing chamber in the form of an emulsion. The volume of fuel in the well is sufficient for a high one-time supply at the time of start. After starting the engine, the fuel level in the well decreases and the composition of the mixture becomes leaner. To turn off the starting device, you need, of course, to turn the rod back by about 90°, after which, under the action of the return spring 36, the plunger will take its original position. The starting device is protected from dust and dirt by a rubber cap placed on the spring guide 35. A cable-driven starting device is similar to the one described - but it does not have a rod 40, and the position of the plunger 37 is adjusted by a cable connected to the shifter. The corrector-enricher differs in that its fuel comes directly from the float chamber (there is no fuel well A). Fuel consumption is limited by jet 43. With the plunger fully raised, the greatest enrichment of the mixture necessary to start the engine is achieved. As the plunger is lowered, the mixture becomes increasingly lean as the gap between the needle 42 and the channel wall decreases. When the plunger is completely lowered, the needle with the sealing rubber band 38 locks the fuel channel 48. Additionally, a starting device (float quencher) is used at air temperatures from +5C and below. Using it requires no explanation. Having examined the design and operating principle of individual systems, we can now move on to issues of operation and adjustments. Before installing the carburetor, you need to remove its cover 2 with the throttle assembly. The cover is a rather complex subassembly on which the throttle lift screw 27, guide 28, gasket 26, throttle lift limiter 30, throttle 21 and its spring 24, and protective cap 29 are installed. Screw 27 is connected to the throttle by a rod. The throttle spring 24 simultaneously holds the needle 7 through the lock 22. The U-shaped brass throttle has two shaped holes and one round one. The latter, located in the center, serves to install and fasten the needle, the shaped one on the cutout side is for fastening the throttle cable, and the T-shaped one is for attaching the rod of the screw 27. The radial cutout on the throttle wall, facing the air filter, provides the necessary vacuum in the area sprayer, There is a limiter 30 inside the cover - it is recommended to remove it after the break-in is completed. Having installed the carburetor on the engine, you need to attach a cable to the throttle and secure the cover to the carburetor. After this, lift the throttle using the throttle and check whether it opens the diffuser completely. Do this several times to ensure that the throttle is not stuck in any position and that the diffuser closes and opens completely. Using screw 27, raise the throttle to a position where a gap of 2 - 3 mm appears between its lower edge and the diffuser generatrix. If the carburetor has a starting device or a corrector, you need to unscrew part 35, remove the corrector assembly and attach the cable to the piston 27, and then install the unit in place. Adjust the position of the stops 28 of the sheaths of the throttle and corrector drive cables (if the latter is present) so that they have a free play of approximately 2 - 3 mm (this is done so that when the steering wheel is turned, the position of the throttle or corrector does not change). , Screw screw 11 until it stops, and then unscrew it 0.5 - 1.5 turns. Attach the fuel hose to fitting 20. Make sure that fuel does not leak at the connection points and open the starter or corrector. If, due to weather conditions or the individual characteristics of the engine, it is necessary to use a float quencher, it is better to do this while simultaneously opening the throttle fully, then the reception efficiency increases. Smoothly pressing the kickstarter, turn the crankshaft 2 - 3 turns, turn on the ignition and start vigorously. After starting and warming up the engine, the starting device or corrector must be turned off. In conclusion, let's talk a little about carburetor adjustments - every motorcyclist has to deal with them from time to time. It makes more sense to start by setting the fuel level. To do this, you need to turn the carburetor over, remove the bottom of the float chamber and measure the distance from the plane of the connector to the line dividing the float in half (the mark from the mold connector). This distance should be 13±1.5 mm. If the size of your carburetor does not fall within these limits, you need to carefully bend float tongue 18 in one direction or another. One more note in passing. If during operation the carburetor suddenly begins to overflow, you need to check whether the float is leaky. To do this, immerse it in a bath of hot water for at least a minute. Bubbles will appear - the float is bad, if not - everything is fine. Before making adjustments, which will be discussed later, the engine needs to be warmed up. After this, lowering the throttle with screw 27, set the minimum stable idle speed, and then, slowly turning screw 11 in one direction or another, increase the speed to the maximum possible. Again, use screw 27 to try to reduce them, and then use screw 11 to raise them as far as possible. These operations sometimes have to be repeated 2-3 times. Now check how the engine responds to the throttle. If it stalls when you open the throttle sharply, turn the mixture quality screw 11 to ? - ? turnover (the mixture will become richer); if the engine, on the contrary, stalls when the throttle is closed abruptly, screw 11 needs to be unscrewed by the same amount (the mixture, naturally, will become leaner). The quality of the mixture is adjusted in operating modes by moving the dosing needle 7 relative to the lock 22. You should start from its middle position. When the lock is moved upward, the mixture becomes leaner (of course: the needle lowers, and there remains a smaller gap between its cone and the wall of the atomizer!), when the lock is moved downward, it becomes richer. The criterion for needle movement can be the color of the insulator of the central electrode of the spark plug. If after a run of approximately 30 - 40 km in normal operating mode it has a whitish color, the mixture is too lean and the needle needs to be raised at least one notch; if the insulator is dark brown, with traces of soot, the mixture needs to be made leaner by lowering the needle. Finally, if the motorcycle does not reach maximum speed, you should replace the main fuel jet with a different one with a larger calibrated hole. The characteristics of the new family of carburetors are shown in the table.

Motoblog

A little bit about everything

No, I won’t talk now about how beautiful our sunrises are, although they undoubtedly deserve attention. I’m trying to give the blog a motorcycle theme, so I want to talk about the experience of using my motorcycle, which I’ve been driving for about 11 years.

Over its entire life, the motorcycle traveled 40-50 thousand kilometers, it is impossible to say more precisely, because the speedometer was broken, replaced, and for a long time the motorcycle drove without this device at all. He has seen a variety of roads, from good asphalt to tractor ruts filled with mud. And everywhere the motorcycle showed its good side, it was reliable, contrary to the established opinion that Voskhod is the most “breakable” motorcycle. “I bought Voskhod - fuck all year,” I usually respond to such barbs by nodding towards my motorcycle, “it’s not about him.”

find 10 differences

To be honest, I never liked this name - Voskhod, it is not motorcycle at all. Apparently the choice of such a name was influenced by the specifics of the Degtyarev Plant, which has a defense focus, and harmless names like “Peony”, “Hyacinth”, “Pinocchio” are the order of the day for deadly devices here. I didn’t put up with this and slightly upgraded the name for my motorcycle)

For me personally, the Voskhod is a light city motorcycle; its power and dynamics, coupled with maneuverability and small dimensions, are quite enough for moving around the city. Its “range” is approximately 100-150 km in one direction. More is possible (power reserve is about 350 km), but it’s tiring. The seating position is not very comfortable, vibrations, and limited speed make themselves felt when driving along the highway outside the city. In a word, it’s not suitable for a touring motorcycle) But Voskhod copes excellently with the task of quickly getting around the city from point A to point B. Often drivers at traffic lights, leaning out of their cars, ask “. Where did you dig it up? This is a rarity. What year. “What the hell delivers) Now, point by point, what can I say about Voskhod, I will note the disadvantages, advantages, what changes I made and what it led to.

Adjusting the K62 carburetor

The carburetor is one of the main components of a motorcycle, which affects the operation of your bike’s engine. Its correct adjustment affects how it starts, runs, and engine power. The second element is the ignition system. In this article we will talk about adjustments that can be found on motorcycles Minsk, IZH Jupiter and Planet, Voskhod.

The K62 carburetor has two adjusting screws, with which you can change the idle speed, and a needle, by changing the position of which, you can change the property of the mixture (enrich or lean it). When we raise the needle, we enrich the mixture; when we lower it, we make it leaner. Adjusting the quality of the mixture is carried out by walking 2-3 km (at a speed of about 60-70 km/h) and looking at the spark plug. If the candle is covered with the working mixture (the candle is oily, dark brown or black), we lower the needle; if it is too dry (the color is white, light straw), we raise it. As a result, a light brown soot should appear. But this is just part of the adjustment; each time you need to set the carburetor idle speed. So we continue to adjust further:

To adjust the idle speed on the K62 carburetor there is a “quality screw”. This screw supplies air even when the throttle is closed. We repeat, the propeller produces air, although some people think that this propeller is designed for fuel. Therefore, by tightening the quality screw, we close the air flow, that is, we enrich the mixture. If we unscrew the screw, the mixture becomes leaner. As was said, this screw provides air in all positions of the damper, and therefore at idle speed of the crankshaft. Therefore, the quality screw belongs to the idle air regulator. At this moment, it significantly affects the operation, but if the gas is at medium or high speeds, then the influence is not large, but it is present. So, it all comes down to the fact that the idle speed is adjusted, and this automatically affects all engine frequencies. Now, after a short introduction, let’s talk about the idle speed adjustment itself. To keep things simple, let’s talk about adjusting K62 K carburetors and similar ones for Minsk and Voskhod motorcycles. But by analogy, the adjustment of all types of carburetors is the same, so it will also work on IZH and other motorcycles.

Why choose us

Despite the fact that Voskhods were produced relatively recently, it is becoming increasingly difficult to buy spare parts for the Voskhod and Sova motorcycles. Buyers will find much of what they need for repairs in the catalog of the Russian Motor store. All motorcycle parts offered for sale are scattered according to categories, have a detailed description, and motorcycle enthusiasts can order both used and new spare parts of ideal quality, for the production of which high-quality materials and the most modern technologies were used. If the required part is not available, it can be found to order, which will take a little time.

In order to buy spare parts for Voskhod, you don’t even have to leave your home, since the order can be made remotely. Our store is open seven days a week, we do not know what holidays and weekends are. For customer convenience, we accept up to 40 payment options and offer delivery by mail or courier. In addition to two stores in St. Petersburg, shipping is organized to any region of Russia. The cost and speed of delivery depends on the efficiency of the post office or courier service. If for any reason you are not satisfied with the spare part, we will arrange its replacement or refund within the time limits established by law.

Adjusting the K62 carburetor:

Hello! Please tell me, I have a Minsk 125, it’s a Pakko (original, new), it’s not in use, it works fine, that is, the idle is normal, it picks up speed briskly, but as soon as you start to move out of place, it doesn’t pull well, or it may even stall, you just need gas open more than halfway. The quality screw is screwed in completely, but if you unscrew it by 1-1.5 rpm, you won’t be able to move it at all - the engine will stall. The spark is normal, the ignition is set correctly, the needle is in the middle position. Please tell me what’s wrong, this is the first time I’ve encountered such a problem?

Adjusting the K65V carburetor (part 2)

Published May 24, 2018

This is how I adjust the carburetor and I think it is a pretty effective way of adjusting. JOIN QUIZGROUP PARTNER PROGRAM: https://join.quizgroup.com/?ref=318523

this is of course good, but I get severe flooding during suction, or rather after it.. Please help.. Help me

check the floats! most likely they are stuck when they fill up with gas!!

Check to see if the needle that opens the choke jet is sticking. It depends on what kind of carburetor you have, of course.

I did everything as you said in the first and second parts, but for some reason my Jupiter 3 won’t start, it just catches, can you help?

Is the ignition adjusted correctly? How long have the seals been in place? So how's the compression?

It's a tedious thing to adjust the carburetor

hi, I did everything as in your video, and noticed that when you open the damper sharply, it seems to stall, I tightened the screw and unscrewed it, nothing helped, then I decided to raise the needle all the way (fully), when you accelerate in place, it works fine , and when you are about to accelerate, it immediately stalls at first speed, I decided to drive straight and began to suck it up while driving, and it got better, I think it doesn’t have enough gasoline, the quality screw was turned out 2.5 turns, the fuel level was done as in the video . tell me?

You can try to make a larger level, maybe this level is not applicable to every motorcycle.

can you give me your email? so that I can turn to you for help

A good device (it was).

Hello to all fans of Soviet technology!

Since childhood, I have been passionate about motorcycles. Around 12 years old I saved up money for my first moped. Then there were several more. At the age of 13 I was already sick of a motorcycle. In my dreams, of course, there was Java. A job turned up in a production cooperative and, at the same time as going to school, I started earning money for my first motorcycle. In Soviet times, you could take your driving license as an external student at the age of 14. But you could only ride when you were 16 years old. I just turned 14, I went to the then traffic police and paid a fee of 1 ruble for passing the exam as an external student. But I never passed my license then, because there was a problem with the purchase of the motorcycle. Having collected the required amount, I submitted an ad to the newspaper and began to wait for publication. Exactly three weeks later, when my ad was supposed to be published, the advertising newspaper went bankrupt. How sad I was. The advertising newspaper was the only one in the city at that time. Fortunately, the publishing house was reassuring: the newspaper might be published again in about six months. And so it happened, having survived financial difficulties, the newspaper came out, and my ad was published. Unfortunately for me, there was severe inflation in the country (the 90s) and my savings for Java were no longer enough. But somehow I agreed to see the almost new Voskhod-3M at an affordable price. I also considered it as an alternative. I remember an article about him in a magazine from 1989. How many thoughts then slid in impatient anticipation.

The seller brought Voskhod to my house in a minibus. According to the words, his younger brother owned it, but due to the accident on their relative’s motorcycle, in order not to tempt fate, it was decided not to ride the motorcycle anymore. To make the decision more meaningful, the older brother cut the clutch cable with pliers. This is how the motorcycle appeared before me: a little older than a year, with a mileage of about 1000 km, for 1300 Soviet rubles. After starting the engine and some haggling over the cable, the deal was done. I brought the motorcycle into the barn, hung chains and locks on the wheels, and the agonizing wait began.

I immediately repaired the clutch and on a Saturday morning in April, I got up at 5 am and rolled the motorcycle out onto the street. The timing was chosen for a reason. After the moped with its two speeds, the power reserve of my Voskhod seemed to last forever. There were absolutely no cars on the street then, and after a short warm-up I drove off. Wow, you have to experience this, it makes no sense to describe it. Having made a circle of honor of several kilometers and reaching speeds of up to 80 km/h in the city, I returned home safely. Afterwards there were several more similar outings, and after that I transported the motorcycle to the dacha for the summer holidays.

On the technical side. The single-cylinder engine turned out to be dull at low speeds. But speeds 1 and 2 with full clutch release brought trembling in the knees. This was more pronounced, since even with a fairly low base, handling was far from ideal. Consumption was around 4-5 liters at any intensity of use. I was pleased with the depreciation. The front fork absorbed bumps clearly. The stock of rear shock absorbers was also enough, they also had 5 degrees of stiffness adjustment. The maximum was 115 km. at one o'clock. The speedometer quickly shrank because its worm drive was very poor. During the summer I bought a cooperatively produced fairing. The rear was raised by 8 cm, which, surprisingly, only improved handling. Added a second stop signal on the man-made antennae. The wheels are decorated with imitation cast spokes. I became the first guy in the village. Trips to the river, with girls and for beer became the main operational mileage over the summer. Then the winter was slowly passed through.

By the following summer, a fuel shortage hit. You spend two hours at a gas station to get your 20 liters. Plus the clutch began to slip, which could not be repaired. It was decided to sell the motorcycle under pressure from a buyer who appeared. The amount was impressive - 50 US dollars. I was glad to get rid of my friend who had begun to mope. And the buyer, having brought the motorcycle to its original condition, put it up for sale for other money.

DIY motorcycle repair Voskhod

Motorcycles Voskhod, Voshod-2(M) and Voshod-3(M) were produced from 1965 to 1993 and were distinguished by excellent technical and operational qualities for their time. All of them were equipped with 173 cc two-stroke engines, which had one air-cooled cylinder and carburetor power. This allowed the motorcycle, depending on the modification, to reach a maximum speed of 90-105 km/h with a fuel consumption of no more than 4.5-5.5 liters per 100 km. In general, Voskhod has established itself as a reliable and durable vehicle, capable of operating for many years with proper maintenance. However, time takes its toll, and the need to repair Soviet equipment arises more and more often. Let's try to figure out what features are characteristic of restoring the main components and assemblies in the process of repairing a Voskhod motorcycle.

The “heart” of a motorcycle, even with the most careful use, gradually wears out - this is facilitated by the abundance of heterogeneous mechanical loads in the cylinder-piston group and other moving parts, temperature effects on the metal, the chemical composition of the working mixture and exhaust gases. DIY motorcycle repair Voskhod most often includes the following engine work:

- removing the power unit from the motorcycle frame;

- partial or complete disassembly of the internal combustion engine;

- replacing piston rings;

- restoration of the cylinder mirror;

- repair or replacement of the piston, connecting rod, crankshaft;

- replacement of support bearings, liners, seals;

- lubrication, fastening, adjustment work.

Engine repair, like the repair of other units, must be preceded by a comprehensive diagnosis of its technical condition, which includes an analysis of operational parameters (approximate indicators of developed power and speed, fuel consumption, sound of operation, color and character of the exhaust). If necessary, diagnostics are performed on the bench, and specialized instrumentation is used.

It is important to navigate the structure of a two-stroke internal combustion engine of a motorcycle and understand how each specific type of repair is performed. So, when replacing piston rings, you can do without removing the engine. It is enough to unscrew the stud nuts, remove the cylinder cover and, opening access to the piston, bring the piston to top dead center. Then the worn rings are removed and new ones are installed. The engine is assembled, not forgetting to replace the gasket. This completes the repair.

Much more complicated is the process of replacing the crankshaft bearings and its seals, the need for which, especially if the motorcycle is used incorrectly, arises quite often. You will need to disconnect and remove the internal combustion engine, clean its external surfaces, disassemble the crankcase, allowing access to the crankshaft, and dismantle the latter. It is important to be careful when knocking out old bearings - if they become distorted, they can damage the seat. And, no matter how trivial it may sound, do not forget to remove the retaining rings. Then the new bearings are carefully pressed in, the crankshaft is installed on the left side of the pan and the engine is turned over. A pin is put on the nuts and the assembled module is screwed into the studs. The power unit is assembled in the reverse order. In case of wear of the inner surface (mirror) of the cylinders, they are bored to repair size and ground. This is a complex and highly precise job that must be carried out by experienced professionals and using special equipment. However, preliminary work - removing and disassembling the internal combustion engine - can be done independently. After the repair, you will have to replace the piston with rings with parts from the corresponding repair group.

Voskhod 3M: Technical characteristics, Review and photos of the motorcycle

The Voskhod 3M motorcycle is not just a bike. This is a legend, this is the dream of hundreds of thousands of young citizens of the Soviet Union, who could not even imagine imported Czechoslovak “Java” and “CZ” because of their high cost. This model is not without its shortcomings, but by releasing it, the plant helped many motorcyclists realize an impossible dream and acquire their own two-wheeled vehicle.

Design

Contemporaries often called Voskhod 3M unsightly and unattractive, comparing it with “Java”, “Planets” and “Jupiters”. We can agree with them, but let’s not forget that this motorcycle was noticeably cheaper than all of the competitors listed above, so for such a price one could put up with a mediocre design.

Specifications

The bike was completely in keeping with its time. It was repairable, moderately reliable and affordable, which predetermined its popularity. Many hundreds of thousands of copies were produced, so there is a chance of finding one in good condition even now. The characteristics of the model were not enough stars from the sky even then, during the years of release, but now retro technology is still valued for completely different reasons.

Engine

The 3M Voskhod motor has always been considered capricious, but at the same time tenacious, and it really has a good resource. The two-stroke engine of the motorcycle is a single-cylinder air-cooled power unit, with roots going back to the 60s of the 20th century.

Volume - just under 200 cubic meters (173 to be exact), power - 15 horsepower. Good traction is available from low revs, although power peaks at 5500 rpm and the bike begins to vibrate mercilessly. Alas, this is a design feature of an archaic motor.

The maximum speed it is capable of is 110 km/h.

Transmission

A good 4-speed transmission for its time with a classic scheme (1-N-2-3-4), almost unchanged, migrated to the Voskhod 3M from its predecessors. But the gearbox is very demanding on proper settings; you need to carefully observe the tightening torques of the bolts and set all the gaps. Otherwise, there is a chance of encountering a common problem with this gearbox, when 2nd and 4th gears begin to engage very slowly. In the future, this can easily lead to transmission failure.

Chassis and brakes

Compared to the 2M model, this model has more advanced suspension, the rear shock absorbers have been modified, improved, and also have preload adjustments. At the front, as before, there is a regular telescopic fork, the stays of which are covered with rubber corrugations. It’s difficult to call the suspension soft or energy-intensive, but it also has an undeniable advantage - it is simply indestructible, and even in the event of an oil leak, you can drive for more than one week. But we can’t say anything good about the brakes; the drum brakes on both wheels cope with their task, at best, to a C grade. As, indeed, on any other Soviet motorcycles.

Electronics

It was on the third generation of Voskhods that designers switched from a 6-volt on-board network to a 12-volt one. More precisely, on the Voskhod 3 model a 7-volt generator was installed, but in 3M all the electronics were already 12-volt. But still, this motorcycle has a minimum of electronic components - a generator, a dashboard and lighting optics.

Weight and dimensions

The weight of the motorcycle decreased by 3 kg compared to the previous model, amounting to 122 kilograms of dry weight. This provided Voskhod 3M with good power supply and dynamics compared to its heavier competitors. Its other modifications differed slightly in weight, but how much each of them weighs is now difficult to say, years ago. But the dimensions were unchanged - exactly 2 meters in length and 85 cm in width at the extreme points.

Controllability

Due to the archaic design, the maneuverability of the motorcycle leaves much to be desired, and the braking distance on dry asphalt at a speed of 60 km/h is, according to official data, 20 meters. But for its time, the technical characteristics of this model were quite good, and Voskhod 3M was not inferior to other Soviet bikes that were produced at the same time and sold at a similar price.

Fuel consumption

On average, gasoline consumption is 4.5-5 liters per 100 km, noticeably less than some other models of those years. The engine was originally designed for AI-76, so it is not recommended to fill it with high-octane gasoline. The gas tank volume is the same for all modifications - 14 liters, which is enough to travel up to 300 km without refueling.

Motorcycle price

Now it is impossible to become the owner of a new Voskhod - its last modification, “Tourist”, was discontinued in 2008. Used copies cost from 10 thousand rubles for the cheapest options, and a bike in collectible condition can cost 100-150 thousand rubles or more. But it’s worth considering that many sellers offer motorcycles that have stood motionless for a decade or two in a garage, often without documents. In theory, they can be restored by the traffic police, but to do this you will have to go through nine circles of bureaucratic hell.

Repair and tuning

The undoubted advantage of any Soviet motorcycle equipment is its ease of repair and maintenance. But the disadvantages include the fact that you have to poke around in the garage more often than you would like. This is largely due to the advanced age of all surviving motorcycles, and Voskhod 3M was no exception to this rule.

Repair

You can fix anything in it! No, seriously - almost all components are repairable to one degree or another. Many bikers who now ride Hondas and Harley-Davidsons started with Soviet motorcycles, and it was with their help that they acquired the first motorcycle mechanic skills that are necessary for any lover of two wheels. So if you have never even held a wrench in your hands, there is no need to be afraid of repairs with this model - everything is simple in it.

Spare parts

Nowadays, spare parts can only be found secondhand or in highly specialized stores, and often used, not new. Due to their lack, some owners are trying to adapt Chinese or Japanese components. In some cases, this can be done, but you will have to try hard and also spend a lot of time selecting suitable hardware.

Tuning

If you want to restore the bike to its original condition, as it deserves, then forget the word “tuning” like a bad dream. But if you use Voskhod 3M for its intended purpose, that is, as a transport, then options are possible. Most often, owners change shock absorbers to more advanced ones (there are plenty of inexpensive Chinese options), or replace the carburetor. This is especially true for copies that were equipped from the factory not with Czechoslovakian carburetors, but with Soviet ones of lower quality. We have a separate article on this topic: How to make tuning Sunrise 3m with your own hands.

Motorcycle modifications

- Standard Voskhod 3M. It is a modified version of model 3, which, in turn, was developed on the basis of 2M.

- Luxury Produced in a limited series, it featured higher quality paintwork and more chrome. Rarely found on sale now.

- Tourist. It had a reinforced steering wheel, saddlebags, trunk, roll bars and a higher maximum speed, up to 145 km/h. All differences are clearly visible in the photo. This model was produced right up to 2008!

Advantages and disadvantages

Soviet technology was good, but nothing was perfect. And the Voskhod 3m motorcycle was considered by Soviet bikers to be a rather capricious piece of equipment, which periodically began to take on a life of its own—either it wouldn’t start, or some other misfortune. In fact, caring for your two-wheeled friend and timely maintenance will help you avoid most potential problems.

Advantages

- Modified engine air cooling system, increasing its service life.

- Modern by the standards of that era, 12-volt electrical equipment.

- High-quality carburetors made in Czechoslovakia (not for all years of manufacture).

- Availability of brake pad wear indicator.

- Built-in anti-theft system (mechanical steering wheel lock).

Flaws

- Short service intervals. Your motorcycle needs to be serviced frequently.

- Strong vibrations at high speeds, due to which the image in the rear-view mirrors begins to blur.

- General capriciousness of the Voskhod 3 M engine and gearbox in terms of settings. If you set any gaps incorrectly, problems will not be long in coming.

Owner reviews

I had such a spendthrift once, then everything was a blast, but then Java broke down for cheap, and I realized that in hell I would definitely get credit for part of the torment. Compared to it (and the comparison is correct, the motorcycles are almost the same age) the Voskhod has zero comfort, it starts when it wants, and shakes at speed like a fitful Chihuahua. There were no serious problems with the engine and gearbox, but little things kept falling off, so now I can assemble and disassemble this motorcycle with my eyes closed. The only advantage it had was that it was cheap, and everything else was a complete disadvantage. Ivan, Tver.

It was a good jalopy for its time, completely indestructible. I didn’t do anything with him - I ran away from traffic cops through the fields, standing on the steps so as not to fly out of the saddle, and I carried three passengers at once, and I poured gasoline that had been standing in a barrel in the garage for about five years, but he couldn’t give a damn. Iron and reliable, like the Soviet Union! It's a shame they haven't made motorcycles like this for a long time.

Ignition and carburetor

It is these two components that, as a rule, determine the stability of the engine. Often, interruptions in the crankshaft rotation speed, loss of traction, and difficulties starting the engine are associated precisely with their malfunctions. Repairing the ignition and carburetor usually comes down to adjusting them. Setting the ignition includes setting the gap between the coil core and the sensor magnet within 0.295...0.305 mm. The piston ignition timing should be 3.5-5 mm to top dead center.

Adjusting the carburetor is somewhat more difficult. If you are repairing a Voskhod-3M motorcycle, then you will have to deal with the K65V carburetor, and the main tools will be the quality and quantity screws included in its design. Using the first, you can lean or enrich the mixture - change the proportion of fuel and air entering the cylinder. The second determines its volume per working cycle. With the standard setting, the quality screw is screwed in completely and then unscrewed half a turn. Then the rotation of the quantity screw achieves the minimum stable speed and the quality of the mixture is re-adjusted. Finding the optimal adjustment balance is a search for maximum traction and stability with minimum fuel consumption.

Basic rules for repairing a K65 carburetor

The K65 carburetor replaced the K62 carburetor.

Due to constant breakdowns and shortcomings, technologists decided to modernize it. Despite the fact that the K65 carburetor appeared quite recently, its adjustment is not difficult. There are some nuances that you need to know, but they can affect everyone. Even those who want to know how to adjust the carburetor on a scooter.

Before you begin your own repairs, you must fulfill some conditions.

- It is necessary to warm up the engine thoroughly;

- The carburetor must be in good condition. Otherwise, it must be blown out and cleaned;

- You should pay attention to the air filter. If necessary, it is washed.

Direct carburetor repair work begins with adjusting the free play of the throttle cable and the idle speed.

— The free play of the throttle cable is adjusted as follows: the lock nut on the bolt is loosened, the adjusting bolt is tightened and unscrewed until the free play of the cable is 1-2 mm.

This is interesting: Adjusting the carburetor of a 4T 50CC scooter China

— Adjusting the idle speed is done as follows: unscrew the bolt and thereby increase the speed. In order for the speed to be reduced, the bolt must be tightened. The idle speed will then be adjusted when the engine runs stably at minimum idle speed.

The K65 carburetor adjustment itself

This also includes adjustment of the main dosing system. For this purpose, several grooves are carved into the needle. By moving the latch along them, you can precisely adjust the fuel consumption. If the mixture needs to be enriched, the needle rises. If it is necessary to lean, the latch moves so that the needle drops.

Since the boundary at which the fuel is located in the float chamber greatly affects the quality of the mixture at all stages of engine operation, it also needs to be adjusted. To help the amateur car mechanic, there is a tongue on the float.

The fuel level will change if the tongue is bent or straightened. The best option for accurately adjusting the fuel level would be to measure using an ordinary ruler. It must be placed on the connector plane. The tongue should be bent so that the float strip is at the mark of 13 mm or plus/minus up to 1.5 mm.

To normalize the quality of the idle mixture, a special screw is provided that controls the volume of air entering the channel of the idle design. If you listen to the advice of specialists who have independently adjusted the idle system more than once, you need to perform the following steps:

- The screw is screwed in all the way and the idle speed is adjusted;

- You should check the motorcycle in action, that is, ride it;

- If acceleration, starting, and idling occur in normal mode, then it is worth unscrewing the bolt a little and checking how much worse or better these characteristics have become;

- If the parameters have become better, the bolt is unscrewed a little more, if worse, it is tightened;

- Similar procedures should be carried out several times.

This concludes the work on adjusting the carburetor of the K65 model.

Transmission

During transmission repairs, the following work may be required:

- Adjusting the clutch, replacing its disc and bearing;

- Clutch drive repair;

- Replacement of gearbox bearings;

- Repair of switching module parts;

- Restoration or replacement of gearbox gears.

Most of them require high qualifications and are difficult to do at home. The exception is the repair and replacement of drive mechanisms. So, sometimes there is a need to restore the splines for the gearbox foot, replace the clutch cable or its jacket, or adjust the clutch. These works are carried out without disassembling the crankcase.

Repair and operation of the Voskhod motorcycle are closely interconnected due to the age of the model. However, with the proper approach to organizing and carrying out repairs, the motorcycle will remain your faithful friend and assistant for a long time.