Owners of Java motorcycles, in particular model 634, know firsthand how much suffering a native generator can bring. These are burnt wires, lack of normal headlights and eternal problems with ignition. To avoid this, you can install the scooter ignition in Java and forget about your problems.

Advantages of ignition from a scooter on Java 634:

- Stable operation of the head light;

- Ability to start the motorcycle even with a discharged battery;

- 12 volts;

- By installing cdi ignition on Java, you get built-in ignition timing adjustment;

- More stable operation of all electrical-related systems;

- Relative simplicity of motorcycle conversion.

Flaws:

- Cost of a complete set of re-equipment;

- It is necessary to redo all electrical systems to 12 volts;

- Requires special skills, such as knowledge of motorcycle wiring.

What will you need?

To install the ignition from a scooter in Java, we will need a specific conversion kit. First of all, there is the generator itself; there are two models to choose from. The simpler QMB-139 will perform all the necessary functions, but problems may arise with the light at night, since the winding for the head light is rather weak and will greatly depend on the speed. If this parameter is important to you, then choose a stator from the QMI-157 or 152QMI model - they will be sufficient to achieve your goals.

You will also need an ignition coil with two terminals, here again there is plenty to choose from. For our purposes, motor coils ZMZ-406 or from Oka are suitable.

You will need a 12 volt battery. We don't need a new one; any used motorcycle or new Chinese battery will do. Its role is to smooth out voltage drops in the turn signal and stop signal circuits.

Also, do not forget about the set of wires/terminals. It is better to take the latter from Japanese scooters.

The last item is the adapter plate. Alas, it cannot be found on sale, but kind people have prepared the exact drawings presented below, according to which you can assemble your own adapter plate or order it. The thickness of the metal is 4 mm, this is an important parameter, because if you make the plate larger or smaller, some elements of the system may not fit or work incorrectly.

Top ads View all

Contactless ignition JAWA/JAWA 634-360-CHESET/CZ 472/3

Motorcycle parts and accessories » Motorcycle parts

1,000 UAH

Java Panonia Voskhod IZH BSZ generator 12v without battery cdi vape ignition

Motorcycle parts and accessories » Motorcycle parts

1,200 UAH.

BSZ Java IZH MT electronic ignition contactless system. Set.

Motorcycle parts and accessories » Motorcycle parts

440 UAH

CDI electronic ignition with Generator New on IZh Java Dnepr

Motorcycle parts and accessories » Motorcycle parts

1,000 UAH

CDI BSZ Java Jawa IZh Electronic ignition

Motorcycle parts and accessories » Motorcycle parts

Guaranteed to receive the goods or money back to the card More details.

1 150 UAH.

We install the ignition from the scooter to Java

First of all, we check whether our adapter plate is suitable, if so, then we attach it, install the rotor and stator. The latter should fit completely into the rotor; for convenience, we adjust the distance with washers. We install the sensor and make sure that everything rotates with a reserve and does not touch anything.

Now we need to modify the rotor. From the existing mark on the rotor, after 180 degrees we install a new mark. To maintain the accuracy of the procedure, it is best to use special devices that measure the angle of rotation; you can also use a lathe for this. We solder or weld the mark, obtaining 100% reliability of the unit.

The next step is to set the ignition timing. From the TDC point, we move the mark out from under the sensor by 2.5 mm, while the core should be located on the edge of the mark. The process is complex, so you should ask someone for help. The main thing is to securely fix the mark, turn it a few times and make sure that the settings still match.

Next, we set the gap, the optimal distance, between the plane of the mark and the core - 0.5 - 0.7 mm. To adjust, take a suitable probe and insert it between the mark and the core. The latter, under the influence of magnetic forces, will become at the optimal clearance distance. Next we make sure that the second gap is within the tolerances. If you have deviations in the gaps between the marks, you should make sure that they are within the acceptable values, otherwise the mark will have to be redone.

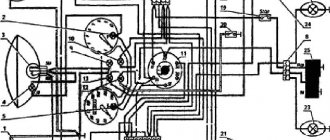

The next step is to assemble the circuit (wires, coils, etc.). To make it easier, you can use the diagram below.

Now, if you did everything correctly, you should check the operation of the entire system. First, we crank the crankshaft using a kickstarter, having previously unscrewed the spark plugs and placed them on the cylinders. The presence of a spark indicates that the electrical circuit is assembled correctly, but the accuracy of its settings can only be determined after the engine has been started. Smooth engine operation and responsiveness to gas are the first sign of success.

Extraordinary JAWA tuning in action!

Here, too, I simply have no words. On the one hand, most of the motorcycle is kept original - the lower part. The pipes are shiny, no oil is leaking from them, good tires are installed, the engine is clean

. Most likely, technically everything is fine with this motorcycle, but why “decorate” it like that?

I remember as a child I was perplexed when I saw motorcycles passing by, whose seats were covered with some kind of skin, carpet, fur coat or something like that. Is this really convenient?

What's wrong with standard casing? Even if it was in short supply, is it really impossible to use another, more suitable material?

Well, I’m generally silent about the fairing. The solution with lighting devices is strange, in my opinion. At the very least, very extraordinary. And yet it is not clear why he was wrapped in a rag. Probably to match the seat.

What to do next?

Most likely, the ignition you assembled from a Java 634 scooter is rough and consists of twists, which is why you should replace them with normal terminals and twist the wires into braids. There is only a small matter left to do - completely replace all the remaining electrical elements, starting from the dashboard and ending with the head lighting and turn signals. Fortunately, now you have full 12 volts, so you can replace everything with spare parts from older models. On the other hand, 12 volts open up the opportunity to install almost any modern turn signal, high-quality lighting and many other useful devices such as a charger for a smartphone or an on-board audio system.

History of appearance and description of the motorcycle

The motorcycle's history dates back to 1929, when Frantisek Janicek acquired a license for the production of two-wheeled vehicles from the Wanderer company. The first motorcycles were not very popular due to their high cost, complexity of design and operation.

During the occupation of Czechoslovakia, the factory stopped producing equipment altogether and was completely transferred to the needs of the German military department. The jawa 638, familiar in the Soviet Union, began production in 1984 and had a modification of the jawa 638 5 00. This model replaced the previous machine with the index 350-633. Here the driving and performance characteristics of the motorcycle have been thoroughly improved.

The appearance of the motorcycle, although not very outstanding, is nevertheless eye-catching. Among its other brethren, it is distinguished by elements characteristic only of Java: a large headlight and turn signals protruding from it, a harmoniously located instrument panel above the headlight, a large, neatly shaped tank and a double, straight seat.

There are compartments under the seat and on both sides of the tank for storing tools or belongings. The maximum speed that the Java 350 638 motorcycle can reach according to its passport is 130 km/h, but many enthusiasts tuning the Java 638 achieved much higher figures.

The Java 638 engine is air-cooled, and this fact also left its mark on the appearance of the motorcycle. The engine is completely open, with clearly visible structural elements. The engine also operates at higher speeds than all Soviet motorcycles produced at that time.

The Java 638 gearbox leg served as a kick starter. To do this, it was necessary to press it a little into the gearbox housing and lift it up. In the Soviet Union there was only one drawback for the owners of this motorcycle - the almost complete lack of spare parts and zip kits for repairs.

The motorcycle has proven itself remarkably well in motorsports. This bike was used in both speedway and stage racing. Motorcycles with sidecars were also used for racing.

INSTALLATION OF BSZ

To do this, you need to prepare the following in advance:

- tools: screwdrivers, pliers, hammer, anvil, multimeter (preferably electronic), narrow ruler (up to 10mm wide) or calipers, file and needle files

— parts: switch (VAZ-2108), Hall sensor, connecting wire harness for them (ready-made for sale), two-terminal ignition coil from Gazelle or Oka, modulator (butterfly is made of magnetic metal 0.7-1 mm thick according to the drawing below) high-voltage wires (armored wires) high power (preferably silicone)

1.Initial stage

First, let's make a modulator if you haven't already made one. The easiest way to do this is to print out the drawing in real size (the dimensions of the drawing correspond to real measurements), stick the printout on a metal plate and cut out the modulator along the contours of the drawing

ATTENTION. Millimeter precision is important here! So no “glaring” can be allowed here

The edges of the modulator must be processed with a file so that there are no nicks or burrs.

2.Dismantling

— Disconnect the high-voltage wires from the spark plugs.

— Disconnect the inductor wires from the ignition coils

— Remove the ignition coils along with the high-voltage wires (we won’t need this anymore)

— Disconnect the capacitors from the breaker contacts

— Disconnect the inductor wires from the breaker contacts

— Remove the contacts from the ignition plate

— Unscrew all the screws from the ignition plate and remove it from the generator

3.Preparation

— Place the anvil on a flat surface

- Place the ignition plate on the anvil and smooth out all the bends with a hammer, and remove the breaker pins with pliers

— Unscrew the generator rotor bolt

4.Installation

— Hang the 2-pin ignition coil in a convenient place under the tank

— Connect wires 1 and 4 of the commutator to the coil as shown in the diagram, as well as high-voltage wires to the spark plugs (ATTENTION: NEVER USE HIGH-VOLTAGE WIRES FROM YOUR OLD COILS

FOR ELECTRONIC IGNITION YOU NEED POWERFUL WIRES, PREFERABLY SILICONE, SOLD IN ANY CAR SHOP!)

— Screw the modulator to the rotor with a standard armature bolt

— Attach the Hall sensor to the plate as shown in the photo

— Secure the switch in a place convenient for you (it is recommended to install it on the right cover of the air cleaner directly under the facing cover)

— Lay the connecting wires of the switch and the DC and connect to the switch and the DC

— Ground wire 2 of the switch to the motorcycle frame (do not ground to the tank!)

5.Adjusting the ignition timing (IPA)

5.1. Set the left piston to top dead center, and using a ruler (or caliper) move the piston back 3mm

5.2

Loosen the generator bolt securing the modulator (ATTENTION DO NOT ALLOW THE SMALLEST ROLL OF THE CRANKSHAFT.)

5.3. Connect the multimeter like this: the red clamp to the green wire of the hall sensor (at the input to the sensor from the green wire, you need to move the white heat shrink and gain access to the bare wire), and connect the black clamp of the multimeter to ground (for example, to the engine crankcase)

5.4. Set the multimeter to read voltage in the range of 0-20 volts

5.5. Turn on the ignition (the multimeter should show a value either equal to or close to zero)

5.6. Rotate the modulator very slowly so that its metal enters the Hall sensor while keeping an eye on the multimeter!

5.7. As soon as a reading of 4-12 volts appears on the multimeter, stop rotating the modulator, and turn it even more slowly in the opposite direction so that the device just shows zero again!

5.8. Tighten the alternator bolt WITHOUT TURNING THE MODULATOR AND CRANKSHAFT!

5.9. Check the position of the piston again and recheck the position of the modulator and the readings in this position of the device when it is tightened; if the readings deviate, then adjust by loosening the screws securing the plate with the DC and slowly rotate the entire plate until the readings are correct.

5.10. Check the readings for the right piston, only if the readings deviate, do not move anything from its place (neither the plate nor the modulator), but use a file to sharpen the edge of the modulator that enters the Hall sensor at this moment.

Electrical diagram

The electrical circuit of the YAVA 638 has been modernized based on the wiring of the previous model. The experimental 12-volt equipment was completely replaced and required the installation of a larger battery. Features of this innovation:

- the appearance of a 210-watt generator;

- possibility of installing an additional fog lamp;

- The stroller consumers were provided with current from a standard generator.

Thanks to the new system, the level of luminous flux was increased, which ensured driving safety at night. Spark formation has also improved, which contributes to more uniform and dynamic engine operation.

The new generator contains such basic elements as a rotor, stator and a metal casing. Its efficiency significantly exceeds the previously used 6-volt generator. This system allows charging even when the engine is running at low speeds.

However, the created system generated direct current, which needed to be converted into alternating current. For this purpose, a rectifier was built into the system. Its convenient location under the saddle makes it easy to carry out maintenance yourself.

However, when installing such equipment, the problem of overheating of the generator walls arose. It became impossible to use the rectifier inside a metal casing, so it was located under the driver's seat, providing air flow to cool the system.

The permissible power to a temperature of 150 degrees Celsius was 15 amperes. With the stroller and the use of all devices, it became possible to connect one additional consumer that does not require more than 40 watts of power.

Unfortunately, using a motorcycle in high temperature conditions of more than 30 degrees can lead to electrical equipment failure. For example, if the YAVA 638 does not start, there is a high probability that the stator winding has overheated or even the insulation has been damaged.

In general, we can say that innovations in the motorcycle have had a good effect not only on electricity consumers. Thanks to the new spark supply system, the engine began to work more evenly, as a result of which the bike became more dynamic. We can say that this unit was one of the best on the Soviet market.

Econostat

The econostat is a system that enriches the mixture at a high throttle position. Its device is very simple. The essence of the work is to take fuel from the float chamber with a pipe. Through the channels, the fuel rises into the diffuser and is sprayed in front of the throttle. This helps air bypass the throttle when it opens low.

In conclusion, we note that after each work carried out, adjusting the YAVA 638 carburetor is very important, see the video about which at the end of the article. It is also necessary to carry out timely maintenance of the carburetor, the essence of which is to clean the main working elements. Washing should be done as often as possible, preferably with diesel fuel or gasoline. It is better to treat resinous areas with caustic substances, for example, acetone. Otherwise, the system will not cause you problems.

Advantages of BSZ over KSZ

While writing the article, I sat and thought and thought, and still did not come to the conclusion of what exactly is the main advantage of BSZ; for me, all the advantages listed below are the main ones and are equal to each other.

— High stability of engine operation (synchronous operation of the cylinders, strictly in turn)

— Frisky review of the throttle

— Better engine thrust (which allows you to easily use the largest drive stars without difficult acceleration!)

— Candles “live” four times longer than on KSZ (I’ll write about this separately below)

— Less well-known “snot” from Java mufflers (since fuel and oil are burned much better)

— Longer service life of all crank bearings (as there is less extraneous detonation and vibration)

— Less fuel consumption (since it burns better, the carburetor must be adjusted to a lower fuel supply)

Adjusting the ignition timing of Jawa 350

Motorcycle engines have constant or variable ignition timing. With constant ignition timing, the beginning of the breaker break, and, consequently, the appearance of a spark, remains unchanged in all engine operating modes. With variable ignition timing, the moment of spark appearance is changed manually or automatically - with a centrifugal regulator, which, as the speed increases, increases the ignition timing from 10 to 30°. (see continuation)

In domestically produced motorcycles, the ignition timing is set according to factory data:

For two-cylinder engines M-61 and K-750, the breaker cam is a continuation of the camshaft, so the ignition timing is set at the factory. These machines have the same hammer break value for the right and left cylinders.

- - hole for decompressor;

- - rod for determining c. m.t.;

- — fixed contact of the breaker;

- — breaker lever;

- - fist.

ADJUSTING THE QUALITY OF THE MIXTURE OF THE CARBURETOR JAVA 638 2928CE

The composition of the mixture at full and medium lift of the spool can be influenced in two ways - by changing the size of the main jet or the position of the needle. Moreover, the size of the nozzle has a greater impact on the composition of the mixture when the diffuser is fully open (raising the spool), and the position of the needle affects mainly at medium. Since when the spool is not fully raised, maximum power from the engine is not required, but efficiency is important, it is necessary that the mixture be lean. But excessive leaning will cause a “failure” in the engine’s operation at partial throttle opening modes. Therefore, it is necessary to choose a needle position such that the mixture is lean, and the engine operation remains stable in all modes, without “failures”. Lowering the needle (moving its latch upward) causes depletion, and raising it causes enrichment. Usually, after running in, the needle is lowered, moving the latch up one notch

However, it will be better if, when adjusting the carburetor in Java, moving the needle, you pay attention to the operation of the engine before and after the change, try different positions of the needle. It is advisable to make a selection, since this affects both the quality of engine operation and the overall fuel consumption of the motorcycle

Designations in the figure: 1 cylindrical spool; 2 needle valve; 3 idle jet; 4 additional system jets; 5 main jet; 6 spool needle; 7 needle guard.

Sports option

Tuning for sports, due to the technical features of Java, is the most common way of modifying it.

Basic requirements for sports motorcycles:

- Maximum speed.

- Acceleration speed.

- Controllability.

- Safety.

- Convenience.

One of the obvious disadvantages of the Java 350 is considered by many to be too light a front end, which begins to lose traction at high speeds. Therefore, despite the need for a general lightweight design, when installing a sports front fork, it will not be superfluous to place a counterweight. Changes to the chassis also include the installation of disc brakes, alloy wheels and a more wear-resistant chain from IZh motorcycles.

The performance characteristics of the Java 350 are largely relevant to this day, but the modernity of its design is a big question. The simplest option for external tuning for sports is to install parts from the Yamaha FZR400 and Kawasaki KR250 on a motorcycle. The first option is an excellent donor for the front wing, the second - for wheels, front forks and brakes, rear shock absorber and pendulum.

The last part for installation in the Java socket must be narrowed by replacing the standard bearings with needle bearings from the Volga pins. The combination of these innovations makes the motorcycle more maneuverable, stable and controllable. Body kits are made to order, both in workshops and by “home” craftsmen. Do-it-yourself external tuning of Java is also not uncommon. To do this, it is enough to be attentive and careful, and also to have a sufficient amount of plastic or fiberglass with you.

Motorcycle chassis

The frame of this model is universal and made of durable components and materials. This was necessary in order for the motorcycle to work well with maximum load capacity and the installed sidecar. The telescopic fork Java 350 634 is made in such a way as to ensure confident movement not only around the city, but also in difficult terrain. Therefore, hydraulic front shock absorbers and a wheel with steel coil springs were installed.

To ensure good stability of the motorcycle on slippery roads, it was decided to install a wide rear fork support. By the way, the pendulum-type fork holds the rear wheel perfectly, which ensures traction.

Types of BSZ

— Single-channel (one Hall sensor, two-lobe modulator, one switch, one two-terminal ignition coil operating on two cylinders at once)

— Two-channel (two Hall sensors, one, or better yet two, modulator lobe, two switches, two ignition coils, one for each cylinder)

It is preferable to install a single-channel system, since it will be more stable, because here you won’t have to adjust each cylinder (which you have to do at KSZ); here, if the modulator is made correctly, then only one cylinder is adjusted

Also, in a single-channel one, fewer wires are used, its parts take up less space, and energy consumption is lower (which is very important for 6-volt generators). There are many people who like to “get confused” who install a two-channel one, shouting at the same time that this way they can configure it more accurately, etc.

I assure you that these are unnecessary hassles, and there will be no accuracy here (why is indicated above)

There are many people who like to “get confused” who install a two-channel one, shouting at the same time that this way they can configure it more accurately, etc. I assure you that these are unnecessary hassles, and there will be no accuracy here (why is indicated above)

Spark plug. I said above that spark plugs “live” longer, which begs the question “Why?”

Actually the answer is simple. If you decide to install a single-channel BSZ (or a two-channel one with a two-lobe modulator), then this is what will happen:

When igniting in one cylinder, in the other, a spark will also strike at BDC, since it strikes simultaneously on both spark plugs, that is, spark twice per revolution on each spark plug.