Soviet Ural heavy motorcycles are simple and unpretentious equipment. You could even say reliable if you carefully monitor the engine. The boxer engine of this motorcycle has a very primitive design, but it has a very small resource. Therefore, in order to move carefree in the city and even over long distances, the engine should be serviced regularly. Below, we will tell you how to troubleshoot, disassemble and replace the main engine elements for the Ural models M-62, M-63, M-66, M-67, etc.

Reasons for repair

The most popular reason to repair a Ural motorcycle is considered to be insufficient dynamics of the motorcycle, smoke from the muffler, loss of traction at high speeds, and a decrease in maximum speed. Reasons that even inexperienced riders can note include increased fuel and oil consumption. If such problems appear, there is no need to disassemble the engine right away; first you should check the ignition, then the carburetor settings, measure the compression and check the valve adjustment, and after eliminating all other problems, you should get into the engine and repair the Ural motorcycle engine.

You might be interested in how to tune a Ural motorcycle. A detailed description of possible directions for tuning a bike!

More experienced owners may suspect a problem by the sound of the engine. Specific noise reveals a number of problems that are determined with high accuracy.

There are also a number of reasons to repair the engine that are not related to its breakdown. For example, the engine can be rebuilt during a long period of inactivity, during restoration, after a long mileage, and so on.

Motor defective

The process of disassembling the motor is quite complicated, but what is more important is that the existing gaps “go away.” Thus, if you disassemble the motor and then reassemble it without repair, extraneous noise is likely to appear due to the increase in gaps. Therefore, experienced mechanics advise, first of all, to assess the condition of the motor without disassembling the main elements, or to carry out a partial disassembly, then carry out troubleshooting and, based on its results, decide whether to make repairs or not. A malfunction can be determined “by ear” if:

- The engine rings loudly during operation, in all speed ranges, and the ringing partially turns into loud noise when the engine is warm and at high speeds.

Reason: wear of the piston pin and the appearance of an excessively large gap between the pin and the bushing. Solution: first of all, you can set the ignition later, in some cases this either completely eliminates the noise, or it becomes insignificant, which allows you to use the motorcycle for some time. If this does not help, then the old pins are replaced with new ones, as well as the connecting rod bushings with their subsequent development.

- The engine rings, tapping is slightly audible, the sound is dull, increasing under load and at high speeds.

Reason: the appearance of a gap between the pin and the piston boss. Solution: replace the pin + piston set with new ones of the same group.

- The engine knocks metal on metal at idle, and at high speeds there is a strong ringing and vibration.

Reason: clearance between piston and cylinder. Solution: selecting a new piston of the next repair size and boring the cylinder for a new piston group.

- A dull knock in the crankcase area, clearly audible at idle and when releasing gas.

Reason: This sound may indicate an increase in the gap between the lower end of the connecting rod and the crankshaft crank pin.

By the behavior of the motorcycle you can find out about the following problems:

- High oil consumption, loss of power and excessive exhaust smoke.

Cause: worn piston rings. Solution: complete replacement of the piston rings, and if there is damage to the cylinder plane, boring it, with subsequent repairs.

Owners of the Ural motorcycle most often encounter similar problems. As you can see, most problems are diagnosed by craftsmen “by ear”, and despite all the primitiveness, the result turns out to be very accurate. Assuming there is a problem with the motor, you should stock up on a set of necessary pullers, keys and repair parts, and only then begin disassembly.

avtorep.ru

A Ural motorcycle has been in the garage since 1998. The motorcycle is separate, the engine is separate, the gearbox is in a completely different corner. I spent my entire childhood on this motorcycle, after buying a car, they forgot about it. And so I decided to restore it...

First, it was decided to deal with the engine, since, according to the owner, the crankshaft was knocking. Therefore, we immediately began disassembling the engine.

Removing the cylinders

I removed the heads, checked the piston clearances in the cylinders, everything was fine, only the right cylinder had a rusty emulsion - apparently moisture had gotten in. But fortunately the cylinder mirror was not damaged.

I checked the gaps on the fingers - everything is within normal limits. I pressed out the fingers, marked where the right and left parts of the cylinders were and put them aside.

Removing the clutch

Then I started disassembling the clutch to remove the flywheel. A simple screwdriver and hammer blows were not enough to unscrew the screws the first time. There is no point in buying an impact screwdriver just for one use. I turned on my ingenuity. And so he pressed the engine from the frontal side into the opening of the garage door, and pressed the screwdriver to the bolt with the help of a block and a jack, and with a gas wrench tore off the metal beads. And then everything opened without problems. I removed the clutch and started disassembling the frontal part, since I didn’t have a 36mm socket wrench on hand to unscrew the flywheel.

Removing the timing belt

In the frontal part, everything is disassembled simply, the cover is unscrewed, the ignition is removed, the ignition coil is removed, then the windshield is unscrewed. I unscrewed the two bolts that hold the camshaft and placed two mounting brackets under the camshaft gear using rags. And he pulled out the camshaft and gear. Upon inspection, no wear was found in the timing gears. The bearing is also in excellent condition. I secured the pushers with electrical tape to prevent them from falling into the crankcase and getting tangled.

Dismantling the Ural motorcycle engine

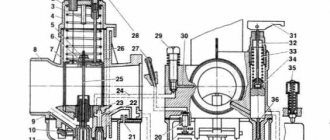

Repair of a Ural motorcycle should be carried out in stages. The first step is to prepare your garage and the engine itself. All dirt and oil must be washed off the engine so that they do not get inside. Laying a film on the floor will help protect the garage floor, because it is easier to throw away a piece of cellophane than to remove the remaining grease from the garage floor. Disassembly process:

- Unscrew the nuts holding the cylinder cover and remove it. Next, unscrew the nuts securing the cylinder head, put the rocker arms and rods into the box and pull the head off the studs.

- Remove the cylinder mounting nuts and, shaking, carefully remove the cylinder from the studs.

- We remove the retaining rings and press out the piston pin with a special puller.

- Unscrew the screws securing the gas distribution mechanism and remove the crankcase cover.

- Unscrew the camshaft flange, remove the plug in the upper part of the crankcase and the oil pump drive.

- Using mounting blades, remove the camshaft.

- We bend the lock washer and then unscrew the screw securing the gear on the crankshaft journal. Using mounting blades, remove the drive gear.

- Unscrew the screws of the upper clutch disc.

- We mark the disks in the position they were in.

- Remove the bolt securing the flywheel to the crankshaft.

- Remove the flywheel from the conical part of the shaft.

- Remove the bolts from the rear main bearing housing.

- We remove the engine sump, and with it the filter and oil pump.

- We press the crankshaft out of the front bearing and remove it from the crankcase.

Following this diagram, you will be able to get to the main parts of the engine in order to conduct a full diagnostic of the gaps and, if necessary, replace the parts with new ones. It is worth noting that if a part has a gap close to wear, then it is better to replace it, since most new spare parts lead to increased load on the entire engine while it is running in. Such increased pressure on old components can lead to their wear, which means the appearance of noise.

We recommend carrying out comprehensive repairs before the start of the season. This approach will allow you to get rid of all problems with mismatched gaps and skate several seasons without worries. Otherwise, the motorcycle engine may break down at the height of the season and make it impossible to move on two wheels for a long time.

Camshaft offset or crankshaft key in wrong place

In general, I’ve been fucking with the motorcycle for the third day after replacing the crankshaft, I only changed the crankshaft, and put the gears in the correct positions. It feels like the camshaft is 5 degrees earlier than normal because... the ignition had to be moved all the way to the late side in order to achieve at least some stable operation, according to the kV mark it is still a couple of degrees earlier than normal. The engine runs strangely, it doesn’t pull at all at low end, it feels like up to 3000-4000 rpm there is a reverse flow of the mixture into the carbs and filter and a strange sound comes out of the filter. At first I thought that the shank had turned again, but there was no runout on the flywheel, the third mark on the flywheel approximately corresponds to TDC, but the ignition does not line up (rechecked everything), has anyone encountered anything like this? Maybe you just need to move the gears 1-2 teeth later?

put your head down and look at what moment the valves open; it is quite possible that the groove for the key is machined in a slightly different place

I used a screwdriver to check the TDC, according to the marks on the flywheel it matches, I adjusted the ignition on the previous crankshaft, it was exactly in the middle, now all the way later and even then it’s not enough. The fact that the problem is in the crankshaft is already clear, either the key is not there or the shank is pressed in with a displacement of 10 degrees along the axis of rotation, the question is whether it is worth simply rearranging the gear by a couple of teeth or whether you need to look for another crankshaft.

I had this problem with my K750 knee.

At TDC, the key on the CV is horizontal and, if you look at the engine from the front, to the right. The camshaft key is to the left and about 10 degrees up.

so it is, the keys are all in place, the knee hits TDC, but there is no ignition, you have to cut off the ears! It's not the runner, it's the camshaft!

Titus, the camshaft must be fine! I adjusted the ignition with the old knee, it was exactly in the middle and worked fine, but now some kind of crap seemed to be placed on the inlet shaft that was too wide, the valve was adjusted, during disassembly I checked for leaks, everything was in order, in general, except for the key on the kv, it was out of place for others no ideas. Who has data on valve lift at TDC at 720 RV?

Well, I don’t know, I wanted to compare it with the 650m, just the knee joint from the K750, but the 650th knee is gone

Have you assembled the advance machine correctly? If you incorrectly installed the plate that is put on the camshaft, something like this could happen. There should be two square holes there. If not, turn the plate over.

Well, my ignition was set almost normally relative to the mark on the flywheel (the marks correspond to the position of the pistons), 1-2 degrees earlier than normal (in principle, almost not significant), the mixture had to be made richer (raised the level) because There were all the signs of over-leaning at full throttle. Due to an unforeseen change in phases, an interesting effect was obtained, yesterday I experimented with the engine all evening, firstly, up to 3000-3500 there is a reverse release of part of the mixture into the carburetor O_O, I removed the hoses from the carbs and watched how the gasoline mist O_O flies out, secondly the torque shelf went into the region high rpm and noticeably narrowed, it feels like a Jeep, it starts to pull at about 4500 and stops at 7000 rpm, at first I was afraid to tumble in after the bulkhead, but in the last few days I put in 200 km and yesterday I tumbled in, I was crazy to say the least, the second is almost 110, but the fourth is pulling only after 120 is normal. In general, I don’t even know if it’s worth replacing the phases; on the one hand, the motor has become completely undriveable in traffic jams, but on the other hand, it spins much more fun and the power has noticeably increased. It’s not me, of course, who is perfectly aware that with such revs I’ll kill this engine even faster, but to hell with it I’ll save money to convert it to 950cc