#RTI_products #replacement_oil seal_scooter #oil seal_wear #reason_for_oil seal_wear #signs_of_wear #replacement_oil seal_crankshaft_scooter

A modern scooter contains various oil seals, differing in seat dimensions, density and shape. Each of them is designed to ensure tight connections between parts that move relative to each other. If such a product fails, trouble may arise. Therefore, let's look at how to change crankshaft seals on a scooter.

Rolling and sliding bearings

Many people have a question - which is more durable: a liner coated with a soft alloy or a hardened metal ball bearing.

Most will answer - of course the bearing. There is always oil pressure in the liners (sliding bearings), which is supplied by an oil pump and the shaft does not work along the sliding plane, it lies on an oil cushion. During operation, it practically does not touch the metal plane.

Pumping effect of bearings

The bearing ball is exposed to more severe conditions. It runs in a gasoline-oil emulsion, barely lubricated. The ball bearing is subject to crazy loads: shocks from load changes, the own inertia of the balls and cage, loads from the connecting rod. The bearing begins to heat up. As it heats up, it intensively evaporates the oil from the treadmill, and this makes it even hotter. At speeds close to the maximum, the ball bearing completely stops lubricating. Centrifugal force throws out the oil film, and the bearing itself goes into the highest stage of load - the pumping effect of the balls themselves is connected to its destruction (in the figure, arrows show the directions of lubricant release). Each ball at 7000 - 7500 rpm begins to work like the blade of a centrifugal pump. At the same time, the balls degrease the treadmill. The bearing begins to “burn”. Only a press fit into the crankcase socket saves the situation a little - the duralumin crankcase takes away some of the heat. During disassembly, characteristic colors are observed on bearings operating at maximum speed - a clear sign of overload in speed.

In addition to the above-mentioned “torsion”, the durability is greatly influenced by the way you ride a two-stroke scooter. A sharp opening of the throttle and jerking the throttle handle transmits sudden acceleration to the support bearings. But the balls, having their own mass, moment of inertia and being burdened with a heavy separator, cannot immediately roll. At the moment of very sharp acceleration of the crankshaft, they slide and poke, rather than roll, which causes mutual wear of both the ball and the track.

The lower connecting rod bearing operates under approximately the same circumstances, although the “pumping effect” is practically not expressed on it.

The figure shows wear on the crankshaft support bearing (radial play). The result is replacement of the bearing and repair or replacement of the crankcase.

Many will exclaim: what about sports engines!? Shock overloads are normal for them! Sportbikes pull, roar, jump and gallop. Of course it is. But they have an exclusively short-term resource - not tens of thousands of kilometers, but hours! In addition, these are not cheap engines with a complex lubrication and power system. In their devices they try to reduce to a minimum the shortcomings of two-stroke engines that you read about above. Expensive sportbikes use different design approaches and different, expensive materials.

Each model of scooter and scooter has instructions, and the instructions contain the average operating speed recommended by the designer. Do not neglect the recommendations, do not pull the throttle! On slopes, descents, intersections - lighten up the gas! Let's give the whole engine a break and let the bearings be well lubricated.

Checking the wear of the lower head of the scooter connecting rod

During any repairs related to replacing the scooter's CPG, it is imperative to check the condition of the crankshaft, especially if play is detected in the upper connecting rod head. To do this, you must first wash the lower connecting rod head using an aerosol carburetor wash. Next, take the connecting rod with your fingers exactly as shown in the figure. You should not squeeze the connecting rod; on the contrary, you should hold it with very little effort. By swinging the connecting rod left and right, we discover horizontal play. This is fine. Next, resting the connecting rod first to the left, then to the right, we select the middle position, when the connecting rod does not exactly touch the cheeks.

Holding it in this position, we carefully make up and down movements at the level of sensitivity of the fingertips. We emphasize once again: you must not make the mistake of mistaking impacts on the side cheeks for vertical play; to do this, swing the connecting rod from right to left until it stops several times in the process in order to make sure that it is in a strictly central position relative to the crankshaft cheeks. The criterion for wear is not the amount of play, if we were able to detect one, but the very fact of its presence. A crankshaft with worn connecting rod heads will experience shock loads when the piston moves up and down, and wear will progress exponentially. If there is vertical play, the crankshaft definitely needs to be replaced. Also, most likely, the oil seals and main bearings of the scooter will need to be replaced. This is especially true if the cause of premature piston wear was driving without an air filter or with an unimpregnated filter, which is the same for a scooter.

Installation of a new product

After inspecting and preparing the working area of the scooter, you can install a new oil seal

Please make sure that it is installed with the correct side in the end, otherwise the functionality of the product will be impaired. Often the concave part faces the mechanism

To ensure ease of installation, the outer edge of the product should be lubricated. A small amount of lubricant is enough. When installing the ring on the seat, do not use a screwdriver or other sharp tools, otherwise the risk of damage to the working surfaces increases.

The product must be sunk, maintaining alignment. To ensure a good seal, a special mandrel should be used. This may be a tube or head of the appropriate size. The diameter should be smaller than the mounting socket. If you select the wrong size, the part may be damaged.

After pressing the ring, you need to check for distortions and lubricate the product. Next, the moving part is installed.

The renovation is complete. All that remains is a test ride on the scooter.

Don't forget to give a thumbs up

and subscribe to our channel to receive more useful information every day.

Source

Symptoms of a problem

Although the input shaft support bearing is an inexpensive part, replacing it is a labor-intensive process. And this is connected not so much with the difficulty of dismantling the rolling unit itself, but with the need to remove other parts and assemblies of the engine. To avoid wasting hard work, bearing failure must be correctly diagnosed. Signs indicating this type of malfunction:

- Noise coming from a running engine when the clutch is depressed. A similar rustling or rustling noise also appears when the release bearing fails. And if the noise from the latter is detected even with slight pressure on the petals of the spring diaphragm of the clutch basket, then the gearbox support bearing will make extraneous sounds only when the clutch is completely disengaged.

- Wear or jamming of the bearing due to lack of lubrication leads to the fact that the input shaft of the gearbox is subject to the action of torque even while the driven disk is completely removed from the flywheel. In fact, this manifests itself with the same symptoms as with a clutch that “drives” - it is difficult to engage first gear when starting from a stop, jerks appear when changing gears while moving, etc.

- An irregular knock that appears from the gearbox indicates destruction of the bearing cage. In this case, the balls can spill out or clump together, causing an unpleasant sound and causing an imbalance in the crank and gearbox input shaft.

The latter happens rarely and indicates that the driver did not pay attention to noise and other signs of malfunction for a long time.

Scooter crankshaft: how to check its serviceability yourself

The crankshaft on a scooter bears an increased load, and its role in engine operation is difficult to overestimate. Any malfunction in the crankshaft can completely disable the engine, so this motorcycle part must be given increased attention every time maintenance work and repairs are carried out on the scooter.

Next, only the main crankshaft faults will be discussed, as well as ways to eliminate them. No attention will be paid to the main bearings.

You need to start diagnosing from the upper head of the connecting rod mechanism. Take carburetor washing liquid or regular gasoline and clean its entire surface from carbon deposits and oil particles formed from previous work. Then the needle bearing is mounted in place and the piston pin is inserted. To determine its correct position, it is necessary to do this in exactly the same way as when installing a finger in the piston.

Place your finger in the center and the check can begin. To check all existing play, both horizontal and vertical, you need to move your finger in different directions diagonally, as well as up and down. When moving your finger to the side, you must remember that there may be a slight horizontal play.

The most common is vertical play, which greatly distorts the performance of the crankshaft. To eliminate vertical play, the finger should be moved up and down. If there is play between the upper head of the connecting rod mechanism and the needle bearing, this means that the connecting rod head is worn out and requires replacement. To draw final conclusions (sometimes used motorcycle parts are used), you should replace the piston pin and separator with new ones, and carry out all the manipulations again. If it turns out that there is no longer any play, then the previous motorcycle parts require replacement, and it is unsafe to ride with them. But it may also happen that the play remains even after replacing the motor parts with new ones. Then it is advisable to replace the entire crankshaft or connecting rod.

These are basic recommendations and may not give cause for concern. Then you should move on to the lower head of the connecting rod mechanism. But sometimes it happens that there is mutual wear, so you should always (regardless of the results of the first diagnosis) pay attention to the following points.

The lower head of the connecting rod mechanism must also be cleaned of foreign contaminants and carbon deposits with gasoline or carburetor cleaning fluid. Then you should pull out the piston pin and separator. The part of the connecting rod that remains loose must be held with your hands, and at the same time, the existing horizontal play must be determined. The connecting rod should move strictly to the right and left, and at the same time a slight play should remain. This is the norm. But when determining the vertical play, it is necessary to remember that there should be no deviations here. It is not for nothing that vertical play is considered the most dangerous: its determination must be made with the highest possible quality.

The connecting rod is positioned strictly in the central part, and at the same time it should not even touch the crankshaft cheeks of the scooter. And then it gently moves up and down. Even a slight play should alert you, not to mention noticeable wobble.

Sometimes the driver hears the sound of a connecting rod hitting the crankshaft and thinks that it is play. But in fact, even with absolutely correct operation of the mechanism, sharp noises can be heard. But it is advisable to carry out the manipulation to determine the vertical play not just once, but several times, in order to completely eliminate the possibility of error.

In addition to these two checks, which are considered basic and are performed during any diagnosis, there is another one that allows you to judge the wear of the scooter’s crankshaft. They call it “scooter crankshaft runout,” but to put it simply, it will be curvature.

The presence of this breakdown will be indicated by strong vibration of both the scooter as a whole and its shaft. It is impossible to check runout in “garage” conditions, because this requires a set of special tools and a special stand. The maximum permissible deviation should not exceed 0.05 mm. If this is not the case, then the shaft must either be aligned or replaced with a new one. But this should be decided by specialists.

Replacing the crankshaft oil seal on a scooter

Replacing the oil seal on the variator side.

Often the crankshaft oil seal leaks from the variator side. To replace it, remove the variator cover, unscrew the mounting bolt, and remove the variator. On some models, the oil seal is covered with an additional metal cover, which is secured with three bolts.

- To remove the oil seal, you will need a rigid but thin wire, from which you should make something like a hook.

- Then push the wrapped side of the wire through sideways and turn it inside.

- Pull towards yourself with a sharp movement. He may not give in right away, then try making two hooks and pulling them alternately.

After removal, wipe the seat dry and install a new oil seal. Follow the markings and check the size with a caliper before installation.

Replacing the oil seal on the generator side.

To replace the oil seal on the generator side, you will need a special generator rotor puller. I don’t recommend trying to remove the generator without it. There have been cases of winding damage and generator failure.

You can also read other articles on the topic:

Source

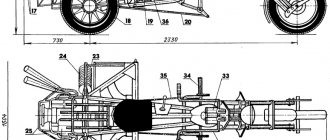

Photo report: Replacing scooter crankshaft bearings

Typically, scooter crankshaft main bearings last as long as the big end bearing, if not longer. But there are situations when, after disassembling and carefully checking all engine parts, it turns out that the crankshaft is still suitable for further use, but its main bearings are not.

And there's nothing you can do about it. Either change the crankshaft to a new one, or get rid of it and change only the bearings, which, by the way, cost pennies, and a new crankshaft is very, very expensive - this is the first important point.

The second important point is that when choosing a repair or diagnostic method, you need to proceed from the available tools, and I have a welding machine and a bunch of various pullers and devices. Therefore, the option of engine repair with replacement of only the main bearings seems preferable to me. If you don’t have tools, replace the crankshaft with a new one and don’t worry (advice).

The oil pump drive sprockets and timing chains, which interfere with the removal of the main bearings, can be removed with a regular automotive three- or two-legged puller. I use a three-legged one because I kind of have it and it’s more convenient to work with.

If I didn't have one, I would remove all the sprockets and bearings using just one puller. And since I have a lot of pullers, I use whatever is more convenient for me.

The oil pump drive gear does not sit on the trunnion with its entire internal surface, but only with a small part in the form of a groove. It can be removed from the shaft very easily, literally with little effort.

The crankshaft journal is thickened where the sprockets fit.

The timing chain drive sprocket cannot be picked up with a simple puller, which I used to pull off the oil pump drive gear. Since it is placed close to the bearing and the puller’s paws rest against the bearing with their hooks and do not allow the sprocket to catch.

To remove the timing chain drive sprocket, it is best to use a regular two-legged automotive puller with a fixing bracket.

The timing chain drive sprocket sits on the axle with its entire inner surface and can be easily removed.

The stars have been removed and nothing stands in the way of further work. The hardest part remains - removing the bearings. The main difficulty is that the bearings sit close to the crankshaft cheek and there is no way to pry them off.

Replacing scooter crankshaft bearings

The crankshaft plays a huge role in the design of the scooter, ensuring the interconnection and operation of several main components and systems at once - the cylinder-piston group, the generator, the gas distribution mechanism and the clutch. In turn, the rotation of the mechanism is ensured by the crankshaft bearings located on its axle shafts.

The internal parts of the system are closed with special seals, which provide reliable protection against the ingress of debris, dirt and dust particles. However, during operation of the scooter, the friction force negatively affects the condition of the balls and bearing race. Over time, the seals also wear out, losing their strength and tightness. All this ultimately leads to the need to replace the crankshaft bearings and oil seals with new ones, in order to avoid wear of more expensive parts of the scooter systems.

External signs of crankshaft problems and engine disassembly

The main reasons for disassembling the engine and crankshaft of a scooter are:

- oil leakage;

- engine vibration during operation;

- loss of power.

To more accurately determine the breakdown and replace worn parts, you must first disassemble the engine. Unfortunately, you can only determine whether the bearings need to be replaced after removing the crankshaft from the scooter.

It is quite possible to disassemble and replace crankshaft bearings in a garage. To do this, you need to stock up on special pullers, a workbench, a hair dryer and a classic set of tools for auto repair.

To disassemble and remove the engine and crankshaft, you must:

- place the scooter on the center stand;

- unscrew and remove the elements of the plastic body kit that blocks access to the necessary components;

- unscrew the spark plug;

- drain the oil from the system;

- disassemble and dismantle the cylinder system;

- remove the impeller;

- unscrew and remove the generator parts;

- remove the starter, carburetor and oil pump;

- Unscrew the bolts holding the engine block;

- wrap the connecting rod with a rag to avoid damage;

- use a puller to separate the block halves;

- Carefully remove the crankshaft.

After this, you can begin the procedure of inspecting the bearings, identifying their damage and wear and, if necessary, removing them and replacing them with new ones. To do this, remove residual oil, dirt and foreign impurities from the surface of the axle shafts. A clean bearing surface will easily show signs of wear, deformation or abrasion. The bearings can be removed from the shaft axle shafts using a special puller, and the oil seals are carefully knocked out using a nozzle of suitable diameter.

Replacing scooter crankshaft bearings and oil seals

To install new bearings, you need to have a vice and a heat gun, as well as instructions for assembling the motor. If you strictly follow all the rules, the result of the repair will be satisfactory; if you break it (even in small things), the scooter will have to be sent to a service center. The bearing replacement procedure consists of:

- reliable fixation of the crankshaft in a vice with the axle shaft up;

- heating the inner race of the bearing to 100 degrees;

- its quick installation on the axle shaft seat;

- driving the bearing until it stops on the axle shaft using a pipe of suitable diameter.

The bearing of the other axle shaft is replaced in the same way. When carrying out such work, you must strictly observe the rules of behavior with fire, as well as the rules of personal safety.

When removing the oil seals, it is necessary to note and record the depth of their seating in order to install new ones in the same place. In addition, the oil seals of many scooter models differ in size, which should be taken into account when purchasing a repair kit. The oil seals are installed in a clean and dry cage using a nozzle of a suitable diameter.

After this, the system should be assembled. To do this you need:

- lubricate the crankshaft axle shafts with oil to avoid damage to the seals during installation;

- heat the bearing seat in the block to 100 degrees;

- install the crankshaft, making sure that the connecting rod does not touch the block;

- very carefully treat the junction of the block halves with sealant;

- warm up the seat of the other half and connect the block;

- Compress the block halves with bolts so that distortions do not form.

Next, install the scooter systems in the reverse order.

And in conclusion, a few general rules for carrying out repair work:

- the room, table, mechanisms, rags and tools must be perfectly clean;

- drain the oil into a prepared container;

- all parts removed from the scooter must be thoroughly washed and dried;

- during assembly, all parts must be dry, and threaded connections must be treated with compressed air;

- A layer of protective lubricant should be applied to the rubbing parts.

Successful repairs to everyone!

Main reasons for replacement

Each engine is equipped with a crankshaft. It moves the piston and also helps move the rear wheel. The crankshaft consists of two disks, the connection of which is ensured by a connecting rod journal. The role of the disks is similar to the tasks of flywheels: to provide uniform movement of this part in the required direction. In the center of the disks there are axle shafts with bearings. These bearings allow the crankshaft to rotate. Due to the ends of the shaft, rotational motion is transmitted directly to the scooter transmission and generator. And so, we list the main reasons for removing and replacing the crankshaft:

- Tuning. Speed lovers who want to get the most out of a scooter install tuning crankshafts.

- Removing the crankshaft is necessary to replace the scooter's crankshaft oil seals. Also, bearings rotating the shaft are often replaced;

- Engine noise, vibration, loss of dynamism.

If you have a garage and the necessary set of tools, then removing the crankshaft will not be a problem for you. First of all, you should have special pullers as tools. To remove the crankshaft, first remove the engine itself: disconnect all fasteners, hoses and wires, as well as the CPG.

Features of product operation

The oil seal prevents oil from leaking out of the mechanism, as well as water, dirt and dust from entering it. Most often it takes the form of a ring with an inner lip (A) and an outer shell (B), inside which there is often a steel frame (C). It affects the durability, rigidity and durability of the entire mechanism.

The lower the quality of the materials used to make the rings, the shorter their service life. Because of this, in many Chinese scooter models it is necessary to change the factory seals quite often.

However, not only the material has an impact on the service life. Great importance is attached to correct installation. If errors were made during installation, this can significantly affect the life of the product. There are cases where incorrect installation led to failure of the ring after 100 km.

16.43. Scooter repair. Oil seals - replacement

16.43. Scooter repair. Oil seals - replacement

Lip seals, or oil seals, are used to seal moving joints of mechanisms, to prevent oil from leaking out of the mechanism and from getting water, dirt and dust into it.

The difference between an oil seal and a simple gasket is that it allows the mating parts to move relative to each other in the longitudinal or radial directions, while maintaining the tightness of the connection.

The oil seal is a shaped ring made of oil-resistant rubber with a steel frame poured inside. The working edge of the oil seal is pressed against the shaft or rod by a bracelet spring.

The key to high-quality work and long service life of the oil seal is the quality of workmanship and correct installation. If we cannot influence the first factor, then the second is completely within our power. An incorrectly installed oil seal will leak within a few tens or hundreds of kilometers, and replacing it is usually a complex and time-consuming procedure that requires disassembling the entire assembly, be it the front fork, engine or gearbox, so correct installation of the oil seal is a way to save a lot of time and strength.

In this chapter we will look at general techniques for replacing oil seals.

1. The oil seal is a one-time installation part. If the oil seal is removed from its socket, then it cannot be reinstalled on the unit, since it is almost impossible to remove the oil seal without damaging it.

2. When replacing the oil seal, it is advisable that the rod or shaft (any moving part working in the oil seal) be first removed from it. If it is a front fork, you need to disassemble it; if it is a gearbox shaft, you need to disassemble the gearbox and remove the shaft on which the oil seal will be replaced from the crankcase.

If it is not possible to remove the part, or the repair is carried out in the “field” conditions, it is necessary to work extremely carefully near the mirror of the moving part. Any, even the most insignificant scratch is, in fact, a groove through which oil will flow out. The oil seal provides a high-quality seal only if the “mirror” of the working surface of the moving part is absolutely smooth. Be extremely careful, especially when dismantling the old oil seal.

3. You can remove oil seals from their sockets in different ways. Since the old oil seal always goes in the trash, there is no point in trying to save it. The oil seal can be pryed out with a screwdriver or a wire hook, or knocked out using a drift and hammer, if it is possible to get to it from the back side. The main thing is not to damage the plane of the oil seal seat, otherwise oil (or other liquid that the oil seal is designed to stop) will seep into the formed cavities and flow out. Such damage is very difficult to repair.

Replacing oil seals: nuances

Before removing unusable oil seals from the crankcase, mark for yourself the depth of the oil seals. New oil seals are installed in place of the old seals. Most motors require the installation of oil seals of different diameters on each side. They are inserted into a cleaned race with a pipe of a suitable diameter. That is, before purchasing new ones, you need to find the appropriate size oil seals.

Always consider the time-tested “moments”:

- In most cases, when the bearings fit into the races without much effort, the crankshaft will fail back.

- It is normal for the bearing to be difficult to install. It’s hard to imagine this installation without a hair dryer.

- When using a hair dryer, you should carefully protect the seal from heat exposure. Otherwise, it may melt and become deformed.

- The two halves of the motor are lubricated with sealant.

- The arrangement of blocks between each other should be parallel to each other.

- The crankshaft axles are thoroughly lubricated with oil to protect the seals from damage.

Before you start “splitting” the main power unit, you need to clean it of dirt and wash it thoroughly. The oil must also be drained. You need to unscrew all bolted connections with a high-quality tool so as not to lick off the bolt heads. The engine halves are washed with gasoline or kerosene. Before assembly, the engine must also be washed and always dry. Using a compressor, remove debris from all hard-to-reach places.

When repairing an engine, always follow the disassembly instructions. As a last resort, use the advice of experienced comrades. Best wishes!

https://www.youtube.com/watch?v=fLxkHznVTGc

Dismantling the old product

Installation of the O-ring must begin by dismantling the old

Attention! Remember the position of the product - this will be useful when installing a new one. You can carry out the work in the garage, even with a small set of tools.

The old oil seal is removed forever, so it is only important not to damage the seat and nearby parts. To do this, it is often necessary to remove the working part, bearings and other components.

If dismantling the cylinder itself is impossible, you will have to work “as is”. In this case, you need to be especially vigilant, as the risk of damage to the device increases significantly. This can lead to water, dirt and other undesirable components entering the workspace. Consequently, the unit will be subject to accelerated wear, and neither lubricant nor a high-quality oil seal will save the situation.

How to change the oil seal on a scooter

Problems with a scooter most often occur during operation, and one of the breakdowns may be a worn oil seal. Let's look at the process of replacing the oil seal on a scooter and the purpose of the oil seals.

Oil seals on a scooter play a very important role, because they prevent oil or gasoline from leaking into unnecessary places. In the design of any scooter there are many oil seals of different sizes, but they all perform one role - to maintain the tightness of the connections. Also, in addition to the fact that the seals do not allow scooter fluids to pass through, it is impossible for dust and dirt to pass through them, so you should always have the seals in excellent condition. But sometimes the seals can fail, that is, wear out. Replacing seals on a scooter is a fairly simple process; you just need to notice the leak and determine the location of the seal.

Installation

Everything would be fine, but the crankshaft has a collapsible design and also does not have a central axis. And if you stuff a new bearing without placing some kind of base under the axle cheek, then there is a high probability that the alignment of the crankshaft axes will be disrupted and then its place will only be in the trash.

Therefore, we are looking for a piece of some kind of iron sheet and cutting out a wedge in it for the connecting rod.

We pass the sheet between the cheeks and, using a mandrel, without fear of disturbing the centering of the axes, we stuff a new bearing, then we stuff the sprocket there. To make the installation process easier, the crankshaft can be frozen in the freezer, and the sprockets and bearings can be heated with a hairdryer or in the oven (no more than 250 degrees!!!) and then everything will fit literally by hand and there will be no need to stuff anything.

Replacing the crankshaft on a scooter

Any equipment fails. If we talk about scooters, problems can arise in various components and assemblies. In this article I would like to cover the topic of engine repair, or rather crankshaft replacement. This detail changes extremely rarely. If you replace the crankshaft properly, you won’t have to return to this issue for a long time. For example, replacing a piston can be done every two seasons. Looking ahead, we will immediately answer the question “how much does a crankshaft cost for a scooter?” On average, the price for this Taiwanese-made part fluctuates around 2000-2700 rubles. The exact price depends on the scooter model.

Bearing Failure Determination

Some recommendations will help you make sure that you need to replace the wheel bearing on your VAZ 2107: The easiest way to find out whether you need to replace the wheel bearing is to grab the front wheel and shake it in different planes

If you feel the presence of play, then it’s time for a more detailed diagnosis and most likely replacing the bearings

The front wheels of the car should be hung on a jack, while being sure to take precautions: pull the handbrake, install shoes and additional stands under the car

Grasp the top and bottom of the front wheel with your hands and then make movements. It is important to wobble the wheel, not the car as a whole.

Thus, you can accurately determine whether the product in question needs to be replaced. Another way to determine the need for replacement is to listen for humming, knocking, and grinding noises in the wheel as it rotates.

Having decided that you really need to replace the VAZ 2107 wheel bearing, you need to purchase new products and begin the replacement workflow.

Replacement features

The front hub of the VAZ 2107 car has a pair of roller bearings, one of which is called internal, and the second external. The manufacturer recommends replacing these products in pairs, on both front wheels of the car. We will find out further what the replacement of the parts in question is.

Initially, it is necessary to tear off the nuts securing the front wheel of the VAZ 2107 car. After this, install the jack and jack up the front part of the car. At the same time, do not forget to install shoes under the wheels, as well as a special safety stop to prevent the jack from falling.

- Removing the caliper. Changing the front wheel bearing is much more difficult than replacing the rear one, but it can be done even with no experience. First of all, the 2 bolts that secure the caliper are uncoiled, after which they are unscrewed. It is not necessary to disconnect the brake hose; it is enough to tie up the removed caliper so that it does not interfere with further work.

- Removing the outer product. The cap is removed using a screwdriver, behind which there is a hub nut. The nut must be unscrewed, for which you will need to use a chisel and a hammer. Behind the nut there is a lock washer that must be removed. Now you can pull out the outer bearing.

- Removing the hub. To remove the hub, you need to pull it towards you. It is removed along with the brake disc. To disconnect the disk itself after removal, unscrew the two “12” bolts. The brake disc is removed to make replacement easier, but it is not necessary to disconnect it.

- Removing the inner bearing. Using a screwdriver, you need to pry off the oil seal located on the inside and covering the inner bearing, then pick it out and pull out the split spacer ring. The ring may not stand, so we focus on the situation. After this, the inner bearing can be removed.

- Next, the old clips are removed using a special puller or an ordinary steel tube of suitable diameter. The next stage of replacement involves cleaning the inside of the hub from old grease, after which you can begin assembly.

Checking the wear of the upper head of the scooter connecting rod

Insert the needle bearing and piston pin into the upper connecting rod head, cleaned of grease with carburetor flushing agent. Gently grasping the protruding ends of the finger with your hands, we try to determine the presence of vertical play. There will be some horizontal play, this is normal. If there is significant vertical play, if a used needle bearing or pin is used, we try to repeat the test with new parts. If the play persists, then the scooter’s crankshaft definitely needs to be replaced. If, when checking with a new pin and bearing, there is no play, then the above parts must be replaced - their wear is more than permissible.

Crankshaft main bearing - design

One of the main parts of the crankshaft, no matter how strange it may sound, is the bearing. It represents an assembly unit, and, accordingly, is the main part of the support. It also performs one of the main functions such as rotation. The bearings take on the entire load and transmit it further along the moving crankshaft assembly. They come in different types, it all depends on the specific use of the bearing. We are currently analyzing the car version, so they come in two types – rolling and sliding.

As a rule, the automobile version has the form of a ring, along the entire perimeter of which there are gutters, or, as they are popularly called, raceways. It is along them that the body rolls during operation. If we analyze the principle of operation of a sliding bearing, then friction occurs in it during sliding of surfaces. Externally, it looks like a smooth body with a cylindrical hole.

Important Features

Usually it is not possible to simply install the crankshaft back into the block; to do this you need

know a few tricks. Bearings must be installed with great difficulty, and to simplify the work, the landing site is heated with a hair dryer. Thermal expansion will help complete the job much faster. When the crankshaft is placed in the first part of the block, the joint is pre-treated with sealant. In the same way, the place of the second bearing is heated, after which the halves of the block are connected. Both parts should be aligned exactly, without deviations or unnecessary distortions.

Any repair involving engine disassembly is comparable to surgery, so all work is carried out extremely carefully. Before work, the engine is washed and the oil is drained. All repair operations must be carried out exclusively on a clean workbench. It is better to disassemble a scooter yourself for the first time under the guidance of a more experienced technician, this will allow you to avoid unpleasant mistakes.

Read also

16.2. Scooter repair. Spark plug - replacement

16.2. Scooter repair. Spark plug - replacement SERVICE INTERVIEWS It is recommended to replace the spark plug after every 8-10 thousand kilometers. REMOVAL 1. Using a hex wrench, unscrew the bolt of the battery compartment cover located under the seat.

16.5. Scooter repair. Engine oil - replacement

16.5. Scooter repair. Engine oil - replacement Before changing the oil in a four-stroke engine, you must first warm up the engine for 5-7 minutes and place the scooter on the center stand. If the engine has a replaceable oil filter, it is also

Replacing the crankshaft oil seal

The scooter's crankshaft also has an oil seal; it is responsible for preventing gasoline from leaking. Therefore, as soon as you notice that gasoline is leaking through this hole, even in a small amount, urgently replace the scooter oil seal. But in order to install a new oil seal, you must first remove the old one, and since it is always tightly secured, removing it can be problematic. Some scooter models have additional oil seal protection, which is a protective metal cover. An old, worn oil seal can be neglected and can be pulled out by force. The easiest way is to take a sharp object and remove the oil seal without damaging other parts. Another way would be to remove the oil seal using a hook-shaped wire. Bend one side into a hook, insert it into the seal and pull it out.

Once you have removed the old part, you need to clear the area to install the new oil seal. The new oil seal should ideally match the dimensions of the old one, but in principle, a different size is unlikely to fit. Find the markings on the old oil seal and compare it with the new part. Insert it tightly and, if necessary, hammer in the oil seal, then check its operation in action. Once you have driven at least 10 km, check the condition of the oil seal. It is also advisable to buy oil seals as expensive as possible, because Chinese parts, according to statistics, break many times faster. The original oil seal has a price of 5-7 dollars, Taiwanese parts are slightly cheaper, the price is about 2 dollars, while a complete set of Chinese-made oil seals can be bought for 2 $. But still, not everyone can afford such an expensive purchase and buys risky, cheap parts. The choice is yours.

Source

Identifying the problem

The car has two types of oil seals:

In order to determine which one to replace, you need to understand which one has started to leak. The front seal fails much more often than the rear one. This can be determined by a breakdown of the working fluid. For example, you notice that a certain substance is dripping from under the crankshaft. This is not antifreeze, since it has a certain color, and it is extremely difficult to confuse it with oil. It is also not windshield washer fluid. It is either colorless or bluish and quite liquid. To diagnose, you need to drop a little liquid into a container of cold water:

- transmission oil will immediately spread over the surface;

- motor is more viscous and will remain on the surface for a long time as one drop.

There are several reasons why the problem occurs. Firstly, wear of the seal. All details have their own resource. In the case of the front oil seal, this is 100–200 thousand km. The inside of the engine front seal is subject to strong shaft vibrations when driven. Therefore, the spare part ceases to perform its functions and a leak occurs.

Secondly, if the car has been parked for a long period in an open area in severe frosts, the soft part of the oil seal hardens and it no longer seals tightly against the crankshaft. As a result, the product is easily damaged by stress.