- home

- Engine

27.08.2020

Minsk is a family of motorcycles of Soviet and Belarusian production. Also includes scooters, ATVs and snowmobiles. The first MMVZ model was presented in 1951. In 2007, the brand of the same name was renamed M1NSK. During the years of the USSR, products were available not only within, but also outside the Union. The brand took an active part in motorsports, especially in cross-country and circuit competitions. Thus, the first cross-country model “M-201K” debuted in 1956, and along with it the M-201M enduro class model was introduced. In 1961, production of the first road-ring motorcycle ShK-125 with a 23-horsepower engine began. In 1971, the company introduced its first racing circuit bike, the M-211, with a developed fairing. Its successors are considered to be the MMVZ-3 216 (1977) and MMVZ-3.227 (1986) models.

Basic model design[edit | edit code]

The MMVZ-3.112 motorcycle model is a further development of the previous Minsk model MMVZ-3.115. The main differences are a new, more comfortable, wide and long saddle (it hinges to the right along the way and can be removed from the frame), brake drums of both wheels increased to 150 mm in diameter, the use of damping elements in the driven sprocket assembly, and the installation of a pendulum fork on silent blocks, the presence of a new yoke on the frame, making it easier to place the motorcycle on the center stand. The rear brake support plate transmits reaction force to the frame not through stops, but through a reaction rod attached to the pendulum. The brake pedal is mounted on a separate bracket rather than on the footrest tube. The diameter of the wheel hubs and the spokes themselves have also been increased. The spokes became shorter, which overall made the wheel more rigid. The comfort of the motorcycle has been slightly improved.

Engine[edit | edit code]

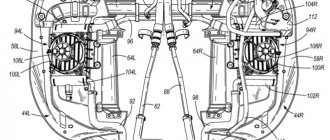

The engine is single-cylinder, air-cooled and dual-channel return blown. Aluminum alloy cylinder head. The cast iron cylinder liner is pressed into aluminum fins. Advanced finning of the cylinder and head ensures effective cooling in difficult road and weather conditions. The engine runs on a mixture of low-octane gasoline A-76 with almost any type of motor oil. The engine on the MMVZ-3.112 model produced in 1982 developed a power of 12 hp. at 6,300 rpm, in 1986 a new modification appeared - MMVZ-3.112.11 with a derated engine so that the motorcycle could be used not only on highways.

Transmission[edit | edit code]

The gearbox is four-speed. The gear shift mechanism is foot-operated. Multi-disc clutch in oil bath. The drive to the rear wheel is by chain, with the main drive protected by stamped casings and rubber chain covers.

Chassis[edit | edit code]

The frame is tubular, closed type. Telescopic front fork with hydraulic shock absorbers, pendulum type rear suspension with hydraulic shock absorbers.

Electrical equipment[edit | edit code]

Electronic contactless ignition system. The headlight and tail light of the MMVZ-3.112 model are identical to those used on the previous model, the electrical equipment of the MMVZ-3.112 is 6-volt (G427 generator, B-300B ignition coil). In 1984, model 3.112.1 began to be equipped with 12-volt electrical equipment (generator 43.3701, coil 2102.3705, lighting devices that meet the requirements of European standards), which distinguishes them favorably from the MMVZ-3.112 model. In 1995, the plant announced a new 14-volt flywheel-type alternating current generator with a power of 90 watts.

Product description:

MOTUL 5100 4T 10W-40

High-tech motor oil for motorcycles equipped with 4-stroke engines. Technosynthese® Ester Technology.

Application

Road and off-road motorcycles, enduro, trial, equipped with 4-stroke engines with integrated and non-integrated gearbox, as well as wet or dry clutch. Designed for engines that meet the requirements of EURO 2 and EURO 3 standards, equipped with an exhaust gas purification system: catalytic converters, air supply to the exhaust tract... Used for specific SUZUKI, YAMAHA, KAWASAKI engines that require oil with a viscosity grade of SAE 10W-40. Other applications: motorcycles without catalytic converters, scooters, all-terrain vehicles, mopeds.

Characteristics

Standards: API SM / SL / SJ / SH / SG Specifications: JASO MA2 under N° M033MOT112

Protection

Technosynthese® oil is enhanced with an ester base to provide guaranteed anti-wear properties and ensure gearbox durability. Improved oil film resistance at high temperatures. Optimum phosphorus and sulfur content (less than 1200 ppm in accordance with the JASO MA2 standard) ensures the correct functioning of exhaust gas aftertreatment systems. Superior gearbox protection is provided by an innovative anti-wear additive package. Ultimate load to failure FLS14 according to the test of the FZG - Research Center for Gears and Gears (Forschungsstelle für Zahnrader und Getriebebau). The test determines the lubricity and anti-wear properties by loading gears.

Comfort

The JASO (Japan Automotive Standards Organization) classification offers a specific standard for motorcycles with a 4-stroke engine - JASO T 903, divided into three categories MA, MA1 and MA2. JASO MA2 has a high coefficient of friction, which ensures precise clutch operation when starting, accelerating and driving at a constant speed.

Recommendations for use

Replacement is carried out in accordance with the engine manufacturer's recommendations and can be adjusted depending on operating conditions. Can be mixed with mineral and synthetic oils.

Read also: Repair of cracks and chips in car windshields

Why should you mix gasoline and oil?

Not everyone knows how to dilute gasoline for a two-stroke Chinese scooter, and why there is a need to mix gasoline and oil in strictly defined proportions. The fact is that the design features and operating principle of a two-stroke engine do not allow the use of pure gasoline for its operation. Thanks to the oil introduced into the fuel mixture, lubrication is provided and friction in the crank mechanism is reduced.

Mixing oil with gasoline when preparing the fuel mixture is a prerequisite for the normal operation of two-stroke engines.

Diluting gasoline with oil allows you to:

- increase the service life of the power plant;

- ensure effective lubrication of rubbing parts;

- avoid jamming of engine parts due to overheating;

- prevent possible damage during engine operation.

In addition, the use of gasoline mixed with oil in the required percentage allows you to avoid the occurrence of scuffing, which is the reason for repairs. A lack of oil can cause overheating of the elements of the cylinder-piston group and failure of the two-stroke engine.

An increased oil concentration will cause increased wear on the engine due to the formation of a thick layer of carbon deposits. That is why it is important to determine the proportion using the table, which indicates the required amount of oil for different volumes of gasoline.

The reason for the formation of carbon deposits in the working chamber is the use of low-quality oil.

IS IT POSSIBLE TO OPERATE THE MMVZ MOTORCYCLE ON AI-93 PETROL?

The answer is yes - you can. To do this, you should slightly increase the compression ratio and use a different spark plug. If you trim the cylinder head by 0.5...0.7 mm, you will get what you need. The compression ratio will increase to 11.5... 11.8. The candle should be used A23B. With such a simple reconstruction, the maximum engine power will increase by approximately 5%, and fuel consumption will become approximately 10% less.

The power system includes a carburetor, an air cleaner, exhaust devices, a gas tank, a tap and a gas line.

Carburetor. Motorcycle carburetors operate on the principle of atomizing fuel in a stream of air, which is sucked through the carburetor into the engine cylinder.

The operation schemes of all carburetors used on motorcycles are identical, but their designs differ significantly from each other.

Let's look at some typical carburetor designs.

The K-36S carburetor with a flat throttle valve and a side-mounted float chamber (Fig. 2.23) is installed on motorcycles M-105, MMVZ-3.111, MMVZ-3.115, produced before 1978.

Rice. 2.23. Carburetor K-36S.

It consists of a float chamber 1 with a cover 4 and a mixing chamber 18 with a cover 7, between which sealing gaskets are installed. The main jet 12 is screwed into the housing, and the idle jet 22 is pressed into place. Throttle valve 17 is made of brass sheet, bent in the shape of the letter “P”. It has a cutout on the air filter side. This cutout ensures a smooth narrowing of the air flow as it enters the cylinder. The quantity adjusting screw 10 serves to limit the lower position of the damper, and the boss 8 on the carburetor cover limits the rise of the damper during the break-in period. After running in it is removed. Plugs 14 are used to drain the sludge, and plug 13 is used to install the jet. Float 2 ensures a constant fuel level, and quencher 5 serves to enrich the mixture by forcibly increasing the fuel level in the float chamber.

The carburetor works as follows. From the gas line, fuel flows through fitting 6 into float chamber 1. When the chamber is filled, float 2 floats up and, using the shut-off needle 3, closes the hole in the fitting, as a result of which further fuel supply is stopped. When the fuel level drops, the float lowers and allows fuel to flow. Thus, the float maintains a constant specified level of fuel in the float chamber, which is necessary for normal operation of the carburetor. From the float chamber, fuel flows through the main jet 12 to the atomizer 11 and the idle jet 22. When the throttle valve 17 is lowered down, when the engine is running, a strong vacuum is created behind it, as a result of which air is sucked in at high speed through channel 15 located on carburetor inlet before the throttle valve. Passing over the idle jet 22, the air captures fuel, creating a vacuum above the jet, mixing with it, after which the working mixture enters the cylinder through the idle hole 20. Adjusting screw 21 can be used to increase or decrease the amount of mixture entering the cylinder.

When the damper is slightly raised, additional fuel begins to flow through hole 19, since a vacuum is also created above it by the air flow in the diffuser 16. At the same time, an increased amount of fuel is supplied to the cylinder, as a result of which the transition of engine operation from one mode to another is facilitated.

As the throttle valve is further raised, the difference in vacuum before and after the valve decreases, and fuel stops flowing through holes 19 and 20. In this case, the air flow in the diffuser creates a vacuum above the atomizer 11, and fuel begins to flow into it. The sprayer contains a throttle needle 9, which has a pointed conical lower part, due to which when the throttle valve, and therefore the needle attached to it, is raised, the flow area of the sprayer increases. At the same time, the amount of incoming air and fuel increases proportionally, and thus the composition of the prepared mixture is maintained.

Disassembly and assembly. We will indicate only a few characteristic points.

When installing the damper, its cutout should be directed towards the air filter. If the damper does not fall into place, you should slightly rock it from side to side. If it doesn’t help, slightly separate the plates. When installing the mixing chamber cover, the latch on the float chamber side must be closed first.

To disconnect the throttle cable, take the valve in your left hand and the mixing chamber housing cover in your right hand. Pressing the cover with your index and middle fingers, compress the spring with your thumb and remove the cable tip from the socket in the damper.

To unscrew the main jet, you need to unscrew the plug on the right side.

The idle jet is pressed into the housing and cannot be removed. Note also that when installing the carburetor on the engine, the stud nuts should be tightened one at a time, gradually increasing the effort. If you tighten one nut all the way and then the second, the carburetor flange may break due to gasket deformation.

When assembling the carburetor (after completely disassembling it), be sure to blow out the jets and clean the recess in the bottom of the float chamber, and check whether the gasket of the mixing chamber housing is installed on the reverse side. The same applies to the laying of the adapter pipe on the cylinder. It is also useful to check the flatness of the flange (on a plate or glass) and, if necessary, grind it.

There are three adjustments made on the K-36S carburetor:

1. Adjust the free play of the throttle lever using a stop and a lock nut. With proper adjustment, the damper should be lowered completely and raised up to full capacity, while the throttle cable sheath should have a play within 1-2 mm.

2. Adjusting idle speed. The engine is warmed up for 3-5 minutes, after which the throttle is completely released. The quality screw is tightened until the engine begins to misfire, and then it is slowly unscrewed (or tightened) until the speed reaches its maximum. By lowering the damper by unscrewing the quantity screw, they set the lowest stable speed and again try to increase it with the quality screw. The operation is repeated until any movement of the quality screw leads to a deterioration in engine performance. After this, the throttle valve is sharply opened - the engine should confidently pick up speed. In this case, the adjustment is considered complete. If the engine accelerates intermittently or stalls, you should find a position for the quality screw (not far from the already installed one) at which the engine will accelerate confidently. If this fails, you need to slightly raise the damper with the quantity screw, and with the quality screw again achieve the best engine performance. After adjustment, it is necessary to check the engine starting both in hot and cold conditions.

3. Quality adjustment is carried out by lowering or raising the throttle needle relative to the damper - when lowering the needle, the mixture becomes leaner, when raised, it becomes richer.

The simplest way to determine the quality of the mixture is to sharply lift the throttle. On a well-warmed-up engine, raise the throttle valve so that the speed is slightly above idle speed. Then sharply raise the throttle and observe the behavior of the engine. If the latter seems to “choke” or even stall, the mixture is lean or poor. If the engine reacts to raising the throttle as if with a delay, i.e. the revolutions begin to gradually increase only after a pause - the mixture is enriched or rich. With a normal mixture, the engine quickly and confidently picks up speed.

The second method is to deliberately enrich the mixture by reducing the air supply. For this purpose, remove the paper air filter, accelerate the engine to medium speed and close part of the receiver inlet with your palm - first small, and then larger and larger (on older models, for example M-106, it is enough to close most of the gap between the fungus and the filter cover with your palm) . It is possible that:

engine speed increases, indicating a lean or lean mixture;

RPM drops quickly, indicating a rich or rich mixture;

the revolutions drop slowly, which indicates a normal mixture;

the engine does not respond even to closing most of the hole, which indicates the presence of air leaks through the connections of the receiver to the carburetor, the carburetor to the cylinder, or even through the gaskets in the connection of the cylinder to the crankcase or in the connection of the crankcase halves.

The quality of the mixture can be determined by the condition and color of the spark plug insulator. To do this, at high speed (about 80 km/h), you need to drive at least 2 km, then set neutral and quickly turn off the ignition. Then you should unscrew the spark plug and inspect it.

With a normal mixture, the insulator will be light gray or light brown in color, and the end of the threaded part will be dark brown. With an enriched mixture, the insulator will be dark brown with deposits of black soot or soot, and with a rich mixture, everything will be smoky and black.

Note that after normal operation, the color of the insulator is always slightly darker than indicated, since the engine often operates at transient conditions, in which, as we know, the carburetor enriches the mixture. That is why it is necessary to drive for several minutes at a high and constant speed and quickly turn off the ignition.

Carburetor malfunctions. The jets are clogged with paint particles, threads, etc. If the main jet is clogged, the engine runs intermittently or stalls, the mixture becomes lean and cannot be adjusted. If the idle jet is clogged, the engine cannot be adjusted to idle speed, and starting it is difficult or impossible. The malfunction can be eliminated by flushing the carburetor and cleaning the jets. To clean the jets it is convenient to use thin copper wire.

Sometimes it happens that particles trapped under the idle jet either clog it, rising with the fuel, or are released, settling to the bottom. In such cases, the engine may start normally, but when you try to increase the speed, it stalls.

If water gets into the fuel, it will cause malfunctions or engine shutdown. Water in gasoline is kept in the form of separate drops, which, when entering the nozzle, clog it. If the drop is small and the vacuum in the diffuser is high, then sometimes it is possible to “push” this drop through the nozzle and the fuel supply is restored. To this end, when interruptions occur, the driver, using the motorcycle's roll, switches to a lower gear and sharply increases engine speed, creating an increased vacuum in the diffuser. If the engine stops, you should clean the gas tap, blow out and wash the carburetor, or better yet, drain the gasoline from the tank and wash the entire power system.

A rich mixture that cannot be adjusted may be caused by an increased fuel level in the float chamber or worn jet. An increased fuel level is a consequence of a leaking float or a leaky shut-off valve. In the first case, gasoline should be removed from the float by evaporation or heating over a closed fire to a temperature of 80 - 100 ° C, after which the float should be soldered (with a minimum amount of solder so as not to make it heavier) or sealed. To repair a plastic float, you can use MC glue or the hot end of a nail, screwdriver, etc.

In the second case, i.e. If the seal of the shut-off valve is broken, the float needle should be rubbed against the hole in the fitting using thin abrasive pastes. (As a last resort, you can use powder made from brick or chalk and diluted in a cart). Wear of the jet can occur only after 20 - 25 thousand kilometers. Its cross-section can be reduced by widening the end of the hole. It is better to replace the worn jet with a new one (see Fig. 2.24).

Rice. 2.24. Main jets of the K-36 carburetor: a - K-36S carburetor (M-106; 3.111; 3.115); b — carburetor K-36M (M-105).

Carburetor leaks most often occur due to an increased level of fuel in the float chamber or damaged gaskets, especially drain plugs. Gaskets can be made yourself from polyethylene, vinyl chloride, paronite or annealed aluminum.

The throttle needle falling out of the valve is a consequence of careless assembly or damage to the locking plate. A sign of a malfunction is the inability to increase speed when the throttle is raised. The engine stalls, although it starts well and idles normally. If the lock for securing the needle is lost or broken on the road, you can use thin copper wire instead.

If the throttle sticks, a sign of which is the inability to reduce speed, you should immediately turn off the ignition and stop the engine, and if this fails, engage fourth gear and, without squeezing the clutch, press both brakes. If the engine is not stopped immediately, it may go into overdrive, which will inevitably lead to destruction of the connecting rod lower head bearing or to breakage of the piston. The cause of the malfunction is sand getting between the valve and the carburetor body due to careless assembly or a loose fit of the mixing chamber housing cover.

Sometimes it is impossible to reduce engine speed due to the cable sheath coming out of the stop in the cover - in this case, the throttle handle rotates freely in both directions.

Destruction of the carburetor flange occurs as a result of improper tightening of the nuts or damage to the gasket, when a significant part of it, together with the hole for the stud, is torn off. If the mounting surface of the flange is not damaged, then you can make a stop (see Fig. 2.25) and use it to secure the carburetor.

The K-62S carburetor (Fig. 2.26) is installed on motorcycles 3.115, 3.112.11. Its main differences from the K-36S carburetor:

the float chamber is located directly under the mixing chamber, as a result of which the carburetor is less sensitive to the inclination of the motorcycle;

in the float chamber there are two floats 25, connected to each other by a lever 4. The valve 23 mounted on the lever is equipped with an elastic lock washer, the presence of which prevents wear of the valve seat;

in the outlet pipe of the mixing chamber, near the flange, there is a drainage hole 24, thanks to which excess fuel flowing out of the carburetor for some reason (for example, if the shut-off valve is not sealed) pours out, but does not enter the crank chamber. This makes it easier to start the engine and prevents the mixture from becoming too rich;

Rice. 2.25. Carburetor flange repair: 1 - carburetor; 2 - emphasis.

Using adjusting screw 16 (quality screw), the amount of air entering the idle system is changed. Therefore, unlike the K-36S carburetor, when this screw is turned out, the combustible mixture becomes leaner, and when screwed in, it becomes richer;

the presence of a balancing hole 17 allows you to reliably maintain atmospheric pressure in the float chamber, which makes adjustment of the quality of the mixture more stable;

The presence, size and location of the idle jet nozzle 21 make engine operation more stable in transient conditions. When starting and idling, fuel enters only through hole 22. As the throttle is raised, fuel (emulsion) begins to additionally flow through nozzle 21, and subsequently through the nozzle of the main jet 2, i.e. Both dosing systems operate simultaneously - the main one and the idle one. The productivity of the main jet of the K-62S carburetor is less than that of the jet of the K-36S carburetor (165 and 200 units, respectively). It should be borne in mind that if the idle jet is clogged, the mixture will become lean in all engine operating modes.

Rice. 2.26. Carburetor K-62S: 1 - main jet; 2 - sprayer; 3 — spray body; 4 — float lever; 5 — air inlet channel; 6 — throttle valve; 7 — carburetor body; 8 - gasket; 9 — carburetor cover; 10 — throttle spring; 11 - lock nut; 12 — cable sheath stop; 13 — throttle lift adjusting screw (quantity screw); 14 — float quencher; 15 — speed limiter; 16 — idle speed adjustment screw (quality screw); 17 — balancing channel; 18 — fuel fitting; 19 — idle air channel; 20 — throttle needle; 21 — idle jet nozzle; 22 — emulsion hole of the idle system; 23 - shut-off valve with an elastic washer; 24 — drainage hole; 25 — floats; 26 — idle jet; 27 — float chamber; 28 — axis and tube of the float lever; 29 — gasket

Rules for the export of goods from Belarus

You cannot export anything from Belarus that is not included in the “personal use” category. This applies to both technology and food.

List of things prohibited for export from the country:

- pasta;

- cereals;

- detergents produced by JSC Barkhim;

- cement;

- gas stoves produced by OJSC "Brestgazoapparat";

- refrigerators manufactured by JSC Atlant.

How many cubes are there at sunrise 3 m?

Motorcycles " Voskhod"

“models up to

3M

had a single-cylinder two-stroke air-cooled engine with a working volume of 175 cm3

(

cylinder diameter 61.72 mm, piston stroke 58 mm).

Interesting materials:

How to connect non-original Airpods? How to connect an Instagram account to Facebook? How to connect active speakers to a TV? How to connect an active subwoofer if there is no line output? How to connect an active subwoofer to a home theater? How to connect acoustics to a Samsung TV? How to connect Alice on Android? How to connect an analog camera to a TV? How to connect an analog camera over twisted pair cable? How to connect an analog TV to the Internet?

Technical characteristics Minsk 125

Due to its owner-friendly technical characteristics, many experts have recognized this model as the easiest to operate. The Minsk Bicycle Plant in Belarus began producing the motorcycle. To maximize seating comfort, the manufacturer decided to set the average saddle height to 800 mm.

For better operation on difficult roads, it was decided to install rear shock absorbers, and 17-inch aluminum wheels are additionally responsible for better acceleration. The maximum speed is 5,900, but even at low speeds the motorcycle can show excellent speed.

In those days, manufacturers installed the most necessary elements on motorcycles, so the steering wheel received a minimum of parts and unnecessary functions. There is a simple instrument panel and audible alarm.

Minsk motorcycle engine - how much oil to fill

MMVZ-3.113 (since 1995)

MMVZ-3.113 is a two-seater road-class motorcycle. Entered production in 1995. Manufactured on the basis of its predecessor MMVZ-3.112. In 1999 it gave way to the more modern model MMVZ-3.114. The 3.113 motorcycle has several modifications. The most modern of them is MMVZ-3.113.8 model 2006. This version has canted rear shock absorbers. Engine capacity – 125 cubic meters. see. Otherwise, everything is the same as the predecessor MMVZ-3.113.5 “Leader”: raised muffler and plastic side trims.

Gasoline engines 1995-1999

MMVZ-3.113, two-stroke, 125 cc. cm, 10 l. pp., oil volume - 1 liter per 20 liters of gasoline (1:20); tolerance and viscosity: JASO M345; SAE 10W-40

M1NSK C4 200

M1NSK C4 200 is the most powerful two-wheeled motorcycle ever produced by M1NSK. The bike is equipped with a 200 cc engine, which produces 112 horsepower per 1 ton. The declared power is 13.5 liters. With. at 8500 rpm. The 4-stroke engine has a modern liquid cooling system. In addition, the C4 model is equipped with an electric starter. The motorcycle has a fairly stiff rear suspension. All modifications are equipped with a practical wind fairing that protects the driver from wind currents. There is also a rear rack, which is also designed to hold a helmet. The basic package includes drum brakes, which can be easily replaced with a disc brake system if desired. The manufacturer allows the motorcycle to be operated in a temperature range from minus 10 to 45 degrees Celsius.

Gasoline engines 2008

Four-stroke, 200cc cm, 13.5 l. pp., oil volume – oil volume – 1 liter per 20 liters of gasoline (1:20); tolerance and viscosity: SAE J300; SAE 10W-40

Also read: Motor oil for Mercedes-Benz W223 engine

MMVZ-3.119

The MMVZ-3.119 motorcycle has the prefix “Lesnik”. This is a universal model with a rear three-sided luggage rack and protective bars. Also distinctive features of this model are the “top” plastic fender and the protective headlight. In the basic version, the motorcycle is equipped with drum brakes. In addition, there is a sealed circuit casing, and the simplified electrical system does not have a battery. The MMVZ-3.119 “Lesnik” model accelerates to 85 km/h.

Gasoline engines

Two-stroke, 1-cylinder, 123 cc. cm, oil volume - 1 liter per 20 liters of gasoline (1:20); tolerance and viscosity: JASO M345; SAE 10W-40

What oil should be used for a Minsk motorcycle engine

Original

For motorcycles MMVZ-3.113 and MMVZ-3.119, oil for two-stroke engines is recommended - M-12TP (TU 38.401.666-87). In addition, MGD14M (TU 38.101.930-87) is also suitable. For the M1NSK C4 200 motorcycle equipped with a four-stroke engine, Motul 5100 4T 10W-40 oil recommended by the MotoVelo factory is suitable.

Unoriginal

For Minsk motorcycles with two-stroke engines, it is recommended to use mineral or semi-synthetic oil Lukoil Moto 2T or TNK 2T. Viscosity – 10W-40 or 15W-40. All-season liquid M-8B is also suitable. The following oils should be used in four-stroke engines:

- Liqui Moly ATV 4T Motoroil 10w-40

- Motul 4T 5100 MA2 10W-40