With the onset of cold weather, motorists every year face problems starting the engine. The problem is that in the cold the air is rarefied and in order to ignite the air-fuel mixture, a more powerful discharge from the spark plug is required.

Diesel engines have a similar problem, but there ignition occurs due to the strong heating of the air in the cylinder due to its compression. To solve this problem, engineers developed glow plugs.

What is the solution for gasoline internal combustion engines? It's clear that something needs to be done with standard candles. Over the course of decades, the technology for creating SZ has developed, thanks to which various modifications have become available to drivers. Among them are iridium spark plugs. Let's look at how they differ from standard ones and how they work.

Operating principle of iridium spark plugs

Iridium spark plugs have the same design as the standard version (more about these elements in another article ). The operating principle is as follows.

A short electrical impulse is supplied through high-voltage wires through the candle holder to the contact nut. The contact head is located inside the ceramic insulator. Through it, a high voltage current pulse is supplied to the sealant connecting the contact head and the electrode. This is a current that has a positive charge.

All spark plugs are equipped with a housing with a threaded skirt. It firmly fixes the device in the engine spark plug well. At the bottom of the body there is a metal antenna - a side electrode. This element is curved towards the central electrode, but they do not connect. There is some distance between them.

A critical amount of current accumulates in the central part. Due to the fact that both electrodes are not insulated and have a high current conductivity, a spark occurs between them. The strength of the discharge is affected by the resistance that both elements have - the lower it is, the better the beam.

The larger the diameter of the central electrode, the smaller the plasma core will be. For this reason, not pure metal is used, but iridium, or rather its alloy. The material has high current conductivity and is not so susceptible to absorbing thermal energy released during the formation of an electric discharge beam.

The electric spark is not scattered over the entire surface of the central electrode, so such a spark plug provides the combustion chamber with a “fat” discharge. This in turn improves the ignition of the cold mixture of air and gasoline (or gas, which in the cylinder has a temperature of about -40 Celsius).

Replacement sequence

p, blockquote 20,1,0,0,0 –>

Despite its apparent simplicity, this operation should be taken responsibly. Replacement should be made as a complete set (!)

. Partial replacement of one or two “lost” spark plugs is only possible for a short time.

p, blockquote 21,0,0,0,0 –>

Different gaps and types of spark plugs and their conditions lead to inevitable failure of ignition timing, increased detonation, and contribute to increased engine wear.

p, blockquote 22,0,0,0,0 –>

The selection of spark plugs should be made for the vehicle based on reference data. You shouldn’t rely on “these are the best” recommendations. It is better to purchase products only from trusted manufacturers.

p, blockquote 23,0,0,0,0 –>

p, blockquote 24,0,0,0,0 –>

As the main tool for replacing spark plugs, it is better to use a special long head with rubber inserts to grip the spark plug being removed. Before purchasing it, you should measure the diameter of the mounting hole.

p, blockquote 25,0,0,0,0 –>

The standard sizes of spark plug heads are 16 and 21. The length of the seating zone can be different, up to 180 millimeters in certain engine models. In some cases, you can use a spark plug tube, but keep in mind that its reliability is less. It’s even worse to use special keys from unknown manufacturers in beautiful packaging. They may break the first time you unscrew them.

p, blockquote 26,0,0,0,0 –>

Sequence of spark plug removal:

p, blockquote 27,0,0,0,0 –>

- remove the installed high-voltage wires, having previously noted or photographed the sequence of their installation;

- if the car has individual ignition coils or a coil block installed in the spark plug space, dismantle them (in V-shaped engines this process can be complicated by the need to dismantle part of the intake manifold and other engine elements);

- be sure to check the spark plug installation areas for the presence of foreign objects (when removing the spark plug, fragments of insulation and other objects may fall directly into the cylinder and cause big problems);

- securely install the spark plug wrench, apply medium force, and begin unscrewing;

- if the dismantling process is difficult, it is necessary to use special means for decoking the threaded connections, and do not try to apply excessive force;

- remove the spark plug (if the retaining rubber band has come off, you can do this using the tip of a high-voltage wire);

- It is better to install a plug or throw a clean rag on the vacated spark plug hole (there are many cases when, during the repair process, nuts, washers and other “surprises” get there, that is, into the cylinder).

Iridium spark plug maintenance process

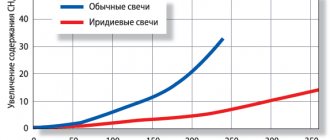

A spark plug with an iridium core does not require special maintenance. In most engines, these modifications last more than 160,000 kilometers. For stable operation of the internal combustion engine, manufacturers recommend changing spark plugs not when they fail, but periodically - in many cases a little more often than after 150 thousand.

Although iridium models do not form so much carbon deposits, due to the low quality of gasoline and frequent cold engine starts, this deposit still appears. For these reasons, it is recommended to refuel your car at reputable gas stations and minimize short trips.