In order for a motorcycle engine to start without problems and gain speed well, at least two systems must work. One of them is the ignition system, the second is the power system. Simply put, there must be a spark in the combustion chamber at the right time and fuel mixed with air must enter the cylinder in the required quantity.

So about fuel. Before setting up the power system, you need to make sure that the ignition system is configured and working as it should. Are you sure everything is fine? Then let's begin.

You need to start with candles.

They can tell you a lot. We unscrew the spark plugs after driving along the highway for about thirty kilometers, at least at medium or higher engine speeds, and carefully inspect them. Black carbon deposits, similar to soot, indicate that there is not enough air for the mixture to burn normally. The mixture is rich. Lots of gasoline and little air. If the spark plug insulator is completely free of soot or white, then the mixture is poor. Too much air and not enough gasoline. Normal color should be sand to brick red. If the spark plug insulator is of normal color, then you shouldn’t go into the carburetor. You should be guided by the rule that the best is the enemy of the good.

If the carburetor gets rich

First of all, we inspect the air filter. It may be dirty. The air passages may also be blocked, for example, a rag has been sucked in, the air pipe is pinched, or the air damper does not open completely. We sorted out the air supply, everything is clean, free, without obstacles. Go ahead.

You can remove the carburetor, completely disassemble it, wash it, blow out all the channels, dry it and reassemble it, but complete disassembly is not always required; more often you can get by with just adjustments. But if your carburetor does not respond to the rotation of the quality adjusting screw, then disassembling and washing is simply necessary.

First of all, check the fuel level in the float chamber

. How to do it?

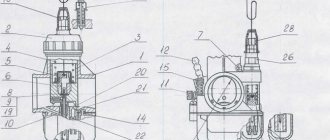

We start by checking the shut-off valve or, simply put, the needle. A shut-off valve that does not hold is the cause of many troubles. Including an increased level of gasoline, which leads to over-enrichment of the mixture. On carburetors K-62, K-63, K-65, K-68, needle valves come in two types. With a ring or a rubber cone. To get to it, you need to remove the bottom cover of the carburetor, which is attached to the body with two screws (be careful when removing, do not damage the gasket), then remove the float, carefully pushing its axis out of the guides. The needle, as a rule, remains on the float tongue or falls out. Be careful not to lose it.

We inspect the needle, if it has a rubber cone, then we inspect the cone, it should be free of damage and foreign objects (hairs, grains of sand, etc.). If the needle has an o-ring, then look at how this ring sits on the head of the needle. If the ring is loose or missing altogether, it is necessary to replace (install) either only the o-ring or the needle. The ring should fit tightly. The needle must move along the seat without jamming, otherwise we replace the entire valve.

With the carburetor removed, you can check the level like this.

We turn the carburetor over with the float up and measure the distance from the plane of the body to the very top of the float. It should be within 26-27 mm. If it does not match, then adjust the size by bending the float tongue.

Is it possible to check and adjust the fuel level without removing carburetors in the Urals? Are they installed on the cylinder heads at angles to the horizontal and vertical planes?

With some skill this is possible. To do this, you will need a free float from the same carburetor. In a motorcycle mounted on the central stand (we are talking about a single motorcycle), open the gas tap. We wait a while for the carburetors to fill with gasoline. Close the gas valve and disconnect the gas hose from the carburetor. Remove the bottom cap of the carburetor with gasoline and lower the spare float into it. Next, we lean the lid against the lower plane of the body so that the planes of the lid become a continuation of the plane of the body (we simulate the installation of the lid, set the actual angle of inclination of the lower part), while the fuel level should be below the edge of the lowest corner of the lid and not overflow through it . If it does not correspond, then by bending and bending the tongue we achieve the desired level. In this case, the bottom cover and gas hose will have to be removed and replaced several times to test filling with gasoline. After adjusting the level, we proceed to the next one.

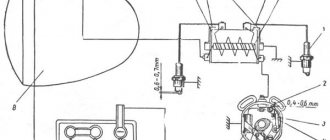

Adjusting idle speed and mixture quality (Carburetor K-62, 63, 65, 68).

We make adjustments on a warm engine. The procedure is approximately this:

1. Set the minimum stable engine speed by rotating the quantity screw (on K-62,63,65 this is the top 13mm wrench bolt, on K-68 this is a horizontal screw for a screwdriver). 2. Slowly rotating the quality screw in one direction or another (on all of the listed types of carburetors this is a vertical screw for a screwdriver), we catch the moment the speed increases to the maximum (approximately 1.5-2.5 turns from the fully tightened position, but deviations in that direction are possible or other party). 3. Repeat steps 1 and 2 until normal idle speed is established. 4. Check the adjustment by opening and closing the throttle. 5. If the engine stalls when you sharply open the throttle, turn the quality screw 1/4-1/2 turn (enrich the mixture). 6. If the engine stalls when the throttle is suddenly closed, turn out the quality screw 1/4-1/2 turn (lean the mixture).

Owners of motorcycles not only made in Russia, but also of foreign cars often face the problem of “shooting” from the muffler. This happens due to improper care of the air-fuel mixture ignition system. The motorcycle shoots the muffler in several cases:

- when using low-quality gasoline;

- malfunction of the electronics system responsible for fuel supply;

- gasoline does not enter the combustion chamber in pure form;

In such cases, you don’t need to wonder why the muffler on a motorcycle shoots. Poor quality gasoline has a very high combustion temperature due to the addition of water, so it does not ignite completely. The remaining drops fall on the walls of the heated muffler

. Their ignition creates pops.

The motorcycle also shoots into the muffler when releasing the gas. The lower the pressure created in the internal combustion chamber, the more droplets enter the muffler. On some bikes, fuel accumulates in the muffler, followed by rare but very loud bangs.

Most often, but not always, owners of the Russian motorcycle industry face this problem. For example, a Ural motorcycle shoots into the carburetor. This occurs due to direct clogging of gasoline in the carburetor itself. To avoid this problem, it is necessary to constantly clean the filters and change the consumables responsible for cleaning the engine. Proper operation of your bike will not only ensure good engine performance, but will also maintain factory specifications.

Popping noises in the muffler of a scooter: causes and solutions

A scooter is a mechanical vehicle with an internal combustion engine. As a complex technical device, it is not immune to malfunctions. For example, frequent or single extraneous sounds resembling pops begin to be heard from the muffler. These uncomfortable noises can occur both during continuous operation of the engine and when it is started or stopped.

The unexpected occurrence of popping noises is not a serious failure; the owner can continue to use the vehicle. However, prolonged ignoring of the situation is fraught with negative consequences for the engine, deterioration in the performance of the machine, and failure of the exhaust system of the scooter. It is advisable to correct such malfunctions immediately. Shots in the muffler indicate that the fuel mixture in the exhaust system is burning out, and this leads to loss of power, increased fuel consumption, and unstable engine operation.

The main reasons for the appearance of pops

1. The nature of the phenomenon is considered to be the ignition of the working mixture that has accumulated in the muffler. That is, fuel that does not burn out in the engine in a timely manner ends up in the exhaust system. As it accumulates at a certain temperature, combustion occurs. There are several reasons for the formation of shots in the exhaust pipe.

2. Most often, the spark plug is to blame for this, as it does not produce a spark in time. During the operating cycle, the required volume of the fuel mixture does not ignite, and it goes into the exhaust system. Such a cycle negatively affects the operation of the engine and negatively affects the condition of the muffler. The spark plug needs to be removed and cleaned, its suitability for further use must be determined, and, if possible, adjusted. It is advisable to always have a spare working (new) spark plug.

3. In some cases, the cause of popping is an overly rich mixture. The situation may arise if the carburetor is incorrectly configured or if dirt gets into it. To correct the problem, just check the cleanliness of the carburetor and its settings. The composition of the fuel-air mixture of a scooter directly depends on the proper functioning of the starting enrichment. Its breakdown can also contribute to significant enrichment of the fuel.

4. Popping noises that appear after heating the power unit indicate a violation of the adjustment of the thermal clearances of the valves. To prevent the fuel mixture from entering the exhaust manifold, the valve plate must close the seat tightly enough.

Every scooter owner should be prepared for the possibility of technical problems. There is no need to panic here; any malfunction can always be successfully fixed.

Messages [18]

1↑ Topic from Ural*4uK 07/05/2012 02:35:35

- Ural*4uK

- Elder

- Inactive

- Name: Igor

- From: Russia, Bryansk region, Mglin

- Registered: 03-03-2012

- Messages: 1 451

- Reputation: 39

- Motorcycle: Ural IMZ 8103 with sidecar

Topic: Top hat sneezes!

In my Urals, the left cylinder sneezes at idle, as if air were flying out (when everything is going fine!). Ignition, carbs and valves are tuned! I thought maybe the valves were leaking?

2↑ Reply from mexanik62 05-07-2012 07:20:09

- mexanik62

- Mechanic from the 30s.

- Inactive

- Name: Uncle Vitya

- From: Evpatoria

- Registered: 03-08-2011

- Messages: 10 832

- Reputation: 1 151

- Motorcycle: 12-volt K-750, ZAZ Sens Hatchback

Re: cylinder sneezes!

Lean mixture on the left, unscrew the quality screw

3↑ Reply from Ural*4uK 07/06/2012 14:07:53

- Ural*4uK

- Elder

- Inactive

- Name: Igor

- From: Russia, Bryansk region, Mglin

- Registered: 03-03-2012

- Messages: 1 451

- Reputation: 39

- Motorcycle: Ural IMZ 8103 with sidecar

Re: cylinder sneezes!

I thought so, but because of this sneezing, the candle is sometimes black! At idle it will run fine, at speed it will be normal!

4↑ Reply from mexanik62 07/06/2012 14:40:36

- mexanik62

- Mechanic from the 30s.

- Inactive

- Name: Uncle Vitya

- From: Evpatoria

- Registered: 03-08-2011

- Messages: 10 832

- Reputation: 1 151

- Motorcycle: 12-volt K-750, ZAZ Sens Hatchback

Re: cylinder sneezes!

5↑ Reply from Ural*4uK 07/06/2012 14:41:15

- Ural*4uK

- Elder

- Inactive

- Name: Igor

- From: Russia, Bryansk region, Mglin

- Registered: 03-03-2012

- Messages: 1 451

- Reputation: 39

- Motorcycle: Ural IMZ 8103 with sidecar

Re: cylinder sneezes!

tuned in! I synchronized 2 times!

6↑ Reply from mexanik62 06-07-2012 17:20:55

- mexanik62

- Mechanic from the 30s.

- Inactive

- Name: Uncle Vitya

- From: Evpatoria

- Registered: 03-08-2011

- Messages: 10 832

- Reputation: 1 151

- Motorcycle: 12-volt K-750, ZAZ Sens Hatchback

Re: cylinder sneezes!

Well, when one spark plug is black at idle, it means there is no synchronization at idle IF BOTH PLUGS AT IDLE ARE EQUALLY BLACK SO IT SHOULD BE IN general, after adjusting the idle, you need to slightly enrich the mixture, tighten the quality screw 1/4 turn, then when taking on a load there will be no sneezing or dips

Edited by mexanik62 (06-07-2012 17:23:56)

7↑ Reply from Ural*4uK 07/06/2012 19:09:43

- Ural*4uK

- Elder

- Inactive

- Name: Igor

- From: Russia, Bryansk region, Mglin

- Registered: 03-03-2012

- Messages: 1 451

- Reputation: 39

- Motorcycle: Ural IMZ 8103 with sidecar

Re: cylinder sneezes!

But then how to synchronize at idle?

8↑ Reply from mexanik62 06-07-2012 19:40:11

- mexanik62

- Mechanic from the 30s.

- Inactive

- Name: Uncle Vitya

- From: Evpatoria

- Registered: 03-08-2011

- Messages: 10 832

- Reputation: 1 151

- Motorcycle: 12-volt K-750, ZAZ Sens Hatchback

Re: cylinder sneezes!

You adjust the carbs one by one and remove the caps one by one on one boiler there should be the same speed and the sound of course. You also try the throttle response, lift the carb cable which you check. It should not sneeze and the boiler should pick up speed. If not, you enrich the mixture by tightening the screw, accordingly, you will most likely have to turn it up a little lift with quantity screw

9↑ Reply from Ural*4uK 07/06/2012 21:01:06

- Ural*4uK

- Elder

- Inactive

- Name: Igor

- From: Russia, Bryansk region, Mglin

- Registered: 03-03-2012

- Messages: 1 451

- Reputation: 39

- Motorcycle: Ural IMZ 8103 with sidecar

Re: cylinder sneezes!

and by the way: the right boiler heats up more than the left one

10↑ Reply from mexanik62 06-07-2012 21:53:02

- mexanik62

- Mechanic from the 30s.

- Inactive

- Name: Uncle Vitya

- From: Evpatoria

- Registered: 03-08-2011

- Messages: 10 832

- Reputation: 1 151

- Motorcycle: 12-volt K-750, ZAZ Sens Hatchback

What to do if your motorcycle sneezes?

Publication date 08/09/2014 18:18

Find out what to do if your motorcycle sneezes in this article, useful tips from experienced bikers and motorcyclists, and just rural mechanics. In their lifetime, they have accumulated a lot of experience and soot, they will help you solve the problem and get back on the iron horse, good luck to you, friend.

This life situation happens to anyone who in one way or another comes into contact with motorcycles or mopeds, scooters and other two-wheelers with a motor on board. There may be several reasons for these mechanisms to sneeze, so we will look at each of them and explain in detail what needs to be done in such cases.

A moped or Adler motorcycles may not sneeze, but simply be out of sorts. This is how it happens to a person, he gets up on the wrong foot. So it also happens in transport that the day has not gone well since the very morning. You turn him on, and he only sneezes in response. Well, it’s okay, it goes by quickly, you just need to let your motorcycle know that you won’t leave it in the rain or in the heat of summer, it’s yours forever and you’ll go through life together. Don’t hang your nose, and your iron comrade will also reciprocate your feelings, immediately perk up and won’t sneeze.

Troubleshooting motorcycle electrical equipment

The hit parade of malfunctions in motorcycle electrical equipment is as follows:

1. Poorly screwed battery terminal.

Symptoms: The motorcycle shows no signs of life at all, or the instrument panel lights up, but when you press the starter button, the relay clicks and everything goes out (if an alarm system with an autonomous siren is installed, it starts screaming).

Reasons: Even a well-tightened terminal can come loose when driving on bad roads. If it's not tightened well, it will come loose anyway. A weak current still flows through the poor contact, but the high current required to operate the starter leads to sparking and complete loss of contact.

Treatment: Tighten the battery terminals securely. Poor contact at the terminals leads us to the following malfunction.

2. Low battery

Symptoms: The starter turns poorly, the sound signal is barely audible. The battery voltage is below 12.4V. (During starter operation – below 8-9V). If an alarm system with an autonomous siren is installed, when you press the starter button, it starts screaming.

Reasons: Old battery, long-term storage in a discharged state, undercharging due to oxidized wiring, malfunctions in the generator or relay regulator.

Treatment: Charge or replace the battery. You only need to charge the battery by disconnecting it from the motorcycle. The fact is that chargers are usually stabilized in current, that is, they provide the 1 or 5 Amperes we need (depending on the type of battery). There is usually no such control over the voltage, and with a current of 5 Amps the voltage can be 20 Volts or higher. For a disconnected battery, such voltage does not pose any danger. On the contrary, you can try to pump up a battery that does not want to accept a charge by briefly increasing the voltage to 25V. But for other electrical devices on a motorcycle, such voltage can be fatal. If the new battery is soon discharged again, it is necessary to diagnose the electrical equipment and troubleshoot problems. Constantly recharging the battery using a charger will lead either to its complete death, or, what is much worse, to the death of the relay regulator.

3. Overcharged battery

Symptoms: The battery is hot, boils, whistles. The voltage on the battery with the motorcycle turned off is above 13V, and with the motorcycle running - above 15V.

Causes: Malfunction of the relay regulator or oxidized wiring

Treatment: Check all electrical wiring, paying special attention to the ignition switch and the harness connector going from the generator to the relay regulator. Carry out diagnostics of the relay regulator.

4. Short circuit in wiring

Symptoms: The tidy shows no signs of life, the headlight or turn signals do not work.

Causes: A frayed wire, or a sensor connector shorted to ground, a turn signal broken off in a fall, etc. Despite the simplicity of the malfunction, it can be quite difficult to find the cause, especially if the short circuit sometimes appears and sometimes does not.

Treatment: Check fuses. The main fuse is usually installed directly on the starter relay, connected by a thick red wire to the battery. The remaining fuses are collected in a neat block, on the cover of which it is written which fuse is responsible for what. Having determined which fuse has blown, we narrow down the area of troubleshooting that must be found. After all, a frayed wire can cause a fire. Never use bugs instead of fuses!

Procedure for checking the electrical equipment of a motorcycle.

- We charge the battery, measure the voltage on the battery. It is advisable to install a known good battery. A working battery without load shows 12.4-12.9V, with the starter turned on - 8-10V (both conditions must be met). If after winter the voltage drops below 7-9V, a modern maintenance-free battery is already a candidate for the trash heap. Monitor the charging current; many batteries do not allow fast charging and require a charging current of around 1A.

- If everything is in order with the electrics, you should get the following picture:

- With the ignition off and the engine off, the battery voltage is 12.4-12.9V

- At 2500 RPM > 13V

- At 5000 RPM < 15V

- If the numbers are very different, we move on.

- We check the voltage drop between the battery and the relay regulator at idle (check the condition of the wiring):

- Between (+) battery and (+) relay <0.2V

Between (–) battery and (–) relay <0.2V

- Between (+) battery and (+) after ignition on the relay (if there is such a wire) <0.2V

- We measure the resistance of the generator windings by turning off the ignition and turning off the relay regulator:

- Between windings - 0.1-2 Ohm, (Usually 0.2 Ohm, but the main thing is that it is the same for all three windings)

There is infinity between the windings and ground.

If the voltage drop is greater, clean the contacts. If there is no voltage drop, we move on.

We start the motorcycle and measure the voltage from the generator windings at 5000 RPM. (without connecting the relay regulator)

- Between all three windings > 50V (Maybe less, but always the same for all three windings)

If resistances and voltages fluctuate, we treat/change the generator. If they are normal and the same, we move on.

- Red probe to the positive contact, black probe to each of the generator outputs - no readings or above 1.5 V for each of the three measurements.

moto-electro.ru

Main reasons

So, let’s look at why the 4t scooter won’t start – the reasons can be roughly divided into the following categories:

- fuel system malfunctions

- ignition system malfunctions

- piston group malfunctions

- malfunction of the gas distribution mechanism (GRM).

Each of these 4 categories has its own several possible causes. When diagnosing a scooter, you should carefully pay attention to each category and the problem in it. Step by step, eliminating faults, you will definitely find the cause. And then it’s a matter of technology!

Advice! Remember that there may be several reasons. Therefore, having eliminated one breakdown, you should still check the serviceability of other devices from the list of possible faults.

Fuel system malfunctions

If there is no gasoline in the tank, the scooter will not start - everyone knows. The same situation occurs when the fuel system malfunctions - gasoline does not reach the combustion chamber. The consequence is that there is nothing to burn, so the engine does not start. The reasons may be as follows:

- faulty fuel valve

- clogged fuel filter

- contaminated carburetor, failure of its individual parts

- The vacuum suction supplied to the fuel tap does not work.

It is recommended to start repairs with the simplest ones. In this case, the diagnosis begins with the fuel tap (if there is gasoline in the tank). To check operation, remove the fuel supply hose from the carburetor, then crank the engine with the starter or crank. The serviceability of the tap will be visible by the stream of gasoline flowing from the hose.

A constant flow of fuel, even when the engine is stopped, or a lack of fuel supply through the hose indicates a breakdown of the fuel valve. If fuel is constantly leaking, change the valve immediately. Otherwise, you should pay attention to the condition of the fuel hoses, and only then replace the fuel tap.

Filter

The serviceability of the filter is diagnosed visually and by blowing. A dirty filter should be replaced immediately. If the filter looks clean, but does not blow in the desired direction, it means it is clogged and requires replacement.

Carburetor

A dirty carburetor is another reason why fuel does not reach the combustion chamber. The device becomes dirty due to poor filters (fuel and air) and poor fuel quality. Here is a list of actions necessary to eliminate carburetor malfunction:

- remove the carburetor and disassemble it

- rinse and blow out the holes with compressed air (if compressed air is not available, use a regular pump)

- pay attention to the condition of the float chamber, both the float itself and its adjustment; condition of the locking needle - is it worn out or sunk?

- Clean the fuel nozzle thoroughly.

Messages [17]

1↑ Topic by Frol 05-10-2014 20:48:24

- Frol

- Participant

- Inactive

- Name: Alexey

- From: Tula region

- Registered: 29-01-2013

- Messages: 57

- Reputation: 2

- Motorcycle: Ural

Topic: sneezing into carburetor

hi guys. I have the following problem: the right carburetor sneezes and sometimes the engine detonates. I've already tried everything: I changed the carburetors as many as 3 pieces. I ground the valves, I changed the ignition coil to another one, I changed the slider. Turning the ignition doesn't help. What could be the reason, please tell me!

2↑ Reply from mark11 05-10-2014 21:05:15

- mark11

- Assistant

- Inactive

- Name: mark

- From: Rostov region. st.bagaevskaya

- Registered: 19-11-2013

- Messages: 193

- Reputation: 17

- Motorcycle: Dnepr 11

Re: sneezing into carburetor

3↑ Reply from Frol 05-10-2014 21:12:56

- Frol

- Participant

- Inactive

- Name: Alexey

- From: Tula region

- Registered: 29-01-2013

- Messages: 57

- Reputation: 2

- Motorcycle: Ural

Re: sneezing into carburetor

4↑ Reply from shaman507 05-10-2014 21:14:49

- shaman507

- Angry moderator

- Inactive

- Name: Evgeniy

- From: Tambov region

- Registered: 28-05-2013

- Messages: 4 389

- Reputation: 423

- Motorcycle: Dnepr MT 10-36, M-72, Ural IMZ-8.103-10, M-63, IZH-49, Militia Ural single, Minsk M-106

Re: sneezing into carburetor

Did you wipe the headlight? kicked the wheel?

5↑ Reply from Frol 05-10-2014 21:19:25

- Frol

- Participant

- Inactive

- Name: Alexey

- From: Tula region

- Registered: 29-01-2013

- Messages: 57

- Reputation: 2

- Motorcycle: Ural

Re: sneezing into carburetor

funny

6↑ Reply from RaaF37rus 05-10-2014 21:47:20

- RaaF37rus

- Pro

- Inactive

- Name: Sergey

- From: Ivanovo region. Kamenka village

- Registered: 27-07-2013

- Messages: 568

- Reputation: 67

- Motorcycle: IMZ 8-103-10

Re: sneezing into carburetor

there is little fuel and try to make the mixture richer.

Edited by RaaF37rus (05-10-2014 21:47:47)

7↑ Reply from 14 22:07:10

- 666

- Technical support, materials scientist

- Inactive

- Registered: 06-05-2010

- Messages: 6 628

- Reputation: 616

Re: sneezing into carburetor

The intake valve may be pinched or burnt, and if this is observed on both cylinders, it is worth checking the ignition timing.

8↑ Reply from Frol 05-10-2014 23:30:32

- Frol

- Participant

- Inactive

- Name: Alexey

- From: Tula region

- Registered: 29-01-2013

- Messages: 57

- Reputation: 2

- Motorcycle: Ural

Re: sneezing into carburetor

The intake valve may be pinched or burnt, and if this is observed on both cylinders, it is worth checking the ignition timing.

a new valve has been installed, there is a gap, only the right side sneezes and degenerates. I’ve already tried everything. only sneezes at idle

Edited by Frol (05-10-2014 23:32:24)

9↑ Reply from 14 23:33:23

- 666

- Technical support, materials scientist

- Inactive

- Registered: 06-05-2010

- Messages: 6 628

- Reputation: 616

Re: sneezing into carburetor

perhaps air is being sucked in, listen with the engine running, or better yet, whip up some foam and lubricate the head/cylinder and carb/head connections

10↑ Reply from RaaF37rus 06-10-2014 04:32:38

- RaaF37rus

- Pro

- Inactive

- Name: Sergey

- From: Ivanovo region. Kamenka village

- Registered: 27-07-2013

- Messages: 568

- Reputation: 67

- Motorcycle: IMZ 8-103-10

Re: sneezing into carburetor

or better yet, whip up the foam and lubricate the head/cylinder and carb/head connections

11↑ Reply from shaman507 06-10-2014 08:38:16

- shaman507

- Angry moderator

- Inactive

- Name: Evgeniy

- From: Tambov region

- Registered: 28-05-2013

- Messages: 4 389

- Reputation: 423

- Motorcycle: Dnepr MT 10-36, M-72, Ural IMZ-8.103-10, M-63, IZH-49, Militia Ural single, Minsk M-106

Re: sneezing into carburetor

It's worth checking the ignition timing...

From personal experience I will say that the moment has nothing to do with sneezing. Everyone can check it. It is enough with the engine running (working properly and not sneezing, of course) to loosen the screws securing the ignition base and try to move it from the earliest to the latest. Engine speed and operation change, but interruptions do not occur