The fuel supply system is necessary for engine operation. Even if there are craftsmen who can ride without a battery, then without a carburetor the scooter will not even start. However, a more modern analogue is becoming increasingly common - an injector. It is common in Europe and Japan, but in our country the owner of an iron horse, as a rule, has to deal with a traditional device. It is important to correctly configure the carburetor on a scooter, otherwise excessive fuel consumption and breakdowns cannot be avoided.

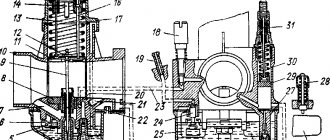

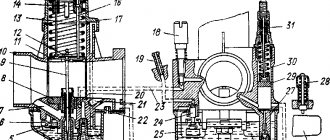

The design of a scooter carburetor and its operating principle

The design of a scooter carburetor is quite simple; Once you understand it, you will be able to understand how to properly configure the carburetor so that the vehicle does not let you down in bad weather, how you can tune it and improve the performance of the engine. You will be able to control the quality of the mixture and many other processes that affect the operation and operation of the device.

Removing the carburetor

To clean the Keihin carburetor, it will need to be removed. To get to it, you will need to remove the airbox and gas tank. Then the clamps of the manifold pipes are loosened. The suction (enrichment) cable is dismantled.

The Honda scooter and other models of similar vehicles have a system of carburetors that are in the same row. They do not need to be separated from each other for cleaning. However, to replace the seals you will have to disassemble the ruler.

During dismantling, the carburetor block is removed, as well as the throttle cables. Now you can easily perform system maintenance. The top covers must be removed (the screws are unscrewed). Next, you need to inspect the condition of the gaskets, needles and rubber bands.

The insides of the carburetor itself, as well as the parts around it, must be thoroughly cleaned. A bath of gasoline and a regular paint brush are suitable for this.

The principle of operation of a scooter carburetor

The carburetor design of a 4t scooter is not very complicated. The basic principle of its operation is as follows: a certain amount of fuel and oxygen enters the float chamber of the device, where they are mixed in the required proportions and supplied to the combustion chamber of the engine.

The design of a 4-stroke scooter carburetor may vary slightly depending on the model, but in general it is the same for all types of carburetors. The float version of products is most often used. It is distinguished by the presence of a float chamber in which fuel is mixed with air, after which the finished mixture is fed into the cylinder. In order for air to enter the fuel in the required proportion, the carburetor includes the following elements:

- Jets.

- A needle that meters the supply of oxygen.

- Spool.

- Throttle valve.

Sometimes the design of a 4t carburetor on a 50cc scooter includes an element such as an accelerator pump. It works in tandem with a starting mixture enricher. These devices help the scooter engine to work correctly and start in damp and wet weather. The correct operation of the motor depends on the coherence of the devices, so it is important to pay attention to their settings.

Scooter starter booster

Most often, scooters are equipped with an electric starting enrichment; on older models you can find a manual one. The task of this device is to create the right mixture in order to start the engine after a long period of inactivity.

The carburetor has an additional channel for connecting the enricher. If the device is automatic, the channel opens itself when you try to start the scooter and closes as the engine warms up. If the enrichment is manual, you need to close its valve yourself. The operating principle of the device is as follows:

- Inside the housing there is an element heated by electricity, which pushes out a needle that blocks the fuel channel.

- After the engine is stopped, the needle will be retracted.

Float chamber device

Mixing of fuel with air in the carburetor occurs with the participation of the float chamber; Thus, the finished fuel, saturated with the required amount of oxygen, enters the combustion chamber, where it explodes and sets the scooter in motion.

From the gas tank, fuel enters the carburetor through special pipes. But mixing cannot occur in them, so first the fuel ends up in the float chamber, and only then it is enriched with oxygen and further moved. To ensure that gasoline does not flow continuously, but in the right quantity, the carburetor is equipped with a special system with a float and valve. When the chamber is full, the float rises and the valve blocks fuel from entering the carburetor; when the float is lowered, the flow of fuel resumes.

Fuel dosing system design

The mixture is supplied to the cylinder in finished form, so it is necessary to control its quality. For this purpose, the carburetor has a special needle with grooves and a locking ring. The position of the needle depends on the position of the ring: the higher it is, the richer the mixture, and vice versa. Modern carburetor models allow you to tune them without disassembling them.

For proper operation of the device, the diameter of the main jet is important. It is selected based on motor power and diffuser size. When tuning, the nozzle hole can be enlarged.

Idling - principle of operation

If you need to start the scooter after a long period of inactivity or when it is cold, adjust the carburetor idle jet. This is necessary in order to enrich the mixture with oxygen at startup. As a result of correct adjustment, the engine will idle smoothly and stop stalling.

The system has a special valve that, at the right time, blocks the possibility of mixing fuel and air. In order for the engine to stop stalling, we make adjustments with the quality screw, adjusting the idle speed to the desired value. The adjustment screw is located on the side and is accessible while the engine is running. There is no need to disassemble anything, just carefully turn it with a screwdriver to the left or right. As a result, the speed will rise or fall.

If the quality of the mixture is insufficient, we achieve maximum idle speed. When the engine warms up, it will be enough to reduce the speed again to normal.

Carburetor structure

It is worth noting that the location of the carburetor is also different in different scooter models. Therefore, before you start adjusting it, you need to thoroughly study all the components and assemblies of your vehicle, their characteristics and location. The structure, in contrast to the location, of the carburetor is approximately the same.

The carburetor includes the following components:

- Venturi tube;

- valve with needle;

- float chamber;

- idle system;

- starting enrichment;

- spool;

- accelerator pump.

Venturi tube

So, the first element of the carburetor, called the Venturi tube, plays the most important role in its operation. This part is characterized by a diameter that varies throughout the entire length of the tube. This is due to the fact that it narrows towards the center, after which expansion follows again. It is the narrowest point of the tube that is intended for the air flow to pass through it.

The characteristic narrowing of the tube contributes to the formation of low air pressure, which is aligned to the point of expansion of the tube. If another smaller tube with gasoline is placed inside this tube, then the gasoline, on its way to the low-pressure zone, will begin to leave the small tube, spraying and evaporating, interacting with the air flow inside the large tube.

Flap with needle

The valve with the needle is installed directly in the center of the Venturi tube described above. It is necessary in order to regulate the amount of mixture that enters the combustion chamber. This adjustment is carried out by pressing the gas. However, the damper cannot operate without a needle. It is this that determines the volume of fuel entering the engine. So, when the pilot presses on the gas, the damper begins to move, thereby raising the needle, due to which the required amount of gasoline is supplied. In a word, the harder you press on the accelerator pedal, the more the damper opens, and, accordingly, the more fuel enters the combustion chamber.

Float chamber

To prevent the engine from stalling, it must be constantly supplied with fuel, a certain amount of which must be in the tube. For this purpose, a float chamber was invented, the operation of which is carried out on the principle of a toilet tank. Those. There is a float inside the chamber that moves to its lower part immediately after the gasoline level in the tube drops. Thus, the displacement of the float ensures the opening of a special valve through which fuel enters. After filling, the float rises, thereby closing the valve. This ensures a continuous and correct supply of fuel.

Idle system

The idle system in the carburetor is responsible for idling. However, its work is carried out not only at idle, but also at low speeds. In the case of idle speed, fuel is supplied through another channel of the carburetor, which is located behind the limiter. The idle system consists of:

Screw system

It is responsible for the volume of air that passes through the entire system, thereby regulating the quality of the mixture entering the combustion chamber. By tightening and unscrewing this screw, the pilot can adjust the amount of air. Accordingly, the less air volume enters the system, the tighter the screw is tightened, and vice versa. It turns out that when there is a lot of air, the fuel is leaner, when there is little, it is richer, since it contains more gasoline than air.

Special channel

The fuel mixture leaves the carburetor through it. This channel is closed by a special valve at the moment when the carburetor throttle valve opens

The valve is an important part because it prevents the system from negatively affecting the operation of the scooter's power unit at high speeds

Jet

Responsible for configuration.

It is worth noting that the carburetor idle system is its most vulnerable part. In this regard, faulty jets with a small cross-section are often the cause of carburetor malfunction. This is due to the fact that they are prone to clogging very quickly.

Thus, knowing the structure and principle of operation of the carburetor, you can begin to adjust it.

Why adjust the carburetor?

Carburetor adjustment may be required in the following cases:

- The spark plugs are serviceable, but do not work very well; their color has changed to black or yellowish.

- The engine does not provide the required power

- Scooter won't start

- Fuel consumption has increased excessively.

All these problems in most cases are caused by an insufficiently enriched or, conversely, overly enriched mixture with oxygen, and they can be corrected by correctly adjusting the carburetor.

The settings, regardless of whether you have a 2t or 4t scooter, have three phases and are made as follows:

- Idle speed adjustment

- Setting the fuel level

- Adjusting the quality of the mixture.

On some carburetor models there is no screw that adjusts the fuel quality, so you have to disassemble the carburetor to change the position of the needle.

The idle speed adjustment is carried out after the engine has warmed up: this takes no more than 15 minutes. For this purpose, the design provides an idle screw. It allows you to make the engine stable by selecting the desired idle speed. When the screw is tightened, the speed will increase, and when it is rotated counterclockwise, it will decrease.

It is important to adjust the quality of the mixture. If it is too lean, the scooter will ride with difficulty, and the engine will noticeably lack power. If the mixture is too rich, the spark plugs will turn black and quickly fail. Fuel quality adjustment is usually carried out using a screw located on the carburetor body. To enrich it you need to turn it clockwise, to lean it counterclockwise. If there is no screw, the carburetor is opened, the locking ring on the needle moves up for a richer mixture, down for a leaner one.

Adjustments are made as follows:

- Start the engine and warm it up for 10 minutes, after which you need to turn it off

- The screw must be tightened clockwise until it stops, but without force.

- After this, it is unscrewed counterclockwise 1.5 turns

- The engine needs to be started and the screw turned an additional 1/3 turn in the same direction. Wait 2 minutes

- As the speed increases, you need to unscrew the screw an additional 1/4 turn and observe the reaction for about 2 minutes. If the speed does not drop, repeat the steps

- If the speed begins to decrease, the screw must be turned clockwise 1/4 turn.

Ideally, the engine will operate exactly at 1.5-2 propeller revolutions, but its position depends on the quality of the fuel. In the case of a needle, the quality of the mixture will vary depending on the position of the needle locking ring. The disadvantage of such a carburetor is the small number of needle positions and the need to disassemble it each time to make adjustments.

You can adjust the fuel level in the chamber as follows:

- Unscrew the drain screw

- The phone is lifted up

- You need to check the fuel level while the engine is running. The melting level is slightly below the skirt located on the float chamber cover

- Most often, the level rises above normal and the carburetor overflows, so you need to adjust the float so that it fires earlier. To do this, the needle holder is usually bent. A lot of force is not required, only a few mm are needed.

How to adjust the carburetor on a scooter yourself

139Qmb manual russian

Its adjustment begins with maintenance:

- the device must be removed, purged and cleaned of contaminants, the channels and jets are recommended to be washed with gasoline, and any remaining contaminants must be removed by blowing with compressed air;

- if the rubber pipe has already “acquired” cracks, then they can be covered with sealant;

- all contamination of the air filter should be removed or replaced with a new one;

- the exhaust system must be inspected and cleaned;

- Assemble the cleaned device and install it in place.

The performance of a scooter engine largely depends on the quality of the fuel mixture. The engine overheats, operates incorrectly and loses power with a lean mixture, while a rich mixture provokes excessive fuel consumption, carbon deposits and fuel overflow. You can check the operation of the carburetor by the color of the removed spark plug - if it is black, this indicates that the fuel mixture used is too rich, and white indicates a lean mixture; their quality will have to be adjusted during tuning. The brown color of the spark plug indicates normal fuel quality; in this case, the mechanism does not need adjustment.

To adjust you need:

- Screw the fuel mixture quality bolt (FMC) first all the way, then unscrew it up to 0.5 turns, while the idle speed is set to the middle position;

- start the scooter - if the equipment does not start or the speed is low or high, then increase it (at low speed) or reduce it (at high speed) by setting the idle speed;

- gradually unscrew the KTS bolt until the engine reaches maximum idle speed and tighten it again by 0.25-0.5 turns;

- start the engine and drive - if there are interruptions and dips when starting to move, then you need to tighten the KTS bolt again by 0.25 turns.

When the bolt is turned clockwise, the mixture becomes richer, and when turned counterclockwise, it becomes leaner. If excessive fuel consumption is detected, the spool needle moves down one notch and the adjustment is carried out from the very beginning. If there is a shortage of fuel, on the contrary, the needle moves up one notch and the adjustment procedure is repeated again.

Correctly configured operation of the engine system of any vehicle should ensure smooth operation, without jerks or dips. A specialist will tell you how to most accurately adjust the carburetor on your scooter, however, we hope that our recommendations will help you cope with this simple job yourself.

Design and connection of a Yamaha scooter carburetor

The Yamaha Jog scooter is one of the most popular on the Russian market: this is explained by the simplicity and reliability of the model, and its affordable price. The carburetor design of this scooter is standard, so you can figure it out using the description given above. However, when installing it, inexperienced owners may encounter some difficulties, which we will help you sort out.

The device is worth considering in more detail. This will help you understand not only how to adjust the carburetor and use it correctly, but also how to connect it correctly.

- A starter enricher is attached to the carburetor body: it is small in size and housed in a plastic case. It has two bolts with rubber seals. The enricher is powered via a 12 V battery. This device is used to start the engine when cold, as it allows you to automatically enrich the mixture with oxygen.

- The fitting is connected to the fuel supply hose coming from the gas tank tap.

- If the enrichment unit needs to be removed, you will need to not only unscrew the bolts, but also disconnect the electric valve, to which there are only two wires.

- The mixing chamber has a special cover to which a bolt is attached. If you unscrew it, you can get to the throttle valve. This allows you to check whether the throttle cable is connected, and also to get to the needle that regulates the level of fuel and air supply. If the carburetor needs cleaning, you will definitely need to remove the throttle.

- The enrichment connector has two wire outputs, the yellow one is connected to the generator, the green one goes to ground. In principle, if you reverse the polarity, nothing will happen and the device will still work.

- For the enricher to operate, voltage must come from the battery. When the element inside the device heats up, the needle will extend.

- A special fitting is connected to the air filter, and there is a rubber elbow between them.

- There are several screws on the carburetor body with which you can adjust the idle speed and mixture quality.

- The float chamber is screwed from below and has 4 mounting bolts.

- There is an additional fitting for oil supply: it is the smallest.

- The second fitting is needed for communication with the atmosphere; you do not need to put anything on it.

- The third one is connected to a gas hose. It goes to the gas tank vacuum valve.

Carburetor block maintenance

The carburetor on a scooter may need to replace the diaphragm. In some cases, it is also necessary to completely replace one of the elements of the block. The internal metal surface of the device may oxidize over time. Therefore, the diaphragm will need to be replaced. It is removed very carefully using a screwdriver.

This element can be obtained with a dosing needle and a flap. Then, if necessary, the old components can be replaced.

After this, you need to unscrew the screws of the float chamber. Its cover is removed. You can evaluate the operation of the float by lightly pressing it. If this element springs, then its operation is correct. No replacement required. When disassembling, it is very important to use the correct size screwdrivers. All work must be carried out very carefully.

Carburetor design (video)

For clarity, we suggest watching a video instruction about the design of carburetors and the principle of their operation:

Knowing the structure of the carburetor and understanding what needs to be connected where, you can easily disassemble, reassemble, clean and adjust it yourself, regardless of what brand and model of scooter you have, with some skill. All these procedures will not take much time and will help you save money on car services. The ability to carry them out will help you out when the engine does not want to start.

Adjusting the carburetor on a 2t scooter: setting it up together

We continue to discuss DIY motorcycle repairs.

The carburetor has been cleaned, the next step is to adjust the carburetor of the 2t scooter. Over the summer, you have to adjust and adjust the operation of the engine several times.

Anyone who is at least a little familiar with the structure of the carburetor will be able to set it up on their equipment themselves. On 2-stroke engines, carburetors are adjusted according to the same principle. Therefore, the topic will be of interest to owners of any brand of 2t 50cc scooters. Whether you have a Honda Dio 27, 34, 35, stroke, Yamaha Jog, BVS or other 2-stroke mopeds.

Idle speed adjustment

After proper cleaning, the idle speed is adjusted. To do this, the engine must be warmed up well. To do this, you will need to start the vehicle and wait 10-15 minutes.

Next, you should refer to the manufacturer's instructions. It shows where the adjustment screws are located. Guided by this knowledge, you can begin the process. It is better to mark the screwdriver with which all settings will be made. You need to stick a marker on one side of it. This will allow you to understand how many revolutions were made.

At idle speed it is necessary to tighten the corresponding screw. If you clamp it, the speed will increase, and vice versa. The adjustment is performed until stable engine idle operation is achieved.

Diagnostics

Before installing the air filter, turn on the ignition and jerk the kickstarter foot several times until the engine starts.

If it does not start, then the most common reason is that the cold start system is malfunctioning.

We check this way: cover the carburetor hole with your fingers to maximally enrich the mixture with gasoline, and continue to push the kickstarter.

If the engine starts and the speed does not drop during operation, then look for the reason in the cold start system.

If the cold start system is working properly, then after starting the engine the speed will rise and gradually, within 10 minutes, begin to fall. On a warm engine, gradually unscrew the large screw (amount of mixture) until the speed drops to medium, confident idle.

At the same time, drops of gasoline should not splash or pour out of the carburetor.

If gasoline splashes out of the air supply hole, this indicates a malfunction of the reed valve in the engine. Then the valve needs to be removed and cleaned or replaced with a new one.

And if gasoline leaks out, this indicates a high level of gasoline. Adjust the float level and ensure the needle valve is sealed.

The need for carburetor maintenance

If you have a Honda, Kwasaki, Navigator or other two-wheeled motor vehicle, you should understand the importance of periodic carburetor maintenance. The power, ease of starting, speed and control of the motorcycle depend on this system.

To ensure that the same quality fuel mixture is supplied to the cylinder block, it is necessary to correctly regulate the operation of the carburetor. Synchronization allows you to adjust the amount of gasoline and air that mix and flow to the engine.

Experienced drivers know that the carburetor on a scooter must not only be adjusted, but also cleaned during maintenance. Gasoline contains a certain amount of additives and impurities. When the engine operates, they settle on the walls of the system, forming contamination in the jets. To ensure that the carburetor can perform its functions fully, it is necessary to periodically clean it from dirt and carbon deposits accumulated inside.

Intermediate setup

Adjusting the carburetor of a 2t scooter is carried out after installing the air filter in its place.

Start the engine and let it run for about five minutes to warm up.

Adjust the idle speed (ISR) with the quantity screw: by tightening it, the throttle rises and the idle speed increases; and when unscrewing, the throttle is lowered and the CO is reduced.

Set the speed so that the scooter operates at a lower speed.

Carburetor assembly

After proper cleaning and replacement of all obsolete parts, the carburetor is installed in its previous position. Assembly is performed in reverse order. When installing diaphragms, the return spring must be installed correctly in the seat. If you can’t easily install it in place, you just need to turn the part.

When installing the damper, you must monitor the position of the needle. It should not move to the side. If necessary, parts must be lubricated with grease.

The cylinder block is then assembled in reverse order. To do this you will need to prepare the appropriate tool. All carburetors are different. Therefore, when disassembling it is necessary to number them. Installing a carburetor requires careful attention. All bolts and springs must be assembled very carefully. It is better to write down the sequence during disassembly so as not to lose a single structural element.

Lifehacks for the last time

- — Before adjusting, you need to check that the air filter is clean and soaked in engine oil. How to clean the air filter, read the article: Scooter maintenance.

- — If the rubber cuff on the quality screw is torn, then it can be replaced with a cuff from the quality screw of the classic Lada carburetor.

- — On Suzuki Sepia models, lets 2,

In the latest models of Honda Dio 34 everything is simpler. The carburetor has only one large screw, which is used to regulate the XO. The small one on dio 34 is located under the plug.

The first time the setup will take 15 - 20 minutes, and then everything will be automatic. Feel free to get down to business and share your experience in the comments.

Subscribe and see you for new articles!

Scooter carburetor. Correct adjustment

The carburetor is a unit whose importance cannot be overestimated. Since it is in the carburetor that gasoline is mixed with air and, thus, a fuel mixture is formed before it is directly supplied to the scooter cylinder. The quality and correct composition of the fuel mixture determines fuel consumption, wear of the cylinder-piston group and spark plugs, maximum speed and dynamics of the scooter, and much more. This is why it is so important to take a responsible and comprehensive approach to setting up the carburetor. A properly adjusted carburetor will ensure stable, reliable and productive engine operation, as well as make driving comfortable and safe.

Unfortunately, scooter riders often, due to ignorance or lack of experience, underestimate the importance of comprehensive carburetor tuning. For example, there is an extremely widespread misconception that adjusting the degree of richness of the mixture only means adjusting the quality screw on the carburetor. In fact, this setting allows you to achieve the correct mixture only at idle and low speeds. At the same time, at medium and high speeds the proportions of the fuel mixture can be completely disrupted. Let's figure out how to properly configure the carburetor.

Adjustment

The carburetor of a scooter can be located in different places. It depends, first of all, on the brand of the scooter. For example, on the Honda Dio-35 this element is located on the left side, closer to the rear wheel. A throttle cable and a fuel hose lead to it. Everything is clearly visible and you won’t have to look for the carburetor for long.

Adjusting the scooter carburetor is necessary in the following cases:

- The engine does not start or it takes a long time to start;

- The equipment loses its former dynamics and acceleration;

- With unstable idle;

- When the scooter engine speed is too high;

- With increased fuel consumption;

- When black smoke appears from the muffler.

The adjustment should be made with the engine warm. But before starting it, it is recommended to rinse and thoroughly clean the carburetor. First of all, the idle speed is adjusted, then the mixture quality is adjusted and the fuel level is adjusted.

The idle speed is adjusted using a screw. This adjustment will come in handy if the scooter has been sitting idle for a long time. After it, the carburetor will seem to gain a new life.

- If you need to increase the speed, the screw must be tightened.

- To reduce the speed, unscrew it.

We remind you that the adjustment is carried out after warming up the engine for at least ten minutes!

Adjusting the mixture quality

Adjusting the quality of the mixture is also very important. It is recommended to always adjust it according to the factory proportions. If the mixture is too lean, the scooter will often overheat and lose power and dynamics. On the contrary, if the mixture is too rich, fuel consumption will increase and carbon deposits will accumulate in the chamber more often.

This parameter is adjusted using a special screw or by moving the needle in the throttle valve. Often adjustment is carried out in the second way, since the screw responsible for this parameter may be damaged or simply missing in this model.

- Clockwise ? the mixture becomes richer.

- Counter-clockwise ? depleted.

In the case of a needle:

- Does the needle rise? enriches itself.

- Does the needle go down? depleted.

The most noticeable results can be achieved by combining these two adjustment methods.

Again, before making adjustments, the scooter engine must be warmed up for several minutes, and the carburetor must be clean inside.

The quality of the mixture is correctly adjusted in the following cases:

- The scooter began to accelerate smoothly;

- While driving, there are no failures in engine operation;

- There are no jerks;

How to find out the degree of enrichment of a mixture using a candle

- What if the scooter's spark plug is black and has a lot of carbon on it? mixture is too rich.

- If the spark plug of the scooter is white and looks like it’s brand new? mixture is too lean.

Level setting

The fuel level is adjusted after checking. At the very bottom of the scooter carburetor there is a transparent tube, by which you can determine the level.

- Unscrew the butter screw;

- We lift the handset up;

- Checking the level;

- If the level is just below the carburetor cap curb, everything is fine.

- If not, then adjustments are made: The cover is removed;

- The tendril of the needle, which acts as a locking mechanism, is bent. This type of tuning must be done in very small ranges.

Let us remind you once again that the carburetor must be clean during adjustment. It is necessary to fill only with fuel with the octane number recommended by the manufacturer, and the jets and other parts must be standard, and not homemade or removed from the carburetor of another scooter.

https://youtube.com/watch?v=a0rMb8efxkM

Scooter carburetor - design and principle of operation - Scooters Maintenance and repair

Before you start making adjustments, you need to warm up the engine, and if there is contamination, the carburetor should be cleaned.

Carburetor settings

It's like another miniature carburetor in the main carburetor.

Honda Dio 27 does not hold xx installed a new carburetor, when it is started it is necessary to constantly The device and ...

Scooters of the Tact family are designed for novice drivers.

Float chamber It is important that the fuel in the float chamber is always within certain limits and does not drop below the permissible norm.

We tried to start it, but the result was the same.. Still, I think that I’ll go buy the enricher tomorrow, because when disassembling this unit I also discovered that the needle itself does not hold in the latches inside, one of the 3 latches is broken, and the wiring is broken, it cannot be repaired. There is only a big plus from RACING around equipment - broken and torn bolts are changed in parallel, brake pads are replaced and so on. If they had started the scooter right away, then they definitely wouldn’t have gotten around to it until the fall Reply Reply with a quote Quote Report to moderator 0 Alexey82ua After capitalization on a Honda tact fullmark, gasoline flows from the carb from the lower tube, and not from the tube where the drain screw.

It completely refuses to start, and if it does start, you have to squeeze the gas all the way down, as if it was missing something.

The principle of idle operation is very similar to the main one. This is a kind of miniature carburetor within a carburetor. It is needed for idle speed, which prevents the scooter engine from stopping during a temporary stop when you do not turn off the engine.

When is maintenance required?

The carburetor (Keihin PZ30, CVK - it doesn’t matter) of all popular models has a similar maintenance principle. Therefore, the signs of the need for this procedure in all cases will be similar symptoms.

The main reason requiring carburetor adjustment is uneven engine operation. It appears at idle. Popping noises coming from the muffler and increased gas consumption may also appear. The driver should periodically pay attention to the appearance of the spark plugs. Significant changes in their color indicate violations in the preparation of the fuel mixture.

Candles can be considered the main indicator of carburetor performance. If they are white, the mixture is considered poor. Too much carbon deposits on the candles indicate that a rich mixture is being prepared. This is a deviation from the norm. The cause may be a carburetor clogged with dirt or a malfunction in its settings. In this case, maintenance is carried out as soon as possible. The system should also be cleaned periodically. It depends on how often the motorcycle is used.

My account

You should monitor the tread height of your tires and replace them as necessary. Riding a scooter with worn tire tread is extremely unsafe.

The turn should be done “pull”, controlling the gas or releasing it in advance. Always turn on low beam headlights when riding a scooter.

Float chamber It is important that the fuel in the float chamber is always within certain limits and does not drop below the permissible norm. It is also important that gasoline does not rise above the permissible standards - this will help to avoid overfilling.

Actually, the float, which on the opposite side has a shut-off needle at its disposal, is responsible for the optimal level of fuel in the float chamber. Gasoline filling the chamber raises the float as it enters, which is constantly afloat.

cleaning the carburetor Honda Dio 27

When it reaches its maximum fulcrum, it closes the channel through which gasoline is directed from the gas tank to the carburetor. This is how the stable presence of a small amount of gasoline in the float chamber is regulated.

These are probably all the main systems of the Honda Dio 27 carburetor, so once you understand the operation of this device, it will not be difficult for you to put your scooter in order using the instructions in the manual.

Adjusting the fuel level in the float chamber.

How to clean a carburetor with your own hands

You can check the fuel level in the float chamber using a transparent tube located at the very bottom of the carburetor. Unscrew the butter screw,

lift the tube up opposite the carburetor and check the fuel level

Please note that the fuel level must be checked with the scooter engine running, and the tube should always be located above the carburetor. The fuel level should be just below the cap curb

If there is little, or usually a lot, remove the cover and adjust the moment of operation of the locking needle by bending the needle holder in very small ranges.

It should be noted if the carburetor has not been washed for a long time and there are signs of contamination of its channels and jets, if gasoline has been or is being filled with an octane rating lower than that recommended by the manufacturer (for example, A-80), if the installed jets and other parts do not correspond to those recommended by the factory parameters, then before adjusting the carburetor you need to eliminate all this, since further adjustment will only be temporary and you will not achieve the desired result.

What is a starting enrichment

A starting enricher (electrovalve) is a device designed to supply an additional amount of air-fuel mixture into the combustion chamber during a cold start of the scooter engine. The fact is that when starting the scooter when cold, the engine requires an enriched mixture. The supply of such a mixture is ensured by the carburetor solenoid valve . If the starting enrichment is in good working order and there are no breakdowns in other engine elements, the scooter engine starts easily even at temperatures around zero degrees.

Scooter starting enrichment device

There are two types of starting concentrators - manual and automatic.

The manual (mechanical) starting enrichment requires adjustment - it must be opened at startup and closed after the engine warms up using a cable on the steering wheel. But manually opening and closing the additional channel for supplying the mixture is inconvenient. An automatic starting enricher (thermoelectric valve) is installed on most modern 2t and 4t scooters. We will learn about the device of the automatic starting enrichment further.

Solenoid valve body- Ceramic heater

- Drive (powder)

- Stock

- Pusher

- Damper

- Fuel chamber

- Float chamber

- Starting fuel jet

- Spring

The scooter carburetor has a small additional fuel chamber 7, which is connected to the main float chamber 8 through the start nozzle 9. The tube from chamber 7 leads to the mixing chamber into which air is supplied and from which the air-gasoline mixture goes into the engine. A valve 6 can move in the mixing chamber, similar to a carburetor throttle valve, only much smaller in size. Just like the throttle valve, the starting valve contains a spring-loaded needle that closes the fuel channel when the valve is lowered. Valve body 1 is wrapped in thermal insulation (polyethylene foam) and covered with a rubber boot. This enricher design is used on almost all modern scooters.

Older models may use a design without an electric heater, heat is transferred to the drive through a copper heat-conducting cylinder directly from the scooter's engine cylinder, and a membrane . One cavity of the flask, where it is located, is connected through a thermal valve to the intake manifold, which is mounted on the cylinder head.

What determines the cost of a carburetor?

First of all, this is the engine volume, its cubic capacity. Different scooters have different motors, which means they need a certain “portion” of mixture to work correctly. But for some models this is one volume, and for others it is completely different. It is for this reason that modern scooters are divided into the following categories: 50 cubic centimeters, 110, 125, 150, 170, 180, 600 - maxi scooters.

For example, a new carburetor for an engine with a volume of 110 cc costs 980 rubles , for a 50 cc engine - 890 rubles .

The second factor that influences the final assessment of the cost of a given element is the scooter manufacturer , that is, its brand. As you know, scooters are produced in different countries, which means the cost of their maintenance will be completely different. A carburetor for a Chinese scooter will be much cheaper than for a Japanese one.

The third reason that determines the price tag is the carburetor manufacturer. Today in the world there are a huge number of firms and companies that manufacture spare parts for equipment that they do not produce. The leading positions in the spare parts market are the following three:

- Teikei.

- Mikuni.

- Keihin.

The carburetors manufactured by them are suitable for all brands of two-wheeled vehicles, which were discussed above.

The fourth reason that affects the price is the year of manufacture of the model. It’s clear here that the newer the scooter, the more expensive the spare parts for it. The older it is, the cheaper the repair costs.

The principle of operation of the scooter carburetor solenoid valve

When the engine is cold, the valve with the spool needle 6 is raised as high as possible (open). The needle opens the fuel supply channel, and the flap opens the air supply hole. At the first engine revolutions, a vacuum is created in the emulsion channel and gasoline located in chamber 7 is sucked into the engine through channel A, causing a strong enrichment of the mixture and facilitating the first flashes in the engine. After the engine has started, but has not yet warmed up, it still needs a rich mixture. The enricher works like a parallel carburetor - gasoline enters it through jet 9, mixes with air and enters the engine.

When the engine is running, alternating current from its generator is always supplied to the contacts of the ceramic heater 2 of the thermoelectric valve of the starting system. Heater 2 warms up drive 3. As the engine and drive warm up, the rod gradually extends by 3 ... 4 mm and drives the damper through pusher 5. Thus, the engine warms up along with the thermoelectric valve, the spool with the needle drops and closes the air and fuel channels, and the mixture gradually becomes leaner. After 3...5 minutes, the damper closes completely and the degree of enrichment of the mixture on a hot engine is regulated only by the carburetor idle system .

When the engine stops heating of the valve stops , the damper drive cools down (the powder is compressed) and under the action of spring 10, pusher 5, rod 4 and damper 6 return to their original position, opening the channels for subsequent start-up. Cooling down and returning to its original position also occurs within a few minutes.

The disadvantage of this type of enrichment is that it operates separately from the engine. For example, very often, especially in warm weather, while the engine is still hot and there is no need to enrich the mixture, the thermoelement is already cooling down. We start the engine and it gets a rich mixture.

Operating principle of the second type of starting enrichment (with a membrane)

When cold, the valve is open . After starting the engine, a vacuum occurs in the manifold and is supplied to the membrane through a thermal valve. As a result of low pressure, the membrane rises and opens a channel for additional air supply. As the cylinder head warms up, the valve closes and the valve with the needle is lowered under the action of a spring, cutting off the additional fuel supply.

With this design principle, the connection with the actual engine temperature is maintained, and fuel dosage is carried out more correctly.

Carburetor setting 139qmb

The mixture prepared by the carburetor, depending on the ratio of gasoline and air, can be rich, enriched, normal, lean and lean. I listed them in descending order of the percentage of gasoline (that is, a lean mixture contains the least gasoline and the most air). The engine cannot operate normally on rich and lean mixtures - they are too far from the optimum. The mixture with the maximum amount of gasoline on which the engine can still operate without interruption is called enriched. Accordingly, with a minimum - depleted. The middle between them is conventionally considered normal. Notice the nuance? The composition of the mixture is not tied to numbers - so many grams of gasoline per liter of air, but to the operation of the engine. That is, this is to some extent a relative parameter. For example, a mixture that is rich for a cold engine will become rich for a hot engine.

The composition of the mixture, logically (well, since it consists of gasoline and air), can be adjusted either by changing the amount of gasoline supplied or the amount of air sucked in. But to achieve maximum power, you need to give the engine the opportunity to suck in as much air as possible, and to match this amount, select such a proportion of gasoline so that the mixture turns out to be normal or slightly enriched.

There is a proboscis on the front of the filter cover through which air is sucked in. And at its end there is a plug with four holes. It was needed for the break-in period, and after the break-in is completed, it can be removed. We pull it out. The next thing that is in the way of air entering the engine is a foam filter. You can't remove it, but you can reduce the resistance. To do this, you need to wash it in a certain way. We prepare a mixture of motor oil and gasoline in a ratio of 1:10, wash the filter in this mixture, then squeeze it forcefully in your fist without twisting it, put it in to dry for about five minutes (not in the sun), then put it back. With this method of washing, the filter has low resistance and at the same time retains sufficient filtering properties. We increased the amount of air. Now we need to increase the amount of gasoline.

It is adjusted by a needle on the air damper (spool). The higher the needle is raised, the more gasoline. The needle rises with the spool, and its position relative to the spool can also be changed. The spool is located under a plastic cover in the center of the carburetor, the needle is inserted into a hole in the bottom of the spool, it can be removed with tweezers. But first, the lid. In its center there is a protrusion (pin) on which the spool spring is fixed. But with such a length (about 20mm), it also makes it difficult to lift the spool all the way up, which is quite justified during break-in and is completely unnecessary after it. To fix the spring, 6 - 7 mm is enough. We bite off the excess. The photo shows the cover with a pin up to

And here she is after:

Now nothing prevents the spool from rising to its maximum limit.

The last object of adjustment is the needle. In the carburetor of GX scooters, it does not have adjusting grooves, so it can be raised by putting on washers of appropriate thickness, for example from M2.5 fasteners. The maximum by how much it makes sense to raise it is 1.5 mm, in increments of approximately 0.25 mm.

The photo shows a needle with two textolite washers of approximately 0.5 mm each:

Now you can move on to fine tuning. To begin with, place a 0.5mm washer under the needle stop, assemble, and close the carburetor

and start it up. Let's warm up. If the engine runs smoothly, but when accelerating it changes its tone to a hoarse tone (dr-dr-dr instead of oo-oo-oo, this is working through a stroke) - the mixture is rich, you need to lower the needle, that is, put a thinner washer. To clarify, insert a plug into the proboscis. It got even worse - as if the mixture was rich. And if the engine operates with dips, especially noticeable at high speeds, and after the dip there is often a jerk (oo-oo-bu-bubu-oo!) - the mixture is poor. Let’s clarify again with the plug: it’s better with her - just like she’s poor. Raise the needle. Finally we find a position in which there are no symptoms of either a rich or lean mixture.

And the last thing is idle speed adjustment. This is done on a warm engine. We start it, release the gas and use the quality screw (it’s on the side, see the last photo of the article) to achieve the maximum increase in speed. Then use the quantity screw to reduce the speed to the minimum stable and again

we use the quality screw to raise them to the limit (in principle, this second iteration may not be needed). That's it, the carburetor adjustment is complete. You can go for a ride. You will see that your dynamics have improved and your maximum speed has increased by 3 or even 5 km/h.