Main breakdowns and methods for solving them

On scooters, the electric starter often fails. Of course, Kickstarter can help out, but it’s not very convenient to use. The engine may not start due to a faulty battery: the contacts have come loose, the charge has run out, the device is worn out. If there is no spinning sound when the starter turns on, then the problem is in the battery. If you can’t charge it, it means it’s out of order, worn out and you’ll have to install a new one.

If pressing “Start” does not produce a click in the electric starter relay, the problem is more serious. The unit may be faulty and needs to be replaced. The problem can arise when various components wear out. Most often they need to be replaced.

You can fix some scooter problems yourself

Electric starter does not work

If the scooter does not start from the foot, then its operation is impaired. If the electrical circuit is working properly, but the relay clicks when you press “Start,” then the problem is a bad contact or a broken starter.

To evaluate its performance, you need to apply voltage to it without activating the relay. If the electric starter does not turn, then it needs to be replaced.

Starter relay failure

The relay maintains the voltage at the required level for further distribution to headlights, dashboard indicators and other elements. Its durability depends on the battery. If the voltage in the generator increases or decreases, the relay is faulty. Because of this, the starter does not start. In this case, the relay needs to be replaced.

Problems with the button

When the Start button is pressed, the starter rotates and drives the engine gears. If the scooter does not start with the electric starter button, there is a malfunction. The wiring in the engine starting system could have come loose. If the scooter starts from the foot, but not from the “Start” button, then the fuse is faulty: the voltage in the generator drops, so the button does not work.

To check the functionality of the fuse, you need to measure the voltage at the battery terminals and in the fuse. If losses are detected, a new fuse must be installed. After replacing the part, the moped will start from the “Start” button.

If the scooter breaks down, the electric starter may not work.

Broken brake contact (toad)

The brake system needs regular inspections, as driving safety depends on it. A breakdown of any other scooter system is easy to identify, since engine operation is disrupted. Brake failure can only be detected by diagnosing the vehicle. During the inspection, you need to check the integrity of all parts and the amount of brake fluid.

Replacing brake fluid is necessary every 8-11 months, depending on the intensity of use. In this case, you need to use the liquid recommended by the manufacturer. If the brake pads are worn down by 2 mm, they need to be replaced. Hoses need to be replaced if there are cracks or abrasions.

If system parts are worn out, brake contact is lost. Because of this, the engine will not start.

Contacts have come loose or oxidized

If the scooter does not start, the reason may be the contacts with the battery. It is necessary to check if they are charged. This must be done carefully to avoid electric shock. If there is no spark, you need to check the electronics. Most often the reason is oxidation of the terminals. When they become coated, the scooter does not start moving from the starter. You can clean the contacts with sandpaper or gasoline.

Contacts with the battery may be the reason if the scooter does not start

Bendix doesn't work

The starter fails due to careless handling of the bendix - the starter wire that engages with the engine flywheel and powers it. When the engine starts, a special mechanism with a relay pulls the bendix into the starter, stopping the engagement. Inexperienced drivers most often encounter Bendix breakdowns.

If in winter the engine does not start on the first try, they hold the "Start" button for a long time and spin the engine. The flywheel cannot rotate at the specified speed, causing the drive to jam. As a result, the starter overheats and the bendix fails. This may cause the starter housing to burst. Depending on the degree of damage, replacement of the bendix or the entire system is required.

The battery is dead or damaged

If the scooter refuses to move after starting the starter, you need to try starting it using the kickstarter. The battery may have run out. If you couldn't charge it, it means it's completely out of order.

Fuse blown

Due to damage to the power system, no current flows to the battery, so it does not charge. When the battery is charged, the engine stalls and does not start either with the kickstarter or the electric starter. The most common reason is that a fuse with a lower capacity than recommended by the manufacturer is installed. If the new fuse fails quickly, the electrical circuit is faulty. If a short circuit occurs, the wires need to be replaced.

Inexperienced drivers most often encounter bendix failure

Crankshaft seals are leaking

The front oil seal may leak after a mileage of more than 100 thousand km. In working condition, it fits tightly to the crankshaft. When the crankshaft beats, the inner surface of the oil seal cracks. Because of this, it cannot press tightly to the surface. Leakage can also occur due to the use of low-quality oil.

Another reason for the malfunction is related to engine failure. As pressure increases, crankcase gases create a gap in the oil seal through which oil flows out. The reason for leaking of the new oil seal may lie in the poor quality of the part itself or improper installation. If you bend the inner edge of the rubber when installing it, oil will flow out through it. In this case, the oil seal must be replaced.

If the rear oil seal leaks, oil can get onto the clutch disc and render it unusable. To replace it you will need to remove the box, clutch and flywheel.

Low compression

Compression in an engine is related to the mixing of fuel with air. The process is important for normal engine operation. A decrease in the indicator is very easy to determine: the engine does not start on the first try or does not start at all with low compression in all cylinders. Most often this occurs due to overheating or wear of the valves. Gases escape too quickly, causing compression to decrease.

The compression test takes about an hour. The indicator is measured by a compression meter. If low compression is detected, you need to check the condition of the cylinders, valves, gaskets and pistons. After replacing the damaged parts, compression will return to normal.

Old fuel

This problem occurs after winter. The tank is full of gasoline, but the electric starter does not start the engine. The reason is old gasoline. You need to drain it and fill the gas tank with new fuel.

No spark in spark plug

Diagnosing a breakdown is easy. You need to unscrew the spark plug, connect it to the ignition coil using a wire and place it on the cylinder. If there is no spark when the crankshaft rotates, the spark plug needs to be replaced.

Poor contact at battery terminals

Oxidation or poor terminal contact on the battery prevents the engine from starting. Diagnostics can be easily performed by visually inspecting the connection points between the terminals and the battery. If they are covered with a white coating, it means that the contact has been broken. It's easy to fix the situation. You need to remove the terminals and clean the deposits with sandpaper, then screw them onto the battery and cover the connection points with a special lubricant. If it is not there, you can use technical Vaseline.

Carburetor clogged

Difficulty starting the engine or failures in its operation occur when the carburetor becomes clogged.

To remove it, you need:

- unscrew the pipes;

- disconnect the terminals;

- remove the tube and drainage;

- remove the throttle cable;

- disassemble the carburetor assembly, clean it and put it back.

No compression

If the spark plug and battery are working fine, but the engine still won't start, then there is a compression problem. You need to check the pressure using a compression gauge. Lack of compression indicates a broken compressor ring. After replacing them, you can continue using the scooter. The procedure is quite complicated, so it is better to contact the service.

Cold weather

If the scooter stalls in the cold, it means that the spark plug cap or its connecting element is broken. It is necessary to unscrew the cap, bring the wire 3 mm to the motor element and rotate the crankshaft. In cold weather, a moped conducts current when a bare section of wire comes into contact with a metal element.

How does the starter work?

The design of the device is defined as a four-pole electric motor. Different car models have starters with engines of different power. The classic starter assembly consists of the following elements:

- The body, which, in essence, is an electric motor. It contains electromagnetic cores in a winding made of copper wire.

- The steel anchor to which the cores and commutator plates are attached.

- The starter retractor relay provides power to the device from the ignition. With the help of movable jumpers and electrical contacts, it also ensures the ejection of the bendix.

- Overrunning clutch or bendix. Through the meshing gear, it transmits the torsional moment to the flywheel.

- Brushes with their holders, which conduct voltage to the commutator plates, increasing starter power.

The assembly diagrams of starters of various models may differ slightly from the classic model. The main differences are in the methods of separating the gear. On cars with automatic transmission, starters have additional coils to prevent spontaneous engine starting.

Rules for operating a moped

The service life of a moped depends on maintenance. Care comes down to following the rules recommended by the manufacturer.

The main ones include:

- Testing a new scooter. The first concerns the running-in of a new scooter. The scooter must not be overloaded for the first 1000 km. When driving for a long time, you must stop every 30 minutes to prevent the engine from overheating.

- Correct use in winter. You need to drain the fuel before storing the scooter in the garage for the winter. Remaining fuel can destroy the tank and flood the carburetor. If you plan to use the scooter in winter, you need to change the fuel, check the battery charge, oil level, condition of the filters and tire pressure (it should be about 1.5 atmospheres).

- Correct use in summer. In hot weather, it is important to prevent the scooter from overheating. When driving for a long time at 30 degrees, the cylinders will be constantly overheated. This could cause the belt to break or the engine to break down. You should also not squeeze the throttle for too long, and when stopping, immediately turn off the engine.

- Use quality fuel. Gasoline must be at least 92. On a new moped, you need to change the oil for the first time after a run of 500 km. Subsequent replacement will be required every 1000 km. The first time to change the oil in the rear gearbox is after 200 km, then every 5000 km.

- Replacing the variator belt. This part is considered a consumable item, as it wears out quickly due to the high power load. If the moped stops squeezing out high speed, then the part and its components need to be replaced.

- Carburetor maintenance. The procedure includes a visual inspection for leaks and gasoline consumption levels, checking the condition of the connecting elements and the serviceability of the unit elements.

- Filtration quality control. The filter must be replaced promptly and impregnated with a special product after installation. This is necessary for high-quality air purification. Dirty air reduces the life of the motor.

If the electric starter on a scooter does not work, then there is always a kick starter that will help out.

But using a manual starter is not always convenient. Therefore, in this article we will find out why the starter on a scooter does not work. The electric starter is powered by a battery and passes through a special relay. Therefore, the first reason why the starter on a scooter does not work is the battery . It may have malfunctioned or simply run out of power. If you hear a spinning sound when starting the scooter through the electric starter, then the problem is with the battery. In this case, check the contact at the terminals . If it's not the contacts, it's the battery. If it is simply discharged, then it is enough to start the scooter with a manual starter and drive several tens of kilometers. This is enough to slightly charge the battery. If it still does not charge, then most likely it is faulty and needs to be replaced.

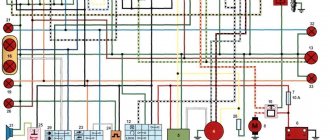

But if you hear the starter relay click when you press the starter button, then the problem will be more complicated. In this case, you can find out what the problem is by using the diagram:

Using this diagram, you can easily determine why the starter does not work on a scooter . This can be done quite quickly, since it does not require much effort and there are only a few things to check.

If you have any questions , leave them in the comments and you will receive an answer as soon as possible.

Now you know why the starter does not work on a scooter.

Starter working process

The whole process proceeds cyclically, the time period of passage is 3-4 seconds. The actions of one cycle can be divided into three stages:

- Connecting the gear to the flywheel;

- Direct start of the motor;

- Uncoupling the gear from the flywheel.

Immediately after turning the key in the ignition, electric current from the battery flows to the relay, setting the Bendix in motion. It engages the flywheel, which closes the circuit. As a result, voltage is supplied to the motor, increasing the rotor torque. Its transmission to the shaft of a car engine, through coupling with the flywheel, gradually increasing due to the ignition of several portions of the fuel mixture, leads to the final start of the engine. After this, the starter is turned off and will not be used for anything else.

Starters in cars with diesel and powerful engines are reinforced with gearboxes. This is an element with several gears that increases the voltage many times over. The use of gearboxes provides a number of advantages:

- increased efficiency;

- consumption of weak electric current;

- works even at very low battery levels.

Recently, hybrid starters with generators have gained widespread popularity.

The scooter does not start - the starter does not turn: causes and solutions to the problem

The driver of any vehicle may encounter a malfunction such as a non-working engine. The inability to start the power unit, in particular on mopeds and scooters, may be due to failure of the starter device. What to do if the scooter does not start, the starter does not turn - the main recommendations for diagnosing and repairing the mechanism are described in this article.

Features of the starter on a scooter and moped

First, let's analyze the structure of the mechanism. Structurally, this unit is quite simple in structure.

The starter is a DC electric motor, which consists of:

- permanent magnet;

- rotary device;

- collector;

- brush assembly;

- bearing;

- oil seal;

- as well as the housing in which all the constituent elements are enclosed.

Photo gallery “Location and device”

Principle of operation

The rotor mechanism is a cylindrical part, which is also called an armature. An insulated wire is wound on this element in a certain order, which forms several coils, and they are independent of each other. At the ends of these coils there are contacts connecting the device to the collector. Directly in the body itself there is a permanent magnet, or rather two, that go around the rotor device.

When the driver tries to start the engine, voltage from the battery is supplied to the power contacts of the unit, the brush assembly, and then through the contacts of one of the windings. As a result, a constant magnetic field is formed around the armature axis, which contributes to the appearance of direct current. This field will then interact with the field of the installed permanent magnets. The commutator element rotates, the next pair of contacts fits onto the brush assembly, as a result of which the rotor mechanism again deflects. This way the unit will work until the driver stops turning the starter.

Possible starter malfunctions: causes and symptoms

What malfunctions are typical for a moped starter:

- Worn brush assembly. This problem is usually associated with natural wear and tear of the mechanism, so it cannot be prevented. Brushes can also become stuck over time.

- Collector contamination. This problem can be caused either by wear or by engine fluid entering the mechanism housing, which can come out of the crankcase of the power unit. If the commutator element becomes dirty, this will not allow current to pass through the assembly to the winding contacts. The problem can be solved by dismantling and cleaning the parts.

- Short circuit of winding elements.

- Interturn closure. Such problems are solved by replacing the rotor device.

- Loss of contact between the winding output and the contacts of the collector component.

- Violation of the wiring insulation, which can also be associated with its burning (the author of the video is the Moto-Scooter fanat channel).

As for the signs of problems, symptoms of a unit malfunction can be indicated by the appearance of uncharacteristic noise during operation, a sharp decrease in engine speed, and overheating of the mechanism. If the disassembly and cleaning procedure does not produce results, most likely the reason lies in the windings. As stated above, they could burn out, be damaged, in particular, we are talking about a breakdown to ground, or simply short out.

Starter diagnostics before replacement

The mechanism can be checked without removing it from the motor. Find the power contact on the case, then disconnect the cable from it. The battery should be removed from the moped, but you must be sure that it is charged. You will need two pieces of copper cable, which should be thick - they are connected to the battery terminals on one side, and the other - the negative wire is connected to the mechanism body, and the positive wire to its power terminal.

Then the following should happen:

- If the device works, this indicates that it is working; accordingly, the cause of the malfunction will be in the relay, ignition switch or wiring that is connected to the device.

- If the mechanism does not start, this indicates its failure. As stated above, there may be several reasons, so the device will need to be dismantled and disassembled (the author of the video is Sanya Slesar).

DIY mechanism repair and replacement

How to dismantle and disassemble the starter:

- First, you should find the device - as a rule, it is located in the upper part of the power unit, immediately behind the cylinder. There is a power connection on the case; it should be disconnected.

- Next, unscrew the screws that secure the device to the power unit housing, and then remove it from the vehicle. If the device is equipped with a flange mount, then its screws will be located at the base of the case.

- After this, you need to unscrew the screws that secure both parts of the device’s body; their number may vary depending on the design features of the model. The shaft should be visible from the housing; it should be carefully clamped, and then, slowly, disconnect the halves.

- Having done this, you can remove the rotor element from the device body. Carefully inspect the condition of the commutator, as well as the brush assembly. If you notice that the first one is dirty, then you should clean it of dirt and then treat it with clean fuel. As for the brushes, worn components should also be removed and replaced with new ones. Before changing them, check their length - in optimal condition it should be at least 5-6 mm.

- All worn parts must be replaced. As stated above, problems with windings are usually not solved.

Features of checking the performance of elements of the starting system of a car engine

After visual inspection of the condition of the starting system parts, they begin to dismantle the starter to test its components:

- It is possible to determine how worn out the brush assembly is only after disassembling the starter housing. Despite the long service life of the brushes, they still wear out. At the same time, their development on some starter models does not allow the traction relay to be activated. In this case, the clicks it makes will not be heard.

- Burning of the windings on the coils can be easily determined both visually and by the presence of a burning smell. Since it makes no sense to restore their functionality, you will have to replace the starter.

- It is possible to perform a traction stress test without its housing. To do this, you need to close the two large terminals on the relay using a screwdriver, being careful not to catch the housing elements. The presence of problems with the retractor will be signaled by the beginning of shaft rotation. Note that one of the unpleasant consequences of this is the burning of the relay contact groups. Since they contain a special protective coating to prevent damage, it is not recommended to clean carbon deposits from them. In this case, only a complete replacement of the traction rod is indicated.

Why does the starter on a scooter not work?

If the electric starter on a scooter does not work, then there is always a kick starter that will help out. But using a manual starter is not always convenient. Therefore, in this article we will find out why the starter on a scooter does not work.

The electric starter is powered by a battery and passes through a special relay. Therefore, the first reason why the starter on a scooter does not work is the battery. It may have malfunctioned or simply run out of power. If you hear a spinning sound when starting the scooter through the electric starter, then the problem is with the battery. In this case, check the contact at the terminals. If it's not the contacts, it's the battery. If it is simply discharged, then it is enough to start the scooter with a manual starter and drive several tens of kilometers. This is enough to slightly charge the battery. If it still does not charge, then most likely it is faulty and needs to be replaced.

But if you hear the starter relay click when you press the starter button, then the problem will be more complicated. In this case, you can find out what the problem is by using the diagram:

Using this diagram, you can easily determine why the starter does not work on a scooter. This can be done quite quickly, since it does not require much effort and there are only a few things to check.

If you have any questions, leave them in the comments and you will receive an answer as soon as possible.

Now you know why the starter does not work on a scooter.

The starter turns hard

Forum rules MUST indicate the model, unit and symptoms of the malfunction in the topic title.

Heading form: [SCOOTER MODEL] – unit malfunction Example: [Dio] electric starter does not work.

If the topic concerns general repair issues, the model may not be specified.

The main rule is that the title of the topic should be brief, but as fully as possible reflect its content. Topics whose title does not indicate at least the approximate essence of the question, such as “AAA. Save!”, “I have a problem, tell me,” will be DELETED.

One of the problems motorists face on mopeds is a knocking sound in the engine. There are different types of knocking, but a knocking sound in the engine means that it definitely needs to be repaired.

Causes of engine knocking on a moped:

- The most harmless thing is that your valves are knocking. To check this, you will need (in the simplest version) a screwdriver; it is best to use a medical stroboscope or, well, or a professional one, if you have one. Next, take a screwdriver and apply the handle to your ear, and lean the other end against the engine. And so lean it against each part of the engine and you will be able to approximately position where you are knocking. Valve knocking differs from other knocking sounds in that it is more metallic. It feels like light pieces of metal are hitting each other. If the valves are knocking, the knocking will be louder on a cold engine than on a warm one. Typically, valve clearance decreases as it warms up, so the valves knock louder when cold.

- The timing chain may also be knocking. In lower engine engines, the timing chain cannot knock, because it is not there, there are pushers. They will also knock, but in this engine this is not a breakdown. The timing chain may be knocking because the timing chain tensioner is broken; if it is broken or worn out, the timing chain will start knocking. This is only checked when you disassemble the engine and check the chain. The timing chain can also stretch and the tensioner can no longer tension and the chain begins to knock. There is only one way to check this. Remove the tensioner, then you need to press on it, and if you understand that the chain does not tension when fully pressed, when the tensioner is fully recessed, then the chain definitely needs to be changed.

- The bearings may also be knocking. Bearings can knock in the basket, they can knock in the box. If you heard an engine knock on the right side, then if you depressed the clutch, the knocking stopped, and when you released it, the knocking started again. In this case, your release bearing has died or your clutch basket has simply weakened. Further, if the knocking occurs at idle, or when engaging any gear, then the bearings may be to blame. You will definitely have to disassemble the engine and see if you have worn out bearings, if the seal is broken and if the bearing is intact. If suddenly you experience a knocking noise only when you engage a certain gear, this means that you have a broken tooth on the gear, either a tooth or a hook. This is very bad, under no circumstances should you drive such an engine, because it could jam at one moment.

- The most unpleasant type of knocking that occurs on engines. If suddenly there is an oil starvation or you have driven a huge number of kilometers on this engine, then the crankshaft and connecting rod may lift up. How can one understand such a knock? The knocking sound will be as if throughout the entire engine, as if someone is hammering the crankcase with a hammer. A very sharp, loud sound that does not disappear at any speed. If you hear such a sound, turn off the engine immediately and do not try to continue driving. If your valves or timing chain are knocking, then you can drive to the garage and get it fixed; if the gearbox is knocking, then you can also get there, but it’s not advisable, and if the crankshaft is knocking, then stand still and don’t move.

- Bendix may also knock. When it is produced, it develops a slight imbalance. If you hear a knock from here, then you need to check the bendix.

- What else could a knock mean when you heard such dull knocks, but a grinding sound is added to them? If you heard that grinding and knocking and when you add gas they only intensify, then it means that the crankshaft bearings in your engine have fallen apart. Because in such engines the crankshaft lies in bearings. The main bearings are immediately replaceable.

The scooter does not start - the starter does not turn: causes and solutions to the problem

The driver of any vehicle may encounter a malfunction such as a non-working engine. The inability to start the power unit, in particular on mopeds and scooters, may be due to failure of the starter device. What to do if the scooter does not start, the starter does not turn - the main recommendations for diagnosing and repairing the mechanism are described in this article.

First, let's analyze the structure of the mechanism. Structurally, this unit is quite simple in structure.

The starter is a DC electric motor, which consists of:

- permanent magnet;

- rotary device;

- collector;

- brush assembly;

- bearing;

- oil seal;

- as well as the housing in which all the constituent elements are enclosed.

Photo gallery “Location and device”

Principle of operation

The rotor mechanism is a cylindrical part, which is also called an armature. An insulated wire is wound on this element in a certain order, which forms several coils, and they are independent of each other. At the ends of these coils there are contacts connecting the device to the collector. Directly in the body itself there is a permanent magnet, or rather two, that go around the rotor device.

When the driver tries to start the engine, voltage from the battery is supplied to the power contacts of the unit, the brush assembly, and then through the contacts of one of the windings. As a result, a constant magnetic field is formed around the armature axis, which contributes to the appearance of direct current. This field will then interact with the field of the installed permanent magnets. The commutator element rotates, the next pair of contacts fits onto the brush assembly, as a result of which the rotor mechanism again deflects. This way the unit will work until the driver stops turning the starter.

Possible starter malfunctions: causes and symptoms

What malfunctions are typical for a moped starter:

- Worn brush assembly. This problem is usually associated with natural wear and tear of the mechanism, so it cannot be prevented. Brushes can also become stuck over time.

- Collector contamination. This problem can be caused either by wear or by engine fluid entering the mechanism housing, which can come out of the crankcase of the power unit. If the commutator element becomes dirty, this will not allow current to pass through the assembly to the winding contacts. The problem can be solved by dismantling and cleaning the parts.

- Short circuit of winding elements.

- Interturn closure. Such problems are solved by replacing the rotor device.

- Loss of contact between the winding output and the contacts of the collector component.

- Violation of the wiring insulation, which can also be associated with its burning (video author - Moto-Scooter fanat channel).

As for the signs of problems, symptoms of a unit malfunction can be indicated by the appearance of uncharacteristic noise during operation, a sharp decrease in engine speed, and overheating of the mechanism. If the disassembly and cleaning procedure does not produce results, most likely the reason lies in the windings. As stated above, they could burn out, be damaged, in particular, we are talking about a breakdown to ground, or simply short out.

Starter diagnostics before replacement

The mechanism can be checked without removing it from the motor. Find the power contact on the case, then disconnect the cable from it. The battery should be removed from the moped, but you must be sure that it is charged. You will need two pieces of copper cable, which should be thick - they are connected to the battery terminals on one side, and the other - the negative wire is connected to the mechanism body, and the positive wire to its power terminal.

Then the following should happen:

- If the device works, this indicates that it is working; accordingly, the cause of the malfunction will be in the relay, ignition switch or wiring that is connected to the device.

- If the mechanism does not start, this indicates its failure. As stated above, there may be several reasons, so the device will need to be dismantled and disassembled (the author of the video is Sanya Slesar).

DIY mechanism repair and replacement

How to dismantle and disassemble the starter:

- First, you should find the device - as a rule, it is located in the upper part of the power unit, immediately behind the cylinder. There is a power connection on the case; it should be disconnected.

- Next, unscrew the screws that secure the device to the power unit housing, and then remove it from the vehicle. If the device is equipped with a flange mount, then its screws will be located at the base of the case.

- After this, you need to unscrew the screws that secure both parts of the device’s body; their number may vary depending on the design features of the model. The shaft should be visible from the housing; it should be carefully clamped, and then, slowly, disconnect the halves.

- Having done this, you can remove the rotor element from the device body. Carefully inspect the condition of the commutator, as well as the brush assembly. If you notice that the first one is dirty, then you should clean it of dirt and then treat it with clean fuel. As for the brushes, worn components should also be removed and replaced with new ones. Before changing them, check their length - in optimal condition it should be at least 5-6 mm.

- All worn parts must be replaced. As stated above, problems with windings are usually not solved.

How to check the solenoid relay

You can check the VR in two ways - without removing it from the car and after removing it together with the starter. If you suspect that the signal from the lock is lost somewhere in the circuit, first carry out a regular test on the car, then, based on the results, the unit can be removed and checked more accurately - with a multimeter.

Check without removing from the car:

- Put the car on the handbrake, make sure it is in neutral gear.

- Turn on the ignition and leave the key in the lock.

- Remove the connector (thin wire) from the control terminal BP.

- Using a screwdriver, close the terminal with the upper power bolt (plus from the battery).

If after this the car starts, the problem is in the control circuit (the pulse from the lock does not reach the terminal). If the starter continues to click but does not turn, check the devices separately. To do this, the “traction” needs to be disconnected from the starter housing (it’s easier to remove them from the car together, and then separate them).

Check after removal:

- Turn the multimeter into audible dialing mode.

- Connect one probe of the device to the control terminal.

- The second one has a lower power bolt (terminal for brushes).

- If there is a signal, the pull-in winding is intact.

- Leaving the first probe on the terminal, attach the second one to the body.

- If there is a signal, the holding coil is also intact.

- Install the device vertically, on the anchor, with the terminals facing up.

- Throw the probes onto the bolts - one on the top, the other on the bottom.

- Press the relay, pressing the armature all the way.

- If there is sound, the power terminals are closed correctly, the plate is working.

- If there is no sound, but the display displays numbers, it does not work. The reason is external resistance.

Checking the solenoid relay with a multimeter

If at least one breakdown is detected, the part is replaced with a new one or a known good one. If both coils are intact, and the plate closes the “nickels” normally, all that remains is to test the force with which the spare part moves the armature plunger. To do this, first measure the free play of the plunger by inserting the relay into place in the housing until the loop tightly touches the fork lever, and use a ruler to measure the distance between the electric starter housing and the retractor itself. Pull out the part, push the plunger in until it touches the spring, now set the resulting distance on the plunger from the edge of the body. Mark (with marker or awl).

From the equipment you will need: a charged battery, three pieces of wire with a cross-section of 2 squares, with alligator clips and a plug for the control terminal (connector 50).

- Fix two wires with one end to the “ground” (body) of the part.

- Connect one of these wires to the negative terminal of the battery.

- Place the third wire with the plug on the positive battery.

- With one hand, press the part to the surface, “squeezing” the plunger to the mark.

- Place the plug on connector 50.

- Touch the end of the free wire (from the housing) to the lower power bolt.

- If the core overcomes the resistance and retracts, there is no problem, the solenoid relay is working.

To evaluate the force, you need to securely fix the device (by the loop on the anchor) on a flat, solid base. The surface should not conduct current - for example, a wooden or cardboard-covered table.

Scooter starter malfunctions: identifying and fixing the problem

The presence of a starter in a scooter, unlike a car, is not mandatory. However, it makes life much easier for the driver, adding a little comfort while working. Everyone knows that the starter works thanks to the battery, and it consists of:

- brushes;

- covers;

- anchors;

- support washer;

- two springs;

- o-ring;

- metal stator housing.

The principle of its operation is no different from any other starter, although some breakdowns may differ from the usual ones.

Why doesn't the starter work?

Initially, you need to exclude battery discharge from the list of possible breakdowns. If this were the case and the battery suddenly became low, you would hear a peculiar sound when you press the “start” button. This sound indicates that the starter is not engaged with the bendix and is running without load, idle. If you still hear this sound when starting up, do certain things:

- you need to check the terminals and clean them if necessary;

- inspect the wiring for damage;

- Check the condition of the battery (voltage level), recharge or replace it if necessary.

In most cases, these points will help you solve the problem with your scooter.

However, there may be other breakdowns, which in themselves are considered more serious when compared to a dead battery. We are talking about audible clicks when the starter operates. This is a deeper problem and it is necessary to look for its causes.

Causes and solutions

Step 1: With the ignition on, try honking the horn. If everything worked out and you could hear a loud and ringing sound, everything is fine, you can start the engine. If the sound was very quiet or could not be heard at all, there were problems with the battery or power supply (recharge the battery, clean the terminals).

Step 2. When you press the engine start button, you hear the sound of the relay turning on. If yes, then try bridging the power terminals of the relay. If there is no sound, disconnect the relay from the power supply, and then use the wires to connect the battery and starter.

Step 3. Once you have connected the starter, it works fine. If yes, then you just need to replace the relay. If not, check the contacts of the start button, the wires from the starter, and replace all worn parts.

Step 4. If, after you bridge the power terminals of the relay, the starter begins to operate normally, replace the relay. If not, then you are faced with a more serious task: you need to disassemble the starter and check the condition of its parts (brushes, windings and springs).

By analyzing your scooter breakdown using these simple steps, you can easily identify and fix the breakdown. Of course, you don’t have to worry too much about this and just bring your scooter to a service station. But at the same time, you will spend your money and will not be able to gain that invaluable experience that you will gain when diagnosing and repairing yourself.

Relay clicks when starting

#1 ONLINE Bumblebee

- users

- 629 messages

- Rostov-on-Don

- Bike:HD Sportster 1200

Greetings!

This morning an incident happened: I inserted the ignition key, the lights on the dash are on normally, there is light, I press the electric starter button - it doesn’t turn and I hear a click under the seat every time I press it. I rolled the engine back and forth - I tried it again and everything was absolutely fine, it started without any problems. Oh guru, it’s time for “diagnosis from photography”, tell a noob what this could be connected with? I even made a video. True vertical.

#2 OFFLINE Uncle OZZE

- photos&contacts

- Bike:BMW R1100R

Strip the contacts on the battery wires that go to ground (- ) (frame-engine) and + of the starter, and especially the contacts that go to the starter relay.

Post edited by Uncle OZZE: April 28, 2022 - 15:45

#3 OFFLINE Vovka

Awards

#4 OFFLINE Dabbuger

- photos&contacts

- City: Rostov-on-Don, western

- Bike:Yamaha Majesty s155

This happens to me from time to time, I don’t worry too much. And about contacts, this is all correct, most likely there is no other reason

#5 OFFLINE Ksu

- photos&contacts

- City: Azov

- Bike:Suzuki V-Strom DL1000, Honda XR250 Baja

I inserted the ignition key, the lights on the dash are lit normally, there is light,

Vit, I don’t know anything about the main problem, but here’s some advice about this phrase:

Do not turn on the light before starting.

That's where the bi-xenon is installed, it consumes a lot of energy when starting up

And your battery is almost a year old and has been in active use.

I quickly destroyed the previous tired battery with the lights not turned off upon arrival.

In the morning I turned the key, the light came on, I started it from the pusher)

Post edited by Ksyu: 28 April 2022 - 15:58

#6 OFFLINE ViK_Pro

- Rostov-on-Don

- Bike:HONDA CBR1100XX

A friend had the same symptoms last year. The starter relay clicks. He doesn’t like to figure it out himself, so he took me to MotoDon, and the investigation showed that the battery was faulty.

#7 ONLINE Bumblebee

- Rostov-on-Don

- Bike:HD Sportster 1200

I understand the direction, thank you!

Why the scooter does not start with the button - we identify the reasons

A scooter is a practical vehicle, economical and easy to drive. Modern models are reliable and easy to maintain, but various problems may arise during the operation of the scooter.

One of the most common breakdowns is the failure of the scooter to start with the button.

As a rule, at first the scooter starts from the button every other time , and then does not start at all using the electric starter. How to be in this case?

To fix a problem, you need to identify the cause of its occurrence. As practice shows, there can be many such reasons, but there are also quite common ones.

What to check if the scooter does not start with the button

We list the most common reasons and give ways to solve them:

- Fuel sensor malfunction. No matter how trivial it may sound, this happens quite often: the sensor shows that there is still gasoline left in the tank, and the owner of the scooter looks for the cause of the “breakdown” in a completely different place. Therefore, it would not be superfluous to first look into the gas tank and make sure that there is fuel in it.

- The battery is low. This often happens when equipment is idle for a long time. To solve the problem, just charge the battery.

- Old fuel. Many scooter owners face this problem after winter. There seems to be gasoline in the tank, the electric starter seems to be turning, but something is missing to start the engine itself. The cause of this problem may be old gasoline, try draining it and adding fresh fuel.

- There is no spark in the spark plug. To check this version, you need to unscrew the spark plug, apply it to an unpainted part of the engine (for example, to the cylinder), and use the kickstarter to crank the crankshaft. At the same time, you should not neglect precautions: you should not hold the candle with your bare hands. If there is no spark, the spark plug must be cleaned of moisture and carbon deposits, sanded with zero-grit sandpaper and dried. Ideally, the spark should be white.

- Poor contact at the battery terminals - over time they can become covered with oxide, which is a dielectric. To get rid of this problem, just clean the contacts with the same fine sandpaper.

- The fuel tap and/or fuel line is clogged. If gasoline does not flow into the ignition system or is supplied intermittently, the scooter will not start either from the kickstarter or from the button. To fix the problem, these elements of the fuel system need to be cleaned.

- The carburetor is clogged. Difficulty starting the engine, “floating” speed, failures in engine operation - all this indicates that the carburetor needs cleaning. To remove the carburetor, you need to unscrew the inlet pipe and the air filter pipe, disconnect the terminals of the starter enrichment, remove the gasoline supply pipe and drainage. Then you need to disconnect the throttle cable and you can remove the carburetor. Next, you should carefully disassemble the power system assembly, clean it and put it back together. After cleaning the carburetor, do not forget to adjust the floats to a horizontal position!

- No compression. Inspect the piston group. When the piston moves to top dead center, pressure should appear in the cylinder. This can be checked using a special device - a compression meter. To do this, screw the compression gauge fitting in place of the spark plug and turn the crankshaft using the kickstarter. On 2-stroke scooters the compression should be 7-8 kg/cm2, on 4-stroke scooters - 9-10.

If the scooter starts with the kickstarter, but does not start with the button

If the scooter starts without problems from the “leg”, but does not want to start from the electric start button, then you should pay attention to the central fuse (it is located in the compartment with the battery). If the voltage in the scooter’s electrical network is too low due to a faulty fuse, it will no longer start using the “Start” button.

To check the serviceability of the central fuse, you should measure the voltage at the battery terminals and compare with the voltage after the fuse.

If losses are detected during measurements, the fuse should be replaced. In most cases, after replacing the faulty fuse, the scooter starts without problems.

The problem when the starter button on a scooter does not work may not only be in the fuse. It is likely that the integrity of the connecting conductors in the engine starting circuit is broken.

VIDEO INSTRUCTIONS » alt=»»> It will be difficult for a beginner to deal with such a malfunction, so for a complete diagnosis of the electrical circuit it is better to contact an auto electrician.