When choosing power equipment, special attention must be paid to the type of engine. There are two types of internal combustion engines: 2-stroke and 4-stroke.

The principle of operation of an internal combustion engine is based on the use of such a property of gases as expansion when heated, which is carried out due to the forced ignition of a combustible mixture injected into the air space of the cylinder.

You can often hear that a 4-stroke engine is better, but to understand why, you need to take a closer look at how each works.

The main parts of an internal combustion engine, regardless of its type, are the crank and gas distribution mechanisms, as well as systems responsible for cooling, power supply, ignition and lubrication of parts.

The useful work of the expanding gas is transferred through a crank mechanism, and the gas distribution mechanism is responsible for the timely injection of the fuel mixture into the cylinder.

Four-stroke engines - Honda's choice

Four-stroke engines are economical, while their operation is accompanied by a lower noise level, and the exhaust does not contain a combustible mixture and is much more environmentally friendly than that of a two-stroke engine. That is why Honda uses only four-stroke engines in the manufacture of power equipment. Honda has been introducing its four-stroke engines to the power market for many years and has achieved the highest results, while their quality and reliability have never been questioned. But still, let's look at the principle of operation of 2 and 4 stroke engines.

Operating principle and main characteristics

The operating cycle of an internal combustion engine (ICE) consists of a series of processes that increase the power of the engine acting on the crankshaft. The work cycle consists of several stages:

- the cylinder is filled with the fuel mixture;

- the mixture is compressed;

- the fuel mixture ignites;

- the gases expand and the cylinder is cleaned.

In an internal combustion engine, the piston moves in one direction (up or down). The crankshaft makes one revolution in two strokes. The working stroke of the piston is the one during which useful work is performed and the burnt gases expand.

Two-stroke engines are those in which the cycle is completed in one revolution of the crankshaft or in two strokes. Four-stroke units are characterized by completing a working cycle in two revolutions of the crankshaft or in four strokes .

Main characteristic indicators of a 4-stroke engine:

- Due to the movement of the working piston, gases are exchanged.

- The unit is equipped with a gas distribution mechanism that allows the cylinder cavity to be switched to inlet and outlet.

- An exchange of gases occurs at the moment of a separate half-turn of the crankshaft.

- Gear reducers and a belt chain drive make it possible to change the timing of gasoline injection, ignition and gas distribution mechanism drive in relation to the crankshaft speed.

Launch

In order to start a cold engine, a rich mixture is needed. Some carburetors have a float stopper in the chamber for this purpose. When its rod is pressed, the fuel level in the chamber rises sharply to a level above the permissible level. Because of this, fuel begins to flow into the intake manifold. And some of the fuel leaks out. For some time now, however, carburetors have been designed in such a way that vapors do not escape outside. Such designs involve the use of an enrichment mixture, which is an air damper or another fuel channel. It is used instead of a drowner.

Recently, four-stroke motorcycle engines often have an electrically controlled fuel injection system. It consists of an electrically driven fuel pump, a battery, electromagnetic injectors, an electronic control unit, which is connected to various sensors, and a distribution pipeline.

There are also engine control systems where the control of the power supply and ignition systems are combined, which increases the efficiency and at the same time the power of the unit.

The main malfunction of the power system, due to which a motorcycle engine may need to be repaired, is a reduction or even cessation of fuel supply due to a blockage. To avoid this, use a fuel filter. In addition, it is necessary to monitor the condition of the air filter and the tightness of the pipes.

Story

Around 1854-1857, the Italians Felicce Matoczi and Eugene Barsanti created a device that, according to the information available today, was similar to a four-stroke engine . The invention of the Italians was lost only in 1861. Alphon de Rocher patented an engine of this type.

The first workable four-stroke engine was created by the German engineer Nikolaus Otto . The four-stroke cycle of operation was named in his honor as the Otto cycle, and a 4-stroke engine using spark plugs is called an Otto engine.

Combustion and expansion (piston stroke) - four-stroke engine

Shortly before the end of the compression stroke, the combustible mixture is ignited by a spark from the spark plug. As the piston moves from TDC to BDC, the fuel burns, and under the influence of the heat of the burned fuel, the working mixture expands, pushing the piston. The degree of “under-rotation” of the engine crankshaft to TDC when the mixture is ignited is called the ignition timing angle. Ignition advance is necessary so that the gas pressure reaches its maximum value when the piston is at TDC. Then the use of energy from burned fuel will be maximum. The fuel combustion rate practically does not change, that is, it takes a fixed time, therefore, in order to achieve maximum engine performance, you need to increase the ignition timing in proportion to the crankshaft speed level. In older engines, this adjustment was made by a mechanical device (centrifugal and vacuum regulator acting on a breaker). More modern engines use electronic ignition timing to adjust the timing.

Features of a 4-stroke engine

In a two-stroke engine, lubrication of the piston and cylinder pins, crankshaft, piston, bearing and compressor rings is carried out by pouring oil into gasoline. The crankshaft of a 4-stroke engine is located in an oil bath, which is a significant difference. That is why there is no need to mix fuel and add oil. All the car owner needs to do is fill the fuel tank with gasoline.

The car owner, therefore, has no need to purchase special oil, without which a two-stroke engine cannot function. In addition, with a four-stroke engine, the amount of carbon deposits on the piston mirror and on the walls of the muffler is reduced. Another important difference is that in a two-stroke engine, a flammable mixture splashes into the exhaust pipe, which is due to its design.

It should be recognized that four-stroke engines also have minor disadvantages. For example, their working moments for regulating the thermal valve clearance are not particularly high-quality.

"Wet" and "dry" sump

Four-stroke engines use three methods of oil supply:

- gravity;

- splashing;

- supply under pressure.

Moreover, most of the rubbing pairs are lubricated under pressure from the oil pump. But there are also those that are lubricated by oil mist formed as a result of splashing of the crank mechanism, as well as parts to which oil flows through channels and gutters. In this case, the oil pan serves as a reservoir. In this case it is called “wet”.

Other motorcycles have a “dry” sump system, where one section pumps oil into the tank, and the other supplies it under pressure to the friction points.

In spirit-tactics, lubrication occurs with oil, which is found in fuel vapor. It is pre-mixed with gasoline, or it is supplied to the inlet pipe by a metering pump. This latter type is called the “separate lubrication system.” It is especially common on foreign engines. In Russia, the system is included in the engine of the Izh Planet 5 and ZiD 200 Courier motorcycles.

Unit design

The camshaft of a four-stroke engine is located in the cylinder cover. It is driven by a drive wheel mounted in the crankshaft. The camshaft opens and closes one of the valves: exhaust or intake, depending on the location of the piston. The camshaft also contains cams that operate the valve rocker arms.

Once triggered, the rocker arms It is important that there must be a thermal gap (narrow gap) between the adjusting screw and the valve. When heated, the metal expands, so if the gap is too small or there is none at all, the valves cannot completely close the exhaust and intake passages.

at the intake valve should be smaller than at the exhaust valve, because the exhaust gases are hotter than the mixture. Accordingly, the intake valve heats up less than the exhaust valves.

What is ICE 4-mix and what is it intended for?

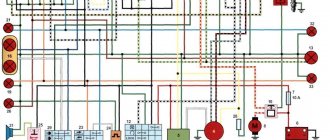

If you are wondering what a 4-mix engine is or why the Stihl lawn mower is fueled with a gasoline-oil mixture, but the instructions indicate that it is four-stroke, then this is where you will find the answer. Stihl has patented a new type of engine called the 4-MIX. Its peculiarity is that it combines the advantages of two-stroke and four-stroke engines. How this type of engine works, and the most interesting thing is how the lubrication of the crankshaft is ensured, we will find out in detail. Below is a diagram of a 4-mix internal combustion engine.

The diagram shows that such an engine is equipped with a timing belt, and the unit operates in 4 strokes. At the same time, in order to save on the cost of gasoline tools, manufacturers do not use a separate lubrication system. The crankshaft lubrication is carried out together with fuel, as is typical for two-stroke engines. Gasoline and oil enter the crankshaft chamber from the container where the rocker arms of the intake and exhaust valves are located.

This container is connected to the crankshaft chamber using channels in which valve guides are located, one part connected to the rocker arm, and the other to the cam on the camshaft.

The air-fuel mixture from the carburetor is sucked into the sealed valve chamber and sent through channels to the crank mechanism. To have an idea of how the 4-mix internal combustion engine works, let’s look at the step-by-step operation of each stroke.

This is how 4-mix internal combustion engines work, which have become very popular. Among the advantages of such motors, the following factors should be highlighted:

As a result, Stihl managed to combine all the advantages of 4-stroke and 2-stroke engines, creating a unit called 4-mix. Simplicity of design, unpretentiousness, affordable cost, high power and other advantages are inherent in this modern type of internal combustion engine.

Engine operation

As already noted, the operation of a four-stroke engine consists of four strokes of the piston or two revolutions of the crankshaft.

Stages of work:

- Inlet . The piston moves downward, opening the intake valve. From the carburetor the combustible mixture enters the cylinder. When the piston reaches the bottom position, the intake valve closes.

- Compression . The piston moves upward, causing the combustible mixture to compress. When it approaches the top point, the compressed gasoline ignites.

- Extension . Gasoline ignites and burns. As a result, the flammable gases are stretched and the piston moves downwards. In this case, two valves are closed.

- Release . The crankshaft continues to move around its axis by inertia, and the piston moves upward. At the same time, the exhaust valve opens and exhaust gases enter the pipe. When the valve passes the dead center, the intake valve closes.

Four-stroke engine, its structure and how it works

The engine operating diagram of a four-stroke model is more complex than that of a two-stroke model. The mixture is ignited every second turn of the crankshaft. The power unit has from eight to 16 cylinders in pairs. There are an even number of cylinders on each side.

Some valves are intake valves, others are exhaust valves. Gasoline, oil and air are mixed in the combustion chamber. And they do it separately. Oil and gasoline injection occurs simultaneously. Next comes the ignition of the mixture.

Through the intake valves, fuels and lubricants enter the combustion chamber, and through the exhaust valves, exhaust gases exit.

Let's take a closer look at the operation of engine cylinders with a stroke of 4.

Attention! Thanks to this device, four-stroke engines are considered economical, but not easy to disassemble or repair for an inexperienced car owner.

It is important that the valves fit tightly to the cylinder head. Then there will be no loss of compression, and the engine will produce all the power that is put into it.

Compression stroke - two-stroke engine

The piston of a two-stroke engine rises from the BDC of the piston (in this position it is in Fig. 2) to the TDC of the piston (the position of the piston in Fig. 3), blocking first the purge 2 and then the exhaust 3 windows of the cylinder of a two-stroke engine. After the piston closes the outlet hole in the cylinder, compression of the previously entered fuel mixture begins. At the same time, in the crank chamber 1, due to its tightness and after the piston closes the purge windows 2, a vacuum is created under the piston, under the influence of which a combustible mixture enters the crank chamber of a two-stroke engine from the carburetor through the inlet window and the opening valve.

Types of internal combustion engines in motorcycles, as well as differences.

Novice drivers sometimes think that the most important quality that motorcycle engines have is the amount of horsepower, and they believe that the vehicle will only run well if it has more than a hundred horsepower. However, in addition to this indicator, there are many characteristics that affect the quality of the motor.

Types of motorcycle engines

There are two-stroke and four-stroke engines, the operating principles of which are somewhat different.

Also, motorcycles have different numbers of cylinders.

In addition to the original carburetor engine, you can often find injection units. And if motorcyclists are accustomed to fixing the first type on their own, then it is already problematic to repair an injection engine with a direct injection system with your own hands. Diesel motorcycles and even those with an electric motor have been produced for a long time. The article will discuss the characteristics of a carburetor-type motorcycle engine.

https://www.youtube.com/watch?v=e1lbqglXJaI

How the engine works

In the engine cylinders, the thermal energy of burning fuel is converted into mechanical work. In this case, the piston moving due to gas pressure causes the crankshaft to rotate through the crank mechanism. This mechanism consists of a crankshaft, connecting rod, piston with rings, piston pin, and cylinder.

Differences in design lead to different operation of a two-stroke and a four-stroke engine.

Four stroke engine

Such engines have a duty cycle of four piston strokes and two crankshaft revolutions. The engine diagram clearly shows the structure of a piston internal combustion engine and its working process.

- On intake, the piston moves down from top dead center, drawing mixture through the open valve.

- During compression, the piston rising from bottom dead center compresses the mixture.

- During the working stroke, the mixture, ignited by an electric spark plug, burns, and the gases move the piston down.

- When exhausting, the piston, rising, pushes the exhaust gases through the open exhaust valve. When it reaches top dead center again, the exhaust valve closes and the whole process repeats.

The advantages of four strokes are:

- reliability;

- efficiency;

- less harmful exhaust;

- little noise;

- Oil and gasoline are not pre-mixed.

The design of this type can be depicted by the following engine diagram.

Two stroke engine

The engine capacity of this type of motorcycle is usually smaller, and the working cycle takes one revolution. In addition, it does not have intake or exhaust valves. This work is performed by the piston itself, which opens and closes the channels and windows on the cylindrical mirror. A crankcase is also used for gas exchange.

The advantages of this engine are:

- with the same cylinder volume, it has a power that is 1.5-1.8 times greater than a four-stroke;

- does not have a camshaft and valve system;

- production is cheaper.

Cylinders and the work process in them

The working process of one and the other engine occurs in the cylinder.

The piston here moves along a cylindrical mirror or insert sleeve. If air cooling is used, then the cylindrical jackets have ribs, and with water cooling they have internal cavities.

The crankshaft, through the connecting rod, perceives the movement of the piston, transforming it into rotation, and then transmitting torque to the transmission. It also powers the gas distribution mechanism, pump, generator and balance shafts. The crankshaft has one or more elbows depending on the number of cylinders.

In a four-stroke engine, in order to better fill the cylinder with the mixture, the intake begins before the piston reaches top dead center, and ends after it passes bottom dead center.

Its cleaning begins even before reaching bottom dead center, and exhaust gases are pushed out as the piston moves to top dead center. The exhaust valve then closes to allow the gases to leave the cylinder.

The following types of gas distribution mechanism are used on this type of engine:

- OHV;

- OHC;

- DOHC.

The latter type has a minimal number of elements, so the crankshaft can rotate faster. Therefore, DOHC is becoming increasingly common.

Four-stroke engines have a more complex design compared to two-stroke engines, as they have a lubrication system and a gas distribution mechanism that two-stroke engines do not have.

However, they have become widespread due to their cost-effectiveness and less harmful impact on the environment.

Motorcycle engines are most often one-, two-, and four-cylinder. But there are also units with three, six and ten cylinders. The cylinders are in-line - longitudinal or transverse, horizontally opposed, V-shaped and L-shaped. These motorcycles usually have an engine displacement of no more than one and a half thousand cubic meters. Engine power is from one hundred fifty to one hundred eighty horsepower.

Engine oil

Lubrication is necessary to ensure that excessive friction does not occur between engine parts. It is implemented using motor oils that have a stable structure against high temperatures and low viscosity at low levels. In addition, they do not form carbon deposits and are not aggressive to plastic and rubber parts.

Oils are mineral, semi-synthetic and synthetic. Semi-synthetics and synthetics are more expensive, but these types are preferred more, as they are believed to be healthier for the engine. Different types of oils are used for two-stroke and four-stroke engines. They also differ in the degree of forcing.

"Wet" and "dry" sump

Four-stroke engines use three methods of oil supply:

- gravity;

- splashing;

- supply under pressure.

Moreover, most of the rubbing pairs are lubricated under pressure from the oil pump. But there are also those that are lubricated by oil mist formed as a result of splashing of the crank mechanism, as well as parts to which oil flows through channels and gutters. In this case, the oil pan serves as a reservoir. In this case it is called “wet”.

Other motorcycles have a “dry” sump system, where one section pumps oil into the tank, and the other supplies it under pressure to the friction points.

In spirit-tactics, lubrication occurs with oil, which is found in fuel vapor. It is pre-mixed with gasoline, or it is supplied to the inlet pipe by a metering pump. This latter type is called the “separate lubrication system.” It is especially common on foreign engines. In Russia, the system is included in the engine of the Izh Planet 5 and ZiD 200 Courier motorcycles.

Cooling system

When fuel burns in an engine, heat is released, of which almost thirty-five percent is used for useful work, and the rest is dissipated. However, if the process is ineffective, the parts in the cylinder overheat, which can lead to them jamming and damage. To prevent this from happening, a cooling system is used, which can be air or liquid depending on the type of engine.

Air cooling system

In this system, parts are cooled by oncoming air. Sometimes, for better performance of the cylinder surface, its heads are made ribbed. Sometimes forced cooling is used using a mechanical or electric fan. In four-stroke engines, the oil is also thoroughly cooled, for which the surface of the crankcase is increased and special radiators are installed.

Liquid cooling system

The option is similar to what is installed on cars. The coolant here is antifreeze, which is low-freezing (from minus forty to minus sixty degrees Celsius) and high-boiling (from one hundred twenty to one hundred and thirty degrees Celsius). In addition, antifreeze achieves an anti-corrosion and lubricating effect. Pure water cannot be used in this capacity.

Overheating of the cooling system can be caused by overload or contamination of the surfaces that dissipate heat. Also, individual elements in it may break, causing liquid to leak out. Therefore, the cooling operation must be constantly monitored.

Supply system

Gasoline with an octane number of at least 93 is used as fuel for carburetor motorcycles.

Motorcycle engines have a power supply system that includes a fuel tank, valve, filter, air filter and carburetor. Gasoline is located in a tank, which in most cases is installed above the engine in order to flow by gravity into the carburetor. In other cases, it can be supplied using a special pump or vacuum drive. The latter can be found on two-stroke bikes.

The fuel tank has a cap with a special hole where air enters. In many foreign motorcycles, however, air enters through carbon tanks. And some have a lock on the lid.

The fuel valve prevents fuel leakage.

Air enters the carburetor through the air filter. The filter comes in three types.

- In the compact oil type, air enters the center, turns 180 degrees and passes into the filter. At the same time, it is cleaned when the flow turns, where heavy particles settle in the oil. The engine of the Ural and Izh motorcycles is equipped with such a filter. However, other types, paper and foam, are used abroad.

- Paper filters are disposable. They must be changed at every maintenance.

- Foam filters are reusable - they can be washed and re-soaked with oil.

Sports motorcycles with engines of 250 cc and above today have a so-called “direct intake” system, where air is taken in from the front of the fairing, thereby increasing the filling of the cylinders at high speeds.

Carburetor and its types

This device prepares and doses the air-fuel mixture, which then goes into the cylinder. Modern carburetors come in three types:

- spool valves;

- constant vacuum;

- register.

All domestic engines, as well as the Ural motorcycle engine, have spool carburetors. The only exception is the Ural-Vostok, which has a constant vacuum carburetor.

In a spool-type carburetor, the throttle handle is connected to the spool. By acting on it, the air entering the motor is regulated. A conical needle is connected to the spool and enters the sprayer. When it changes, the mixture becomes richer or leaner. A fuel nozzle is installed on the sprayer. And together all the elements make up the dosing system.

In constant vacuum carburetors, the movement of the throttle handle is transmitted to the throttle valve, which is located closer to the outlet of the carburetor. The air in the chamber above the spool interacts with the carburetor mixing chamber. It turns out that the movement of the spool is controlled by the vacuum in the intake tract.

Register carburetors, which are equipped with many foreign single-cylinder four-stroke engines, such as Honda engines, combine the two previous types. It has two mixing chambers, where in one the spool is driven by the handle, and in the other by the vacuum in the mixing chamber.

Launch

In order to start a cold engine, a rich mixture is needed. Some carburetors have a float stopper in the chamber for this purpose. When its rod is pressed, the fuel level in the chamber rises sharply to a level above the permissible level. Because of this, fuel begins to flow into the intake manifold. And some of the fuel leaks out. For some time now, however, carburetors have been designed in such a way that vapors do not escape outside. Such designs involve the use of an enrichment mixture, which is an air damper or another fuel channel. It is used instead of a drowner.

Recently, four-stroke motorcycle engines often have an electrically controlled fuel injection system. It consists of an electrically driven fuel pump, a battery, electromagnetic injectors, an electronic control unit, which is connected to various sensors, and a distribution pipeline.

There are also engine control systems where the control of the power supply and ignition systems are combined, which increases the efficiency and at the same time the power of the unit.

The main malfunction of the power system, due to which a motorcycle engine may need to be repaired, is a reduction or even cessation of fuel supply due to a blockage. To avoid this, use a fuel filter. In addition, it is necessary to monitor the condition of the air filter and the tightness of the pipes.

Exhaust system

The exhaust system consists of a cylindrical exhaust channel, a pipe and a muffler. In two-stroke engines, efficiency and power directly depend on the size and shape of the system parts. Therefore, they use exhaust systems on each cylinder separately. They have a resonator, a pipe and a muffling nozzle.

In four-stroke engines, the exhaust is controlled by valves in the gas distribution system, so resonance does not play a special role in them. In them, usually all pipes are reduced to a single muffler.

On some motorcycles, the exhausts are equipped with catalytic converters that reduce the toxicity of emissions (they are installed, for example, on engines from Honda and other Japanese manufacturers). Such devices were developed as a result of increasingly stringent exhaust gas requirements in the European Union, the USA and Japan. In order to prevent the backflow of mixture from the cylinders at idle and low crankshaft rotation, the exhaust systems of many motorcycles are equipped with special power valves.

Article read by: 23,775