I must say right away that the chain drive itself has been known for a long time; now it is not the only option, but it is still popular to this day. Its main advantages are ease of installation and maintenance, high efficiency, affordable price, and the ability to change the so-called without unnecessary hassle. gear ratio. There are also disadvantages, of course. The main disadvantage is that the chain stretches, wears out and therefore sag - you have to tighten it. And it needs to be lubricated regularly.

Each motorcycle chain of a decent brand has a proprietary index that can immediately answer a number of questions for an informed buyer. Thus, the most widespread products are those with indices 428, 520, 525 and 530. The first number in them is the chain pitch (the distance between the axes of the link fastenings), and the next two are the width (exactly the internal width where the teeth go).

No tightening or loosening should be done to compensate for extra or missing links. When buying a replacement chain, most motorcycle owners take their old one and count how many links there are, and then look for an analogue. There is an option to change the gear ratio and/or drive sprocket, then the number of links will have to be increased/decreased.

According to the type of seal, all motorcycle chains are divided into sealed and sealless. Actually, the name eloquently indicates the features of the device. The stuffing box type is marked according to the type of seal: O-ring, X-ring, W- or Z-ring. The index indicates the service life and friction losses. The oil seals keep the lubricant in the rollers, reducing wear, which greatly increases the life of the entire chain. Naturally, you need to lubricate a motorcycle chain with a compound specially designed for this purpose, and not with any lubricant.

There are several types of oil seals, they differ primarily in their cross-section. At one time, it was thanks to oil seals that the need for protective covers disappeared and the open system gained popularity - now almost all motorcycles are like this. And sealless chains have become niche - they are popular in sports and for models with small cubic capacity.

Locks and sizes

As a rule, locks come complete with chains, less often they are bought separately where they are sold. But by default, they are not meant as safety features, like for bicycles, but rather as connecting locks. You can buy a lock separately, according to the chain marking - the index must match. Different locks differ from each other mainly in the thickness of the plates and pins, as well as in the materials used, so it is highly recommended not to experiment, but to use a lock from the same manufacturer and with the same index for your chain.

As a rule, when choosing a chain, they are guided not only by basic technical parameters, but also take into account the operating conditions of the motorcycle. For example, for powerful sports models with a liter volume by default, a reinforced chain will be needed. It is more expensive than usual, but will withstand working with an engine of a couple of hundred horses. But for a road motorcycle, there is no point in buying the most expensive chain in a car store.

Features of chains from EK Chain

The brand is considered the flagship of its field. It was this brand that first created the O-ring drive, and now offers a range of different types. And for several decades now, motorcycle chains produced by EK Chains have been considered among the highest quality.

The simplest option is considered the standard: a sealless chain for small-capacity motorcycles. Yes, it stretches quickly and requires frequent lubrication. And you need to clean it often. But friction losses are very small. And if you need a stronger analogue, you can purchase the so-called. high-load chain of the same brand. Made from more durable materials, suitable for motorcycles with a volume of up to 0.65 liters.

The O-Ring type O-ring chain of the SRO series is equipped with round seals to retain lubricant and protect friction pairs from dirt. As a result, the product life is half that of sealless ones. But there is also a minus: turning the links increases friction, which reduces power. Ideal for motorcycles with a volume of 0.75 liters.

X-shaped rings in the range of this brand are available in the QX-Ring and Quadra-X chains. There are ventilation holes to keep the chains cooler. And friction is 40% less, thanks to a smaller contact surface. And the seal is better. According to test results, chains with Quadra-X can last approximately half as long as O-Ring. The branded SRX2 series is recommended for motorcycles with a volume of up to 1 liter.

This brand also has products produced using Zero Stretch technology - labeled ZST. They are guaranteed not to stretch during the first thousand kilometers. Initially they were created to preserve the length of the chain for the entire period of operation.

It is also worth mentioning a couple of classes: MVXZ2 and ZVX3 The first of them are chains for powerful “iron horses” with a volume of 1-1.4 liters, and the second are chains with record tensile strength. For example, the original version of the 520ZVX3 holds 11,100 kg per hundred links, and weighs only 2.2 kg - it can be safely installed in any motorcycle used under heavy load.

Useful

HOW TO INCREASE THE TRACTION OF THE ENGINE OF THE “VOSKHOD” MOTORCYCLE?

The traction of the Voskhod motorcycle can be significantly increased by changing the gear ratio in the motor transmission from 2.06 to 2.75. Motor transmission parts from Minsk are suitable for this: the crankshaft drive sprocket from Z-12, the outer clutch drum from Z-33 and the motor chain (PV-9.525-1300). However, the kickstart ratchet, inner clutch drum and disc pack remain the same.

THE SPRING OF THE GEAR SHIFT SHAFT ON THE MOTORCYCLE “VOSKHOD” IS BROKEN. FRAGMENTS OF THE SPRING CAME BETWEEN THE TEETH OF THE GEARS OF THE BOX, WHICH RESULTED IN ITS BREAKAGE. IS THERE A WAY TO AVOID THIS TROUBLE?

To eliminate such consequences, try covering the spring with a homemade casing. It consists of two parts.

Cut part 1 (Fig. 4.18) from a steel sheet with a thickness of 0.5-1.0 mm. To make the second one (Fig. 4.19), you can use the factory cover 1, to which you need to weld plate 2, cut from a steel sheet of the same thickness.

Install the casing as follows: put part 1 on the shift shaft, then the spring, then part 2 (the cover is locked with the existing locking ring).

HOW MUCH HAVE THE TRANSMISSION PARTS OF KOVROVSKY MOTORCYCLES CHANGED IN THE PROCESS OF IMPROVING THE DESIGN OF MOTORCYCLES?

Transmission parts and mechanisms changed little during the production process. True, the 3M-01 engines received a strengthened motor transmission, the chain and sprockets became a little wider. However, this transmission assembly can also be installed on previous models. On motors with forced cooling, the drive sprocket has two additional cams, which are connected to the mountain valve drive shaft through a polyurethane coupling.

The gearbox along with the switching mechanism have not changed fundamentally since the days of Kovrovets-175A. The only modernization was carried out in 1972: gears with a module of 1.75 were replaced by gears with a module of 2. The next change occurred already on the Voskhod-3M-01: the dimensions of the splines for the inner clutch drum on the input shaft were changed, but these two parts ( shaft and drum) assembly can be installed on any Kovrov power unit with a four-speed gearbox.

The clutch release mechanism and the speedometer gearbox are made in a single housing, which has not changed since the time of the Kovrovtsev. The only alteration was carried out when the Voskhod-3 model was put into production: the seat under the speedometer shaft jacket was increased from 13 to 16 mm.

HOW TO REPLACE THE MAIN DRIVE CHAIN WITHOUT REMOVING THE COVERS?

Kovrov motorcycles have a completely closed final drive chain (from the engine to the wheel). Over time, the chain stretches and then it has to be replaced.

However, do not rush to disassemble the casings. This is only necessary if you need to clean them from the inside. Replacing the chain can be much easier and faster.

To do this, you must first clean the junction of the upper corrugated cover with the driven sprocket housing from dirt. Then place the motorcycle on the center stand. Loosen the rear wheel axle and sprocket housing nuts and move the wheel to the minimum chain tension position, sliding it along the swingarm towards the engine. This is done so that there are no difficulties with connecting the new chain, because its length is less than the worn one.

Place a stop under the muffler so that the rear wheel can be moved out. By removing the upper corrugated cover from the driven sprocket casing so that the chain is visible, and turning the wheel, “catch” the chain lock. Lock the chain in this position.

Unfasten the lock and attach a new chain to either end of the chain with the same lock. All that remains is to remove the fixation and pull out the old chain, threading a new one in its place.

Once again, fixing the chain and unfastening the old one, connect the lock. Be sure to install the locking plate with the cut backward along the chain. Cut a strip of tin measuring 7x16 mm and insert it under the locking plate and bend the edges. Finally, attach the upper corrugated cover to the casing and begin adjusting the chain tension.

HOW TO IMPROVE THE TRANSMISSION OF THE "OWL" MOTORCYCLE FOR ITS OPERATION IN OFF-ROAD CONDITIONS?

To travel off-road, it is necessary to increase the transmission ratio. The easiest way to do this is to replace the standard sprocket with a 13 or 14 tooth.

It is clear that in this case the maximum speed on the highway will decrease, and fuel consumption will also increase.

It is better to remove the chain housing and corrugations immediately. The chain and sprockets will wear out faster, but the likelihood of them jamming will decrease.

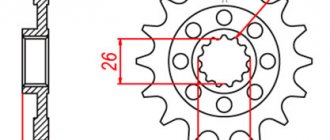

For motorcycle owners who have the appropriate equipment and the necessary skills, we provide design parameters for the manufacture of a rear chain drive sprocket (chain pitch 12.7 mm).

WHAT CHAINS ARE USED IN THE ENGINE AND MAIN TRANSMISSION OF THE VOSKHOD-3M MOTORCYCLE?

The motor transmission of the motorcycle uses a PV-9.525-1300 chain, which has 44 links. The length of the new chain (unfolded) is 419.1 mm. During operation, the chain can be extended up to 427.5 mm.

The letters PV stand for “drive sleeve”. The number 9.525 indicates the chain pitch in mm; the number 1300 indicates the minimum breaking load in kgf. The number 2 placed at the beginning of the designation indicates that the chain is double-row.

IS IT POSSIBLE TO INSTALL THE REVERSE GEAR CHAIN OF “MINSK” TO “VOSKHOD”?

You can also use chains from “Java” (126 or 128 links), “Tula” (116 links) or “Ant” (128 links), shortening them accordingly.

HOW TO REMOVE THE REAR WHEEL CHAIN COVER?

To remove the chain guard:

— remove the right crankcase cover (from the generator side);

— remove the rear wheel;

— remove the front part of the rubber chain covers from the crankcase sockets;

- unscrew the axle nut and separate it together with the covers and chain

pendulum chain housing;

— remove the covers, chain and take out the sprocket base along with the chain casing bushing;

- knock out the axle shaft with light blows of a hammer through a wooden spacer;

— remove the retaining ring and press out the bearing;

— press out the lip seal;

— if it is necessary to replace the driven sprocket, unlock and unscrew the bolts securing the sprocket to the base. The removed parts must be washed and the chain lubricated. If the ball bearing fails, it must be replaced. Assembly is carried out in reverse order.

AT “VOSKHOD” THE REAR CHAIN COVERS TORE. CAN THEY BE RESTORED?

Glue long U-shaped strips of thin (0.3 mm) duralumin into the even parts of the covers using Moment glue. Dry the covers in a warm place for a day, then install them on the motorcycle. There shouldn't be any problems with such cases.

Source

DID brand chains

This Japanese brand is considered the most popular these days. The statement is controversial, but they buy a lot of branded chains. The products fully justify the reputation of Japanese products in terms of quality and cost; the range includes options for almost any type of motorcycle. They are widely used in sports and are often included as standard equipment on conveyor models.

The original marking consists of numbers and letters and is applied to the outside of the chain. First, the pitch and width are indicated there, and then the parameters and purpose. There are almost a dozen main models: DID VX, ZVMX, ERT2, MX, VT2, 520ER3, 520ATV, VO. The first of them is designed for sports and road bikes: X-Ring oil seals, a choice of colors - black or gold. The second is considered the most durable among all the chains of this brand; it is used on road and sports motorcycles. An expensive thing, but for the sake of mileage or for a powerful car it will be just right.

The sealless ERT2 is useful for off-road use. It has high strength and reliability, and a long service life. In motocross and enduro, many riders use this chain. And if you need record strength, for motocross or motards, you should pay attention to MX. In turn, VT2 is recommended for long-distance enduro travel - it is also used on ATVs.

Those who prefer lightweight racing chains will immediately stand out from the lineup with the 520ERV3, with X-Ring oil seals. The company's assortment includes a reinforced oil seal model specifically for ATVs, with a volume of up to 0.75 l - 520ATV. And a budget option is also presented: VO, for medium-power road bikes (volume up to 0.5 l) - an O-Ring chain, steel-colored, which has proven its reliability in practice.

Transmission

HOW TO INCREASE THE TRACTION OF THE ENGINE OF THE “VOSKHOD” MOTORCYCLE?

The traction of the Voskhod motorcycle can be significantly increased by changing the gear ratio in the motor transmission from 2.06 to 2.75. Motor transmission parts from Minsk are suitable for this: the crankshaft drive sprocket from Z-12, the outer clutch drum from Z-33 and the motor chain (PV-9.525-1300). However, the kickstart ratchet, inner clutch drum and disc pack remain the same.

THE SPRING OF THE GEAR SHIFT SHAFT ON THE MOTORCYCLE “VOSKHOD” IS BROKEN. FRAGMENTS OF THE SPRING CAME BETWEEN THE TEETH OF THE GEARS OF THE BOX, WHICH RESULTED IN ITS BREAKAGE. IS THERE A WAY TO AVOID THIS TROUBLE?

To eliminate such consequences, try covering the spring with a homemade casing. It consists of two parts.

Cut part 1 (Fig. 4.18) from a steel sheet with a thickness of 0.5-1.0 mm. To make the second one (Fig. 4.19), you can use the factory cover 1, to which you need to weld plate 2, cut from a steel sheet of the same thickness.

Install the casing as follows: put part 1 on the shift shaft, then the spring, then part 2 (the cover is locked with the existing locking ring).

HOW MUCH HAVE THE TRANSMISSION PARTS OF KOVROVSKY MOTORCYCLES CHANGED IN THE PROCESS OF IMPROVING THE DESIGN OF MOTORCYCLES?

Transmission parts and mechanisms changed little during the production process. True, the 3M-01 engines received a strengthened motor transmission, the chain and sprockets became a little wider. However, this transmission assembly can also be installed on previous models. On motors with forced cooling, the drive sprocket has two additional cams, which are connected to the mountain valve drive shaft through a polyurethane coupling.

The gearbox along with the switching mechanism have not changed fundamentally since the days of Kovrovets-175A. The only modernization was carried out in 1972: gears with a module of 1.75 were replaced by gears with a module of 2. The next change occurred already on the Voskhod-3M-01: the dimensions of the splines for the inner clutch drum on the input shaft were changed, but these two parts ( shaft and drum) assembly can be installed on any Kovrov power unit with a four-speed gearbox.

The clutch release mechanism and the speedometer gearbox are made in a single housing, which has not changed since the time of the Kovrovtsev. The only alteration was carried out when the Voskhod-3 model was put into production: the seat under the speedometer shaft jacket was increased from 13 to 16 mm.

HOW TO REPLACE THE MAIN DRIVE CHAIN WITHOUT REMOVING THE COVERS?

Kovrov motorcycles have a completely closed final drive chain (from the engine to the wheel). Over time, the chain stretches and then it has to be replaced.

However, do not rush to disassemble the casings. This is only necessary if you need to clean them from the inside. Replacing the chain can be much easier and faster.

To do this, you must first clean the junction of the upper corrugated cover with the driven sprocket housing from dirt. Then place the motorcycle on the center stand. Loosen the rear wheel axle and sprocket housing nuts and move the wheel to the minimum chain tension position, sliding it along the swingarm towards the engine. This is done so that there are no difficulties with connecting the new chain, because its length is less than the worn one.

Place a stop under the muffler so that the rear wheel can be moved out. By removing the upper corrugated cover from the driven sprocket casing so that the chain is visible, and turning the wheel, “catch” the chain lock. Lock the chain in this position.

Unfasten the lock and attach a new chain to either end of the chain with the same lock. All that remains is to remove the fixation and pull out the old chain, threading a new one in its place.

Once again, fixing the chain and unfastening the old one, connect the lock. Be sure to install the locking plate with the cut backward along the chain. Cut a strip of tin measuring 7x16 mm and insert it under the locking plate and bend the edges. Finally, attach the upper corrugated cover to the casing and begin adjusting the chain tension.

HOW TO IMPROVE THE TRANSMISSION OF THE "OWL" MOTORCYCLE FOR ITS OPERATION IN OFF-ROAD CONDITIONS?

To travel off-road, it is necessary to increase the transmission ratio. The easiest way to do this is to replace the standard sprocket with a 13 or 14 tooth.

It is clear that in this case the maximum speed on the highway will decrease, and fuel consumption will also increase.

It is better to remove the chain housing and corrugations immediately. The chain and sprockets will wear out faster, but the likelihood of them jamming will decrease.

For motorcycle owners who have the appropriate equipment and the necessary skills, we provide design parameters for the manufacture of a rear chain drive sprocket (chain pitch 12.7 mm).

WHAT CHAINS ARE USED IN THE ENGINE AND MAIN TRANSMISSION OF THE VOSKHOD-3M MOTORCYCLE?

The motor transmission of the motorcycle uses a PV-9.525-1300 chain, which has 44 links. The length of the new chain (unfolded) is 419.1 mm. During operation, the chain can be extended up to 427.5 mm.

The letters PV stand for “drive sleeve”. The number 9.525 indicates the chain pitch in mm; the number 1300 indicates the minimum breaking load in kgf. The number 2 placed at the beginning of the designation indicates that the chain is double-row.

IS IT POSSIBLE TO INSTALL THE REVERSE GEAR CHAIN OF “MINSK” TO “VOSKHOD”?

You can also use chains from “Java” (126 or 128 links), “Tula” (116 links) or “Ant” (128 links), shortening them accordingly.

HOW TO REMOVE THE REAR WHEEL CHAIN COVER?

To remove the chain guard:

— remove the right crankcase cover (from the generator side);

— remove the rear wheel;

— remove the front part of the rubber chain covers from the crankcase sockets;

- unscrew the axle nut and separate it together with the covers and chain

pendulum chain housing;

— remove the covers, chain and take out the sprocket base along with the chain casing bushing;

- knock out the axle shaft with light blows of a hammer through a wooden spacer;

— remove the retaining ring and press out the bearing;

— press out the lip seal;

— if it is necessary to replace the driven sprocket, unlock and unscrew the bolts securing the sprocket to the base. The removed parts must be washed and the chain lubricated. If the ball bearing fails, it must be replaced. Assembly is carried out in reverse order.

AT “VOSKHOD” THE REAR CHAIN COVERS TORE. CAN THEY BE RESTORED?

Glue long U-shaped strips of thin (0.3 mm) duralumin into the even parts of the covers using Moment glue. Dry the covers in a warm place for a day, then install them on the motorcycle. There shouldn't be any problems with such cases.

Source

What are SFR chains?

Chinese products, but of good quality. The assortment includes series made from Japanese components and metal, with the highest parameters. The company itself is relatively young - almost 30 years old (since 1991). Currently, over 1,200 thousand chains are produced under this brand every month: for motorcycles and elevators, timing belts, and industrial equipment. They are sold in Japan and Europe, in the USA.

Branded chains have already proven themselves to be durable and wear-resistant. All products comply with ISO standards, and each product undergoes tensile bench tests. The range includes sealed (various types) and non-sealed (solid core) versions. You can select a suitable chain according to the recommendations of the bike manufacturer and taking into account how it is used. With regular diagnostics and proper care, a chain of this brand will certainly work out its value.

And finally about Tsubaki chains

The brand is represented by the Japanese company Tsubakimoto Chain Co. of the same name. Now it is known as the largest manufacturer of transmission systems; no one else produces them on the entire planet. This is a multinational organization with offices in many countries, but all 4 factories are located in Japan. The company catalog contains chains for industrial equipment and vehicles, for a couple of dozen industries. Incl. heavy-duty, low-noise, lubrication-free, plate, steel, etc.

In the motorcycle sector, Tsubaki is also the undisputed leader. This brand has its own classification of chains: either by power reserve or by durability. For example, products of the Gamma series are designed for a mileage of 5-10 thousand km, Alpha and Omega - from 10 to 20 thousand km, Alpha XRG and Sigma must withstand 20-30 thousand km.

Really good chains don’t just become world leaders. And the company will soon celebrate its centennial anniversary. Invests heavily in improving products, increasing the life of trouble-free operation, increasing productivity, and reducing the cost of products. The company catalog presents chain drives for any technical task - you just need to choose the optimal option. Experienced users can easily navigate themselves, while consultants help those less technically savvy with their choice. It is recommended to select a chain not just for the model, remotely, but for a specific motorcycle, taking into account all the circumstances - this is how the Tsubaki branded chain drive will show itself in the most favorable light.

How to determine if a chain drive is faulty

Unlike the timing belt drive, which is located outside the engine, the chain with gears is located inside the power unit and is completely hidden from view. On the one hand, this is a plus: the mechanism makes less noise and is generously lubricated with engine oil, which increases its service life. On the other hand, without removing the valve cover it is impossible to visually assess the technical condition of the unit.

The first sign of a chain drive problem is a rumbling sound coming from under the cover when the power unit is operating. The rumble of a weakened chain cannot be confused with anything; it is heard from the side where the gas distribution mechanism is located.

Loosening with a gap of up to 1 cm allows the chain to jump when starting the engine

Having heard such a sound, the car owner should check the condition of the drive so as not to encounter big troubles associated with engine repair. There are 2 ways: immediately go for diagnostics to the nearest car service center, or remove the valve cover yourself and make sure that the section of the chain near the camshaft gear is loose. Worsening tension is caused by the following reasons:

If an old-style mechanical tensioning device is installed in the car engine, then when the described symptoms appear, the first action is to tighten the chain with its help. To do this, simply loosen the outer nut holding the plunger spring and manually turn the crankshaft 1-2 turns. After which the nut is tightened again.

Old VAZ 2101–07 engines have a mechanical tensioner with a nut

Modern automatic hydraulic tensioners are not designed for manual adjustment and must be replaced if they break. You can verify that the element has failed only by removing it or disassembling the entire timing belt assembly. The same applies to the damper - on most cars, its wear can only be assessed when the mechanism is disassembled.

Ignoring the rumbling noise made by the chain will sooner or later lead to motor failure. The severity of the consequences depends only on your luck.