In order to increase engine power, Java manufacturers had to increase the diameter of the body kit element, which lowers the lifting part of the vehicle, from 26 to 28 millimeters. In addition, the carburetor was supplemented with systems and became more complex.

The only thing that was left unchanged was the cylindrical spool. But, compared to its older domestic counterparts, it copes much better with uniform and fine atomization of fuel.

In order to attach the carburetor to the engine, it is necessary to use special rubber inserts in the form of rubber rings. Thanks to them, the huge amount of vibrations that are transmitted from the carburetor to the motorcycle is reduced.

In addition, this fastening reduces the likelihood of the fuel supply jet becoming loose. By the way, the technical changes in the Java motorcycle did not affect its efficiency in any way. The most important advantage of mounting on a rubber ring is the possibility of repair and maintenance without removing the carburetor. Once upon a time this was the dream motorcycle for all Soviet motorcycle enthusiasts. However, even now it does not lose its relevance, since tuning Java is much easier than improving other models of Soviet motorcycles, such as the Ural or Minsk. With your own hands you will not only make it more powerful, but also turn a relic of the past into a modern, stylish motorcycle.

Theory

Before moving on to adjusting the carburetor, you need to understand its main element - the float mechanism. A floating device consisting of a plastic mass and a double float - a chamber, as well as a needle valve. He is responsible for draining the liquid.

In order to more accurately adjust the level of fuel fluid in the floating chamber, it is necessary to disconnect the power system unit from the engine. Then unscrew the lid. The required level must be 11 millimeters removed from the surface between the boundary of the power system assembly and the plastic chamber.

Adjusting the carburetor java 638

To begin with, we place the body where the floats are located on the edge of a glass container, preferably with a volume of 0.5. Next, this housing is connected with a hose to the fuel tank. After opening the tank tap, and after a certain time, the fuel level should be established.

It is worth remembering that the bottom height of the case reaches 2 mm, which means the bottom of the collar is nine millimeters from the top edge. Therefore, the level should also be 9 mm. If this indicator cannot be achieved, it is necessary to bend the tabs that are located between the floats until the level becomes normal.

Adjusting the idle speed of the Java 638 carburetor

To begin with, stop the spool, you need to set constant speed using a screw located vertically. For an engine that has already been in operation, average speeds range from 0.6 to 1 thousand revolutions per minute.

Then we try to achieve the maximum number of revolutions by rotating the horizontal bolt. To more accurately determine the number of revolutions, all turns of the screw must be done smoothly. Next, the spool is lowered until the speed drops to the set speed. You can later increase the number of revolutions with the screw.

Important! Turning the horizontal bolt more than 2 times will not lead to changes.

It is also worth noting that all changes when adjusting the power system unit should be carried out only on a warm engine.

How to Adjust Carburetor K 151

1. The fuel level in the float chamber is adjusted with the carburetor cover removed. However, without disconnecting the trigger rod, you can unscrew the screws securing the cover, lift it and, having removed the gasket, turn the cover to the side as far as the gaps in the places where the rod is attached will allow.

Pump gasoline into the float chamber using the manual pump lever until the level stabilizes. The distance from the fuel level to the top plane of the carburetor body should be 21.5 mm.

Rice. 1

When the fuel level is below the specified level, it is necessary to bend up tongue 1 of the float, which rests against the shank of the shut-off valve needle. If the level is higher, bend the tongue down. After each bending of the tongue, you need to unscrew the drain plug of the float chamber, drain the gasoline from it and, screwing the plug back into place, re-pump gasoline using the manual pump lever.

2. Adjust the starting system

You can do this directly on the car by completely warming up the engine and connecting a tachometer to it. After starting the engine with the air filter removed and lightly pressing the accelerator pedal, completely close the air damper using its drive handle. Then use the blade of a screwdriver to open the air damper as much as the lever mechanism will allow. The engine crankshaft rotation speed should be 2500–2700 rpm. If it differs from the specified one, you need to loosen the lock nut on the adjusting screw that rests on the profile lever and screw this screw in or out. After completing the adjustment, tighten the locknut tightly.

Carburetor K 151 idle speed adjustment

Idle speed control option K 151

and ignition on a GAZ engine.

Carburetor K-151. Gazelle on gasoline and gas!

Many times we were asked to show and tell about the K151 carburetor. In this video, Nail Poroshin is live again...

Rice. 2

3. Adjust the idle system

on a warm engine with a tachometer connected to it. To do this, with the engine running, set quality screw 2 to the position that ensures maximum idle speed. Then, using quantity screw 1, set the frequency increased by 100–120 rpm. After this, tighten the quality screw until the rotation speed decreases by 100–120 rpm. This method of adjustment allows you to meet exhaust toxicity standards. However, more precise adjustment is recommended using a gas analyzer.

Adjusting the mixture quality of the Java 638 carburetor

- The quality of the mixture can be influenced by two methods:

- changing the size of the jet;

- change the location of the needle.

Changing the jet size. If you raise the spool, the diffuser responsible for the lift force will open completely, so this will reflect its effect on the composition of the fuel mixture.

When changing the position of the needle, the fuel sprayer should be brought to the middle position.

It is worth noting that incomplete raising of the diffuser is not responsible for increasing the possible engine power, but only for its efficiency. But this requires a mixture with a low air content. That is, the excess air of a flammable substance must be in a ratio ranging from 1 to 1.15.

Important! If the fuel is too lean, the engine may experience problems with the element responsible for regulating the current. This device will not open completely.

To avoid the problem discussed above, it is necessary to select a needle position such that the fuel becomes leaner, but the engine runs without layers.

So, the lower the needle is, the more air deficiency is caused, and the higher it is, its oversaturation.

In general, it is better to listen for a change in engine operation after changing the needle position.

Some motorcycle enthusiasts experiment with jetting conversions to increase maximum engine power. As a rule, to do this, the cross-sectional area of the jet is increased thanks to a regular needle treated with sandpaper. The carburetor is flushed using pure gasoline.

Thus, to adjust the idle speed, a certain number of revolutions is selected with bolts, and to adjust the YAVA 638 combustible carburetor, two methods are used - changing the size of the nozzle or the position of the needle size. The jet operates when the device is fully raised, ensuring atomization of fuel, and the needle changes - when the device is in the middle. The needle influences the adjustment by changing the amount of air in the fuel.

What will you need?

To install the ignition from a scooter in Java, we will need a specific conversion kit. First of all, there is the generator itself; there are two models to choose from. The simpler QMB-139 will perform all the necessary functions, but problems may arise with the light at night, since the winding for the head light is rather weak and will greatly depend on the speed. If this parameter is important to you, then choose a stator from the QMI-157 or 152QMI model - they will be sufficient to achieve your goals.

You will also need an ignition coil with two terminals, here again there is plenty to choose from. For our purposes, motor coils ZMZ-406 or from Oka are suitable.

You will need a 12 volt battery. We don't need a new one; any used motorcycle or new Chinese battery will do. Its role is to smooth out voltage drops in the turn signal and stop signal circuits.

Also, do not forget about the set of wires/terminals. It is better to take the latter from Japanese scooters.

The last item is the adapter plate. Alas, it cannot be found on sale, but kind people have prepared the exact drawings presented below, according to which you can assemble your own adapter plate or order it. The thickness of the metal is 4 mm, this is an important parameter, because if you make the plate larger or smaller, some elements of the system may not fit or work incorrectly.

Carburetor adjustment on YAVA 638

Model 638 replaced the previous JAVA 634, having received a new engine that became a little more powerful without losing its efficiency. However, to obtain this result, the diffuser diameter was increased, which did not allow the use of the old carburetor due to the starting characteristics of the engine. Engineers had to create a new device for the YAVA 638 carburetor. It retained a cylindrical throttle from the previous version, unlike Soviet brands with a U-shaped spool. Making such a mechanism is much easier, but the fuel injection in the new version is denser and more chaotic. Perhaps this feature is the only similar quality between the carburetors of the two JAVA models.

The device with the motor is secured using rubber inserts (rings). This reduces the amount of vibration transmitted from the unit and reduces the possibility of loosening the jet, as well as foaming in the float chamber. Moreover, with such a mount it is possible to repair and maintain the carburetor without removing it from its place.

Rework and repair

A significant drawback of the Ikov 2829CE carburetor is poor starting of the motorcycle in cold weather due to the imperfect design of the enricher. A difficult start is noted not only by the owners of 638 models, but also by the owners of some Kovrov motorcycles on which such carburetors were installed from the factory . The thing is that fuel is taken to enrich the mixture from a separate channel in the float chamber, to which it is connected by a nozzle.

Also, a ventilation duct located on the side of the carburetor is used to draw air to the enricher. The cross-section of this channel is so large that the vacuum in the enricher is not enough to suck fuel through the nozzle. As a result, it is not the enriched mixture that enters the channel behind the throttle, but gasoline vapor mixed with cold air, which of course does not contribute to successful engine starting.

To eliminate this problem, the carburetor needs to be modified. The side channel can be plugged, for example, with a gas-resistant sealant, thereby “pressing in” the air.

In this case, the vacuum will be sufficient to suck the required amount of fuel from the chamber. You don't have to worry about chamber ventilation, because... On the other side of the carburetor there is the same channel.

Another alternative solution to this problem is to install a float suppressor, as on old carburetors (more details in the photo).

Carburetor design

- The float chamber and intake system consists of the following elements:

- launch hole;

float chamber;

- carburetor with starting jet;

- start lever;

- fuel screw;

- float;

- needle valve.

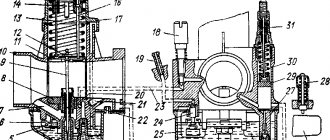

Rice. 1. Float mechanism, starting system: 1 - starting carburetor jet; 2 - float chamber; 3 — starting carburetor; 4 — trigger lever; 5 — fuel fitting; 6 — float; 7 - needle valve

- Idling includes the following:

- idle hole;

- additional hole;

- secondary emulsion pipe;

- throttle stop;

- frame;

- idle speed adjustment bolt.

emulsion pipe;

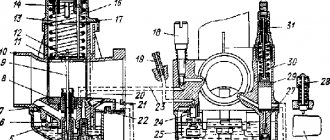

Rice. 2. Idle and transition system: 1 - idle jet; 2 — idle emulsion tube; 3 - additional jet; 4 - additional emulsion tube; 5 — spool stop; 6 — carburetor body; 7 - idle speed adjustment screw

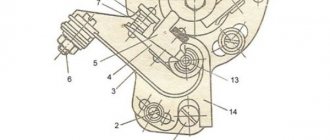

Rice. 3. Main system, econostat: 1 - main jet; 2 — spool needle; 3 - spool; 4 — spool spring; 5 - cover; 6 — econostat; 7 — econostat jet

The float mechanism includes two plastic parts. The first is a spring-loaded needle valve, the second is a float chamber, and there is no sealing fastening. It is important to set the fuel level in the float chamber correctly. It is installed according to regulations to eliminate cases of valve clogging, because the design is quite demanding and sensitive to dust and dirt. If the hole becomes clogged, the engine will simply stall along the way. The good thing is that when disassembling the structure it is not necessary to remove the carburetor. You just need to get to the needle valve and clean it.

What did they put on the motorcycles from the factory?

A distinctive feature of all Czechoslovak carburetors is the cylindrical shape of the throttle valve.

It is driven by a mechanical cable drive, which determines their belonging to slide carburetors. There are numerical and alphabetic indices on the case, which are deciphered as follows:

- the first two digits (29) – carburetor with throttle valve (with variable vacuum);

- 26 (24,28) – diffuser diameter;

- SD - carburetor with a starting device and a main fuel jet located under the nozzle;

- SBD – carburetor without starting enrichment. The main fuel jet is located under the nozzle.

Starting system

The 634 model had its own feature - a float quencher. It served to start the engine in the cold season. The Java 638 does not have such a system, but there is an additional carburetor to start the engine. It is located inside the main one. When starting a cold engine, it makes the fuel mixture more saturated. For it to start its work, a special toggle switch is turned on. After warming up it is turned off. This system only works well when the throttle is lowered, otherwise the starting carburetor will not perform its function.

It is important to keep the jet clean. Its close location and pressed fit in the float chamber ensures injection into the diffuser hole. The amount of emulsion supplied depends on the location.

It is important not to forget that adjusting the YAVA 638 carburetor greatly affects the fuel supply and thereby creates the correct air-fuel mixture. In cases where a lack of power is noticeable or popping noises are heard in the exhaust system, it is necessary to adjust the needle valve that injects fuel into the combustion chamber.

Installation of two

Among the ideas of domestic tuner enthusiasts, there are sometimes quite interesting attempts to install two carburetors on Java. The essence of the idea is clear. Two carburetors should give a significant increase in power. But the matter will not be limited to installing carburetors alone.

The intake geometry of Java is designed for the installation of one manifold. Two carburetors simply won't fit there. In addition, you will need to install reed valves, otherwise the backflow of the mixture will reduce power. And for this you will need to make additional windows in the pistons on the intake side.

In general, this tuning option is not structurally suitable for the Java engine, unlike the same Izh. However, some people managed to make some semblance of a Yamaha RD 350 from Java.

Idling

Immediately after the engine starts, the system begins to idle. Like a starting carburetor, this system operates when the throttle is low. It consists of a hole, emulsion pipes, a bolt that regulates the quality of the mixture and translational channels. Since the air supply is much lighter than fuel, adjustment is made using a bolt. The more you tighten it, the lower the air flow will be. Do not overdo it with the air supply; if there is too much of it, the mixture will become leaner and the loss of power will become very noticeable.

Summing up

Ikov carburetors, like Czech motorcycles, have undergone significant changes today. But any of them in their years were easy to maintain and were of high quality in manufacturing. Ikov 2829 CE can rightfully be called the best and most technologically advanced carburetor in the entire line (the plant eliminated the problem with the enricher by replacing the starting nozzle). It is still installed on new Java motorcycles, model 640. And at one time, some of the domestic motorcycles were produced with it from the factory.

Main dosing system

When the throttle rises to a height of five millimeters, the main dosing system is activated. Here a complete mixture is created for enhanced engine performance. However, before creating the mixture, the fuel passes through an annular channel. A small amount of air gets into it there. After entering the diffuser, the fuel is enriched with air from the main flow.

The quality of the mixture can be influenced by changing the angle of the injection needle or the size of the main hole. In this case, the hole plays the main role of enriching the mixture when the throttle is raised, while the needle only plays a role in the middle position. When the diffuser is fully open, maximum output must be achieved. This can be achieved with a higher quality of the combustible mixture. In this case, you can select the jet of the required size and install it. Usually the new jet is a standard one, in which the hole is enlarged.

Econostat

The econostat is a system that enriches the mixture at a high throttle position. Its device is very simple. The essence of the work is to take fuel from the float chamber with a pipe. Through the channels, the fuel rises into the diffuser and is sprayed in front of the throttle. This helps air bypass the throttle when it opens low.

In conclusion, we note that after each work carried out, adjusting the YAVA 638 carburetor is very important, see the video about which at the end of the article. It is also necessary to carry out timely maintenance of the carburetor, the essence of which is to clean the main working elements. Washing should be done as often as possible, preferably with diesel fuel or gasoline. It is better to treat resinous areas with caustic substances, for example, acetone. Otherwise, the system will not cause you problems.

Carburetor adjustment Java 638 2928CE

For Java 638, a new type of carburetor was created in order to increase engine power. The diffuser diameter was increased to 28 mm (previously 26); introduced additional systems and complications. The only element left from the previous carburetor is a cylindrical spool, which, in comparison with Soviet K-62 carburetors, ensures uniform and fine atomization of the mixture. The carburetor is attached to the engine through an insert ring made of gasoline- and oil-resistant rubber. By turning the carb 90 degrees, it is very easy to remove the cover, move the needle to a different position, clean the jets and float chamber. (See continuation)

ADJUSTING THE IDLE SPEED OF THE CARBURETOR JAVA 638 2928CE

First, using the spool stop, we set the minimum stable speed (screw_1) (for a run-in engine this is 600-1000 rpm). Then, by rotating the quality screw (screw_2), we look for the position at which the speed will be maximum. This is done slowly. Each time the screw must be turned no more than 1/4 turn and wait a while until the rotation speed stabilizes. Of course, we determine the speed using the standard tachometer. Keep in mind that unscrewing the quality screw (screw_2) more than two turns is ineffective; with further unscrewing, there will be practically no depletion. After the position of the highest speed is found, lower the spool slightly until the speed drops to the previously set one. Then you can try to increase the speed with the quality screw, that is, clarify the position of the quality screw. Adjustment of the Java carburetor is carried out only on a warm engine.

Types of BSZ

— Single-channel (one Hall sensor, two-lobe modulator, one switch, one two-terminal ignition coil operating on two cylinders at once)

— Two-channel (two Hall sensors, one, or better yet two, modulator lobe, two switches, two ignition coils, one for each cylinder)

It is preferable to install a single-channel system, since it will be more stable, because here you won’t have to adjust each cylinder (which you have to do at KSZ); here, if the modulator is made correctly, then only one cylinder is adjusted

Also, in a single-channel one, fewer wires are used, its parts take up less space, and energy consumption is lower (which is very important for 6-volt generators). There are many people who like to “get confused” who install a two-channel one, shouting at the same time that this way they can configure it more accurately, etc.

I assure you that these are unnecessary hassles, and there will be no accuracy here (why is indicated above)

There are many people who like to “get confused” who install a two-channel one, shouting at the same time that this way they can configure it more accurately, etc. I assure you that these are unnecessary hassles, and there will be no accuracy here (why is indicated above)

Spark plug. I said above that spark plugs “live” longer, which begs the question “Why?”

Actually the answer is simple. If you decide to install a single-channel BSZ (or a two-channel one with a two-lobe modulator), then this is what will happen:

When igniting in one cylinder, in the other, a spark will also strike at BDC, since it strikes simultaneously on both spark plugs, that is, spark twice per revolution on each spark plug.

ADJUSTING THE QUALITY OF THE MIXTURE OF THE CARBURETOR JAVA 638 2928CE

The composition of the mixture at full and medium lift of the spool can be influenced in two ways - by changing the size of the main jet or the position of the needle. Moreover, the size of the nozzle has a greater impact on the composition of the mixture when the diffuser is fully open (raising the spool), and the position of the needle affects mainly at medium. Since when the spool is not fully raised, maximum power from the engine is not required, but efficiency is important, it is necessary that the mixture be lean. But excessive leaning will cause a “failure” in the engine’s operation at partial throttle opening modes. Therefore, it is necessary to choose a needle position such that the mixture is lean, and the engine operation remains stable in all modes, without “failures”. Lowering the needle (moving its latch upward) causes depletion, and raising it causes enrichment. Usually, after running in, the needle is lowered, moving the latch up one notch. However, it will be better if, when adjusting the carburetor , moving the needle, you pay attention to the operation of the engine before and after the change, try different positions of the needle. It is advisable to make a selection, since this affects both the quality of the engine and the overall fuel consumption of the Java motorcycle.

Designations in the figure: 1 cylindrical spool; 2 needle valve; 3 idle jet; 4 additional system jets; 5 main jet; 6 spool needle; 7 needle guard.

Jawa 634 - review, device and setup

Java 634 motorcycles were equipped with simplified Ikov 2926SBD carburetors. The main difference from the later model Ikov 2928CE is the smaller number of working systems (idle system and main fuel system), the size of the float chamber and its location on the side, relative to the diffuser (with strong lateral rolls, this affected the operation of the engine), as well as the presence of a float stopper ( analogue of the enrichment agent when starting the engine).

Carburetor adjustment is carried out according to the factory table from the user manual.

The table shows the adjustment data for the Java 634 motorcycle carburetor

The break-in period for this engine is approximately 2000-2500 km. After this, you need to change the position of the needle in the groove of the lock (2) and unscrew the quality screw (4) according to the table. The free play of the throttle cable is adjusted with a screw (1) and should be 1.5-2 mm. By default, the throttle lift adjustment screw (5) must be lowered to the minimum stable engine speed.

Carburetor cross-section

A similar adapter was installed on Voskhod 3M motorcycles, which at one time were produced from the factory with Czech carburetors. You can look for it at motor showrooms.

Java motorcycle carburetor

The Java 638 motorcycle often gets clogged in the carburetor , and even the fine fuel filter, which can be installed by cutting the gas line and inserting it in the middle, does not help. A filter for a Java motorcycle can be installed, for example, from a Zhiguli car. To clean the carburetor without removing it from the motorcycle, you need to close the tap while continuing to move and open it when the engine does not have enough fuel and it starts to fail. The flow of gasoline should wash away the speck and normal carburetor operation will be restored.

The carburetor does not have a float suppressor, as on the Java 634 motorcycle. Instead, there is a lever that rises up when starting a cold engine, which is much more convenient. There are no problems with starting up to minus 5-10 degrees. There is another way to enrich the fuel mixture - you need to cover the drainage hole with your hand, located near the starting device under the lever.

Float mechanism and starting device: 1 - enrichment nozzle 2 - float chamber 3 - enrichment 4 - enrichment lever 5 - fitting 6 - float 7 - needle valve.

Idle system: 2 - emulsion tube 4 - additional emulsion tube 5 - throttle lift screw 6 - carburetor body 7 - quality screw.

To prevent a “failure” in the Java motorcycle carburetor when the throttle is lifted slightly, a transition system is provided. It has air and fuel jets. The air to the transition and idle systems comes from a single channel, then part of it goes to the idle system, and part of it goes through the air nozzle to the additional system.

Main dosing system and econostat: 1 - main jet 2 - needle 3 - spool 4 - spring 5 - cover 6 - econostat 7 - econostat jet

The main metering system of the Java motorcycle begins to work when the throttle is raised more than 6 millimeters. The composition of the mixture at medium and full throttle opening is affected by the size of the jet and the position of the needle. When the engine is not fully opened, the efficiency of the engine is more important than its power, so the mixture should be lean, but not excessively, otherwise there will be interruptions at small openings. This is regulated by moving the needle; when lowering, the mixture becomes leaner; when raising, it becomes richer. Experiment with the position of the needle and find the position that suits you best.

Unlike the carburetor of the Java 634 motorcycle, the carburetor on the Java 638 motorcycle is equipped with an econostat that operates at large diffuser openings (more than 14 mm). The ecostat enriches the fuel mixture, increasing engine power. Fuel is taken through a tube from the float chamber and then rises through channels above the diffuser and is injected in front of the spool. The Java econostat atomizer is located in the upper part of the diffuser, so with small openings it practically does not work.

Jawa 250/350

On YAVA-250 motorcycles with indexes 559/02 and 559/04, Ikov 2926SD (before 1967) and 2926SBD (after 1967) carburetors were installed. On YAVA-350 motorcycles models 354/06, 360/00, Ikov 2926SBD carburetors were used.

The first carburetor has a separate starting carburetor (enricher), which is activated by lifting the cable using a lever on the steering wheel. Its presence on the 250 cc motorcycle model is due to the fact that a smaller single-cylinder engine is more difficult to start in cold weather than a two-cylinder one. Otherwise, these two carburetors are almost identical. Later, rotary air dampers were installed on both motorcycles on the carburetor inlet pipe. A separate starting enrichment unit was no longer needed.

Before you begin adjusting these carburetors, you must perform the following procedure:

- Open the gas tank tap and wait until the carburetor float chamber fills. Close it and remove the chamber cover to make sure there is no dirt on the bottom. In case of contamination, remove the carburetor and blow out all channels with compressed air or rinse in kerosene. Attention, to prevent contamination of the carburetor channels, it is necessary to install a fuel filter in the gasoline fuel supply line. Its material should consist of a thin mesh, which will allow the incoming gasoline to be cleaned of oil and foreign impurities.

- Be sure to check it out. Is the ignition timing set correctly?

- Check the condition of the filter element in the air filter. If the paper filter is dirty, it needs to be replaced. It is enough to wash the filter oil element in gasoline and moisten it with a small amount of engine oil.

- Setting the screws according to the table. Set the quality adjusting screw (18) and the throttle needle (25) to the positions indicated in Table 2. Adjust the free play of the throttle cable sheath to 2-3 mm using the stop (1).

- Setting the minimum speed. Start the engine, use the quantity screw (12) to set the minimum stable engine speed. Ride a motorcycle for 5-10 km, warming up the engine.

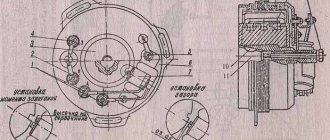

Drawing of carburetor detail Ikov 2926SD

The table shows the adjustment data of the 2926SBD carburetor

The process of adjusting the carburetor itself proceeds in a strict, sequential order:

- Installing the “correct” spark plugs. For driving in warm weather and after the break-in period, install analogues of “cold” Pal -8.9 spark plugs (NGK BP8HS-BP7HS, Brisk N14-15, Bosch W3AC-W4AC, etc.).

- We are looking for minimum speed. Start the engine and use the speed screw (12) to find the minimum engine speed at which the motorcycle does not stall.

- We increase the speed. Turn the quality screw (18) slowly to the left to increase the speed.

- Again, use the quantity screw to “feel for the minimum.” Repeat the operation until the motorcycle begins to stall at idle. When the limit is found, the quality screw needs to be tightened a little, enriching the mixture. Depress the clutch and engage gear. In this case, the motorcycle should work steadily and not stall (of course, with a working clutch). If the motorcycle stalls, you can raise the throttle a little. Attention, to adjust the carburetor in medium load mode, you should find a straight road with horizontal surface, without obstacles. This is necessary to control the adjustment when the motorcycle is moving in direct gear at a speed of 40 km/h and above. The weather should preferably be warm and calm.

- Check the operation of the engine while the motorcycle is constantly moving at a speed of 60-70 km/h. If the engine operates unstably (every cycle), then these are all signs of “flooding” the spark plug due to a rich mixture. In this case, the needle must be lowered until the motorcycle begins to operate normally.

- Check the acceleration of the motorcycle over a 1 km section. Accelerate the motorcycle from 40 to 80 km/h and evaluate the engine performance. The sound should be clear, without interruptions, acceleration should be smooth, with a uniform increase in engine speed.

- Assess engine response. Let's see how the motorcycle reacts when you sharply turn the gas lever, when accelerating over a short distance. Overclocking must be efficient. The main condition is the absence of a “failure” - the effect of a sharp leaning of the mixture due to the rapid opening of the damper. This can happen if, when moving the needle, it was lowered very low or due to air leaks in the intake tract. In the second case, the reason lies in incorrect idle speed adjustment.

Useful video

Visual video material on removing, cleaning, tuning and adjusting the Java 350 model 354 carburetor.

Sometimes, while operating a motorcycle, conditions may arise when it is necessary to change the current carburetor adjustment (weather conditions, number of passengers and motorcycle load, use of fuel with a different octane number). In this case, it is enough to replace the main fuel jet, which can be accessed by unscrewing the plug at the bottom of the carburetor.

For example, if the motorcycle is operated in winter weather, then it is necessary to install a larger fuel jet (main fuel jet). You can select it experimentally by determining the composition of the mixture by the color of the central electrode of the spark plug.

When mixed optimally, the color should be brown, reminiscent of rust or a shade of red brick. Accordingly, if the mixture is too rich, the insulator will be covered with black soot. And with a lean mixture, the electrode will be light yellow or gray. It is the last option that poses the greatest danger. In this case, the electrode may melt, and its parts will fall into the CPG, which will lead to expensive repairs.

Attention! The condition of the spark plugs should be assessed after a short motorcycle ride at a speed of 75-80 km/h (1-2 km). The spark plug must be unscrewed from the cylinder immediately after stopping the motorcycle, and it must be turned off while moving. Only if these conditions are met will the color of the spark plug electrode be closest to the actual one.