Water-powered motors have become widespread for good reason. Now almost all motors are water-cooled, and only a few are air-cooled.

In this post, I equate to water cooling engines with a specially dedicated cooling system, its own coolant (antifreeze), pump (pump) and radiators. They have many advantages, and any air vent simply cannot withstand the competition. But some people still don’t know about the many advantages of water cooling.

At first glance - the view of the consumer, the owner of a touring motorcycle (not a racing motocross or road-circuit) - the advantages of water-cooled engines lie on the surface:

water cooling prevents the engine from overheating in almost any mode

more power can be extracted from a water-cooled motor with the same working volume and less weight

he's not more fragile

it is not more expensive to operate

Everyone seems to have heard about the disadvantages of water cooling, and it would be worth mentioning them here only to maintain the balance of arguments. But in fact, there is only one drawback (and is it a drawback?) of a water-cooled motor that is significant for the consumer:

The presence of an additional cooling system, the maintenance of which boils down to replacing, far from the most expensive, fluid once every 2 years, while their air counterparts are much more demanding on the quality of expensive oil, the operation of which is more difficult for them.

All other disadvantages have either lost their relevance long ago, or have always been idle fairy tales.

Yes, there was a time, 30 years ago, when they said a water-cooled motorcycle, the imagination painted fantastic pictures. No one could even imagine that this would become possible and accessible to everyone.

Suzuki GT750 - The first Japanese water-cooled motorcycle

1. Dropsy has a lower temperature - true

Imagine a simple situation. You are standing at a traffic light, the light turns green and you speed up.

The heat transfer coefficient for the wall-air, even with forced convection and significant fins, is much less than that for the wall-liquid pair. And considering that the pump is connected to the crankshaft, and the speed of washing the cylinders increases in proportion to the revolutions, a water-cooled engine is much more efficiently cooled than its air-cooled counterpart. Hence the increased resource and greater power. Add to this the aluminum block, and you get an almost non-overheating device.

2. Dropsy is brittle - not true

In fact, reliability, in the global sense of the word, is not directly related to the type of motorcycle cooling or the number of components. 80% of engine failures are not related to the cooling system at all. I’ll give you a simple example: here’s an engine with 1 cylinder, and here’s one with 4. The volume is the same. It would seem that an in-line four has 4 times more nodes than in a single-barrel. But why is driving 100 km to the capital on a road inline 4 car the norm, but on any single-barrel car is an almost unattainable result? My road car has 4 times more components, sometimes more power, but it drives longer and is repaired less often. So maybe that's not the point?

3. Sounds like a rice grinder - not true.

"Rice grinder" - DRZ400

Let's be honest, this depends much more on other factors than the type of cooling. The watery DRZ400 with its bass forward flow sounds much more solid than V-shells with stock mufflers. Still think it's a cooling issue?

4. Greater resource - truth

Higher thermal conditions impose a number of restrictions on the operation of a motorcycle, as well as higher requirements for engine oil and its replacement intervals. With increasing temperature, the viscosity of the oil decreases, and its aging occurs more intensely. There has already been a heated discussion on the power supply about the effect of engine temperature on the service life - here. Are you ready to change your oil more often and select it more carefully? Can you go karting if you want? What about long-distance travel to countries where +45 is the norm? Or should we say yes to technology?

5. Dropsy is frail - not true

How long have you seen air engines in motorsports? In a situation where every gram really counts, when every horse in the engine is minus a second to the lap time, there is no place for marketers, whom everyone is so afraid of. Only the best technical solutions that the manufacturers managed to develop remain here, and you know what. There are no airs here...

PS. The post is friendly and positive) The charisma and style of balloonists are often very appropriate; they look cool on classic motorcycles. But sometimes, it seems to me that people are so intimidated by “evil marketers” that they are about to switch from cars and motorcycles to horses.

Advantages and disadvantages…

People, explain the difference between water cooling and air cooling. I mean what are the pros and cons of one and the other...

Subaru Forester SHJ 2.0 2011 Prul))))

Dropsy cools better, which is why it is used on highly accelerated engines, the downside is that it is structurally more complex and has more weight. Air is less effective, but simpler and lighter.

Address: city without metro Posts 6,983

What is the difference between air-oil and air?

I drove all the recent Moscow heat on an air-oil Yamaha - no problems, but the heat comes from the engine, but not so strong as to cause discomfort when riding...

Address: Vladivostok Posts 354

How does air cooling affect special off-road conditions?

Subaru Forester SHJ 2.0 2011 Prul))))

Posted by Ogr1sh

How does air cooling affect special off-road conditions?

There is at least one plus - if you drop your motorcycle, you don’t have to be afraid that you will break the cooling system and disable the motorcycle.

Message from KaLLinoZZ

What is the difference between air-oil and air?

Air cooling cools the engine using air flowing exclusively onto the cylinders, while air-oil cooling has an additional radiator through which oil circulates.

Address: Vladivostok Posts 354

Well, with air cooling you probably won’t get through much mud? In terms of when there are heavy loads on the engines. Or I'm wrong?

Subaru Forester SHJ 2.0 2011 Prul))))

Address: Surgut Posts 6,731

Posted by Ogr1sh

Well, with air cooling you probably won’t get through much mud? In terms of when there are heavy loads on the engines. Or I'm wrong?

You won’t be able to travel much on big muddy roads and with a water one either :-))))

Or do endurikes have fans? (otherwise they are not on the cross-country).

I think I can't think anymore...

Address: Vladivostok Posts 354

Well, I have a small one behind the radiator... =)

Subaru Forester SHJ 2.0 2011 Prul))))

Address: Nakhodka Posts 386

Personally, I prefer air vents (currently I have two motors, with both types of cooling), as mentioned above:

1. Structurally simpler.

2. There is no risk of damage to radiators if dropped.

I rode both. The motor overheated once, the thermostat jammed in the closed position on the XR650R (though without any after-effects, I noticed it in time).

Dropsy is really not so afraid of fords (there is no risk of the piston “sticking” during a sudden release)

Current time: 03:29. Time zone GMT +3.

Flaws

Not without its shortcomings. Before purchasing a car equipped with such a cooling system, you should know the main disadvantages of these solutions.

Thus, the operation of the engine is accompanied by excessively loud noise. This noise is created by a running fan. Another disadvantage is the size, since the motor is equipped with blowing devices. Even at the current pace of technology development, air flows are unevenly directed, which means there is a risk of local overheating. Engines of this type are very sensitive to the quality of gasoline and oil; high demands are placed on the condition of the main parts in the engine.

But cars with such a system have firmly taken their place in the automotive industry. These power units are equipped in trucks, and there are several passenger models. Agricultural and military equipment and some diesel engines operate on air cooling.

Air

The motorcycle engine is cooled by oncoming air. Since heat dissipation occurs through the surface of the engine, it is increased with the help of fins in the most heat-loaded areas. Cooling fins are located on the cylinder head and cylinder, but on the crankcase, where temperatures are not so high, they may be absent.

If the engine is located in such a way that it is not exposed to oncoming air flow, deflectors are used for cooling, redirecting the oncoming flow of cold air to the engine.

The practice of using oil radiators to cool engine oil, one of the functions of which is to cool engine parts, is widely used.

Advantages

- Simplicity and reliability;

- Does not require maintenance;

- The air system is cheaper than the liquid one, which reduces the cost of the motorcycle.

Flaws

- The engine may overheat when the motorcycle is idle for a long time in a traffic jam or when driving for a long time at low speed in hot weather.

- An air-cooled engine is less efficient.

- Oil and filters will have to be changed more often than with water cooling.

- An engine with an air cooling system has a shorter service life.

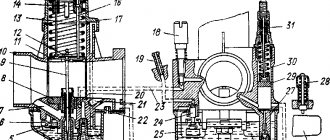

How does the fan work?

This unit is the main one in the air cooling of the engine. The main part is the fan rotor. To optimize the air flow, the shape and design of the elements were carefully calculated by engineers.

The fan is a directing diffuser and a rotor equipped with eight blades arranged radially. The diffuser has its own blades - they have a variable cross-section. Their main task is to create a directed air flow. They are made motionless and evenly distributed around the circumference.

The blades on the guide vane are designed to change the direction of air flow - the air flow moves in the direction opposite to the rotation of the rotor. This increases air pressure and improves engine cooling.

The fan on early designs was driven from the crankshaft pulley using a drive belt. The guide device is stationary and fixed to the engine block. In more modern four-stroke air-cooled engines, the fan is driven by an electric motor. But there are few such models.

Liquid

The principle of cooling motorcycle engines according to this scheme is the same as that of cars. The coolant is antifreeze. Antifreeze simultaneously has an anti-corrosion and lubricating effect. Water in the cooling system is used only in the event of a malfunction and an urgent need to continue driving in the absence of coolant. In this case, there should be no impurities in the water, and it must be replaced with the recommended coolant as soon as possible.

The coolant is pumped through channels in the cylinder walls and cylinder heads of the engine, picks up heat from them and transfers it to the radiator. An incoming flow of cold air passes between the radiator plates and cools the radiator.

One of the most important elements of the system is the thermostat. It divides the cooling system into two circuits - small and large. When the engine is cold, the thermostat valve is closed. The coolant circulating in this case moves along a small circuit. This allows a large volume of coolant to be cut off, allowing the engine to warm up faster. At a temperature of approximately 90°, the valve opens, allowing fluid to circulate through a large circuit and more efficiently cool the engine.

The radiator is usually equipped with an electric fan. It turns on when the coolant temperature rises. For example, when the motorcycle is moving at low speed, when there is not enough air flow.

Advantages

- Allows you to reduce thermal gaps and obtain a higher power density.

- It is necessary to change oil and filters less often than in the case of air cooling.

- Provides longer engine life.

- Easier engine starting at low coolant temperatures.

Flaws

- The liquid cooling system consists of more parts, so it is more likely to break down.

- Liquid cooling makes the motorcycle heavier than air cooling.

- The liquid system is more expensive than the air system, which increases the cost of the motorcycle.

- The fluid system must be serviced periodically.

What type of cooling?

Liquid cooling is mandatory for high-tech engines. This is the only type of cooling for sports motorcycles. For long trips, when good engine airflow is provided, air cooling may be suitable. At the same time, the temperature of air-cooled engines is less stable, it is highly dependent on driving conditions and operating modes, and this increases their wear.

OIL COOLING SYSTEM FOR TRANSFORMERS

This technology is widespread in our country due to its reliability, acceptable service life and relative cheapness. Oil-filled transformers without air blast and with natural oil convection are used in distribution systems - at substations.

This type of cooling is suitable for power transformers with a rated power of up to 16 MV*A and is marked as M.

The heat generated by the magnetic core, winding and other working elements of the device is transferred to the cooler - transformer oil. It circulates through the casing-cooler tank system and is cooled by atmospheric air through radiator fins.

Typical faults

Despite all the reliability of air systems, breakdowns do occur here too. One of the popular faults is electronics. The system has a temperature sensor. For those who don't know where the engine temperature sensor is located, it is located in the oil pan. As a result of excessive readings from this sensor, the system may fail.

If a malfunction lamp lights up on the instrument panel, then most often the reason is a broken belt. The most rarely diagnosed problems are related to the thermostat.

TATRA WILL TAKE YOU FURTHER

TATRA today

History of TATRA

Information

Video and Photo

Latest version

From April this year, the next generation of successful TATRA PHOENIX Euro 6 trucks “2018” will go to its customers. Our spring new product from the oldest, and today the only, Czech automaker will offer customers even more effective solutions to their transport problems.

TRUCKS FOR INDUSTRY

- Defense

- Construction

- Mining

- Logging

- Agriculture

- Mining of oil and gas

- Utilities

- Firefighting

Product catalog

- TATRA PHOENIX

- TERRN°1

- TATRA FORCE

- TATRA TACTIC

NEW TATRA PHOENIX

The latest development of our company. Developed in collaboration with DAF, this new car can take you much further.

Customer Service Center

- Service center

- Consulting and training

another

- Commercial and technical documentation

- Purchasing and Suppliers - Selection Procedures

- TATRA test sites

Original spare parts

- Special offers

- Ordering spare parts

- Sale of spare parts

- Contacts

SPECIAL EQUIPMENT TATRA

- Special equipment

Network of dealers and service centers

With the exception of Antarctica, you will find TATRA on all continents. We offer the largest network of partners in Europe.

Dimensions

Above, among the shortcomings, we highlighted the item about dimensions. If we compare the sizes of motors with different types of cooling and other identical characteristics, then the advantage will still go to the “air vent”.

Even though the fan and deflector are quite bulky devices, the parameters of the “air vent” are smaller than in the liquid-cooled version.

Additionally, housing a traditional water system requires more space under the hood to accommodate additional equipment. A rather large radiator with a fan is installed on the body. Hoses and pipes take up a lot of space.

Oil for four-stroke engines

The viscosity of the lubricant determines the level of engine protection against wear.

If we are talking about lubricant for four-stroke engines, then the key parameter will be the viscosity, in general, as for automobile engines. Viscosity determines the level of engine wear protection. The loads in a motorcycle engine are significantly higher than in a car engine and the oil is quickly displaced from the rubbing pairs, which is what determined that the use of liquid oils is unacceptable. Japanese motorcycle manufacturers strongly recommend using an oil such as SAE 10w40. It is classified as an all-season brand. Experience suggests that such a lubricant can be used in equipment that is used from the thaw to the first snow.

But such motor oil has a significant drawback - with a sharp drop in temperature outside, it can quickly thicken; high temperatures will lead to its dilution to an unacceptable limit.

Installation of temperature sensors in the engine head, general recommendations

Installing temperature sensors in engine heads is not difficult. To install sensors without removing the cylinder heads from the engine, it is necessary to determine in advance where the recesses will be prepared. For example, by examining an analogue head in a store. When drilling a recess for the sensor, use a drill with a diameter 2-3 hundred parts larger than the diameter of the sensor and do not drill through the head! The minimum is considered to be a recess in which the sensor is placed at a height of at least 7 mm (applies to a kit sensor). In this case, a cambric should be placed on the protruding part of the sensors, depriving the sensors of airflow. The ideal option is that the sensors are completely immersed in the body of the head and do not protrude outward. The advantage of this installation is that you install it once and forget it! There is no need to dismantle the sensors in the future, for example when replacing spark plugs, which means there is no risk of damage. The closer the sensors are located to the center of the heads, the more accurate the readings and the faster their change. We do not recommend installing sensors in the engine head, on the exhaust manifold side - the temperature will be too high.

The thickness of the head where the spark plug is mounted is usually equal to the length of the spark plug thread. Quite often, a recess for the sensor is drilled near the spark plug, so that the spark plug is located between the sensor and the fan. This method is correct - the sensor is as close as possible to the center of the head. If you use this method, make sure that when installing the spark plug, the key does not touch the sensor.

Before installing the sensor in the recess, the recess must be filled with KPT 8 thermal paste or similar. Thermal paste fills air gaps and promotes 99.9% of heat transfer from the head to the sensor. After installing the sensor, the edges of the recesses are slightly deformed by the core (it is not permissible to deform the sensors). This prevents the sensor from falling out.

Installing a temperature sensor in the head of a Buran snowmobile

In our opinion, this is not the best place for installation. With this installation of the sensor (from the exhaust side), the readings will be higher. It is clear that exhaust gases have significant temperatures. In addition, the sensor wires were left unprotected and very soon, due to vibration, they would lose their insulation from being closed. About how the kit works Moto thermometer on the Buran snowmobile

Installing sensors in the engine head of a Taiga snowmobile

The sensor installation location is selected in the stiffening rib of the engine head, running crosswise, from stud to stud. The thickness of the metal in this place is about 26 mm

Useful tips

Please note that a decrease in the level of antifreeze or antifreeze does not always indicate problems with the cooling system. Coolant can go directly into the cylinders if there is damage to the cylinder head gasket, there are cracks in the head or block, etc.

In this situation, the engine often emits white smoke as the coolant escapes through the exhaust in the form of steam. In this case, the head or block must be removed; as part of the diagnosis, crimping of the block head is performed. Then a decision is made to repair the cylinder head or replace the element. Also, antifreeze or antifreeze may leak if problems arise with the engine block plugs. Leaks at the plugs will indicate that the engine plugs need to be replaced.

It should also be added that with the onset of the cold season, it is very important not only to have coolant filled strictly to the level, but also to the density of the antifreeze. Remember, if you had to add distilled water during operation, the density of the solution decreases

In simple words, when the temperature drops, the liquid can freeze. Freezing often results in damage to both the cooling system elements and the internal combustion engine itself.

The coolant density is measured with a hydrometer; if necessary, the antifreeze concentration should be increased by adding concentrate. At the same time, mixing antifreeze and antifreeze of different brands is strongly not recommended.

It is also important to remember that coolant concentrate is a strong poison! Do not allow the substance to come into contact with your skin or eyes, and do not take it orally!

Let us note once again that antifreezes or antifreezes based on ethylene glycol contain a package of active additives that prevent the formation of corrosion and have antioxidant and antifoaming properties. However, over time, the additives wear off and stop working.

As a result, the pump impeller is destroyed, the radiator “corrodes” from the inside, and the channels in the BC and cylinder head rust. Also, coolant decomposition products, combined with general contamination, can clog the system channels, disrupt the operation of the thermostat, etc. For this reason, the performance of the cooling system deteriorates, and the service life of its components is significantly reduced. In some cases, corrosion destroys the channels of the engine cooling jacket; antifreeze or antifreeze gets into the cylinders or into the lubrication system.

To prevent possible consequences and avoid a number of problems, the coolant must be changed once every 2 years. This is especially true when it comes to antifreeze. It is advisable to make the replacement by flushing the cooling system. Also today there are new generation antifreezes of the G12+ type, which are designed for 3-4 years of service.

If there are any doubts about the efficiency of the system, or the thermostat, etc. is suspected, an infrared thermometer allows you to measure the temperature of the hoses and pipes during the initial diagnosis. For a quick check, just turn on the heater in the cabin, then measure the temperature of the heater inlet and outlet hoses. The temperature should be almost the same. If obvious abnormalities are noticeable, this may indicate a need for repair.

Finally, we note that when placing hoses in the engine compartment, be sure to check for kinks. First of all, for example, after replacing pipes, you should make sure that the hose is not kinked

It is also important that the hose does not touch hot surfaces, moving parts or sharp edges.

Kinks impair coolant circulation, which can cause overheating under load. As for mechanical damage, moving parts can chafe the hose, sharp edges cause cuts, and contact with heated surfaces causes accelerated cracking of the pipes. The result is a coolant leak, which can cause the engine to overheat.

Types of Motorcycle Engines

Before you figure out the selection of engine oil for a motorcycle, it makes sense what engines are installed on modern two-wheeled vehicles. This is what will have a decisive influence on the choice of lubricant.

Two-stroke engines with oil bath clutch

Such engines have found their application on equipment manufactured at enterprises scattered throughout the territory of the former USSR. As an example, we can name such units as IZH, Minsk and many others.

Engines manufactured outside the country are used in models such as motocross motorcycles, mopeds, scooters, etc. Such engines use a separate lubrication system. That is, the parts of the piston group receive the necessary lubrication due to the oil previously added to the fuel.

The lubricant dissolves in the fuel and enters the cylinder through the windows along with the fuel mixture.

The piston is connected to a needle bearing, just like a connecting rod is connected to a crankshaft. Lubricant is added to these places at the assembly stage. The gearbox and clutch are lubricated by gear lubricant.

Four-stroke engine with dry clutch

The arrangement of the components of this engine is extremely similar to engines that are installed on cars. The difference lies in a single lubrication scheme for the engine and gearbox.

In all other respects, all key components are identical to those installed on car engines. The motor kit includes an oil supply pump, a filter, oil lines and a system pressure indicator. Lubrication in the gearbox is carried out by spraying it from an oil bath common to the piston group.