The stability and reliability of starting the engine of an Alpha moped depends on several factors, including correctly configured ignition. The absence of problems due to an incorrectly configured unit guarantees ease of driving the vehicle at any time of the year - it will start at every kickstart without any extra effort. You will need to adjust the ignition only if the moped was purchased very cheaply and needs to be restored to working condition.

The electrical equipment system (and, accordingly, spark supply) consists of the following elements:

- power supply;

- additional devices;

- other nodes that consume energy.

According to statements, there is no need to adjust the ignition after purchasing a new vehicle, but in reality everything is somewhat different - the conditions of transportation and storage impose their own problems. Most likely, you will have to eliminate the consequences of incorrect ignition settings - in Alpha vehicles it is set on the principle of too much advance. In addition, disassembling the engine inevitably entails the need to adjust the ignition without fail.

You just need to follow the instructions for disassembling and reassembling the moped to achieve an optimal result that will last until the next time the engine is dismantled for maintenance or replacement. Uncertain operation of the engine while driving causes not only discomfort, but also troubles in the form of an increased accident risk on a busy highway, where a sudden stop is extremely dangerous.

Signs and causes of moped motor malfunction

Among the main manifestations of a breakdown of the ignition system are the following factors:

- the moped does not start the first time or does not start at all;

- it takes a lot of effort to start the engine;

- presence of burning on the candle;

- excess noise when the engine operates while driving and idle;

- inability to gain sufficient speed without effort.

- Correct ignition settings can eliminate the following problems in the operation of the moped:

- fuel detonation;

- increased gasoline consumption;

- reduction in power at low speeds;

- noticeable knocking not only when driving, but also when the engine is running without moving;

- strong heating of the motor;

- presence of pops.

Setting up a timely spark supply will also extend the operation of the piston system and the entire engine in general due to the absence of gasoline accumulation inside the engine - soot does not increase, leading to coking and unusability of the engine in general.

Incorrectly set ignition is associated with other problems, including the installation of the piston system. The reasons for the failure of the moped ignition are:

- incorrectly installed ignition coil;

- wear of the piston system, which leads to the release of gases from the inside and the release of fumes onto other components;

- physical damage to the vehicle due to a fall or accident.

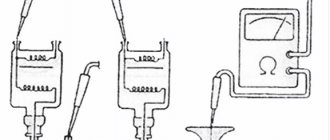

It is necessary to constantly monitor the condition and correct connection of the ignition coil, since it is this part that increases the voltage, resulting in a spark. Lack of sufficient voltage prevents a spark from forming and starting the moped engine. There is a way to diagnose the ignition coil to understand what needs to be replaced, and not just adjusted correctly. You need to take a tester (multimeter) to measure the levels. It is worth considering that a digital tester is preferable, since the needle may not pick up the slightest fluctuations.

The tester probes need to be connected to the terminals of the ignition coil, and the multimeter itself must be switched to resistance measurement mode. After this you will need to apply voltage. An indicator of up to 5 Ohms is considered normal (but not lower than 0.5 Ohms) - the optimal level. Next you need to do everything with the secondary winding:

- one probe is connected to the coil terminal (supply);

- the second must be attached to the spark plug cap;

- you need to look at the value on the screen.

Checking the ignition coil with a multimeter

The norm for the secondary winding is two to three kilo-ohms. If the indicators do not correspond to those mentioned above, you will need to replace the ignition coil, and not just adjust the corresponding system.

Video on how to check the ignition coil on a moped:

The principle of operation of ignition in a 4-stroke scooter engine

Modern scooters are equipped with contactless systems. They are considered the most reliable and easy to use, do not require complex connections, and provide a constant good spark on time. However, the setting is still important; even the presence of a spark does not always allow the fuel mixture to ignite, since its power also plays a role.

The main reasons for the operation of the ignition system are quite simple: its task is to create a spark to detonate the fuel mixture. If this does not happen, you need to carefully examine each node and find out why the spark disappeared.

- In order to check whether there is a spark at all, you need to unscrew the spark plug and apply it to the engine ground; this can be done using metal objects that are not covered with paint. You cannot hold it with your hand: if there is a spark, it can give you an electric shock, and the discharge reaches 40,000 volts, which the coil creates.

The functionality of the spark plug is checked in this simple way: you need to attach the spark plug to the metal body of the engine and turn the starter

- If the spark plug does not produce a spark, it must be replaced with a new one; You can also check it using a special device that can be bought at a car store. It is inexpensive, it is a faster and safer way.

- If the spark plug is working, but there is still no spark, you will have to use a multimeter, with which you can check the wiring of the scooter, find a break or a faulty element.

- You also need to check the generator. It is an important element without which the scooter will not work. You will need to measure the resistance: to do this, you need to disconnect the ignition coil from the wiring, then measure the resistance between ground and the generator. This is usually a black wire with a red stripe. If the resistance is normal, it will be about 80-150 Ohms. If the device malfunctions, the resistance will be significantly less or absent altogether.

- After this, you need to measure the resistance that the coil produces. To do this, a multimeter is connected to its terminals. One of the terminals is connected to the magnetic circuit. If there is no resistance, a coil malfunction is diagnosed. If it is there, but weak, it is worth checking the wiring or the place where the coil connects to it.

- If everything is in order, but there is still no spark, you will need to check the wiring: to do this, you need to select two points to which the multimeter will be connected. One of the points should be the switch or ignition coil, the second should be the generator block. The wires may either be broken or there may be a short circuit between them. If the circuit is fully operational, check the ignition unit. It rarely fails, so it is dealt with last, when more likely causes of failure have been excluded.

Broken ignition is the cause of engine failure

An incorrectly configured or faulty ignition often causes engine failure. It would be wrong to immediately climb into the cylinder and examine the insides of the scooter, especially since this will not solve the problem. Before touching the ignition system, you need to check for other reasons why the scooter may not work.

- The simplest thing is the lack of gasoline in the tank. Quite often, owners forget to refuel their vehicle, and such a trivial reason can be overlooked.

- The carburetor may be clogged, which prevents the formation of a mixture suitable for driving.

- The carburetor needs to be cleaned regularly, so it doesn't hurt to check whether fuel is flowing from it into the cylinder. It is possible that the fuel pipe is clogged. The jets and other parts of the device may become clogged with debris, which causes little fuel to flow or, conversely, the engine does not have enough air, and therefore it does not start.

- The scooter may also refuse to start if the fault is caused by spark plugs. They may be wet or not produce a normal spark. It is advisable to have a spare set and check with it. In any case, the spark plug needs to be unscrewed and inspected.

This way you can visually determine the condition of the spark plug on the scooter.

- If, after checking all the components, you are convinced that they are in order, you can check the ignition system in the manner indicated above and proceed to setting it up if everything is in order with the technical part.

Preparing to set the ignition, necessary tools

It is necessary to start working with a moped with a sufficiently warm engine - if you leave the vehicle to cool for about two hours after the trip or let it sit until the morning, if the vehicle was driven into the garage in the evening, then you need to put it on a stand for a few minutes with the engine running. Among other things, it is worth doing:

- place the moped on a flat and stable surface (asphalt or concrete);

- fix the vehicle on the stand so that it does not move anywhere;

- prepare a small box for the extracted parts (if you have to do something extra). The best option is the cells from the tool box, into which everything can be sorted, eliminating confusion.

To work on a moped you will need several elements:

- a set of tools that came with the moped;

- instructions that came with the transport - it describes the main points of the procedure;

- strobe

If this type of moped repair is being performed for the first time, it is recommended to enlist the help of at least one person so that he can hold individual parts of the vehicle or record the process in a photo/video. The materials will be needed if problems arise when putting the entire mechanism back together.

The whole process is best done outside in dry weather, but without wind, so that sand does not get inside, which would require additional cleaning. Inside a garage or box, the process will not be safe because you will need to start the engine. The instructions for setting up the ignition will be useful to all owners of Alpha mopeds, as well as Honda, from which the model was copied for production in China and sale at a lower price in other countries.

COMMENTARE • 56

It looks more like he switched the 139 engine to the Japanese, the Japanese stopped driving, moved the piston to 80+ cc and got this result. fifty dollars will never work like that

Well, can someone tell me how to rearrange it?

Whether you moved them back or forward, it would be possible to explain in human terms!

And what's the point? Apparently you assembled it correctly for the first time. Well done

Motor from another stool