Any vehicle cannot do without suspension, which is responsible for comfort and handling. Unfortunately, roads are not always ideal, so drivers and passengers have to put up with shaking, bumps and sudden jolts that throw vehicles off their chosen path. This also applies to motorcycles, and for them the issue of dealing with impacts that occur when driving over uneven surfaces is very important, since they are much less stable and difficult to control. The motorcycle suspension has undergone many changes on the way to the form it currently has. At the same time, there is still no agreement among engineers on the question of which type of chassis is better - so we will look at a brief history of motorcycle suspension, as well as the main types of modern designs.

Motorcycle movement and the role of motorcycle suspension

While moving, a motorcycle experiences a variety of loads, including the most unpleasant ones transmitted from the road through the wheels. To reduce the impact of these loads and ensure a smooth ride and stability of the motorcycle, the wheels are connected to the frame through elastic and guide elements - the suspension.

Spiral springs, springs and torsion shafts are usually used as elastic elements.

But elastic elements alone are not enough. Because in this version, after hitting any obstacle, the motorcycle would continue to sway for a long time - after all, the oscillations themselves die out slowly. Therefore, in addition to the elastic elements, vibration dampers and shock absorbers are introduced.

Unlike cars, where elastic elements and shock absorbers are completely independent structural units, on motorcycles they are usually combined into one unit, which is generally called a shock absorber.

At the dawn of motorcycling, friction discs pressed against each other were widely used as vibration dampers. In designs that have survived to this day, this principle lives only in the steering dampers of some motorcycles. Friction devices are everywhere replaced by more advanced hydraulic, gas or gas-hydraulic ones. They operate on the principle of passing liquid or gas through very small holes and gaps.

In this case, the gas or liquid exhibits greater resistance, the smaller the hole or gap.

Finally, in addition to elastic elements and vibration dampers, each suspension also includes a guide device. Its task is to ensure that the wheel moves strictly in a given plane. The role of such devices is played by telescopic pipes and arms of the front forks, pendulums and arms of the rear suspensions.

All of the above applies to the suspension as a whole. On a motorcycle, each wheel has its own suspension. The suspension is structurally divided into front and rear.

Motorcycle front suspension

Front suspension. The age of lever front forks, which used springs and clutches, was very short. They were quickly replaced by telescopic forks. They were continuously modernized, improved, changed and reigned supreme for half a century. What is so attractive about the “telescope”?

Firstly, the ease of steering - after all, the entire fork is mounted in the steering column on ball bearings that have very little friction.

Secondly, the fact that the steering wheel with this design directly affects the steered wheel, which allows you to control the motorcycle very accurately.

Thirdly, since in a telescopic fork there is also a volume of air above the oil volume, the fork acquires to some extent progressive, that is, nonlinear characteristics - despite the fact that long coil springs have linear characteristics.

Fourthly, “telescopes” are quite simple to manufacture and technologically proven. They have been brought to such a degree of perfection that they will not simply give up their positions without a fight.

However, the best is the enemy of the good.

As motorcycles themselves developed, the shortcomings of telescopic forks began to appear.

The most unpleasant of them - the peck effect - was the most obvious. During acceleration and braking, the so-called dynamic load redistribution occurs, as a result of which in the first case the motorcycle fork springs completely “unwind”, that is, straighten out to their full length, while in the second case they are compressed. At the same time, the front part of the motorcycle makes a strong pitching movement. Many companies have tried to combat this drawback by inventing all kinds of anti-peck systems. But no one was able to completely overcome the “peck”.

Big Piston = big piston

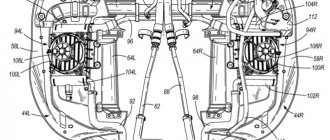

With limited volume shock absorbers housed in narrow shanks in which they work with relatively small and difficult-to-align pistons, the Japanese replaced the Big Piston system . These are hydraulic damping systems with large pistons that provide very sensitive and extremely precise damping.

Big Piston fork that goes straight to the shin. Below are traditional small-diameter fork pistons with rebound damping adjustment (right) and rebound damping, all housed in a single shock cylinder (called a cartridge).

motorcycle front suspension

Large diameters here mean better control over damping control, especially in the low to medium speed range (we're talking suspension speeds of around 10-150mm/s). Thanks to this, a soft response with excellent stability and feedback was consistent.

The next step was to place the damping system in one joist and the rebound suppression in the other. Asymmetrical load sharing is not a problem. The rigidity is quite sufficient to avoid deformation during deep and quick fixation of the fork.

The next step in evolution has already been established in racing: the gas engine fork (closed cartridge) has a small gas-filled shock absorber, which provides a constant damping force because the oil does not mix with the air in it and does not form an emulsion.

Post Views: 4,928

Motorcycle telescopic fork

The second serious drawback of a motorcycle telescopic fork is its lack of rigidity. The “wheel axle – steering column” lever is very long, and the fork, of course, bends, which increases friction in the contact area between the moving and stationary pipes. And this worsens the response of the suspensions and increases pipe wear. In addition, designers must not forget about the steering column, which takes all the loads: it also has to be continuously strengthened as driving speeds increase. This is where the chasing your own tail effect comes into play. Trying to improve the rigidity of the motorcycle fork, engineers began to increase the diameter of the pipes - today there are pipes with a diameter of up to 45 mm! But this, naturally, increases the mass of the fork and requires strengthening the steering column of the motorcycle. As a result, the head of the frame becomes more powerful, and the entire motorcycle frame becomes heavier. Something we have to fight again. And so on endlessly.

In attempts to improve the front suspension, many new options were born. None of them have won yet - which suggests that the age of the “telescope” is not over yet. But you should still get acquainted with some designs. If only because one of them may be used on the motorcycle you buy. And even if it doesn’t turn out to be true, it’s still useful to know about it.

Among the new systems that conditionally retain the design of a motorcycle telescopic fork, but have a different design, the “Mono-Arm” suspension, proposed by the Dutch, stands out.

Here the fork stays are replaced by one stamped fixed post, along which, as if on a guide, the bracket slides, to which the wheel is cantilevered. Needle bearings are installed between the bracket and the guide. For suspension and shock absorption, a standard shock absorber strut is used, the same as those installed in the rear suspension of a motorcycle. Everything seems to be fine, but so far no one has decided to launch this design into series.

The Italians went further. They began to serially install front suspension on motorcycles, very reminiscent of the one used on the front wheel... of airplanes. Why not a sample? The wheel is cantilever mounted to a lever connected to the central shock absorber. And that, in turn, is connected to the steering column. And again: everything seems to be great, but the system has not received mass development. BMW has moved further than others. Since 1993, on motorcycles of the “R” series, it has been standardly installing a new suspension, called “Telelever”.

At first glance, this is an ordinary “telescope”. But the pipes here serve only the functions of a guide apparatus. The bridges are spaced apart: the upper one is connected through a bearing to that part of the frame that can only be called the steering column of a motorcycle, the lower one, connected to the movable pipes, is pivotally connected to the trailing arm resting on the engine. One shock-absorbing strut is placed between the frame and this lever. The “Telelever” system is largely free from the disadvantages of the “telescope”. It has very high rigidity, anti-peck effect and stable performance. There are many other options for motorcycle suspension. Some are developed only theoretically. Others were used on racing motorcycles and even brought high titles. Still others are introduced in the series. There is a fairly clear trend towards cantilever mounting of the wheel to the trailing arm - this promises good handling performance. But the motorcycle telescopic fork still dominates mass production. And therefore there is a very high probability that the motorcycle you purchased will be equipped with it.

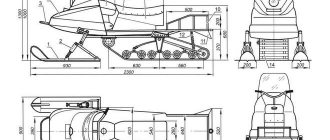

Fundamentally, the telescopic fork of a certain impersonal motorcycle consists of two guide elements (“stays”) connected to each other at the top by two bridges of the steering column, and at the bottom by the wheel axle. In the steering column, the motorcycle fork can rotate on bearings. Each feather consists of a fixed supporting pipe (“glass”), a movable pipe and a spring-hydraulic shock absorber. The fixed pipe at the upper end has a cone that fits into the corresponding hole in the upper bridge. The pipe is secured in the upper bridge with a plug, and in the split hole in the lower bridge with a coupling bolt.

The movable pipe in the lower part has an eye for fastening the wheel axle, bosses for fixing the brake disc and fastening the wing.

The hydraulic vibration damper is fixed inside the pipe and is supported by a cylindrical spring.

A strictly defined amount of liquid (fork oil) is poured into each motorcycle fork leg through the plug holes for the motorcycle fork shock absorbers.

Steering dampers.

As already mentioned, with small fork rake values, the motorcycle steers easily and quickly, but suffers from a lack of stability at low speeds. This isn't much of an issue on sportbikes, which require precise handling while still being quite fast. The problems start when you hit a big enough bump. The motorcycle fork compresses, the wheelbase decreases, the motorcycle loses stability, and the front wheel dances from side to side. And so on until the fork unclenches and the wheelbase returns to its original length.

Once this happens, the gyroscopic effect that occurs on the front wheel causes the motorcycle to "bob its head." The gyroscopic effect causes the motorcycle's front wheel to wobble from side to side. In some cases, the handlebars dangle so much that the grips touch the motorcycle’s gas tank. Usually this all ends in a highside, when the motorcycle throws the rider forward, over itself.

At one time, this behavior of the motorcycle was the reason for the recall of a batch of Suzuki TL 1000S after a couple of weeks after they hit the windows of motorcycle dealerships. And the same reason forced engineers to develop steering dampers for motorcycles. A steering damper is a great thing to use on the track and if you don't fully trust your bike. There are two main types of steering dampers: linear and rotary. Linear dampers consist of a hydraulic cylinder and a rod with a piston, one side is attached to the motorcycle handlebar, the other is attached to the frame. Such dampers are similar in appearance to shock absorbers and are not activated during normal driving, but as soon as the shock begins, the damper takes on most of the load.

Rotor steering dampers are also available. They are mounted on the motorcycle steering column above the bearing and work by increasing the steering column's resistance to sudden left-right movements. The resistance is achieved by damper hydraulics. Just try hitting one of the handlebars with your fist when the steering damper is installed - and you will understand how it works.

Motorcycle front fork operation

When hitting an obstacle (road unevenness is also an obstacle), the motorcycle wheel moves upward, and the movable pipe-cup of the motorcycle fork with a shock absorber moves with it. The spring is compressed. The fluid contained in the shock absorber body and in the sliding pipe flows freely into the upper part of the body, lifting the valve. In this case, the liquid offers virtually no resistance to compression of the spring.

During the reverse stroke of the wheel, when the spring expands, the liquid located above the piston presses the valve to the seat, closing the free exit to the reservoir under the piston. Liquid can now only get there through the annular gaps between the piston and cylinder, as well as between the sleeve and the rod. The fluid resistance during reverse wheel motion is many times greater than during forward motion. Therefore, such a shock absorber is often called a single-acting shock absorber. However, if under the action of the springs the wheel returns to its original position too quickly, this is also bad. Mechanical parts of the shock absorber may hit each other. To prevent this from happening, another valve is introduced into the design, which closes when the wheel moves in reverse (rebound valve).

On modern single-wheeler motorcycles, the ease of turning the steering wheel in the steering column is usually adjusted at the factory and does not change during operation. Unless it has to be restored after the repair of the front fork associated with its dismantling.

On domestic motorcycles, especially those used with a side trailer, there is a damper in the steering column that allows you to change the ease of turning the steering wheel. When it is tightened, the friction force between the stationary friction washer, combined with the steering stop, and the movable metal discs increases. When driving on a bad road, you can tighten the damper to somewhat reduce the influence of side shocks and make the motorcycle easier to control.

The performance of the shock absorber is decisively affected by the amount of fluid poured in and its quality. If the fluid is less than recommended by the manufacturer, hard and very undesirable knocking noises will appear when the wheel moves back. If there is more fluid than necessary, the motorcycle fork will be too stiff and the motorcycle’s handling will deteriorate.

By the concept of “quality” we first of all mean the viscosity of the fork oil (shock absorber fluid is also oil). High-viscosity sight oil will be difficult to press through gaps and calibrated holes - this makes the motorcycle fork stiff, insensitive, and unable to dampen small vibrations. Fork oil with low viscosity, on the contrary, makes the motorcycle suspension too soft: it will work all the way on all bumps and very poorly brake the reverse motion of the wheel.

Typically, the type of shock absorber fluid and its quantity for each shock absorber are indicated in the manufacturer's instructions. And these recommendations must be strictly followed. For example, for the front suspension of IZH motorcycles, these recommendations are as follows: 0.175 liters of MGPYU fluid should be poured into each feather. This special fluid consists of transformer oil, silicone additives, animal fats, antioxidant and anti-foam additives. Such a complex composition allows the liquid to successfully cope with its tasks in the temperature range from -400 °C to + 500 °C.

In extreme cases, the proprietary fluid can be replaced with a mixture of turbine and transformer oils in equal proportions. However, you need to be prepared for the fact that the nature of the motorcycle suspension will change - and not for the better.

A lot of good things

About 20 years ago, the guys from Bimota and Yamaha, like Pinky and Brain of the cartoon, planned to take over the world with motocross motorcycles. In the case of Yamaha we are talking about the GTS 1000, in Bimota we are talking about the even more technically complex Tesi model.

The sport tourer GTS 1000 failed to translate its theoretical merits into everyday use, which is probably why it was not a bestseller among others, which is why it disappeared from the market after five years. Although the Tesi can still be purchased, it is a motorcycle for fans of the brand and alternative solutions. The design solutions of both motorcycles had many disadvantages: they were technically complex and, therefore, expensive to manufacture, provided a turning radius that was too small for a road motorcycle, and did not provide the best transmission of torque.

Countless racing prototypes with alternative suspensions have led to the fact that today, even in racing, the compact and not very expensive USD fork rules the roost.

Motorcycle rear suspension

Both the creators of motorcycles and the motorcyclists themselves got used to the idea that the front wheel needed to be sprung quite quickly. Understanding came through my hands: a motorcycle with a rigidly fixed front wheel was jumping over uneven roads so much that the steering wheel was literally knocked out of my hands.

Another thing is the rear wheel. For many years it seemed that it was enough to spring the driver’s seat and all problems would be solved. I can honestly say: when, back in 1960, I got on my first M1E motorcycle (“a macaque” that already had a front telescopic fork), the saddle with springs seemed fantastically comfortable to me and there was not even any rear wheel suspension thoughts. But time put everything in its place.

As power and speeds increased, the rear wheel, which bounced over bumps, spent less and less time in contact with the road - and created more and more problems in terms of power delivery and controllability.

One of the first designs to become quite widespread was the suspension proposed by the Italian. Triangular in side view with a horizontal base at the top corner, it was hinged to the motorcycle frame. The wheel axle was installed in the sharp lower corner, and powerful springs were attached to the opposite corner, located under the engine and working in tension. Friction discs like the steering damper, which we talked about just above, were used as vibration dampers. This scheme turned out to be so tenacious that it is sometimes found today, although, of course, in a greatly improved form.

Motorcycle rear wheel spark plug suspension

More popular in the thirties and forties was the so-called spark plug suspension of the rear wheel of a motorcycle. Old motorcyclists remember it from the IZH-49 and M-72 motorcycles). It was designed quite simply: a vertical rod was installed between the brackets at the rear of the frame, along which the bracket with the wheel axle fixed in it could slide up and down. The bracket was suspended by a spring that worked in compression. The spark plug suspension had a very short stroke, about 40 mm, but at that time this seemed the height of comfort.